Thermoplastic flame-proof filling compositions

A flame-retardant filling and thermoplastic technology, applied in the field of flame-retardant modified polymer materials, can solve the problems of reduced mechanical properties, unsatisfactory cost performance, unsatisfactory mechanical properties, etc., and achieve the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

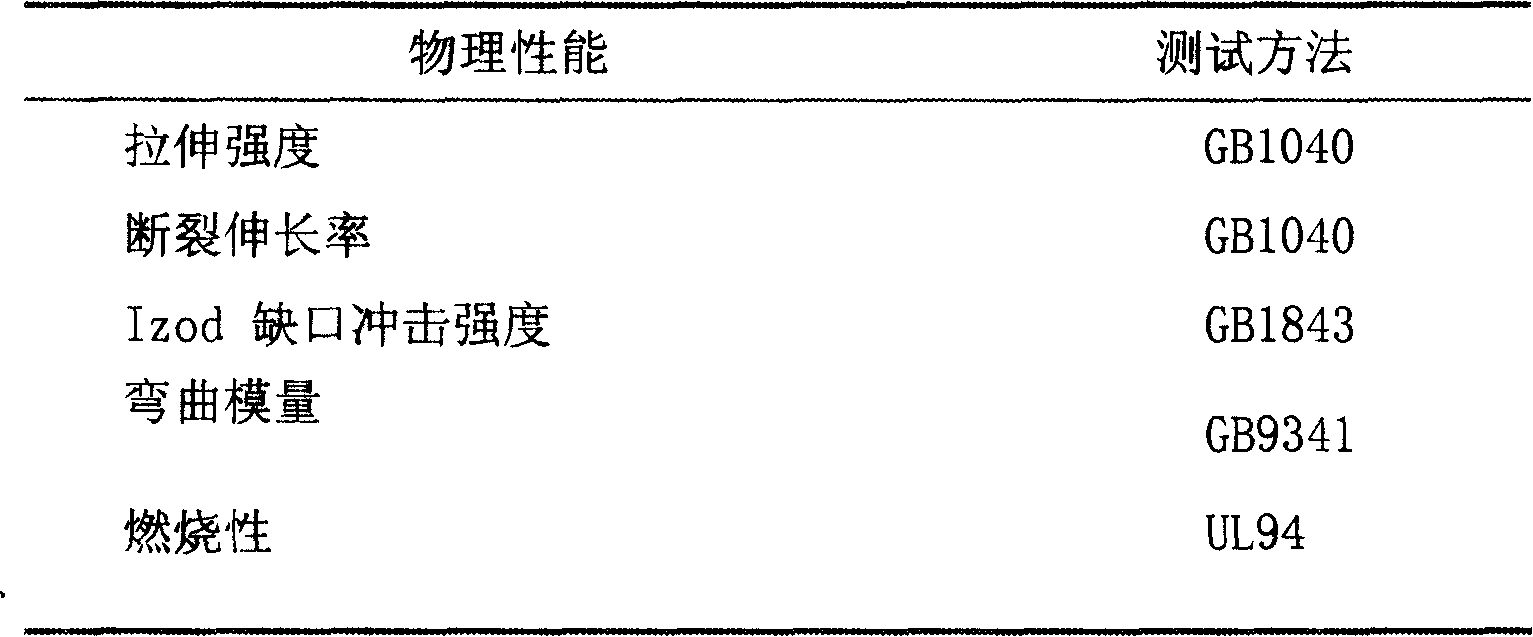

Examples

Embodiment Construction

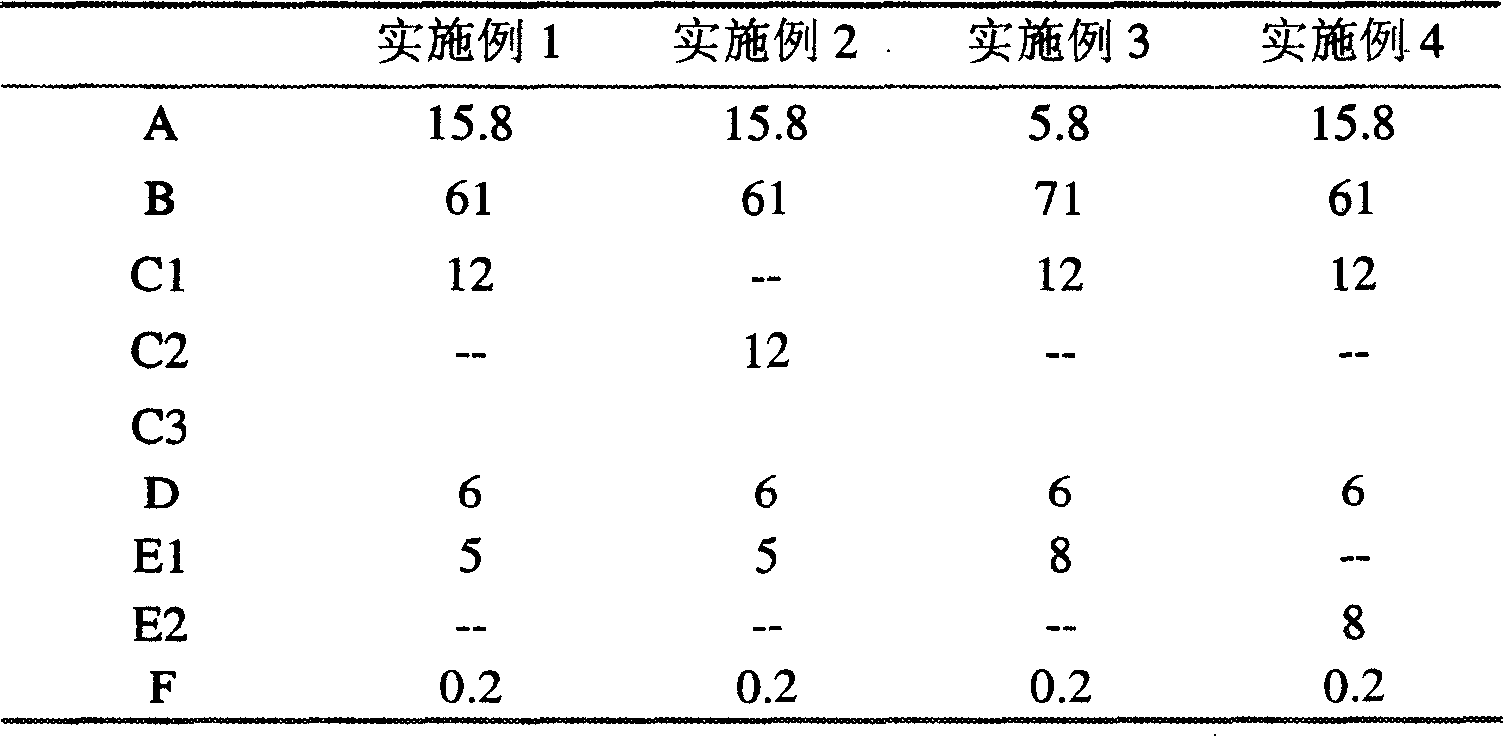

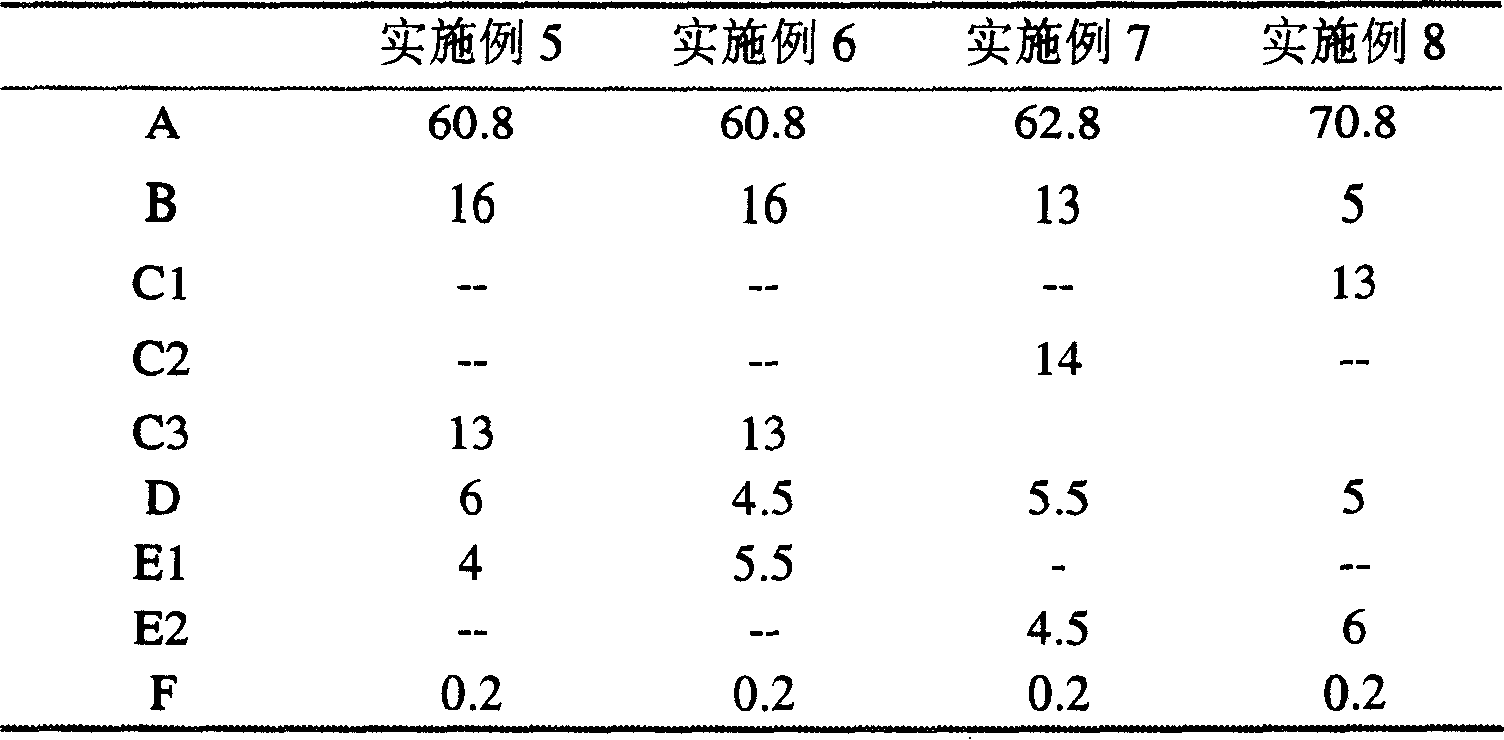

[0026] Component A: 45 parts by weight of styrene and acrylonitrile with a ratio of 75:25 copolymer in 55 parts by weight of granular cross-linked polybutadiene rubber (average particle diameter 50 = 0.25 μm), produced by emulsion polymerization.

[0027] Component B: a styrene / acrylonitrile copolymer having a weight ratio of styrene and acrylonitrile of 75:25.

[0028] Component C1: Tetrabromobisphenol A (provided by Albemarle, USA)

[0029] Component C2: brominated epoxy resin (supplied by Israel Dead Sea Bromine Company).

[0030] Component C3: Decabromodiphenylethane (supplied by Israel Dead Sea Bromine Company).

[0031] Component D: antimony trioxide (provided by Chenzhou Mining)

[0032] Component E1: Organic nano-montmorillonite (provided by NANOCOR, USA)

[0033] Component E2: barium sulfate (provided by Xinji Jimei)

[0034] Component F: Polytetrafluoroethylene (provided by GE, USA)

[0035] Preparation method: Mix each component with conventional processing ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com