Active energy ray solidification type resin composition using reactivity compound with fire retardance and condensate thereof

An active energy ray and reactive compound technology, applied in the field of active energy ray-curable resin compositions, can solve the problem of difficulty in adding extender pigments, undocumented, and uncured flame retardancy, heat resistance, moisture resistance and electrical insulation. problems such as properties, to achieve the effects of excellent moisture resistance, good electrical insulation, and satisfactory adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0107] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples. In addition, unless otherwise specified in the present Examples, "part" means a weight part, and "%" means a weight %.

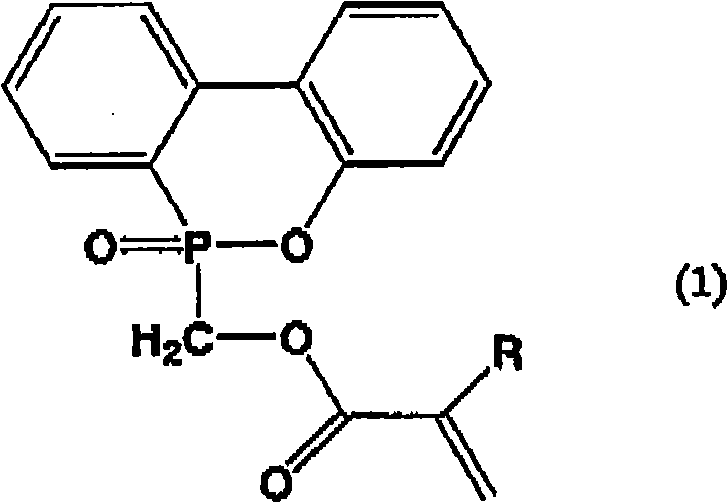

[0108] The phosphine oxide compound (A) represented by following formula (1) was synthesize|combined by the method of the following synthesis examples 1 and 2.

[0109]

[0110] (wherein, R represents a hydrogen atom or a methyl group).

Synthetic example 1-1

[0111] Synthesis Example 1-1: Synthesis of Phosphine Oxide Compound (A-1)

[0112] 216.2 g (1.0 mol) of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (HCA manufactured by Sanko Co., Ltd.) was charged in a 2L reactor equipped with a stirrer, a thermometer, and a condenser. and 246.2 g of toluene were dissolved at a temperature of 80 to 90°C. Next, 30.0 g (1.0 mol) of paraformaldehyde was slowly added with stirring, and it was made to react at the reaction temperature of 80-90 degreeC for 3 hours, thereby obtaining 246.2 g of white crystals.

[0113] Next, 246.2 g (1.0 mol) of the obtained crystals, 144.7 g (2.0 mol) of acrylic acid, 400 g of toluene, 1.5 g of hydroquinone monomethyl ether, and 14.5 g of p-toluenesulfonic acid monohydrate were added, and the Carried out the dehydration condensation reaction for 13 hours, the resulting reaction solution was washed twice with 10% aqueous sodium carbonate and once with 20% brine, and then the toluene was distilled off under r...

Synthetic example 1-2

[0119] Synthesis Example 1-2: Synthesis of Phosphine Oxide Compound (A-2)

[0120] 216.2 g (1.0 mol) of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (HCA manufactured by Sanko Co., Ltd.) was charged in a 2L reactor equipped with a stirrer, a thermometer, and a condenser. and 246.2 g of toluene were dissolved at a temperature of 80 to 90°C. Next, 30.0 g (1.0 mol) of paraformaldehyde was slowly added with stirring, and it was made to react at the reaction temperature of 80-90 degreeC for 3 hours, thereby obtaining 246.2 g of white crystals.

[0121] Next, 246.2 g (1.0 mol) of the obtained crystals, 172 g (2.0 mol) of methacrylic acid, 500 g of toluene, 1.7 g of hydroquinone monomethyl ether, and 17 g of p-toluenesulfonic acid monohydrate were added, and the Carried out the dehydration condensation reaction for 13 hours, the resulting reaction solution was washed twice with 10% aqueous sodium carbonate and once with 20% brine, and then the toluene was distilled off under r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com