Method for preventing delayed coking fractionation tower high temperature section oil collection tank coking

A technology of oil collection tank and fractionation tower, which is applied in the field of preventing coking in the oil collection tank of the high temperature section of delayed coking fractionation tower, to achieve the effect of slowing down coking, slowing down the deposition of coke powder, and avoiding high temperature coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

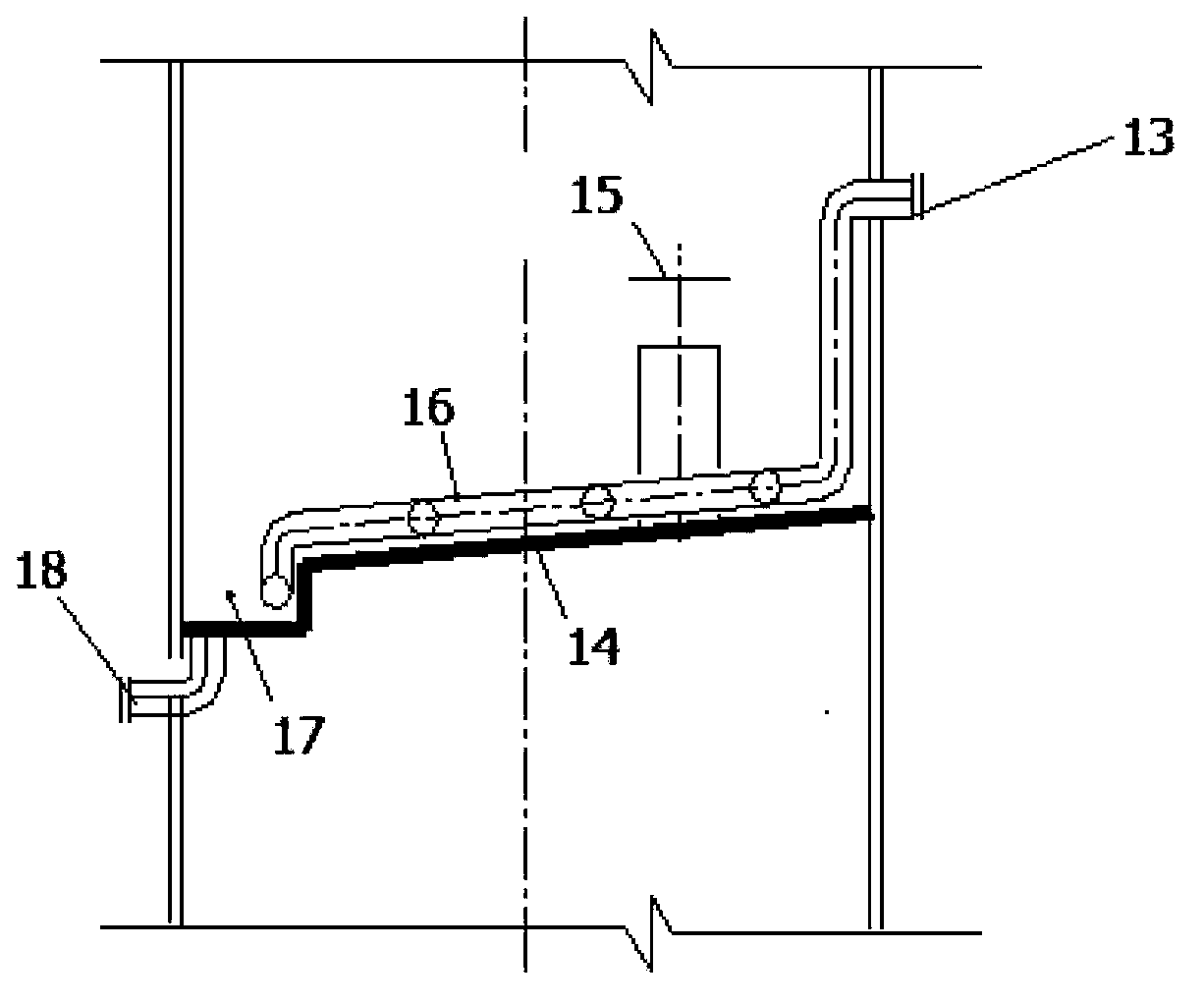

[0021] A kind of method for preventing coking in the oil collection tank of the high temperature section of the delayed coking fractionation tower described in the present invention, its technical scheme is:

[0022] The chassis of the oil collection tank 10 located in the fractionation tower 5 adopts an inclined design, and the liquid sump 17 of the oil collection tank is arranged at the lowest end of the inclined chassis 14, and is connected with the circulating oil or wax oil outlet pipeline 18; the circulating oil or wax oil The oil-cooled return flow inlet pipeline 13 is set at the highest end of the inclined chassis, and is connected to the distributor inlet pipe. The distributor pipe 16 with small holes in different directions is laid on the inclined chassis vertically with the distributor inlet pipe. ; On the inclined chassis, there are evenly distributed air holes; the circulating oil or wax oil extraction pipeline connected to the circulating oil or wax oil outlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com