High glow-wire/high-CTI halogenous flame-retardant polypropylene composite and preparation method thereof

A technology for flame-retardant polypropylene and composite materials, which is applied in the field of high-glow wire and high-CTI halogen-containing flame-retardant polypropylene composite materials and its preparation, and can solve the problems of insufficient high-temperature resistance, high leakage resistance index, and high-temperature resistance of halogen-free flame-retardant materials. Mineral reinforcement and other issues to achieve excellent CTI performance, excellent flame retardant properties, and the effect of increasing the temperature of the glow wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

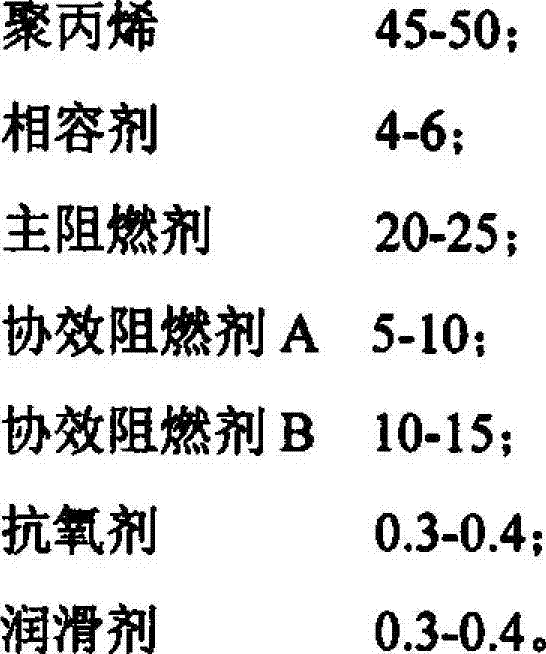

Method used

Image

Examples

Embodiment 1~3

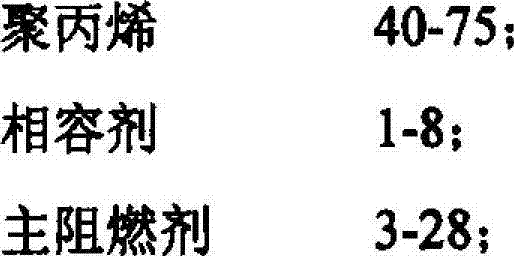

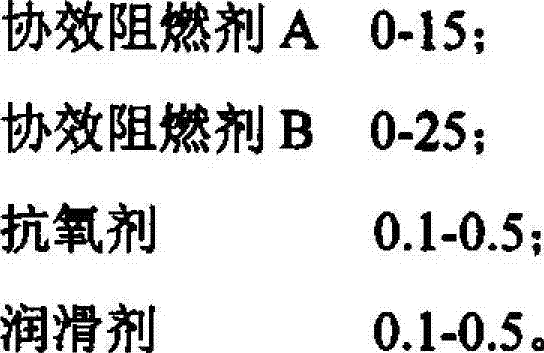

[0025] The proportions (parts by weight) of Embodiments 1 to 3 are shown in Table 1.

[0026] Table 1

[0027] raw material name

Example 1

Example 2

Example 3

49

44

51

Compatibilizer

4

4

4

primary flame retardant

22

22

25

Synergistic Flame Retardant A

-

5

5

Synergistic Flame Retardant B

25

25

15

0.4

0.4

0.4

0.3

0.3

0.3

[0028] Put all the components in proportion into a high mixer and mix for 5 minutes, then use a screw extruder to extrude and granulate. The processing temperature is 200° C., and the screw rotation speed is 250 rpm.

[0029] A kind of high-glow wire, high CTI halogen-containing flame-retardant polypropylene composite material obtained in Examples 1-3 and its preparation method samples 1-3 were compared in performance tests, and the mechanical properties were teste...

Embodiment 4

[0034] A method for preparing a high-glow wire and high CTI halogen-containing flame-retardant polypropylene composite material, the method comprising the following steps:

[0035] (1) Take raw materials by weight: polypropylene 40, compatibilizer 8, main flame retardant 3, synergistic flame retardant A15, synergistic flame retardant B 25, antioxidant 0.5, lubricant 0.5;

[0036] (2) Put all the raw materials into the high mixer and mix for 2-10 minutes, then discharge;

[0037] (3) Put the mixed raw materials into a screw machine to extrude and granulate. The rotating speed of the screw machine is 180-350 rpm and the temperature is 190-220°C.

[0038] The raw materials used are all commercially available products, wherein the polypropylene is copolymerized polypropylene with a crystallinity of 50%-60% and a melt index of 30g / 10min. The compatibilizer is maleic anhydride grafted polypropylene (PP-g-MAH), and the grafting rate is 1%. The main flame retardant is a bromine-anti...

Embodiment 5

[0040] A method for preparing a high-glow wire and high CTI halogen-containing flame-retardant polypropylene composite material, the method comprising the following steps:

[0041] (1) Take raw materials by weight: polypropylene 75, compatibilizer 1, main flame retardant 28, synergistic flame retardant A0, synergistic flame retardant B0, antioxidant 0.1, lubricant 0.1;

[0042] (2) Put all the raw materials into the high mixer and mix for 2-10 minutes, then discharge;

[0043] (3) Put the mixed raw materials into a screw machine to extrude and granulate. The rotating speed of the screw machine is 180-350 rpm and the temperature is 190-220°C.

[0044] The raw materials used are all commercially available products, wherein the polypropylene is copolymerized polypropylene with a crystallinity of 50%-60% and a melt index of 30g / 10min. The compatibilizer is maleic anhydride grafted polypropylene (PP-g-MAH), and the grafting rate is 1%. The main flame retardant is a bromine-antimo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com