Pretreatment method for ammonia-containing high hardness wastewater

A high-hardness, pre-treatment technology, applied in water/sewage treatment, degassed water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem that fresh water increases the load of downstream biochemical treatment system and the existence of downstream biochemical treatment devices. Safety hazards, production operation and maintenance risks, etc., to reduce energy consumption and fresh water consumption of equipment, reduce chemical consumption and operating costs, and achieve good results in energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

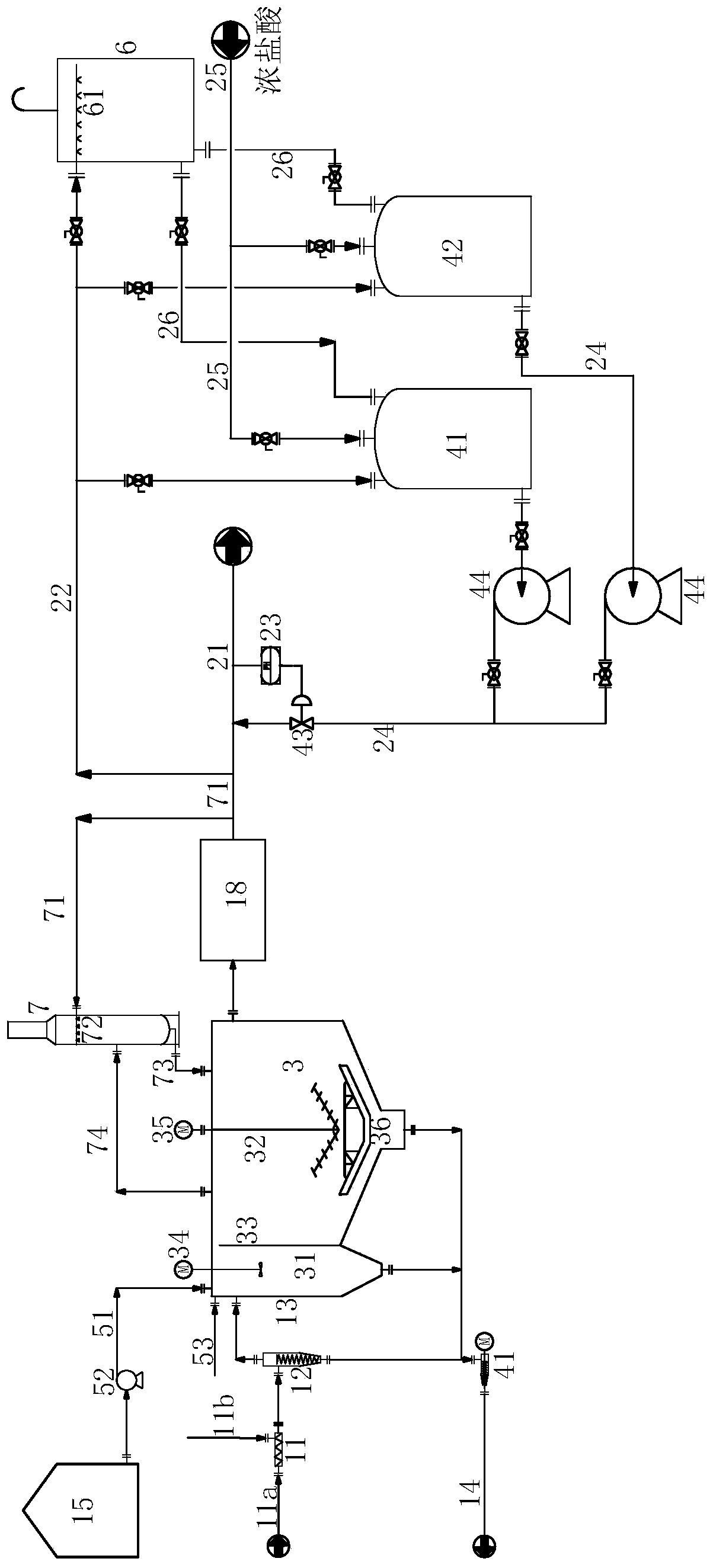

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] Such as figure 1 As shown, the equipment used in the embodiment of the present invention includes:

[0018] Static mixer 11 for mixing initial waste water and Na 2 CO 3 solution, its first inlet is connected to waste water line 11a, and its second inlet is connected to Na 2 CO 3 Solution delivery pipeline 11b, its outlet is connected to the inlet of separator 12;

[0019] Separator 12, used for the waste water and Na that static mixer 11 sends 2 CO 3 The mixed liquid of the solution is separated, and the separator 12 in the present embodiment is a cyclone separator, and the liquid-solid cyclone separation is forced, and the separation effect is better; the bottom outlet of the separator 12 is connected to the sludge discharge pipeline 14, and the top of the separator The outlet is connected to the inlet of the settling tank 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com