Charging pile CTI high glow wire PBT composite material and preparation method thereof

A high-glow wire and composite material technology, applied in the field of polymer material modification, can solve the problems of harsh process requirements, plastic particles are easy to turn gray, and restrictions, and achieve simple production process, simple and controllable production process, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the charging pile CTI high glow wire PBT composite material comprises the following steps:

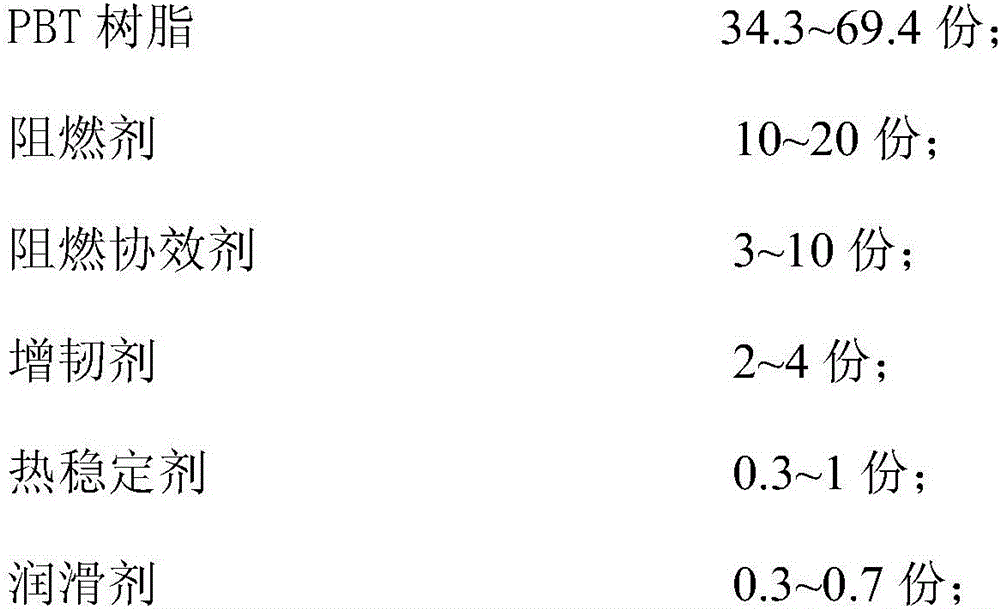

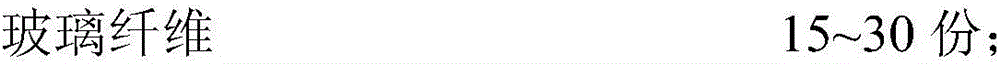

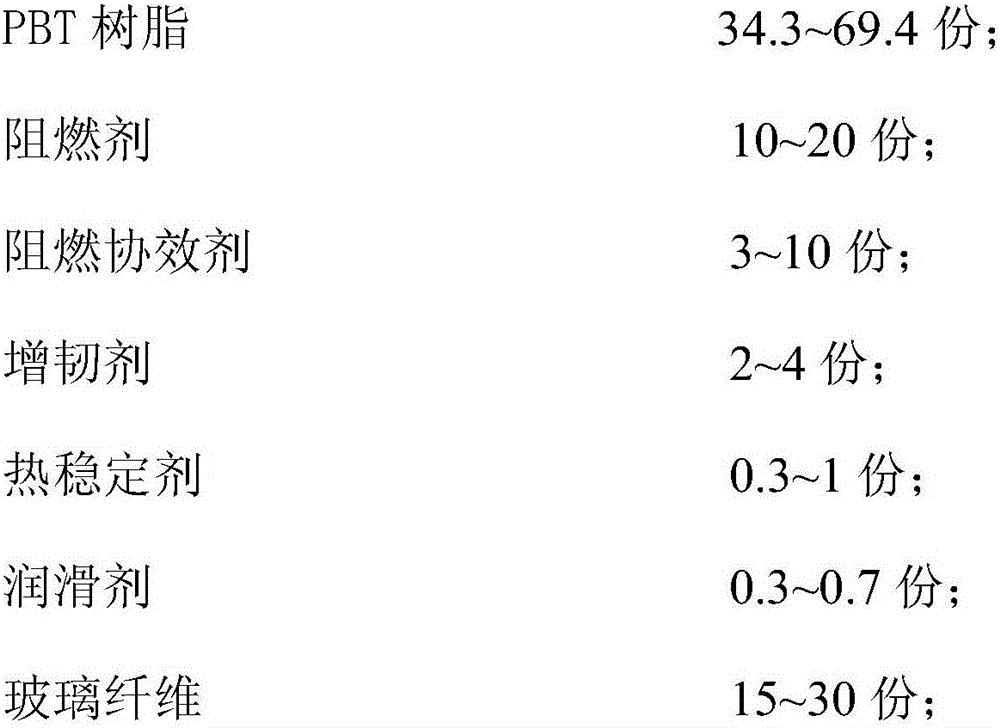

[0046] Step 1: Weigh 34.3-69.4 parts of PBT resin, 10-20 parts of flame retardant, 3-10 parts of flame-retardant synergist, 2-4 parts of toughening agent, 0.3-1 part of heat stabilizer, 0.3-0.7 parts of lubricant, 15-30 parts of glass fiber;

[0047]Step 2: Mix PBT resin, flame retardant, flame retardant synergist, toughening agent, heat stabilizer and lubricant in a medium speed mixer for 3-7 minutes;

[0048] Step 3: Then mix the raw materials mixed in step 2 with glass fibers to form a compound, melt and extrude through a twin-screw extruder, and granulate; the process conditions of the twin-screw extruder are: the first zone of the twin-screw extruder The temperature is 180-240°C, the temperature in the second zone is 180-240°C, the temperature in the third zone is 180-240°C, the temperature in the fourth zone is 180-220°C, the temperature in the f...

preparation Embodiment 1

[0050] Select the following raw materials in parts by weight: 34.3 parts of PBT resin (1100-211M), 0.3 part of heat stabilizer (GX2921), 3 parts of toughening agent (E516), 0.3 part of lubricant (TAF), 18 parts of flame retardant ( It consists of 12 parts of decabromodiphenylethane (RDT-3), 3 parts of triphenyl phosphate (WSFR-TPP), 3 parts of melamine phosphate (MPP-A), 3 parts of flame retardant synergist (composed of three 1 part of antimony oxide, 2 parts of zinc borate);

[0051] Mix in a medium-speed mixer for 5 minutes, then blend with 15 parts of 988A glass fiber, extrude through a twin-screw extruder with a melting temperature of 180-220°C, and granulate. Among them, the temperature setting of each section of the twin-screw extruder is: 180°C in the first zone, 220°C in the second zone, 220°C in the third zone, 210°C in the fourth zone, 210°C in the fifth zone, 200°C in the sixth zone, and 200°C in the seventh zone. for 30 seconds.

preparation Embodiment 2

[0053] Select the following raw materials in parts by weight: 48.2 parts of PBT resin (1100-211M), 0.5 part of heat stabilizer (GX2921), 2 parts of toughening agent (E516), 0.4 part of lubricant (TAF), 18 parts of flame retardant ( It consists of 12 parts of decabromodiphenylethane (RDT-3), 3 parts of triphenyl phosphate (WSFR-TPP), 3 parts of melamine phosphate (MPP-A), 10 parts of flame retardant synergist (composed of three 4 parts antimony oxide, 6 parts zinc borate);

[0054] Mix in a medium-speed mixer for 5 minutes, then blend with 25 parts of 988A glass fiber, extrude through a twin-screw extruder with a melting temperature of 180-220°C, and granulate. Among them, the temperature setting of each section of the twin-screw extruder is: 180°C in the first zone, 220°C in the second zone, 220°C in the third zone, 210°C in the fourth zone, 210°C in the fifth zone, 200°C in the sixth zone, and 200°C in the seventh zone. for 30 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com