Air volume adjustable air control powder feeder

A powder feeding device and adjustable technology, which is applied in the direction of spraying device, liquid spraying device, conveying bulk materials, etc., can solve the problems of discontinuous feeding, high operating cost, lag, etc., and achieve widening of adjustment range, low operating cost, The effect of hysteresis resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

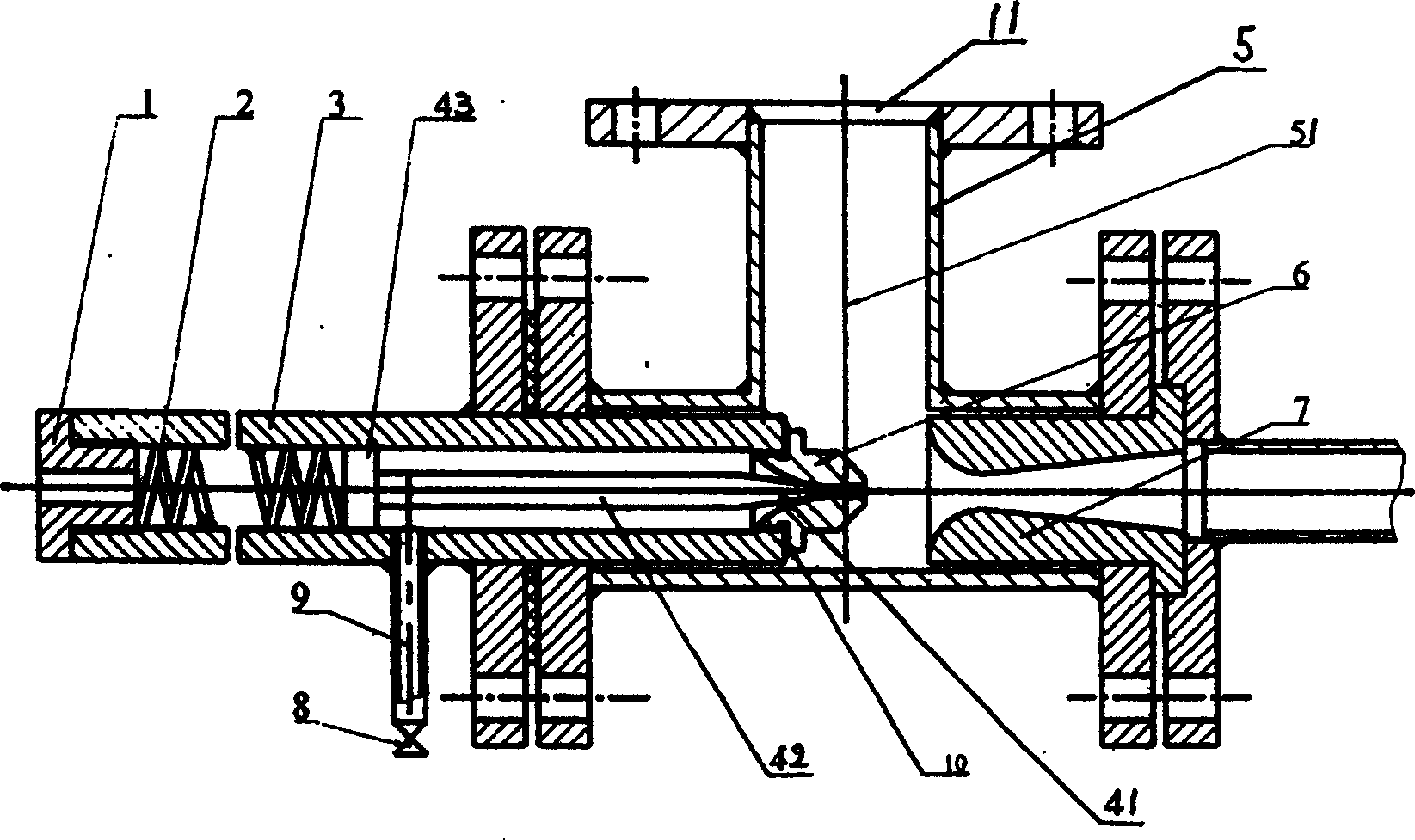

[0015] The structural details of a specific embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings:

[0016] like figure 1 As shown, 5 is the housing of the air-controlled powder feeding device with adjustable gas volume. The gas injection device is installed on the left side of the housing, and the diffuser 7 is installed on the right side. 2. Envelope 1, compressed air inlet pipe 9 and movable guide rod. Nozzle 6 is installed on the head of cylinder 3 through stop washer 10, facing the entrance of diffuser 7. Envelope 1 is installed and fixed on cylinder 3. Tail, the center of which has air vent, communicates with the atmosphere, spring 2 and movable guide rod are installed in the inner cavity of cylinder body 3, movable guide rod is made of rod head 41, shaft 42 and tail plug 43, when rod head When 41 is close to the nozzle 6, the head of the rod head can block the spout of the nozzle, the spring 2 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com