Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Meet the flame retardant performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire-retardant hydrolysis-resistance solvent-free polyurethane synthetic leather resin and preparation method and application thereof

InactiveCN106008892AGood physical propertiesHigh strengthTextiles and paperPolymer scienceFoaming agent

The invention discloses fire-retardant hydrolysis-resistance solvent-free polyurethane synthetic leather resin. The resin is prepared by mixing a component A and a component B according to the mass ratio of 2:1-1:2. The component A comprises 30-60 parts of polyether diols, 20-50 parts of polyether triols, 0-5 parts of chain extender, 0-2 parts of cross linking agent, 0-10 parts of additive-type flame retardant, 0-5 parts of reactive-type flame retardant, 0-1 part of foaming agent, 0-0.5 part of catalyst, 0-0.5 part of foam stabilizer, and 0-1 part of light / heat stabilizer. The component B comprises 50-70 parts of polyether triols, 30-50 parts of isocyanate, and 0-0.1 part of catalyst. The invention further provides a preparation method and application of the resin. The solvent-free polyurethane synthetic leather made from the resin meets BS (British standard) 5852 NO. 0&1 flame standards and FMVOSS (Federal Motor Vehicle Safety Standard) NO. 302 flame standards.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

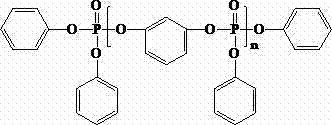

Flame-retardant polylactic acid material of ternary composite flame-retardant system and preparation method thereof

The invention discloses a flame-retardant polylactic acid material of a ternary composite flame-retardant system and a preparation method of the flame-retardant polylactic acid material. The ternary composite flame-retardant system comprises hibiscus cannabinus, nano-zinc oxide and a polymer type phosphorus-containing fire retardant. The preparation method of the flame-retardant polylactic acid material comprises the following steps: (1) performing alkali treatment on the hibiscus cannabinus, and assembling and loading the nano-zinc oxide on the processed hibiscus cannabinus surface; (2) dissolving the polymer type phosphorus-containing fire retardant in chloroform, adding the hibiscus cannabinus loaded with the nano-zinc oxide in the chloroform containing the polymer type phosphorus-containing fire retardant, stirring for a while, adding polylactic acid particles, and when the polylactic acid is completely dissolved and the solution is free of bubbles, forming film on a glass plate, volatilizing at room temperature, and drying; (3) adding the dried thin film in a twin-screw extruder, extruding, cooling and pelletizing the material to prepare the flame-retardant polylactic acid material of the ternary composite flame-retardant system. The flame-retardant polylactic acid material is simple in formula, free of halogen, environment-friendly and high in flame retardant efficiency, can reduce molten drop phenomenon, and effectively reduces further spreading of fire.

Owner:NANJING UNIV OF SCI & TECH

Modified polypropylene composite material and application thereof

InactiveCN103450554AHigh cost performanceSatisfy flame retardancyGlass fiberPolypropylene composites

The invention belongs to the technical field of polymer materials, and discloses a modified polypropylene composite material and an application thereof. The compound material is composed of following components in parts by weight: 50 to 70 parts of polypropylene, 10 to 20 parts of glass fiber, 12 to 15 parts of fire retardant, 3 to 5 parts of flame retardant synergist, 0 to 15 parts of flexibilizer, and 1.5 to 15 parts of auxiliary agent. The invention also provides an application of the polypropylene compound material mentioned above as an electrical panel. The modified polypropylene composite material is capable of being used as an electrical panel. The composite material has a high performance-cost ratio, a low price, an excellent processing property, a lower processing temperature and a good forming property, can fully meet the performance requirements of electrical panel material on mechanical strength, impact toughness, heat resistance, flame resistance, and insulating property, and does not need a drying treatment before processing.

Owner:HEFEI GENIUS NEW MATERIALS

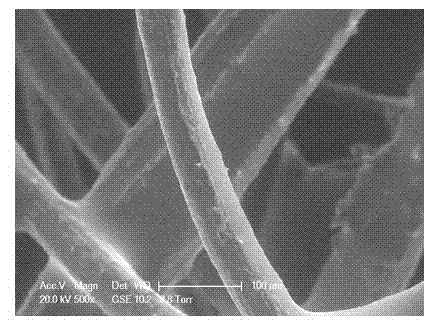

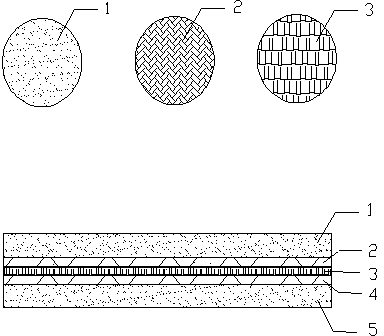

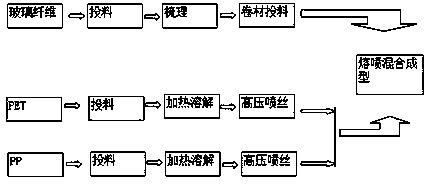

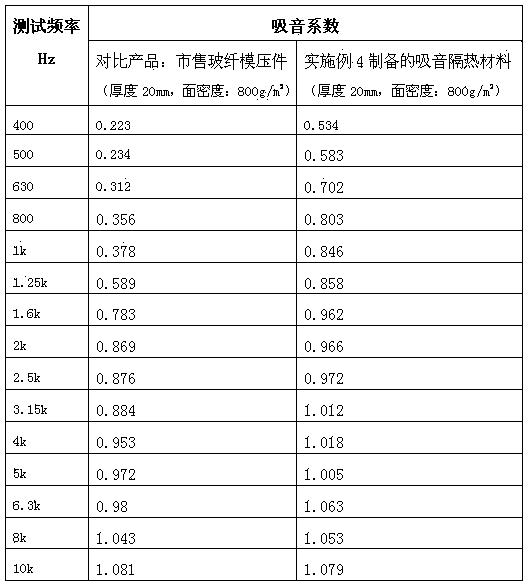

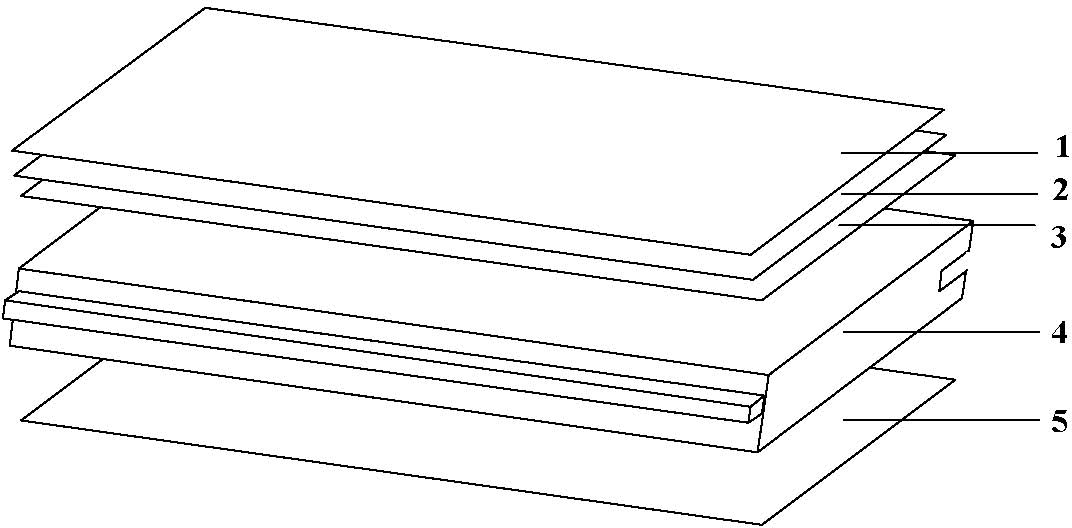

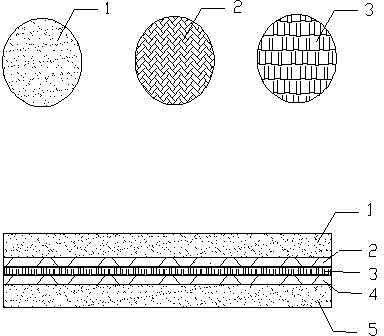

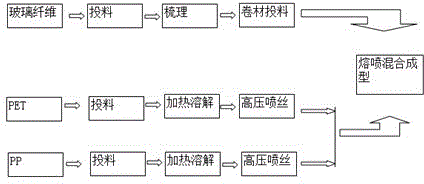

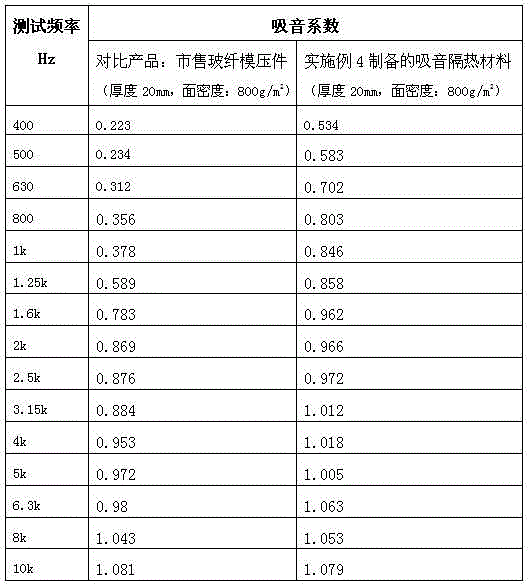

Vehicular sound-absorption and thermal-insulation material, preparation method of vehicular sound-absorption and thermal-insulation material, and prepared vehicular sound-insulating pad

InactiveCN104339782ASatisfy flame retardancyImprove sound absorptionSynthetic resin layered productsLaminationGlass fiberSoundproofing

The invention discloses a vehicular sound-absorption and thermal-insulation material and a preparation method of the vehicular sound-absorption and thermal-insulation material; the vehicular sound-absorption and thermal-insulation material comprises the components including PP, PET and glass fibres; the vehicular sound-absorption and thermal-insulation material is divided into five layers sequentially including a bottom glass fibre layer, a second mixed fibre layer comprising glass fibres, PP fibres and PET fibres, a medium mixed fibre layer comprising a PP material and PET, a fourth mixed fibre layer comprising the glass fibres, the PP fibres and the PET fibres, and a surface glass fibre layer; and the five layers are molten and connected into a whole. By means of the manner, the vehicular sound-absorption and thermal-insulation material disclosed by the invention not only can satisfy the flame-retardant property but also is capable of improving the sound-absorption property; in addition, on the basis of that of a traditional sound-absorption and thermal-insulation material, the sound-absorption property is increased by 30-50%.

Owner:武汉新环球汽车内饰件有限公司

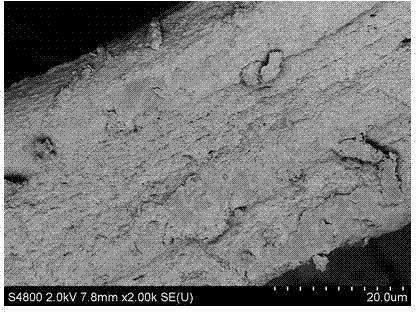

Wear-resisting anti-flaming poplar solid flooring and preparation method thereof

The invention provides a wear-resisting anti-flaming poplar solid flooring which is mainly composed of a modified solid flooring billet layer, and a preparation method of the wear-resisting anti-flaming poplar solid flooring; the wear-resisting anti-flaming poplar solid flooring sequentially comprises a balance moisture-proof layer, the modified solid flooring billet layer, a color blending layer, an ultrathin natural veneer decoration layer and a wear-resisting layer from bottom to top. The method comprises the steps of preparing a composite modified impregnation liquid and performing technologies of vacuum pressurization dipping treatment, drying, assembling and pressing and the like on woods. A composite modification processing technique of the invention enables the strength of poplar to be increased, the stability of the poplar to be enhanced, and enables the poplar to have properties of wear resistance, flame retardant, mildew prevention and anticorrosion and the like, so that the utilization value of artificial poplar is improved greatly. The method is simple and easy; and the wear-resisting anti-flaming poplar solid flooring processed by the method has the advantages of scratch resistance, wear resistance, flame retardant, mildew prevention, anticorrosion, easiness in maintenance, natural textures, comfort, environmental protection and high cost performance.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Mud-resistant low-smoke zero-halogen flame-retardant cross-linked polyolefin sheathed rubber material and preparation method thereof

InactiveCN104761809AGood oil resistanceImprove thermal stabilityInsulated cablesInsulatorsRubber materialCross-link

The invention provides a mud-resistant low-smoke zero-halogen flame-retardant cross-linked polyolefin sheathed rubber material and a preparation method thereof. The mud-resistant low-smoke zero-halogen flame-retardant cross-linked polyolefin sheathed rubber material has the advantages of being good in oil resistance, mud resistance, thermal stability and flexibility, and solves the existing technical problems. The mud-resistant low-smoke zero-halogen flame-retardant cross-linked polyolefin sheathed rubber material comprises 70-100 parts of ethylene-vinyl acetate copolymer elastomer, 0-30 parts of ethylene-propylene-diene monomer rubber, 100-160 parts of flame retardants, 0-40 parts of reinforcing agents, 1-2.5 parts of anti-aging agents and 1.5-3 parts of coupling agents. Accordingly to the technical scheme, the mud-resistant low-smoke zero-halogen flame-retardant cross-linked polyolefin sheathed rubber material and the preparation method thereof well solves the existing technical problems.

Owner:罗晓锋

Preparation method of halogen-free CEM-1 copper-clad plate with high peeling strength

ActiveCN106739376AIncrease crosslink densityReduce dosagePaper coatingLaminationBisphenol AChemistry

The invention belongs to the technical field of copper-clad plate production, and especially relates to a preparation method of a halogen-free CEM-1 copper-clad plate with a high peeling strength. Phosphor containing epoxy resin and bisphenol A type epoxy resin are taken as the main resin; phosphor containing linear phenolic resin is taken as the curing agent, polyfunctional epoxy resin is used to enhance the heatproof performance; a certain ratio of aluminum hydroxide is added to increase the electric tracking resistant index of the copper-clad plate; a nitrogen and phosphor containing fire retardant is added, and through the synergistic effect between nitrogen and phosphor, the fireproof performance of the copper-clad plate is enhanced and can reach the FV0 grade. By processing the surface of used filling material and controlling the particle size, the filling material can be evenly dispersed into resin glue to obtain uniform glue dipped sheets, the toughness of sheets is improved, the obtained copper-clad plate can reach the environment protection requirements and does not contain any halogen, the contents of chlorine and bromine are low, the peeling strength is high, the characteristic of resisting tracking caused by electric leakage is excellent, and CTI>=600V.

Owner:SHANDONG JINBAO ELECTRONICS

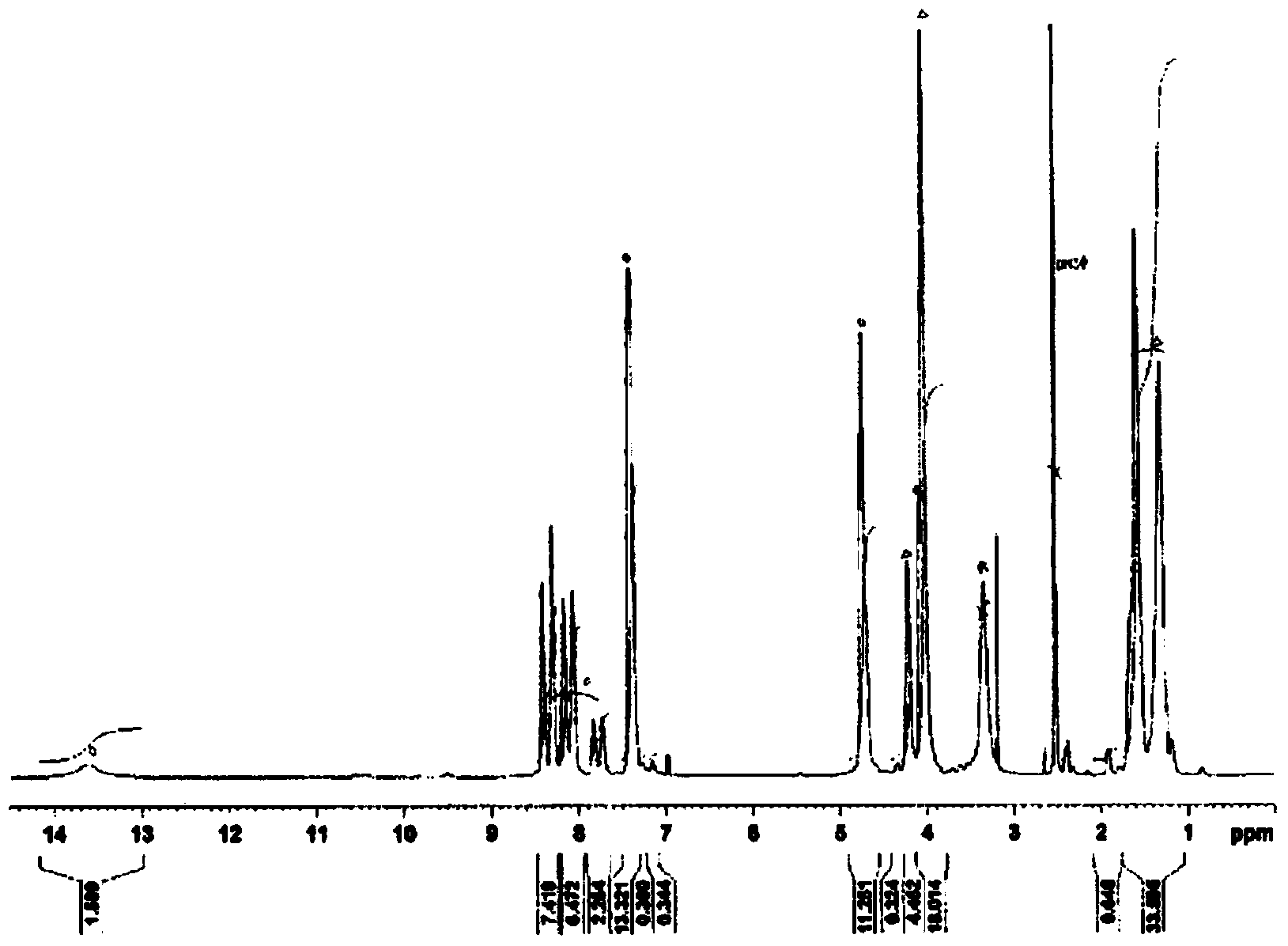

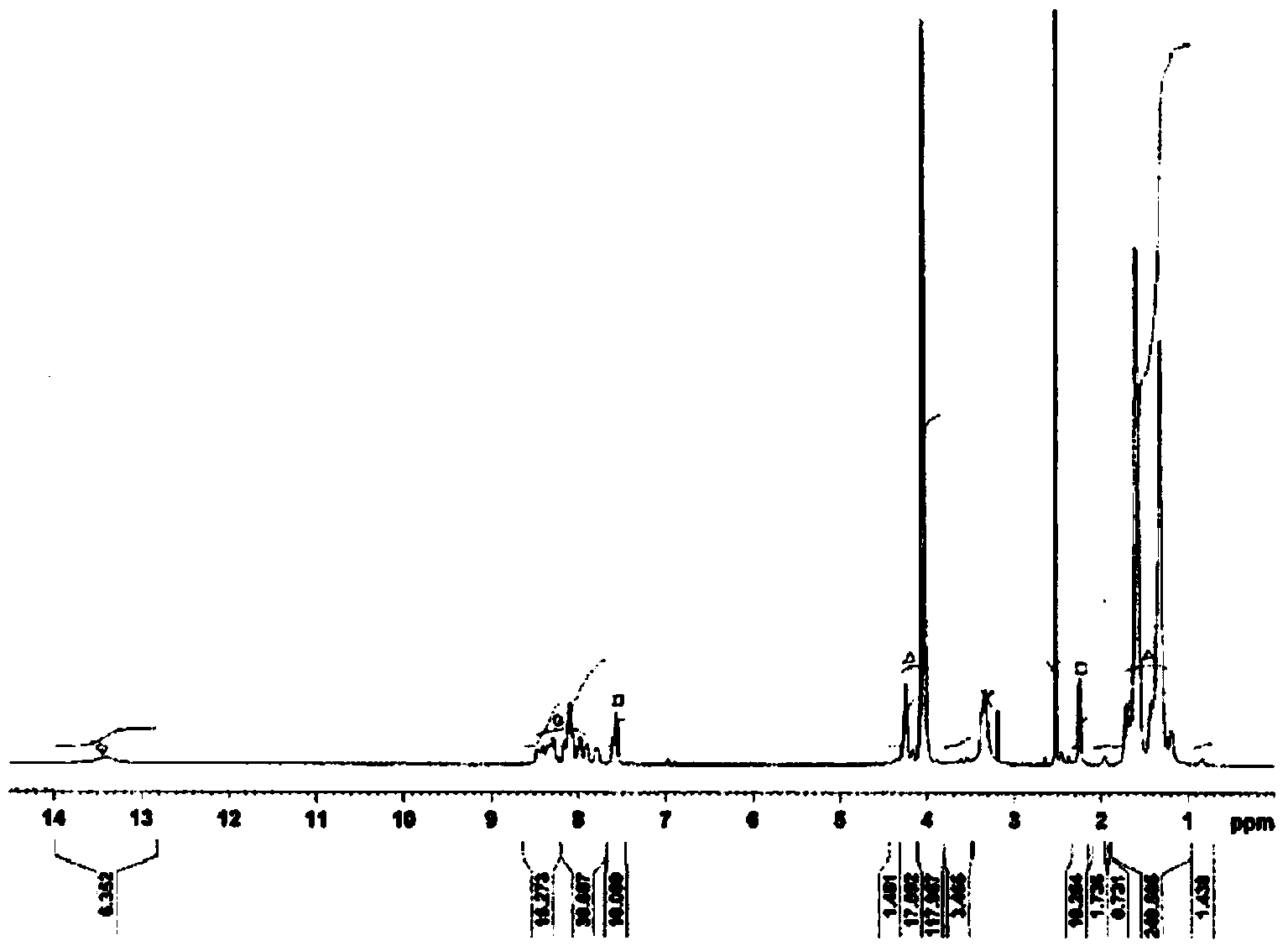

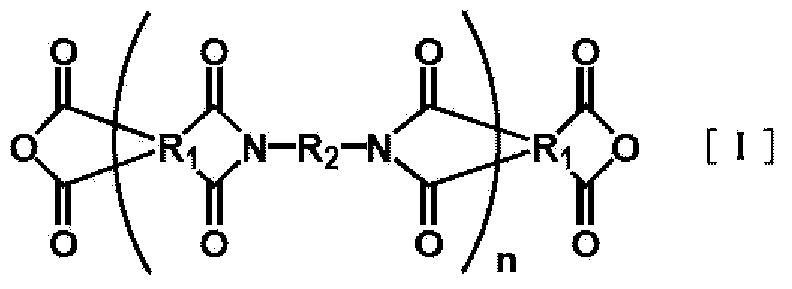

Carboxyl group-ontaining polyimide, heat-curable resin composition, and flexible metal-clad laminate

Provided are a carboxyl group-containing polyimide and a prepolymer thereof, and the carboxyl group-containing polyimide can provide a cured product that simultaneously exhibits heat curing properties, PCT resistance, solvent resistance and peel strength. The present invention relates to an imide prepolymer containing a terminal acid anhydride group and characterized by being obtained by reacting an acid anhydride group in a tetracarboxylic dianhydride with an isocyanate group in a diisocyanate compound. The present invention also relates to the carboxyl group-containing polyimide characterized by having a structure in which the aforementioned imide prepolymer containing a terminal acid anhydride group undergoes chain extension via a polyol compound. Furthermore, the present invention relates to a heat-curable resin composition and a flexible metal-clad laminate that use the carboxyl group-containing polyimide.

Owner:TOYOBO CO LTD

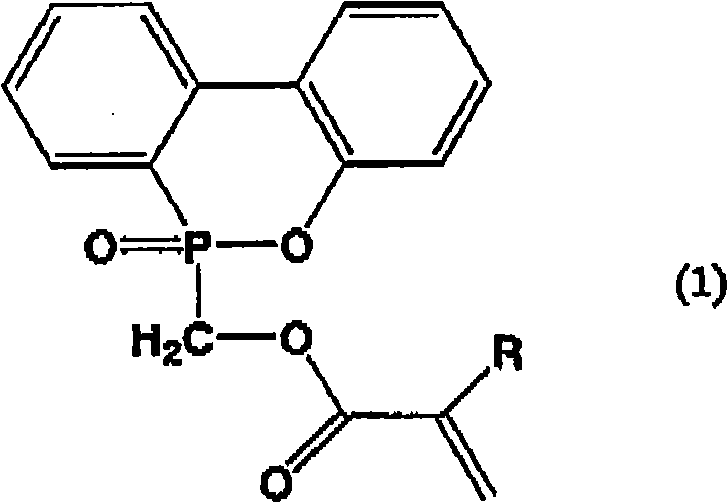

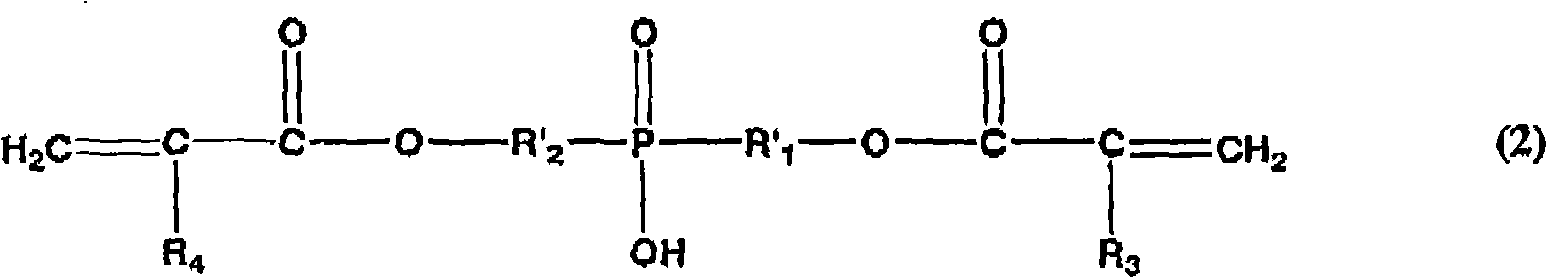

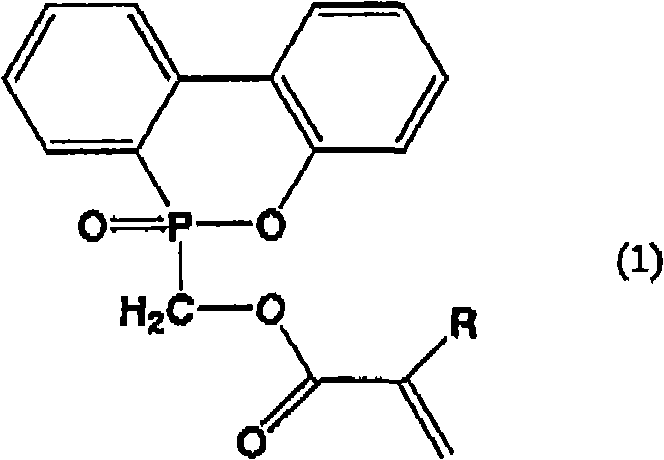

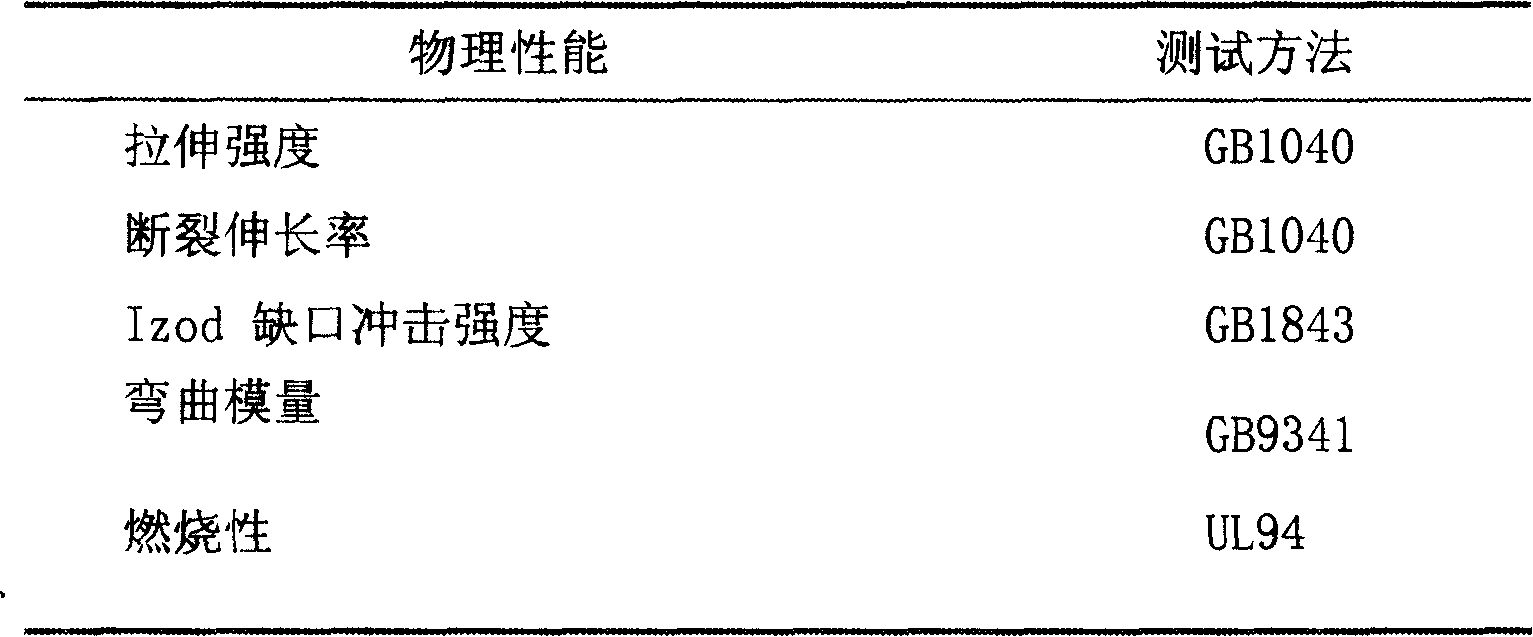

Active energy ray solidification type resin composition using reactivity compound with fire retardance and condensate thereof

InactiveCN101538348ASatisfy flame retardancyImprove heat resistanceOther chemical processesSynthetic resin layered productsHydrogen atomPliability

The present invention provides an active energy ray solidification type resin composition using a reactivity compound with a fire retardance and a condensate thereof. The active energy ray solidification type resin composition has a high fire retardance, a superior light sensitivity, a solidifying film of the composition has a developing character, a solidifying character, a closing character, a HAST resistance, a pliability and the like, and is specially suitable for a light-sensitive resin composition for a welding resistance layer and a light-sensitive resin composition for a flexible printing substrate. The active energy ray solidification type resin composition contains a phosphine oxide (A) represented by formula (1), a reactivity compound (B) having more than two active energy ray reactivity functional groups within a molecule and a optical polymerization initiator (C), in the formula (1), R represents a hydrogen atom or methyl.

Owner:NIPPON KAYAKU CO LTD

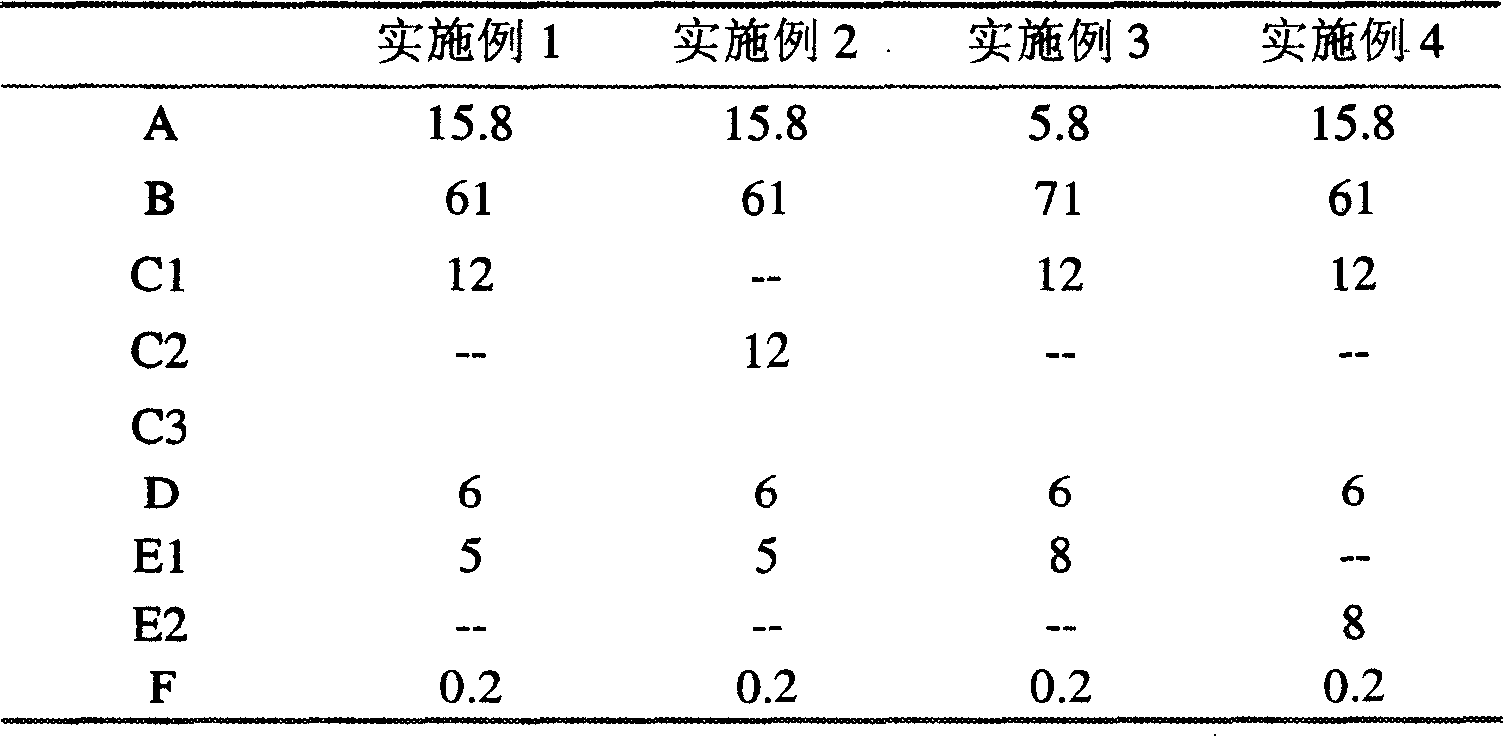

Thermoplastic flame-proof filling compositions

The invention discloses a thermoplastic flame-retarding filling compound, comprising an A component of 1 to 99%, a B component of 0 to 85%, a C component of 2 to 35%, a D component of 1 to 15%, an E component of 1 to 30% and an F component of 0.05 to 2%. The thermoplastic flame-retarding filling compound is characterized in that: the A component is a graft polymer with an A1 grafted on an A2, and the A1 is a vinyl monomer with a weight percentage of 5 to 95, and A2 is a graft base with a weight percentage of 95 to 5% with vitrification conversion temperature below zero DEG C and an even granularity of 0.20 to 0.40 Mum; the B component is a thermoplastic vinyl copolymer; the C component is a flame retardant; the D component is an assistant flame retardant; the E component is an inorganic compound; the F component is a fluorinated polyolefin. The thermoplastic flame-retarding filling compound has the advantages of reducing the infaust effect to the composition mechanical property from inorganic fillers, and satisfying various specific requirements to flame retardance, dimension stability, mechanical property and specific gravity at particular occasions, just as a stereo set product, a special electronic electric appliance and other occasions.

Owner:KINGFA SCI & TECH CO LTD +1

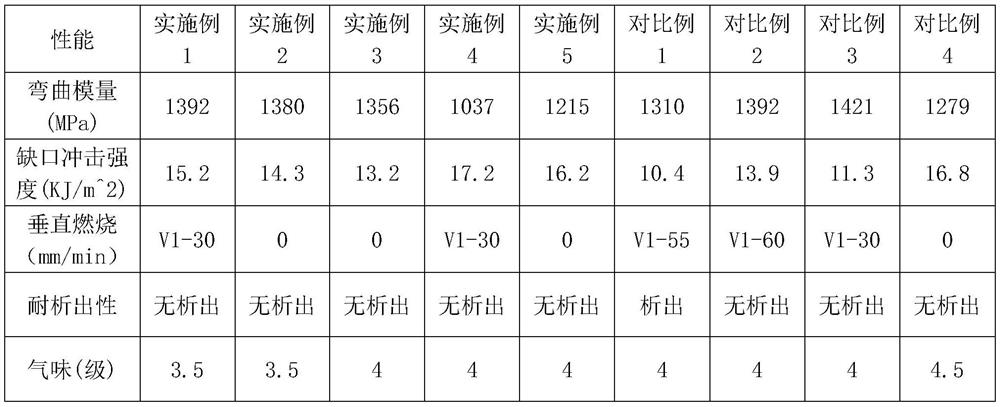

Halogen-free flame-retardant polypropylene material for automotive interiors and preparation method thereof

The invention discloses a halogen-free flame-retardant polypropylene material for automotive interiors, which is prepared from the following raw materials in parts by weight: 40-70 parts of polypropylene, 10-20 parts of coated ammonium polyphosphate, 5-10 parts of piperazine pyrophosphate, 5-10 parts of a synergistic flame retardant, 0.5-2 parts of a compatilizer, 0-10 parts of an inorganic filler, 10-20 parts of a flexibilizer, 0.2-1 part of a deodorant and 0.3-1.5 parts of a stabilizer, wherein the coated ammonium polyphosphate is prepared by carrying out surface coating modification on high-polymer ammonium polyphosphate by using melamine formaldehyde and epoxy resin. The polypropylene material provided by the invention not only meets the requirement for flame retardant property, but also has the characteristics of excellent rigid-tough balance, precipitation resistance and low odor, is suitable for being applied to automobile industry interiors, and is particularly suitable for passenger car interiors.

Owner:江苏尚艾新材料科技有限公司

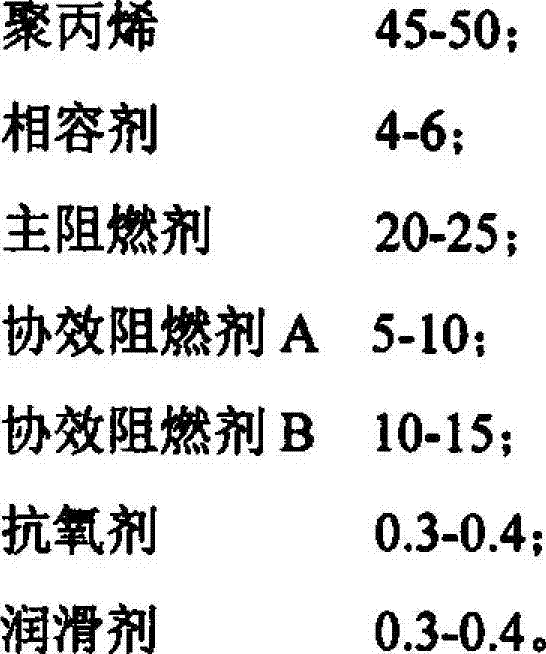

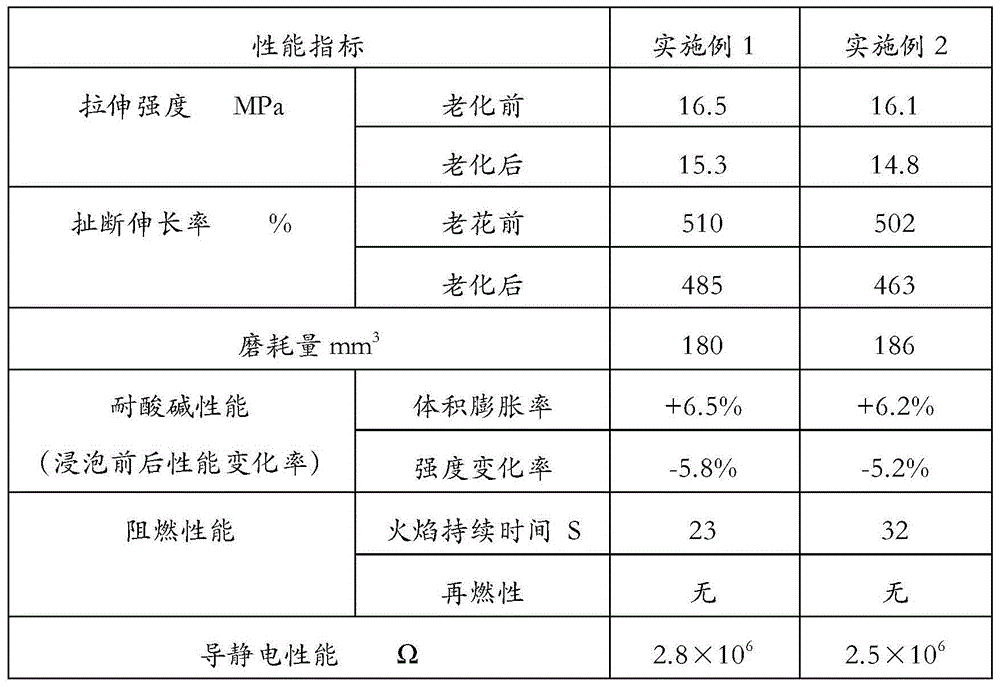

High glow-wire/high-CTI halogenous flame-retardant polypropylene composite and preparation method thereof

InactiveCN102964695AIt is difficult to improve defects such as high requirementsGood compatibilityAntioxidantFire retardant

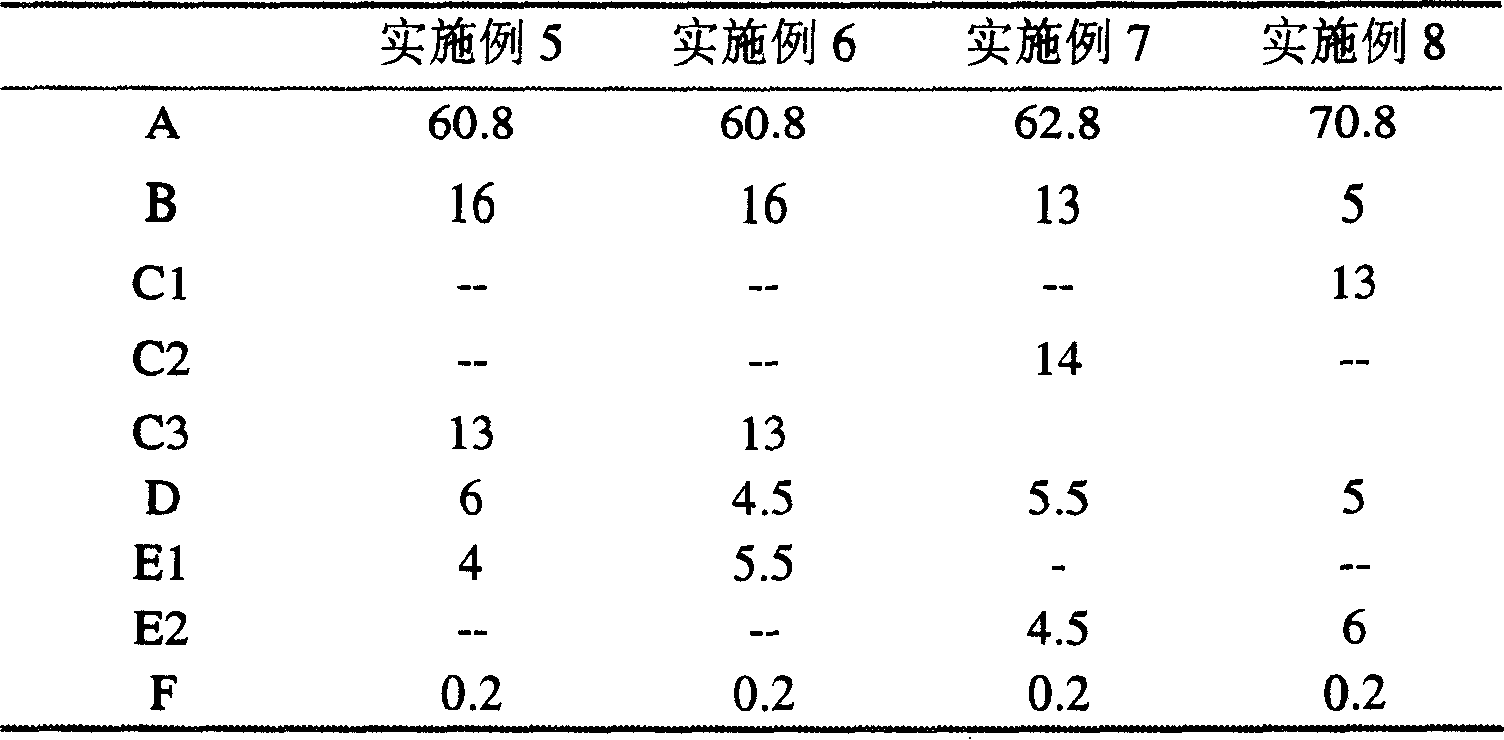

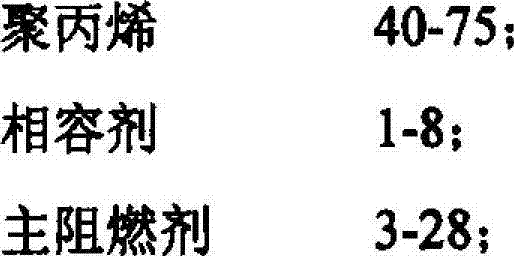

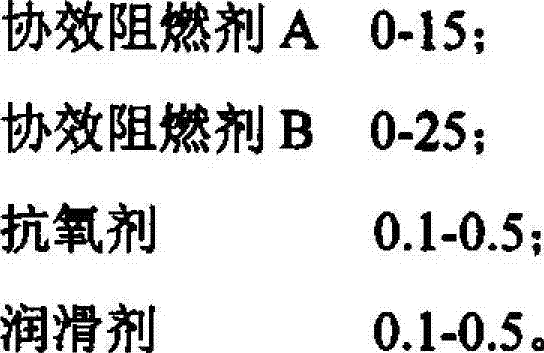

The invention relates to a high glow-wire / high-CTI halogenous flame-retardant polypropylene composite and a preparation method thereof. The composite is prepared from the following raw materials in parts by weight: 40-75 parts of polypropylene, 1-8 parts of a compatilizer, 3-28 parts of main flame retardant, 0-15 parts of synergistic flame-retarded agent A, 0-25 parts of synergistic flame-retarded agent B, 0.1-0.5 part of antioxidant, and 0.1-0.5 part of lubricant. The preparation method comprises the following steps: weighting raw materials in a certain weight ratio, and putting all the raw materials in a high-speed mixer to carry out mixing 2-10 minutes; taking out of the raw materials; and putting the uniformly mixed raw materials into a double-screw extruder to carry out extrusion granulation. The composite disclosed by the invention is developed aiming at the special requirements of electrical appliance products on antistatic and flame-retardant properties of materials; and compared with the prior art, the composite disclosed by the invention meets the flame-retardant properties required by products, and is good in mechanical properties and excellent in processing performance, and the glow-wire temperature of the composite is greatly improved.

Owner:SHANGHAI SUNNY

Antiflaming acid-alkali resistant conveyer belt covering glue and preparation method thereof

InactiveCN104927138ADelay corrosion aging crackingImprove acid and alkali resistanceCorrosion resistantCarbon black

The invention provides antiflaming acid-alkali resistant conveyer belt covering glue which is prepared from the following components in parts by weight: 70 parts of neoprene CR 322, 20 parts of natural rubber, 10 parts of butadiene rubber 9000, 1-2 parts of an antiager RD, 1-3 parts of an antiager 4010 NA, 4-8 parts of zinc oxide, 2-8 parts of magnesium oxide, 1-3 parts of stearic acid, 1-3 parts of mold cleaner 985 P, 5-20 parts of chlorinated polyethylene CPE 135, 15-50 parts of N 220 carbon black, 10-30 parts of N 330 carbon black, 1-4 parts of sulphur, 10-30 parts of superfine barium sulfate, 4-8 parts of antimonous oxide, 10-30 parts of chlorinated paraffin 70, 5-20 parts of zinc borate and 1-3 parts of an accelerant DM. The invention further provides a preparation method of the antiflaming acid-alkali resistant conveyer belt covering glue. The antiflaming acid-alkali resistant conveyer belt covering glue has the advantages of being corrosion resistant and unlikely to age and chap during the transportation process, excellent in abrasion resistance and tearing property, and long in service life.

Owner:江苏凯嘉橡胶科技股份有限公司

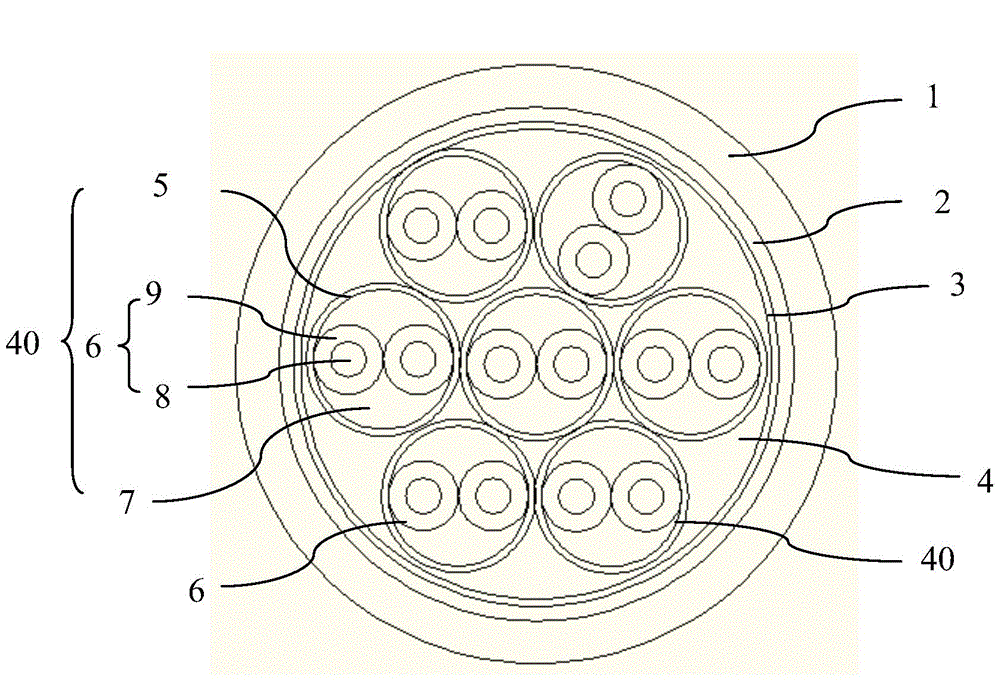

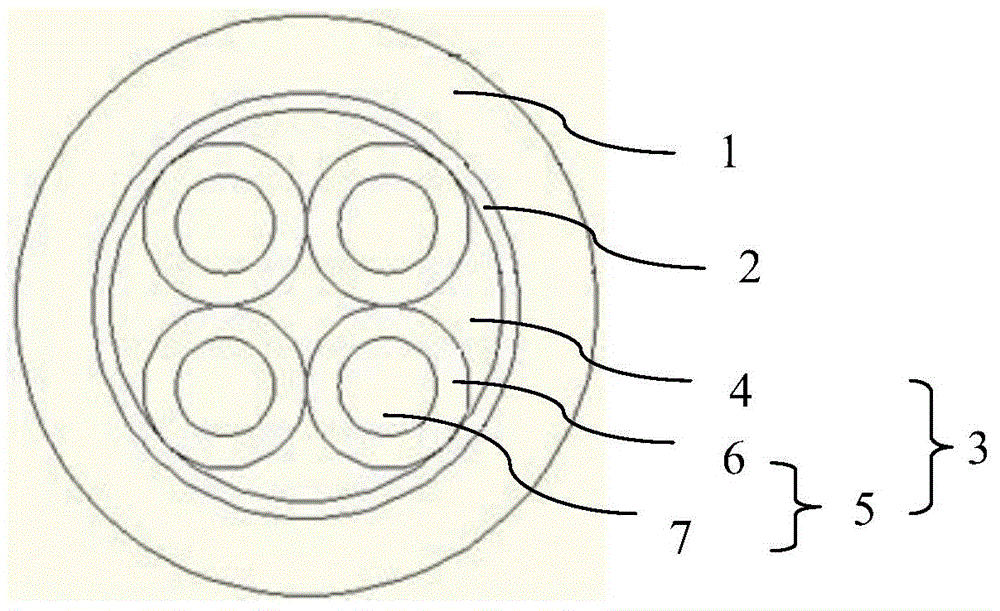

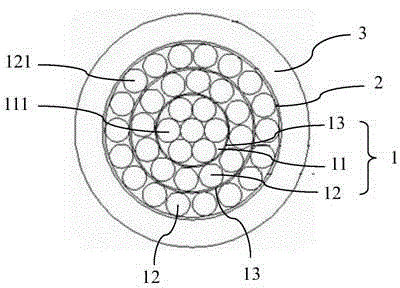

Novel computer transmission cable and manufacturing method therefor

ActiveCN105845263AIncrease transfer speedImprove anti-aging propertiesInsulated cablesCable/conductor manufactureElectrical conductorCopper wire

The invention discloses a novel computer transmission cable and a manufacturing method therefor. The cable comprises cable cores, an isolation layer, a first shielding layer, and a sheath layer, wherein the isolation layer, the first shielding layer and the sheath layer sequentially wrap the cable cores. Each cable core is twisted by a plurality of core units, and each core unit comprises two twisted insulating core wires and a second shielding layer wrapping two insulating core wires. The first shielding layer and the second shielding layer are respectively formed by the braiding of first copper wires, wherein the braiding density of the first copper wires is greater than 80%. The insulating core wires respectively comprise a conductor and an insulating layer wrapping the conductor. The conductors are respectively formed by the twisting of a plurality of second copper wires, wherein the diameter of each second wire is less than 0.18mm. The beneficial effects of the invention are that the insulating core wires employ a double-shielding mode: branch shielding and main shielding; the transmission speed of the cable is further increased; and the dielectric loss and attenuation of the cable are reduced.

Owner:ANHUI LIANJIAXIANG SPECIAL CABLE

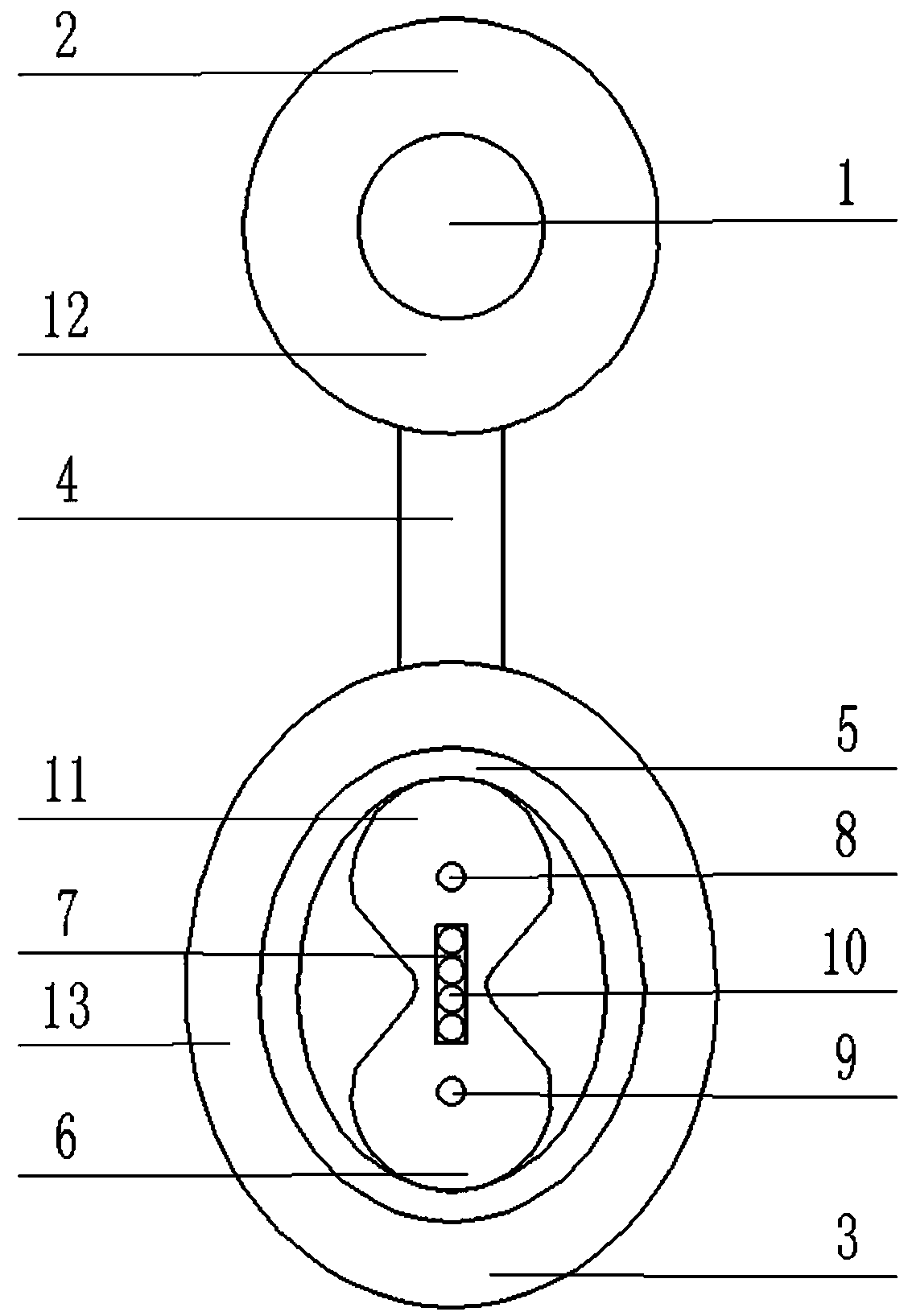

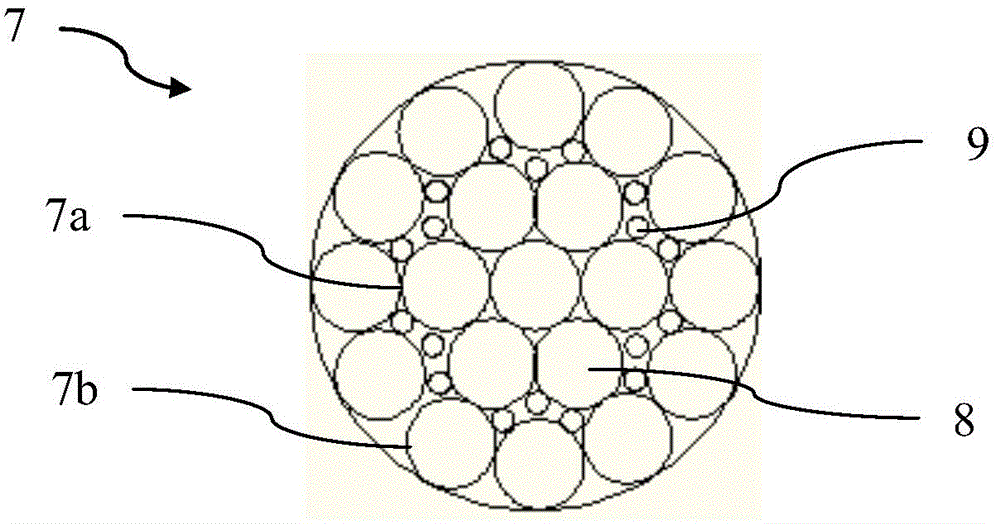

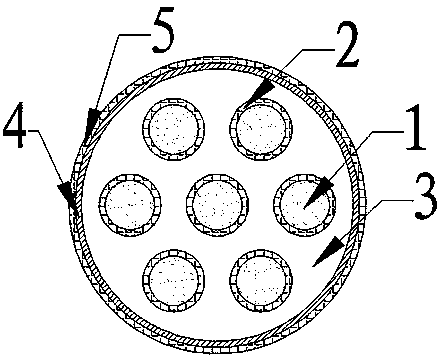

Capacity-expanding weather-resistant rural home-entry leading-in optical cable

PendingCN111399147AGuaranteed performanceLow weather resistanceFibre mechanical structuresComposite materialWeather resistance

The invention discloses a capacity-expanding weather-resistant rural home-entry leading-in optical cable. The optical cable is of an 8-shaped structure. The optical cable comprises a suspension wire part (12), an optical cable part (13) and a suspension tape (4). The suspension wire part (12) comprises a metal self-supporting member (1) and a first outer sheath (2). The optical cable part (13) isoval and comprises a second outer sheath (3), a water blocking tape (5) and a disc cable (11), the disc cable (11) comprises an inner sheath (6), an optical fiber tape (7), a first reinforcing piece (8) and a second reinforcing piece (9), the optical fiber tape (7) is arranged in the middle of the inner sheath (6), and four optical cable cores (10) connected side by side are arranged in the optical fiber tape. The beneficial effects of the optical cable are that the optical fiber capacity can be increased, the large-span introduction of the optical cable can be realized, and the performance ofthe introduced optical cable can be ensured under the rural conditions of severe environment and lack of rods and circuits, thereby providing a reliable broadband network and effectively reducing theconstruction cost of the rural broadband network.

Owner:成都亨通光通信有限公司 +1

Cable material and preparation method thereof

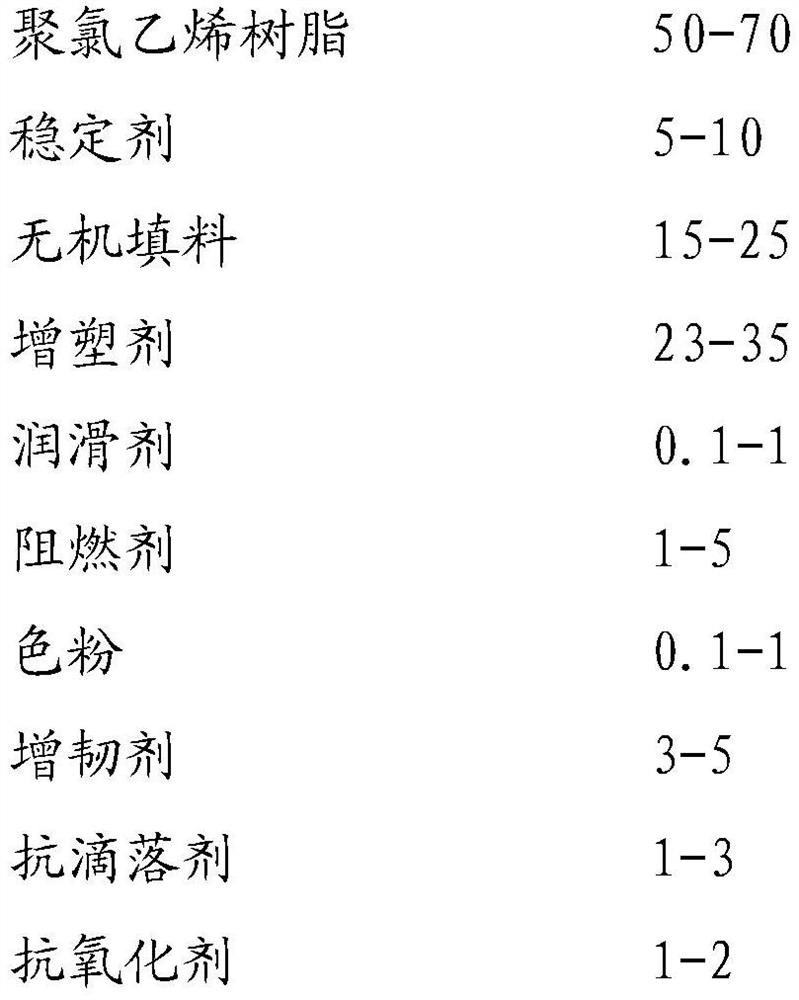

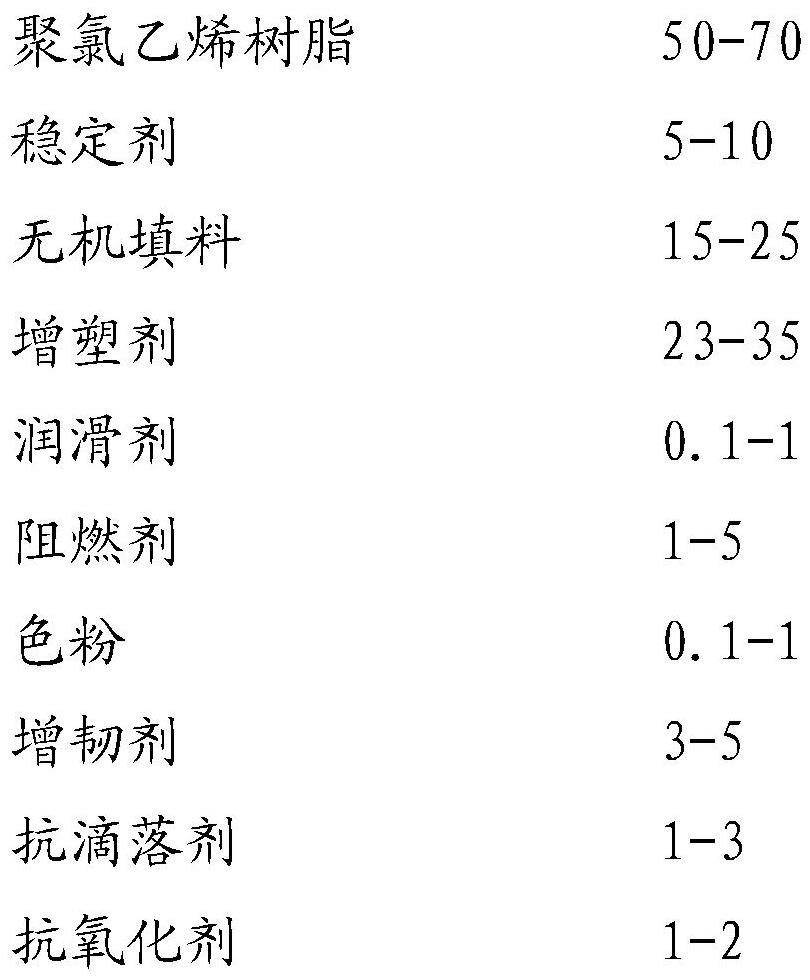

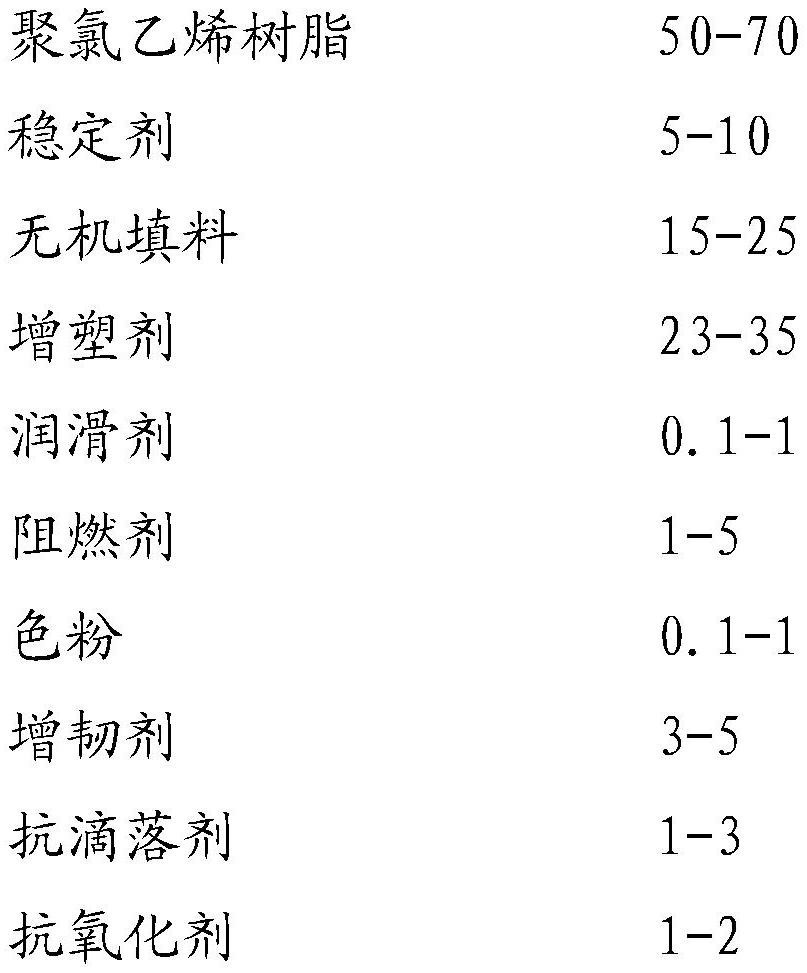

ActiveCN111909470AMeet the tensile strengthSatisfy elongationPlastic/resin/waxes insulatorsClimate change adaptationPolymer sciencePlasticizer

The embodiment of the invention relates to the technical field of cable materials, in particular to a cable material and a preparation method thereof. The cable material is prepared from, by weight, 50-70 parts of polyvinyl chloride resin, 5-10 parts of stabilizer, 15-25 parts of inorganic filler, 23-35 parts of plasticizer, 0.1-1 part of lubricant, 1-5 parts of flame retardant, 0.1-1 part of toner, 3-5 parts of flexibilizer, 1-3 parts of anti-dripping agent and 1-2 parts of antioxidant; wherein the inorganic filler comprises a first filler for improving the peel strength of the cable materialand a second filler for improving the electrical property of the cable material, and the plasticizer at least comprises an epoxy oil plasticizer and a benzene plasticizer. The cable material can satisfy related requirements of European standards, and has high tensile strength, elongation, good flame retardance and the like.

Owner:GUANGZHOU NANYANG CABLE

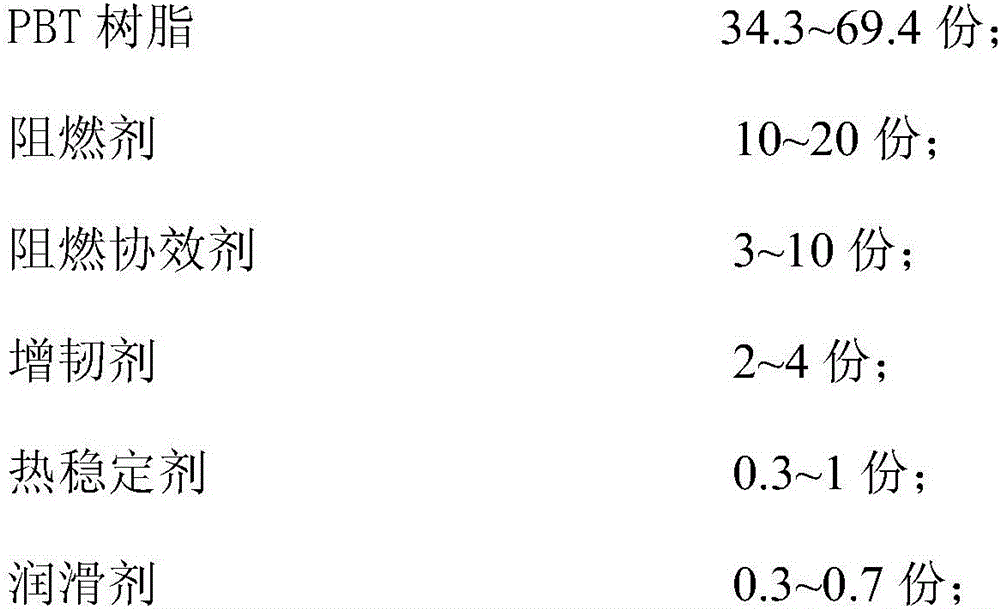

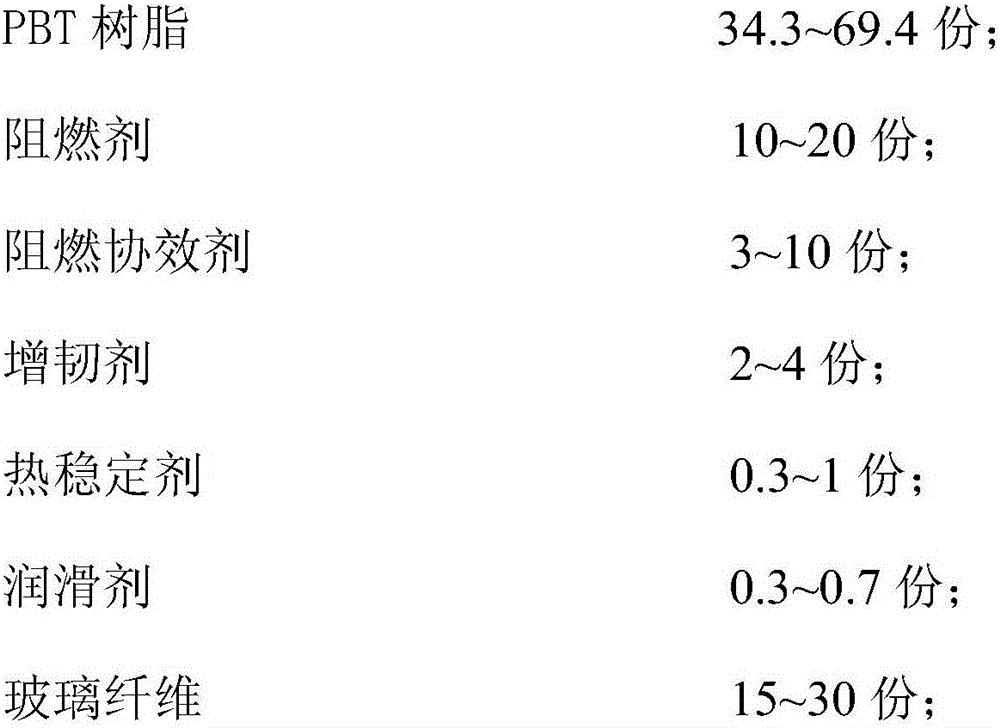

Charging pile CTI high glow wire PBT composite material and preparation method thereof

A charging pile CTI high glow wire PBT composite material consists of the following components in parts by weight: 34.3-69.4 parts of PBT resin, 10-20 parts of a fire retardant, 3-10 parts of a flame-resistant synergist, 2-4 parts of a flexibilizer, 0.3-1 part of a heat stabilizer, 0.3-0.7 part of a lubricating agent and 15-30 parts of glass fibers. The charging pile CTI high glow wire PBT composite material is provided by the invention, directing at the use limitations that tracking is formed on an existing flame-resistant PBT electronic equipment product under voltage of 250 V or above, and a glow wire at the temperature of 850 DEG C ignites easily.

Owner:深圳市高科塑化有限公司

Composite waterproof cable and preparation method thereof

InactiveCN105810338AHas a service lifeReach radialClimate change adaptationInsulated cablesElectrical conductorInsulation layer

The invention discloses a composite waterproof cable and a preparation method thereof. The composite waterproof cable comprises a cable inner core, an isolation layer and a sheath layer, wherein the isolation layer and the sheath layer successively cover the cable inner core from the inside out. The cable inner core is formed by twisting a number of insulation core wires. Water blocking filling layers are arranged in twisting voids of a number of insulation core wires. Each insulation core wires comprises a conductor group and an insulation layer which covers the conductor group. Each conductor group is formed by tow-twisting a number of copper wires and a number of water blocking wires, wherein the filament diameter of each water blocking wire before water swelling is less than or equal to the filament diameter of each copper wire, and the filament diameter of each copper wire is less than 0.2mm. According to the invention, water blocking ropes are arranged in twisting voids of a number of insulation core wires; the water blocking ropes can block radial seepage of the cable and can absorb vertical seepage of the cable; and radial and longitudinal full range stereo waterproof effect of the cable is realized.

Owner:SHENZHEN LIANJIAXIANG SCI & TECH

Small cross section super flexible waterproof cable and preparation method thereof

InactiveCN105810317AGood flexibilityIncrease the flexibilityNon-insulated conductorsClimate change adaptationElectrical conductorWater layer

The invention discloses a small cross section super flexible waterproof cable and a preparation method thereof. The small cross section super flexible waterproof cable comprises a cable inner core, an external water resistance layer and an insulating layer, wherein the external water resistance layer and the insulating layer sequentially cover the cable inner core from inside to outside. The cable inner core is formed by sequentially stacking and coating a number of conductor layers. Each conductor layer comprises a first conductor layer and a number of second conductor layers which sequentially cover the first conductor layer. An internal water resistance layer is arranged between two adjacent conductor layers. The cross section area of the cable inner core is more than 10mm<2>. According to the invention, an internal water resistance layer is wrapped between two adjacent conductor layers; the conductor layers can be fixed and are prevented from loosening; water infiltrating into the cable can be absorbed; the internal water resistance layers which absorb water can expand more than twice their size; radial seepage of the cable can be effectively prevented; vertical seepage of the cable can be absorbed; and conductor oxidizing is prevented.

Owner:SHENZHEN LIANJIAXIANG SCI & TECH

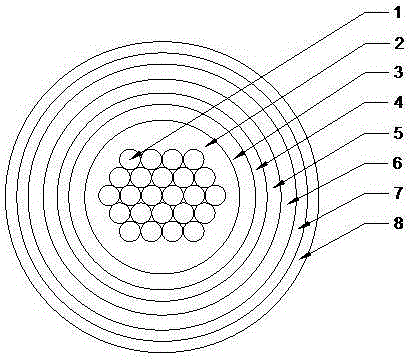

Insulation flame-retardant wire

InactiveCN103745776ALight textureSatisfy flame retardancyPlastic/resin/waxes insulatorsInsulated cablesInsulation layerElectrical conductor

The invention discloses an insulation flame-retardant wire. The insulation flame-retardant wire comprises conductors, first flame-retardant layers, an insulation layer, a noctilucence layer and a second flame-retardant layer, wherein the conductors are connected with the first flame-retardant layers, the first flame-retardant layers are connected with the insulation layer, the insulation layer is connected with the noctilucence layer, and the noctilucence layer is connected with the second flame-retardant layer. Through such a mode, the insulation flame-retardant wire provided by the invention is light in weight, can satisfy the requirements for flame retardation, wear resistance and long-term heat resistance at the same time, and can prevent an accident that the combustion of an inner line ignites a neighboring wire.

Owner:KUNSHAN FENFA INSULATING MATERIALS

Preparation method of flame-retardant composite through dynamic vulcanization

A method for preparing a dynamically vulcanized flame-retardant composite material. Belonging to the field of material preparation, including the following steps: (1) combining PP, EPDM and Mg(OH) 2 Vacuum drying was carried out separately; (2) The mixture of PP and EPDM was added to the torque rheometer and mixed until the torque was balanced, and finally the flame retardant was added and mixed until the torque was balanced. The halogen-free flame-retardant dynamic vulcanized blend; (3 ) The halogen-free flame-retardant dynamic vulcanization blend is put into a molding machine and cold-pressed under pressure to complete the preparation. By using dynamic vulcanization technology, the flame retardant properties of composite materials can be rapidly improved, and the mechanical properties are also better than those of simple blended composite materials. Appropriate surface modification of this magnesium hydroxide can meet the flame retardant properties and limit the experimental resources. Recycle and reduce costs.

Owner:SHAANXI HUANKE BIOLOGICAL TECH CO LTD

Environmentally-friendly acid-and alkali-resistant wire

InactiveCN106710696ASuit one's needsSatisfy flame retardancyInsulated cablesInsulated conductorsElastomerInsulation layer

The invention discloses an environmentally-friendly acid-and alkali-resistant wire. The environmentally-friendly acid-and alkali-resistant wire comprises seven outer protective layers and one kind of conductors; the seven outer protective layers include a galvanized annealed copper strip shielding layer, a nitrile insulation layer, a silver plated copper strip armor layer, a nickel strip shielding layer, an aluminum strip shielding layer, a chlorosulfonated ethylene-propylene polymer sheath layer and a rubber insulation layer which are distributed from inside to outside sequentially; the conductors are silver-plated annealed nickel conductors; and 24 silver-plated annealed nickel conductors are adopted. The raw materials in parts by weight of the rubber insulation layer include chlorinated polyethylene rubber, flame retardant, ethylene-vinyl acetate copolymer elastomer, barium sulfate, microcrystalline wax, carbon black, DOS, high-activity magnesium oxide, antimony oxide, DCP, TAIC, coupling agent and antioxidant. The environmentally-friendly acid-and alkali-resistant wire of the invention has the advantages of high acid and alkali resistance, environmental friendliness, inflame retardant performance, high temperature resistance and low temperature resistance, and can satisfy the needs of special cables such as acid and alkali resistant cables. According to the environmentally-friendly acid-and alkali-resistant wire of the invention, magnesium hydroxide or aluminum hydroxide is adopted to make the fire retardant, and therefore, requirements of a material system for flame retardant performance, low smoke zero and halogen-free performance can be satisfied.

Owner:SHANGHAI LUSHENYUAN IND & TRADE CO LTD

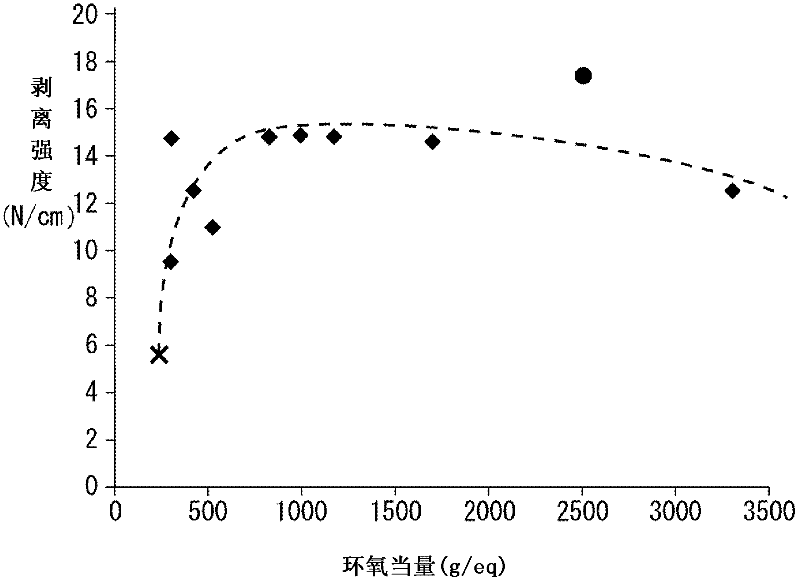

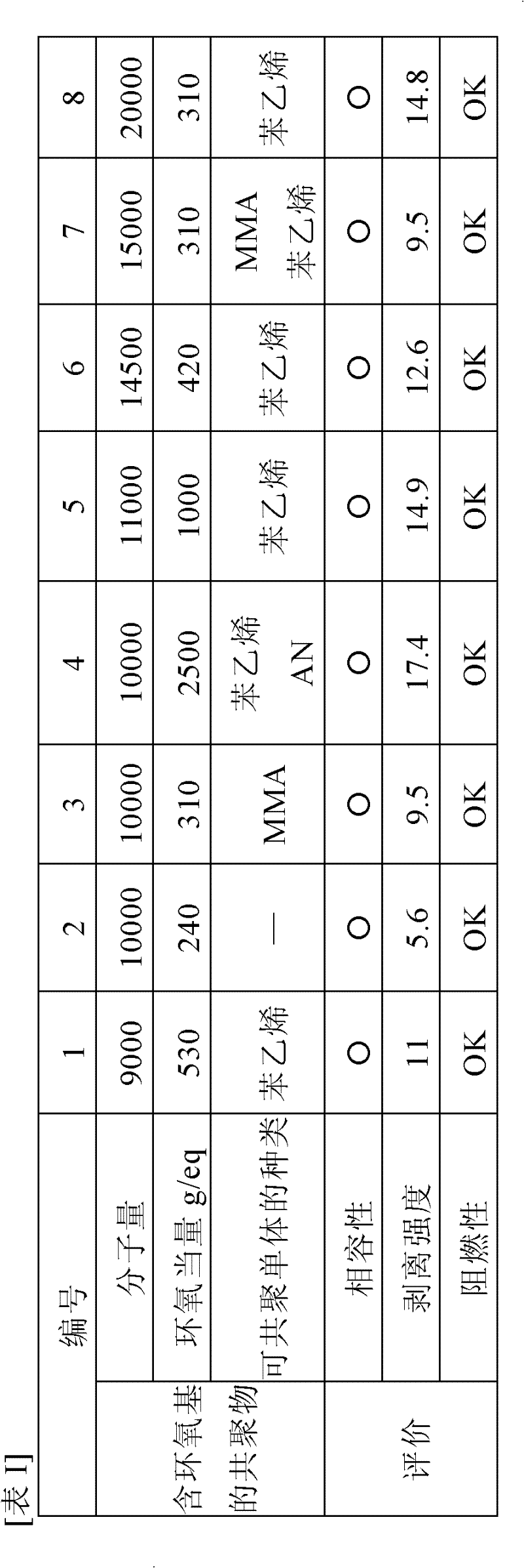

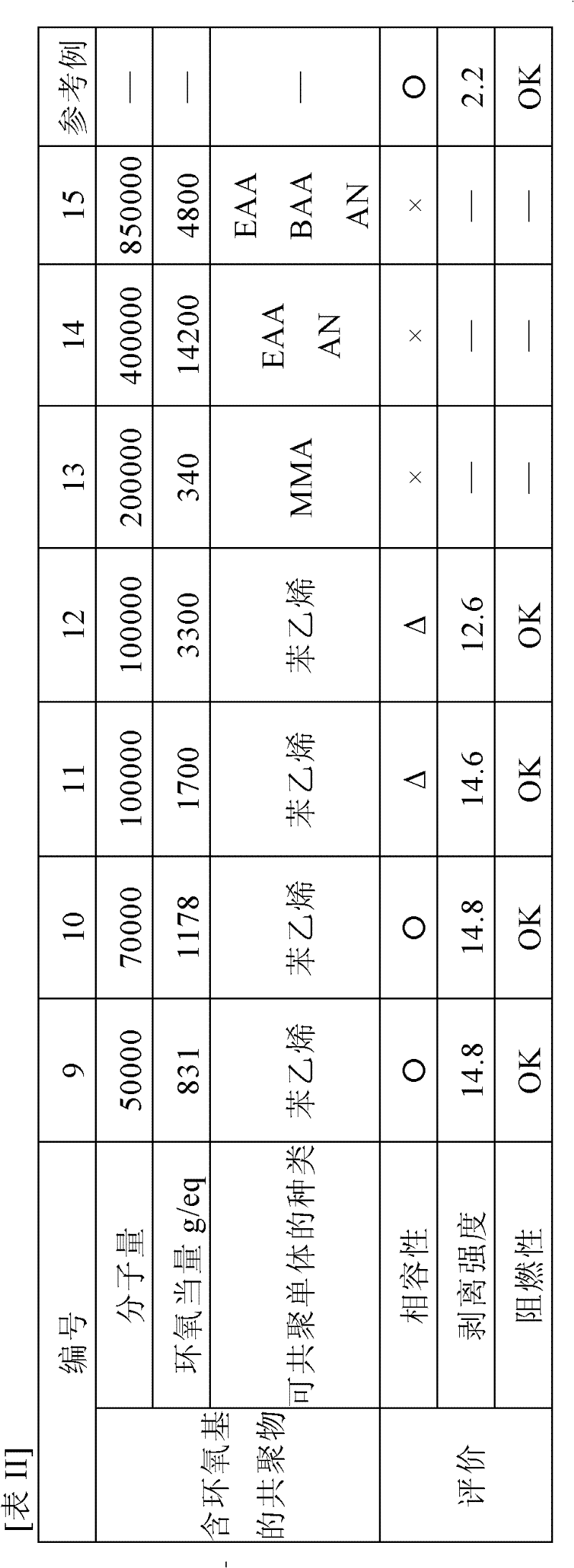

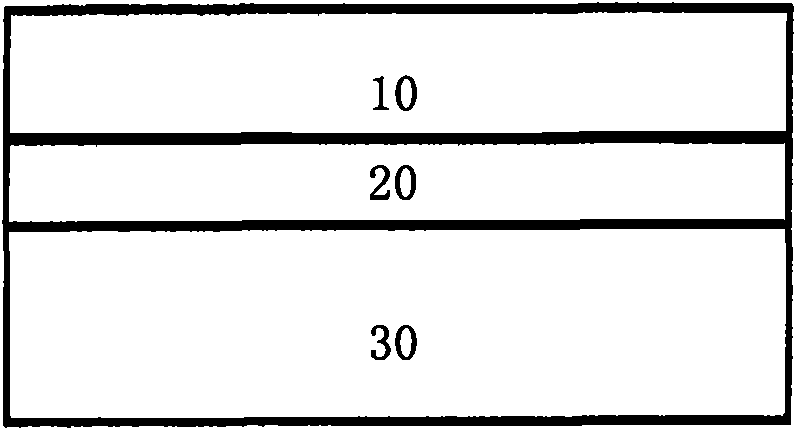

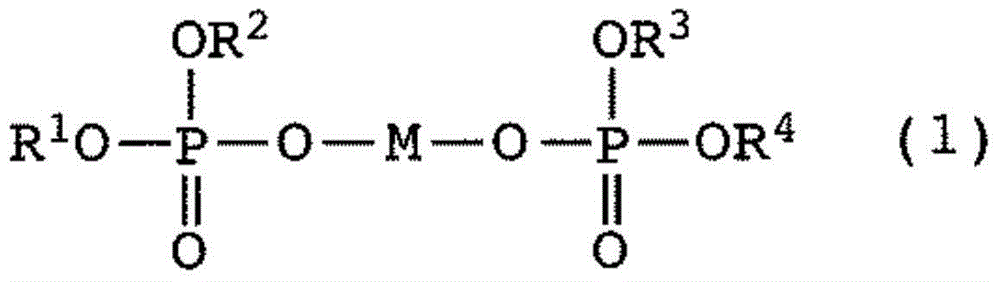

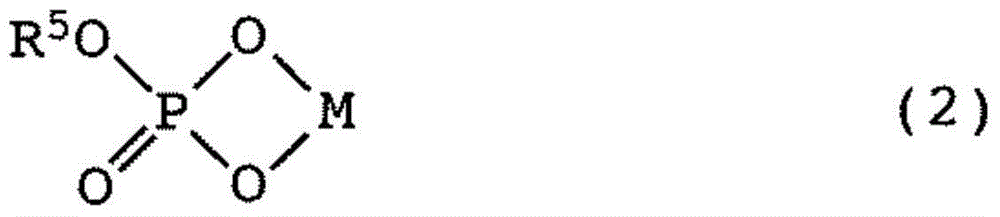

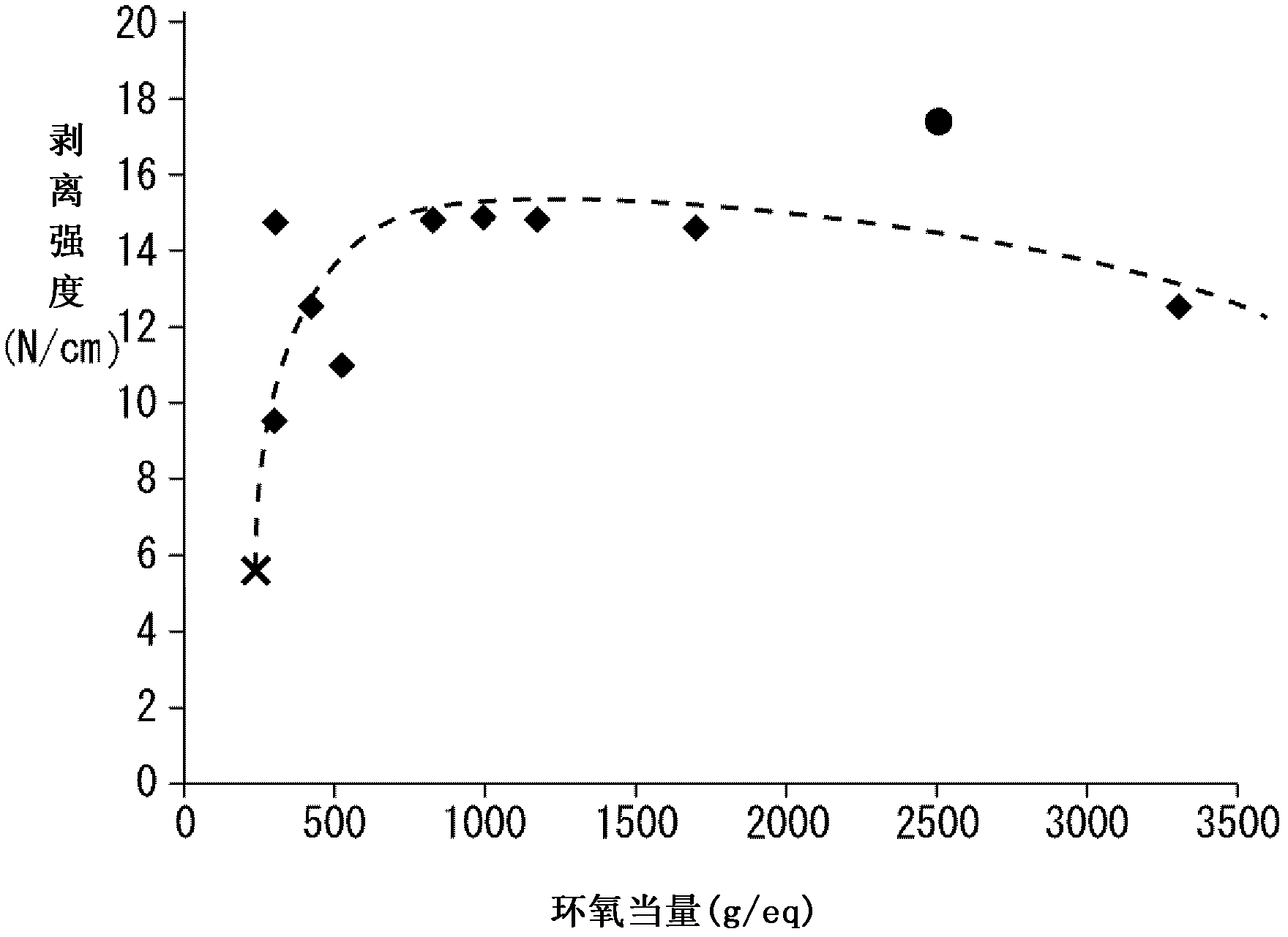

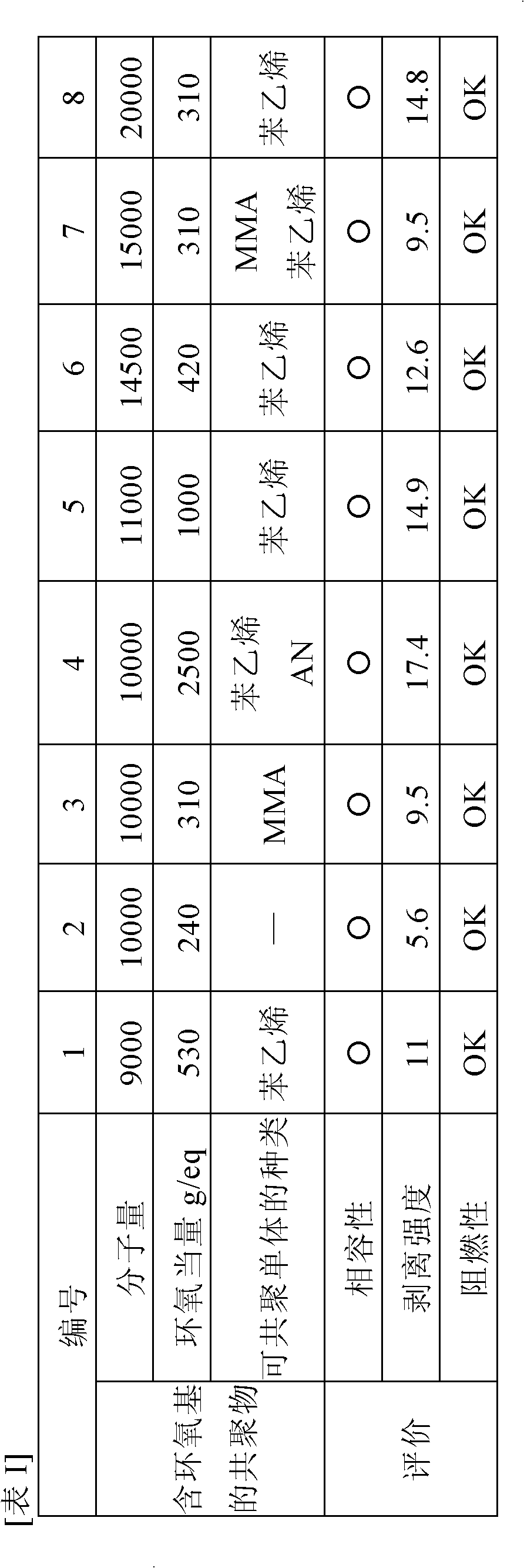

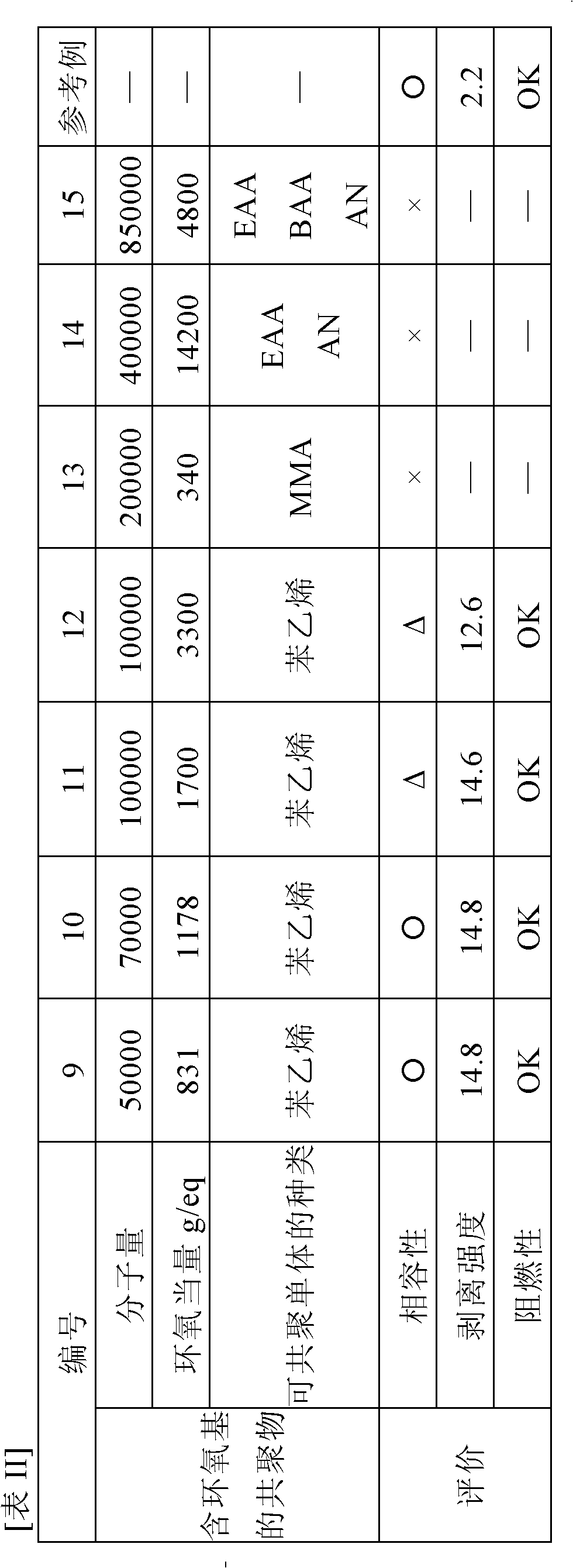

Adhesive resin composition, laminate using same, and flexible printed wiring board

ActiveCN102414288AGood compatibilityGood storage stabilityNon-macromolecular adhesive additivesSynthetic resin layered productsEpoxyHalogen

Disclosed is an adhesive resin composition which contains: an epoxy resin and / or a phenoxy resin; an epoxy-containing copolymer which is obtained by copolymerizing an epoxy-providing monomer and an ethylenically unsaturated monomer that is copolymerizable with the epoxy-providing monomer; a thermoplastic resin; and a curing agent. The epoxy-containing copolymer has a weight average molecular weight of 5,000 or greater but less than 100,000 and an epoxy equivalent of not more than 3,500 g / eq. The adhesive resin composition is capable of providing a one-pack type adhesive solution that is free from halogens and has excellent flame retardancy, excellent compatibility of polymer components, and excellent storage stability. Also disclosed are a laminate using the adhesive resin composition, and a flexible printed wiring board.

Owner:SUMITOMO ELECTRIC IND LTD +1

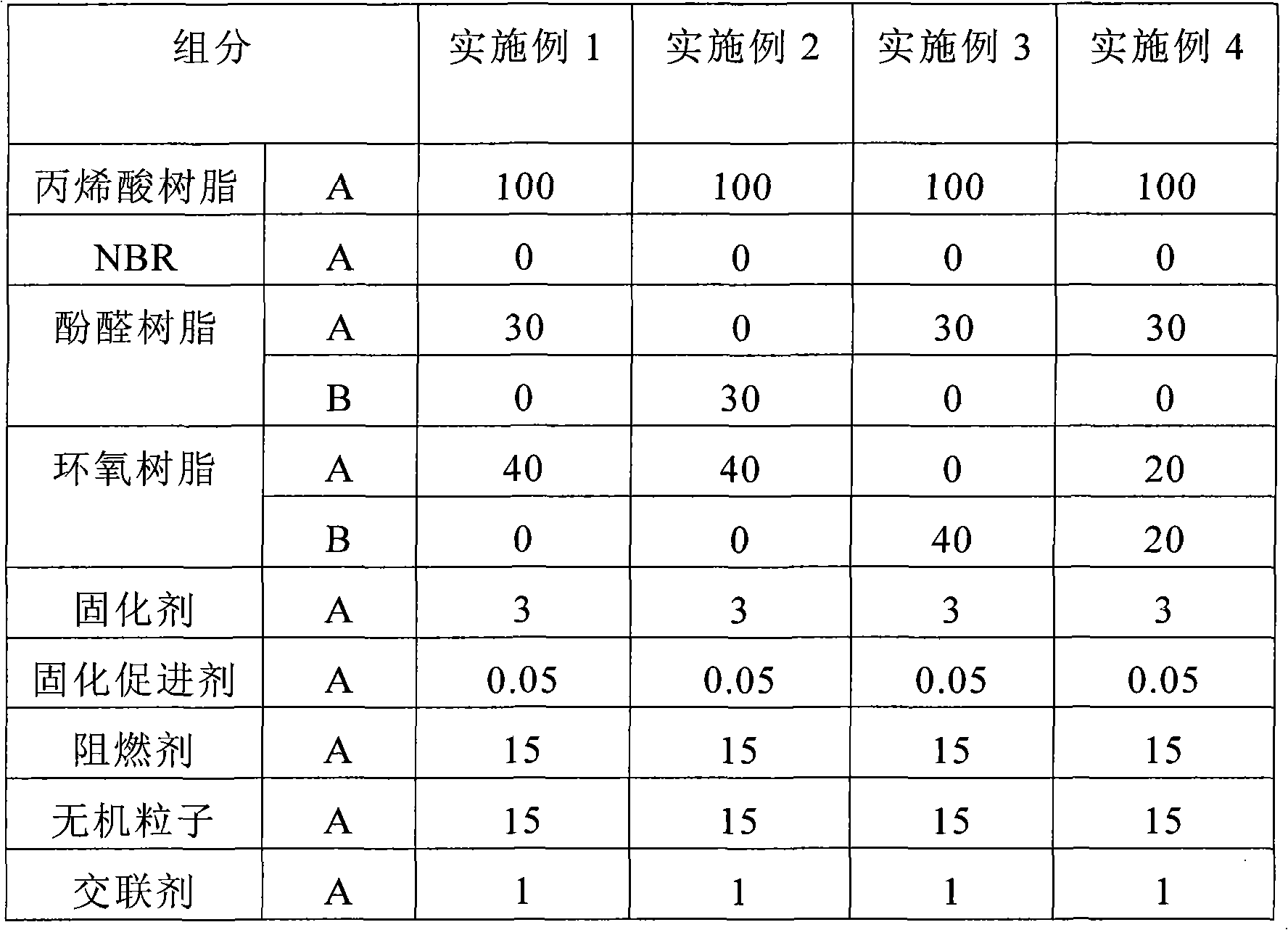

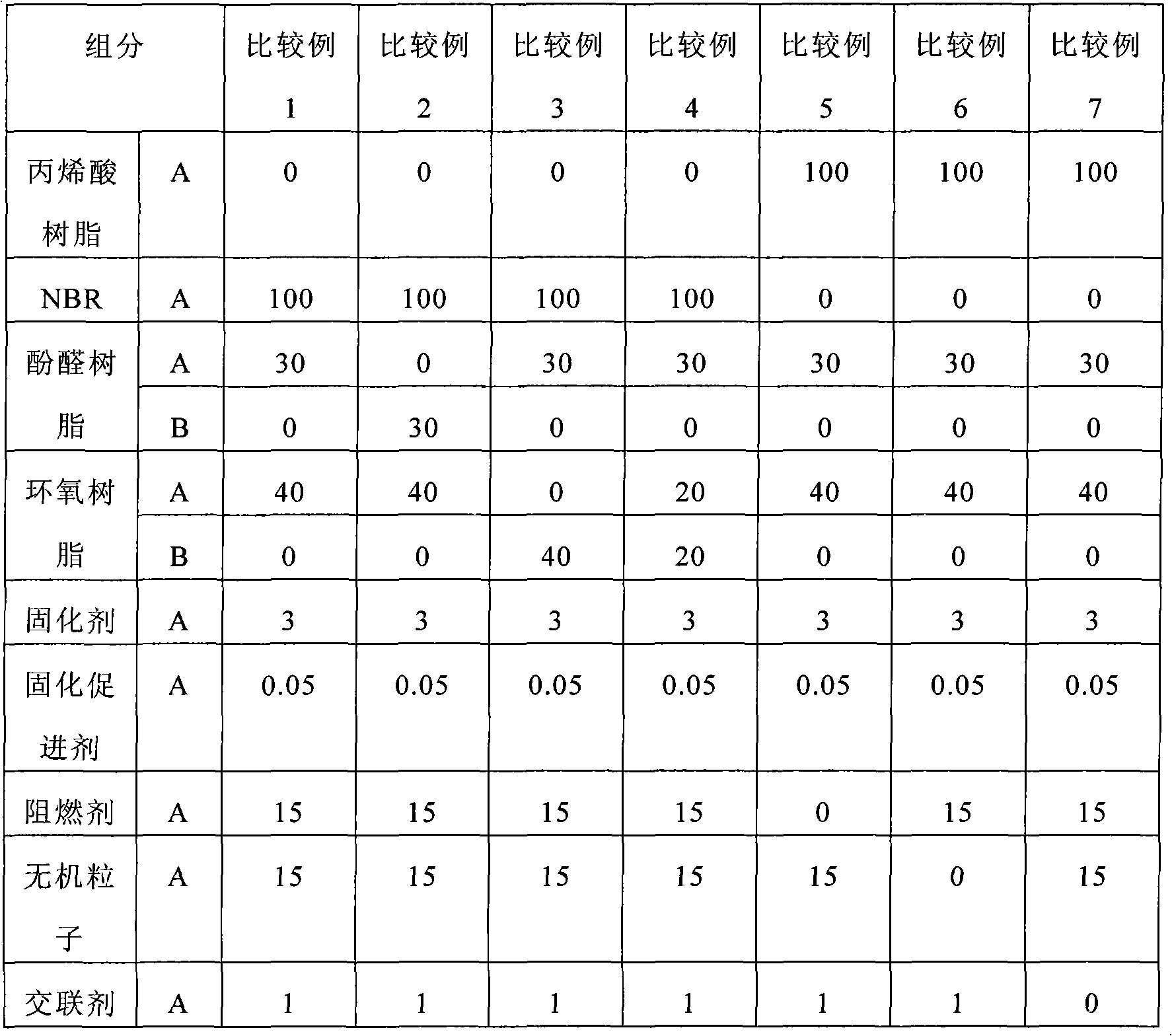

Adhesive composition for halogen-free coverlay film and coverlay film coated by the same

InactiveCN101987947ASatisfy flame retardancySatisfy the adhesive strengthNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyAcrylic resin

The present invention generally relates to an adhesive composition for halogen-free coverlay film and a coverlay film coated by the same. More particularly, the invention relates to the adhesive composition for the halogen-free coverlay film and the coverlay film coated by the same. The adhesive composition has undeteriorated binding strength and heat resistance in a humidity condition in which the covering film is covered through replacing NBR (nitrile butadiene rubber) which is commonly used as the adhesive for cover binding by the acrylic acid copolymer that contains hydroxy and carboxyl. Thus the adhesive composition for the halogen-free coverlay film comprises the following components: (1) acrylic resin which contains hydroxy and carboxyl and has a weight average molar mass of 300,000-800,000 and a viscosity of 800-10,000cP in 25 DEG C; (2) phenolic resin; (3) multifunctional epoxide resin; (4) solidifying agent; (5) solidifying promoting agent; (6) flame retardant based on non-halogen; (7) inorganic particles and (8) cross linker.

Owner:TORAY ADVANCED MATERIALS KOREA

Single-core flexible waterproof cable and production method thereof

InactiveCN105810333AUnaffected by physicsDoes not affect electrical performanceClimate change adaptationInsulated cablesElectrical conductorInsulation layer

The invention discloses a single-core flexible waterproof cable and a production method thereof. The single core flexible waterproof cable comprises a conductor, a water-blocking layer, and an insulation layer. The water-blocking layer and the insulation layer are sequentially, from inside to outside, disposed on the outer part of the conductor in a wrapped manner. The conductor is formed by intertwisting a plurality of copper wires and a plurality of water-blocking filaments, and the cross section of the conductor is smaller than 10mm2. The diameter of the single filament before the water swelling of the water-blocking filaments is smaller than or equal to the diameter of the single filament of the copper wires, and the diameter of the single filament of the copper filaments is smaller than 0.18mm. The radial and vertical all-directional three-dimensional waterproof effect can be achieved by adopting the waterproof filaments in the conductor, the water-blocking tape disposed on the outer side of the conductor, and the insulation waterproof function of the insulation layer.

Owner:SHENZHEN LIANJIAXIANG SCI & TECH

Polycarbonate resin composition and molded product

Provided is a polycarbonate resin composition which has high flame retardance and high impact resistance and exhibits excellent thermal stability. A polycarbonate resin composition characterized by containing, per 100 parts by mass of a polycarbonate resin (A), 0.001 to 1 part by mass of an organosulfonic acid metal salt (B) and 0.5 to 5 parts by mass of a core-shell type graft copolymer (C) which comprises a butadiene-based rubber component as the core and which has an Si content of 300ppm or more, and further containing 0.1 to 3 parts by mass of a metal salt (D) of an organophosphoric ester per 100 parts by mass of the core-shell type graft copolymer (C).

Owner:MITSUBISHI ENG PLASTICS CORP

A kind of sound-absorbing and heat-insulating material for vehicles, its preparation method, and the prepared sound-insulating pad for vehicles

InactiveCN104339782BMeet the flame retardant performanceImprove sound absorptionSynthetic resin layered productsLaminationGlass fiberEngineering

The invention discloses a vehicular sound-absorption and thermal-insulation material and a preparation method of the vehicular sound-absorption and thermal-insulation material; the vehicular sound-absorption and thermal-insulation material comprises the components including PP, PET and glass fibres; the vehicular sound-absorption and thermal-insulation material is divided into five layers sequentially including a bottom glass fibre layer, a second mixed fibre layer comprising glass fibres, PP fibres and PET fibres, a medium mixed fibre layer comprising a PP material and PET, a fourth mixed fibre layer comprising the glass fibres, the PP fibres and the PET fibres, and a surface glass fibre layer; and the five layers are molten and connected into a whole. By means of the manner, the vehicular sound-absorption and thermal-insulation material disclosed by the invention not only can satisfy the flame-retardant property but also is capable of improving the sound-absorption property; in addition, on the basis of that of a traditional sound-absorption and thermal-insulation material, the sound-absorption property is increased by 30-50%.

Owner:武汉新环球汽车内饰件有限公司

Halogen-free cover film adhesion agent

InactiveCN106398590ASatisfy flame retardancySatisfy the adhesive strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyIon exchange

The invention discloses a halogen-free cover film adhesion agent. The halogen-free cover film adhesion agent comprises nine components, wherein the first component is a rubber solution prepared from rubber and butanone, the second component comprises the rubber solution, aluminum hydroxide powder and butanone, the third component comprises the rubber solution, a fire retardant and butanone; the fourth component comprises resin and butanone; the fifth component comprises epoxy resin and butanone; the sixth component comprises dicyandiamide and ethylene glycol monomethyl ether; the seventh component comprises diaminodiphenylsulfone and ethylene glycol monomethyl ether; the eighth component comprises a rubber solution, an ion exchanger and butanone; the ninth component is resin. The halogen-free cover film adhesion agent is reasonable in design, and meets the performance such as fire resistance, bonding strength and heat resistance which are needed in a cover film, the performance of the adhesion agent is not degraded even if the adhesion agent is exposed to the high-humidity condition, the environment is effectively protected, and the cover film can meet the national and international standards.

Owner:深圳市海纳泰兴电子有限公司

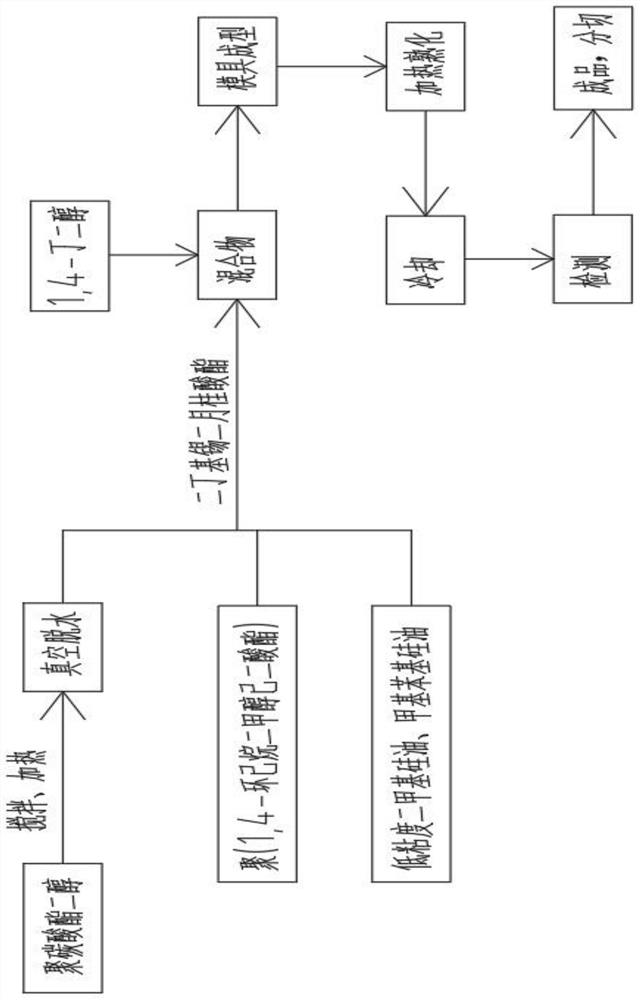

Polyurethane material and preparation method thereof

The invention discloses a polyurethane material which comprises the following components in parts by mass: 32-40 parts of polyisocyanate, 43-50 parts of a polyether polyol, 4-6 parts of a chain extender, 3-7 parts of an organic silicon foam stabilizer, 2.5-5 parts of silica powder and 0.06 part of a catalyst, the polyisocyanate is poly (1, 4-cyclohexanedimethanol adipate), and the polyether polyolis polycarbonate diol. Wherein the chain extender is 1, 4-butanediol, and the catalyst is dibutyltin dilaurate. The preparation method comprises the following specific steps: S1, stirring polycarbonate diol in a reaction kettle, carrying out vacuum dehydration, adding poly (1, 4-cyclohexanedimethanol adipate), and adding dibutyltin dilaurate and the organic silicon foam stabilizer; adding 1, 4-butanediol and silica powder, and quickly stirring for 1 hour; aging and cooling. The performance of the prepared polyurethane thermal insulation material can completely meet various requirements in theapplication process, and the polyurethane material is high in compression strength, resistant to hydrolysis stability, resistant to aging and not prone to combustion.

Owner:南通濠泰化工产品有限公司

Adhesive resin composition, laminate using same, and flexible printed wiring board

ActiveCN102414288BGood compatibilityGood storage stabilityNon-macromolecular adhesive additivesSynthetic resin layered productsEpoxyHalogen

Owner:SUMITOMO ELECTRIC IND LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com