Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Lower the foaming temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing synthetic leather by using solvent-free double-component polyurethane scraping and coating method

The invention discloses a method for producing synthetic leather by using a solvent-free double-component polyurethane scraping and coating method and the synthetic leather produced by using the same. The method comprises the following steps: (1) controlling the flow of a material loading machine so that an M material and an N material are mixed in the mixing chamber of the material loading machine and then poured, scraped and coated to release paper coated with an isolation layer, drying so as to obtain a foamed material layer, wherein the coating amount of scraping and coating is 50-2000g / m<2>; (2) pressing and compounding the foamed material layer, heating and solidifying; and (3) coiling, curing, and separating out the release paper at last, so as to obtain the synthetic leather finished product. According to the invention, an organic solvent and water are not used in the synthesis and mixing of polyurethane resin on a foaming layer and a bonding layer and in the various links of embarkation. Compared with the method for producing the foaming layer with a water-based polyurethane composite material, the method disclosed by the invention can greatly reduce energy consumption; and the synthetic leather has good property and excellent hand feeling.

Owner:佛山市飞凌皮革化工有限公司

Energy-saving and emission-reduction method for production line of PVC artificial leather

InactiveCN101649559ALower the foaming temperatureReduce energy consumptionChemical industrySynthetic resin layered productsProduction lineThermal energy

The invention discloses an energy-saving and emission-reduction method for a production line of PVC artificial leather, comprising the following steps: mixing and grinding high-temperature chemical foamer with low-temperature chemical foamer, or the high-temperature chemical foamer with a foaming accelerant, or the high-temperature chemical foamer, the low-temperature chemical foamer and the foaming accelerant; then mixing with PVC resin, a thermal stabilizing agent, a plasticizing agent and filling material and stirring; and then gelling, plasticating, pressing, rolling, jointing with base cloth to form adhesive tape; putting the formed adhesive tape into a foaming furnace; foaming for 0.5 to 1.5 minutes at the temperature of 185 DEG C to 195 DEG C and decorating the surface to obtain a product. Since the low-temperature foaming or / and direct foaming acceleration of the low-temperature chemical foamer or / and the foaming accelerant is used, the high-temperature chemical foamer begins to foam at lower temperature, thereby reducing the foaming temperature, achieving the purpose of reducing the energy consumption and the harmful gas, especially reducing the emission of the harmful gasand the heat energy produced by the high-temperature volatilization of the plasticizing agent.

Owner:SICHUAN UNIV

Method of preparing foam glass based on boric sludge

InactiveCN101058480AConducive to circular economy and sustainable developmentFine particleQuenchingSolvent

The invention discloses a making method of foam glass based on boron mud in the functional inorganic material technical domain, which comprises the following steps: blending the broken waste glass and magnesium-stripping boron-mud according to proportion; grinding into raw material; heating and fusing the raw material; quenching; drying; grinding into glass powder; adding foamier and booster solvent to form the foam glass mating slurry; placing the mating slurry into the mould; pressing; shaping; heating; foaming; stabilizing the foam; annealing; obtaining the foam glass; adjusting the foam-pore structure according to the adjusted component and technique condition; reaching the goal of insulation, silence or water-retaining.

Owner:DALIAN UNIV OF TECH

Low-temperature microcrystalline foam glass and preparation method thereof

InactiveCN102795780ASimple processLower the foaming temperatureGlass shaping apparatusWater contentHigh intensity

The invention relates to low-temperature microcrystalline foam glass and a preparation method thereof; molar ratios of main components of the microcrystalline foam glass are: 0.1-1.0:1 for the molar ratio of Na2O (K2O) to SiO2, 1.0-20:1 for the molar ratio of SiO2 to Al2O3, and 0-0.2:1 for the molar ratio of B2O3 to SiO2; the preparation method comprises the following steps: (1) mixing and stirring water glass and active aggregates, adding an additive to obtain sol; (2) aging the sol for 1-7 days, drying the aged sol to prepare solid gel with a water content of 10%-50%; (3) triturating the solid gel, adding into a mold, and finally foaming. The microcrystalline foam glass of the invention has low density, high intensity, good heat insulation performance, long service life, and good fireproof performance; and the preparation method of the invention is simple in operation, and reduces the foaming temperature.

Owner:宁波荣山新型材料有限公司

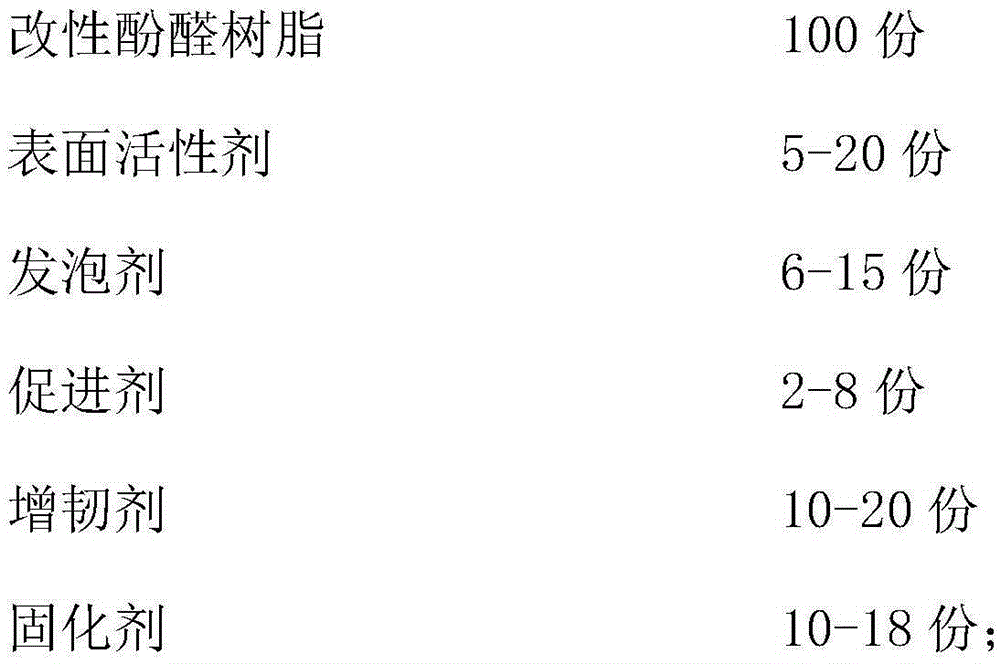

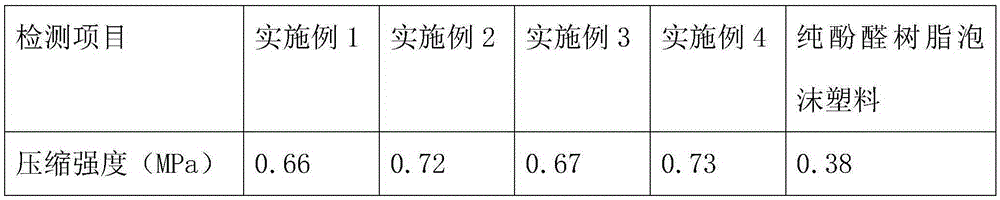

High-inflaming-retarding modified phenolic resin foamed plastic and preparation method thereof

The invention discloses high-inflaming-retarding modified phenolic resin foamed plastic and a preparation method thereof. The high-inflaming-retarding modified phenolic resin foamed plastic comprises the following raw materials in parts by weight: 100 parts of modified phenolic resin, 5-20 parts of a surfactant, 6-15 parts of a foaming agent, 2-8 parts of an accelerant, 10-20 parts of a flexibilizer and 10-18 parts of a curing agent. The prepared high-inflaming-retarding modified phenolic resin foamed plastic has excellent flame retardant property and is improved to a higher extent in tenacity and strength.

Owner:芜湖市京桥精密智造有限公司

Method for preparing foam glass by using waste silicon carbon material

InactiveCN101759346ALower the foaming temperatureImprove performanceSolid waste disposalGlass shaping apparatusFlat glassFoaming agent

The invention relates to a method for preparing foam glass by using a waste silicon carbon material, which comprises the following steps of: putting waste plate glass, a waste silicon carbon rod, borax and sodium fluosilicate into a ball-milling jar for grinding to over 200 meshes to produce mixed materials; and putting the obtained mixed materials into a mould, and preheating, foaming, foam-stabilizing, fast cooling and annealing the mixed materials to produce the foam glass. In the method, the main raw materials and a foaming agent are waste materials, and can be changed into treasure, so the method has a certain economical and environmental-friendly benefit.

Owner:SHAANXI UNIV OF SCI & TECH

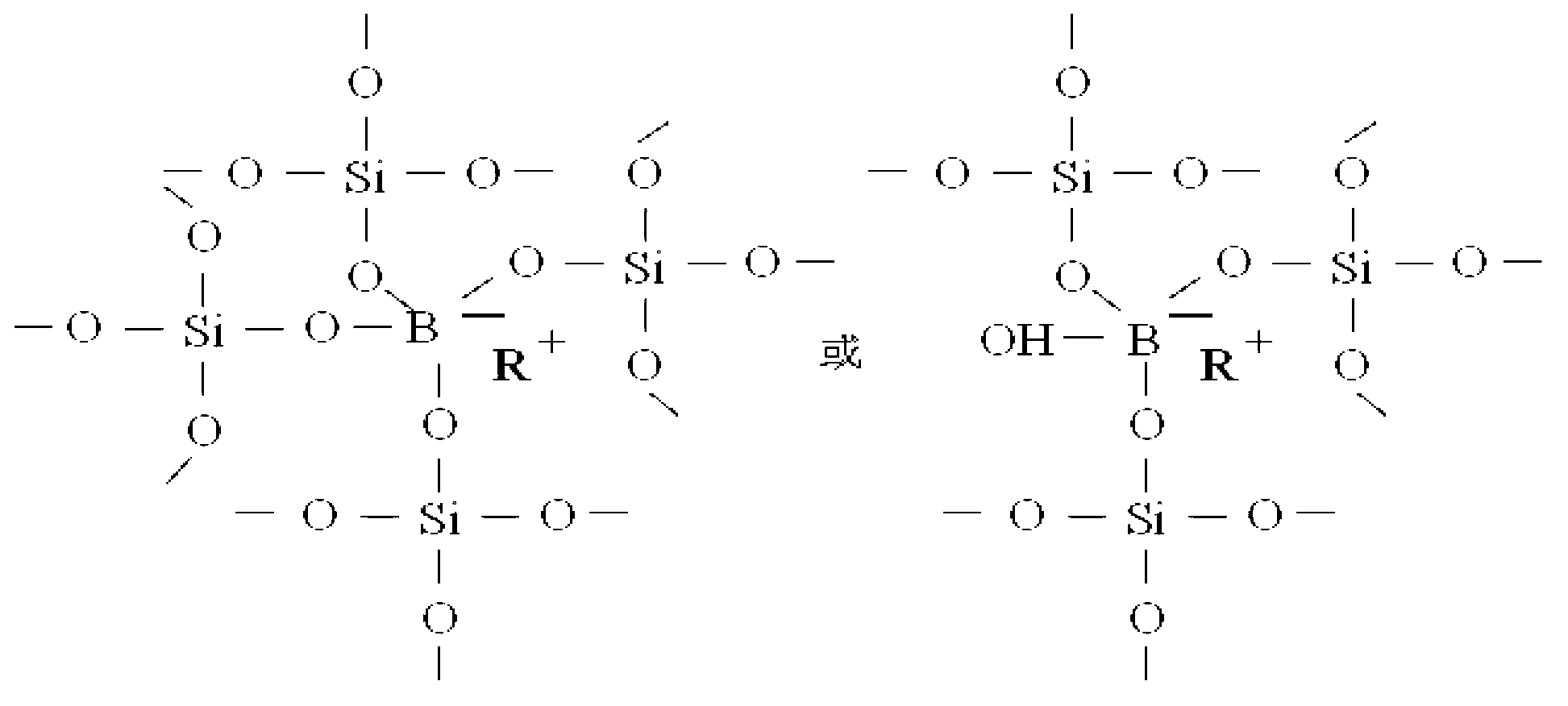

Method for preparing boron-containing foam glass

InactiveCN102101754ALower the foaming temperatureImprove mechanical propertiesGlass shaping apparatusTemperature resistanceCorrosion

The invention discloses a method for preparing boron-containing foam glass, which comprises the following steps of: cleaning waste glass in which boron is more than 12 mass percent, performing ball milling to obtain glass powder; performing ball milling on glass powder, NaNO3, KNO3, LiNO3, Zn((NO3)2, Zr(NO3)4.5H2O and barite in an agate jar to obtain a batch; and adding the batch into a heat-resistant steel mold, and preheating, foaming and annealing in a foam heater to obtain the foam glass. Multiple kinds of waste glass with more than 12 percent of boron are taken as raw materials, the NaNO3, KNO3, LiNO3, Zn((NO3)2, Zr(NO3)4.5H2O and the barite are taken as foaming agents, the barite can reduce the volatilization of boron in the batch, the foam temperature of the foam glass is reduced, and the mechanical properties, thermal stability and corrosion resistance of the foam glass are improved. Therefore, the boron-containing foam glass can be applied to the special fields requiring high corrosion resistance, high temperature resistance and high thermal stability.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing light porous particle controlled release fertilizer

ActiveCN104262005AImprove water absorptionGood fertilizer effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateDipotassium phosphate

The invention discloses a method for preparing a light porous particle controlled release fertilizer. The method comprises the following steps: uniformly mixing CRT screen glass powder, 5-20 percent of monopotassium phosphate, dipotassium phosphate, potassium sulfate, tripotassium phosphate, potassium chloride, zinc dihydrogen phosphate, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, cobalt oxide and manganese oxide, pressing, molding, feeding the mixture into a roller kiln at the temperature of 650-660 DEG C, and preserving the temperature to be 780-790 DEG C for 15-30 minutes; and reducing the temperature to be 50-80 DEG C or below at a rate of 100-200 DEG C per minute, thereby obtaining the light porous particle controlled release fertilizer. The light porous particle controlled release fertilizer prepared by the invention can be widely applied to the fields of indoor horticulture, urban gardening, street planting and farmlands. The preparation process is simple in operating process and low in cost, the production cost of the controlled release fertilizer can be effectively reduced, the environment is protected, wastes are changed into valuable materials, and the light porous particle controlled release fertilizer is suitable for large-scale industrial production and has obvious economic benefits and environmental protection benefits.

Owner:广西丰岭肥业有限公司

Preparation method of low-density thermoplastic polyimide micro-foamed material

InactiveCN102702561AAchieving high-magnification expansionImprove solubilityN dimethylformamideHigh pressure

The invention discloses a preparation method of a low-density thermoplastic polyimide micro-foamed material. In the preparation method of the low-density thermoplastic polyimide micro-foamed material, when thermoplastic polyimide is physically foamed by taking one or more of high-pressure fluids CO2, N2, HFC and HCFC as a physical foaming agent and by taking one or more of tetrahydrofuran, chloroform, ethanol, methanol, acetone, pyridine, N-methyl-pyrrolidone, and N, N-dimethylformamide as an organic co-solvent, the high pressure fluid and the organic solvent are kept in high-pressure saturated states in a polyimide sheet, and then, the saturated polyimide sheet is foamed in a high-temperature oil bath. The obtained polyimide micro-foamed sheet is a light-weight and low-density material, is smooth in surface, soft in texture, free of powder dropping in the using process, uniform in cell structure, high in cell density and excellent in tensile property, and is a foamed material with a wide application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing foamed ceramic by microwave sintering of cobalt smelting waste slag

InactiveCN109553393AMass consumptionSolve environmental problemsCeramic materials productionCeramicwareHigh energySlag

The invention belongs to the technical field of resource utilization of solid wastes, and particularly relates to a method for resource utilization of cobalt smelting waste slag. The invention provides the method for preparing foamed ceramic by microwave sintering of the cobalt smelting waste slag. The method comprises the following steps: carrying out proportioning by using the cobalt smelting waste slag, filler, a liquid phase agent, a plasticizer and a foaming agent, carrying out grinding, mixing, granulating, and mold pressing or mold powder accumulation to prepare a green body; and carrying out microwave sintering to prepare the foamed ceramic. The microwave heating method is adopted, and compared with a conventional electric heating or fuel heating mode, the microwave heating methodhas the advantages that the foaming temperature is greatly reduced, the foaming time is shortened, and therefore energy consumption is greatly reduced. According to the method, the problems of high energy consumption in existing formed ceramic industry and high additional value comprehensive utilization of the cobalt smelting waste slag are solved.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

A preparing method of a selenium rich slow-release particle matrix fertilizer

ActiveCN106242764ARetention contentHigh strengthAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPollutionRaw material

A preparing method of a selenium rich slow-release particle matrix fertilizer is disclosed. Waste glass and selenium rich ore are adhered into a whole part so that fertilizer effects are rich, a slow release effect is good, and disadvantages of fertilizers at present, namely single fertilizer effects, easy soil agglomeration and complex compositions, are overcome. The selenium rich slow-release particle matrix fertilizer prepared by the method is good in fertilizer effects, low in raw material cost, rich in sources, simple in preparing process, free of pollution to the environment and beneficial to industrial production.

Owner:哈尔滨龙粮生物科技有限公司

Environment-friendly foaming artificial leather and preparation method thereof

ActiveCN106087438ALower the foaming temperatureLow toxicityTextiles and paperWAS PROTEINOrganic solvent

The invention relates to environment-friendly foaming artificial leather which comprises a face layer and a foaming layer. The face layer is prepared from, by weight, 100 parts of polyurethane resin, 80-100 parts of organic solvent and 3-7 parts of PU color paste. The foaming layer is prepared from, by weight, 100 parts of polyvinyl chloride resin, 70-90 parts of dioctyl terephthalate, 50-70 parts of filler, 2-3 parts of stabilizer and 2-10 parts of foaming agent, wherein the foaming agent is protein foaming powder. The invention further relates to a preparation method of the environment-friendly foaming artificial leather. The environment-friendly foaming artificial leather contains no azodicarbonamide or dioctyl phthalate, complies with European Union REACH laws and regulations and is more environmentally friendly. The preparation method of the environment-friendly foaming artificial leather has the advantages that the process is simple and convenient, and energy consumption is low.

Owner:FUJIAN POLYTECH TECH CO LTD

Method for preparing foam glass brick based on boric sludge

InactiveCN101125761AFix stability issuesSolve the cost problemSolid waste managementCeramicwarePorosityBrick

The invention relates to a method for producing foam glass mosaic based on boron sludge and pertains to the technical field of functional inorganic material. The invention is characterized in that the invention comprises the steps: waste glass is crushed, mixed with de-magging boron sludge according to ratio and grinded into green stock; the green stock is heated, quenched, dried and grinded into glass powder; certain amount of glass powder is mixed with vesicant, latent solvent and foam stabilizer to form foam glass layer material; certain amount of glass powder, pigment and complete fusion are mixed to form mosaic layer material; the mosaic layer material and the foam glass layer material are put into a die sequentially, pressed and molded and the foam glass mosaic is obtained after heating, foaming, foam stabilizing and annealing. The product of the invention is a bifunctional compound material, one layer of which is foam glass phase and other layer of which is mosaic phase, thus solving the problem that the foam glass can not be directly used as building material due to porosity and uneven color, moreover, the invention can reduce the cost of foam glass mosaic without wastes being discharged during the whole process, has greening and environment protective functions and pertains to environmental friendly technology.

Owner:DALIAN UNIV OF TECH

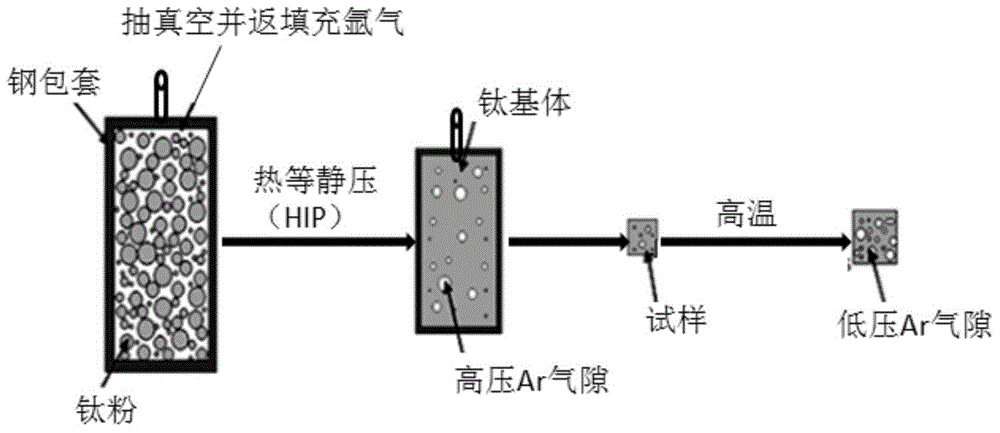

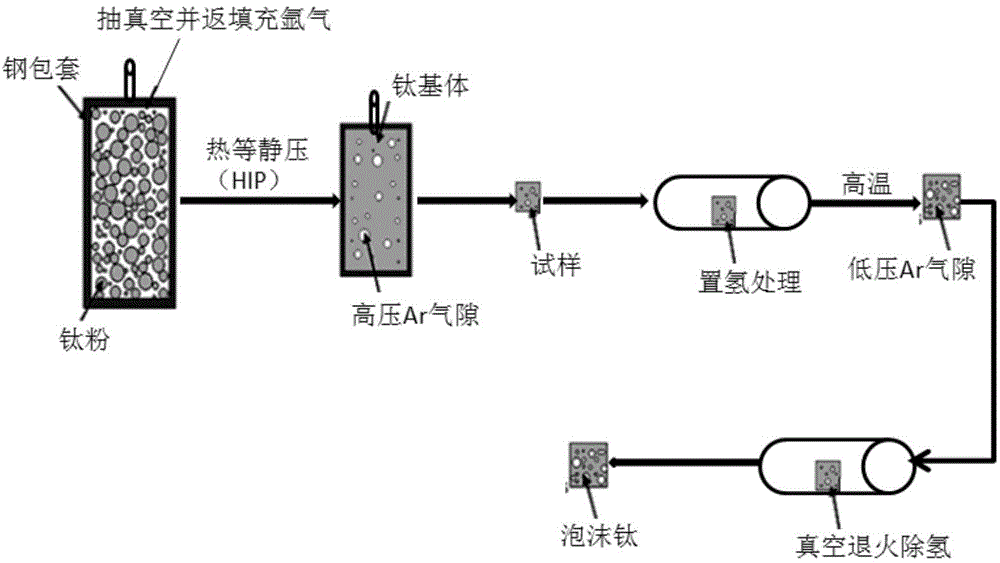

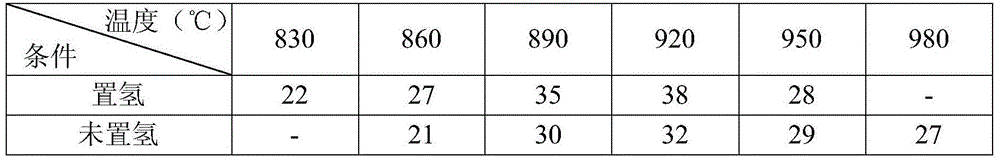

Preparation method of foam titanium under hydrogen-assisted action

The invention provides a preparation method of foam titanium under the hydrogen-assisted action. The preparation method comprises the following four steps: preparing a preformed blank test sample, hydrogenating, foaming at high temperature and removing hydrogen, and specifically comprises the following steps: filling titanium powder into a steel capsule, performing vacuum-pumping, re-filling a certain pressure of argon, carrying out hot isostatic pressure and processing a preformed blank formed by the hot isostatic pressure into a cuboid shape; then putting into a hydrogen treatment furnace and filling a certain content of hydrogen; carrying out high-temperature foaming in the vacuum environment; finally putting into the hydrogen treatment furnace to carry out vacuum annealing to obtain the foam titanium. The preparation method of the foam titanium under the hydrogen-assisted action has the benefits that the hydrogen is introduced in the process of preparing the foam titanium by adopting a gas capture method, hydrogen-induced high-temperature plasticity is utilized to improve the foaming performance of the foam titanium and improve the foaming efficiency and the porosity of the foam titanium, and finally, the hydrogen is removed to optimize the mechanical property of the foam titanium. The preparation method has the characteristics of high product porosity and low preparation cost, and the industrial production can be realized. The preparation method can be applied to the fields of aerospace and the like.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Manufacturing method of lithium slag lightweight ceramic panel

InactiveCN109053150ASolve technical problemsLower the foaming temperatureCeramic materials productionCeramicwareLithiumFoaming agent

The invention relates to a manufacturing method of a lithium slag lightweight ceramic panel. The lithium slag lightweight ceramic panel is prepared from the following raw materials: 30-65 wt% of lithium slag, 10-30 wt% of feldspar, 10-30 wt% of quartz powder, 1-10 wt% of alumina powder, and 0.2-3 wt% of foaming agent; the preparation method comprises the following steps: 1) take raw materials fordry milling and mix in proportion to obtain a mixture; 2) add water to the mixture, stir, granulate, dry and sieve to obtain granules; 3) pack the granules in a sagger, spread out and then fire to obtain a lightweight ceramic panel after cooling. By the manufacturing method, a certain proportion of alumina powder, quartz powder and feldspar are added to the lithium tail slag, thereby overcoming the technical problem of preparing the lightweight ceramic panel from the lithium tail slag, and obtaining a qualified lightweight ceramic panel.

Owner:江西庾岭晶硕新材料有限公司

High-temperature-resistant and fire-proof external wallboard

InactiveCN105713506AImprove lipophilicityEnhanced heat and compression resistanceFireproof paintsCovering/liningsPalygorskitePolypropylene

The invention discloses a high-temperature-resistant and fire-resistant exterior wall panel, which comprises a base layer, a fire-resistant insulation layer, a plastering mortar layer, a waterproof layer, a decorative coating and a wear-resistant layer arranged sequentially from the inside to the outside; Parts include: 27-30 parts of hydroquinone, 11-14 parts of hexachlorocyclotriphosphazene, 18-22 parts of polyoxypropylene glycol, 65-70 parts of isophorone diisocyanate, trimethylpentanediol 50-60 parts, 3-4 parts of glucose, 0.3-0.6 parts of organic bismuth catalyst DY-20, 25-35 parts of foaming agent, 9-12 parts of foaming aid, 19-22 parts of palygorskite, 13 parts of dolomite ~16 parts, diatomite 6-9 parts, glass fiber 5-8 parts, straw silk 12-15 parts, magnesium hydroxide 16-19 parts, anti-aging agent 2-3 parts. The high-temperature-resistant fire-proof exterior wall panel proposed by the invention has excellent high-temperature resistance and fire-proof performance, excellent water resistance, high hardness and good compression resistance.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

Low-temperature type ADCA (Azodicarbonamide) foaming agent and preparation method as well as application thereof

The invention relates to a low-temperature type ADCA (Azodicarbonamide) foaming agent. The low-temperature type ADCA foaming agent is formed by combining one or more activating agents and ADCA according to a certain proportion, wherein the activating agent can be selected from metallic compounds such as chromium, zinc and lead, urea derivatives, nitroguanidine and the like. The lowest decomposition temperature of the foaming agent provided by the invention can reach 150 DEG C-112 DEG C; the forming agent is a novel heat absorption type forming agent and has a stable, compact and regular foam structure; and the foaming agent can be widely used for rolling leathers and rubbers and is simultaneously used for foaming medicines.

Owner:ZAOZHUANG ZHONGKE CHEM

Coal gangue pottery sand and method for preparing same

ActiveCN102674878AImprove insulation effectSmall bulk densitySolid waste managementCeramicwarePorosityFoaming agent

The invention belongs to the field of preparation of building materials, and particularly relates to a method for preparing light and fireproof pottery sand by using coal mining solid waste, namely coal gangue. The coal gangue pottery sand is prepared from the following components in part by weight: 30 to 70 parts of coal gangue, 20 to 70 parts of glass powder, 2 to 10 parts of foaming agent and 10 to 25 parts of binding agent. The coal gangue pottery sand is prepared from the glass powder used as the raw material, the foaming temperature in a foaming step can be reduced greatly by using the high dispersibility of the glass powder, and the coal gangue pottery sand has the characteristic of porosity, so that the pottery sand is good in heat insulation effect; the bulk density of the prepared coal gangue pottery sand is leas than 650kg / <3>, so that the coal gangue pottery sand is light in weight; and the thermal coefficient of the coal gangue pottery sand is less than 0.15W / (m.K), so that the coal gangue pottery sand is strong in heat insulation effect.

Owner:北京建工华创科技发展股份有限公司

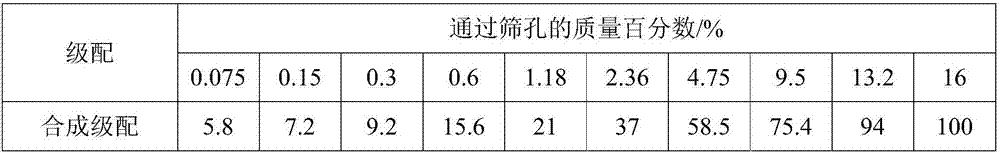

Method for preparing warm mixing foamed asphalt

InactiveCN106883628ALower the foaming temperatureImprove stabilityClimate change adaptationBuilding insulationsSodium BentoniteCalcium bicarbonate

The invention provides a method for preparing warm mixing foamed asphalt. The method comprises the following steps: stirring and mixing asphalt, a surfactant, dimethyl formamide, bentonite, hydroxypropyl methylcellulose and water, and cooling to the room temperature so as to obtain mixed asphalt I; further heating the mixed asphalt I, adding polyvinyl alcohol, calcium bicarbonate and absolute ethyl alcohol, stirring, and leaving to stand so as to obtain modified emulsified asphalt; mixing the asphalt, 2-acrylamide-2-methylpropanesulfonic acid and ethylene glycol dimethacrylate, heating till the mixture is in a fluid state, cooling, adding glycerol, and stirring for mixing, so as to obtain mixed asphalt II; finally, heating the mixed asphalt, adding the modified emulsified asphalt in a stirring state, and keeping stirring after the modified emulsified asphalt is added, thereby obtaining the warm mixing foamed asphalt. The warm mixing foamed asphalt prepared by using the method has a relatively high expansion rate and a relatively long half-life period, and is stable in foaming state.

Owner:无锡市城市道桥科技有限公司 +1

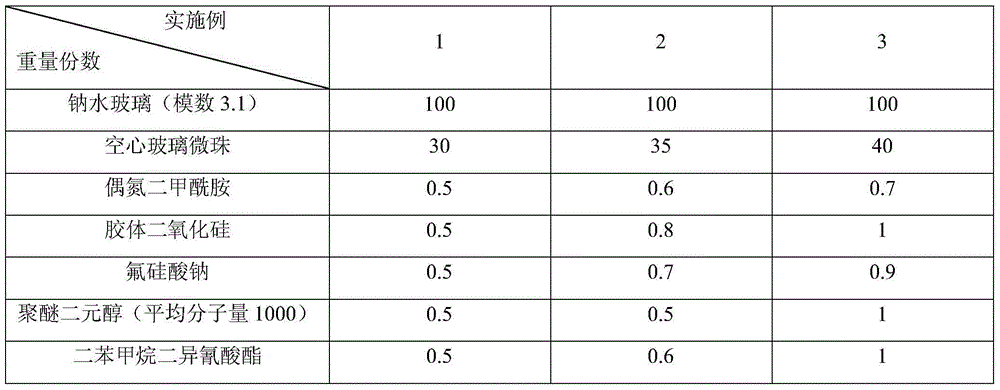

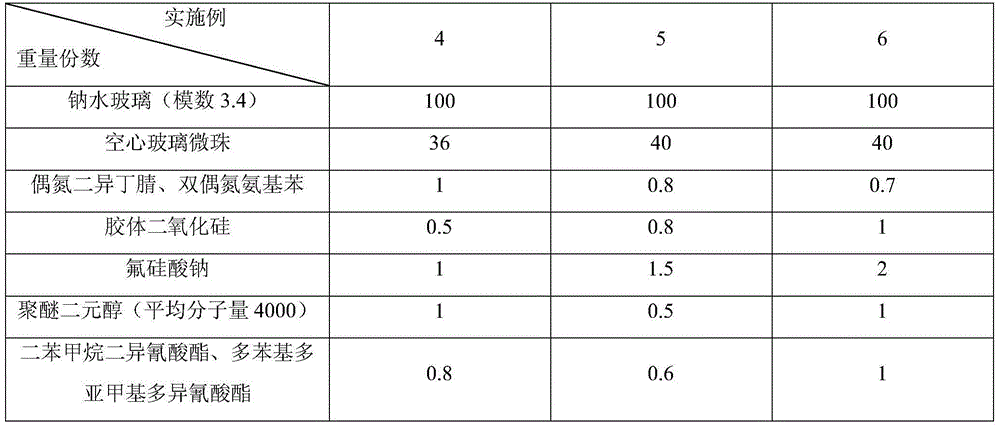

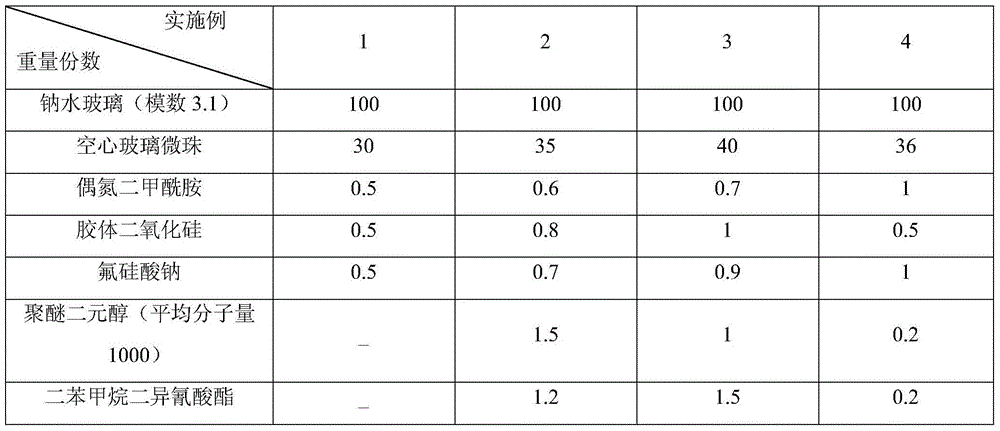

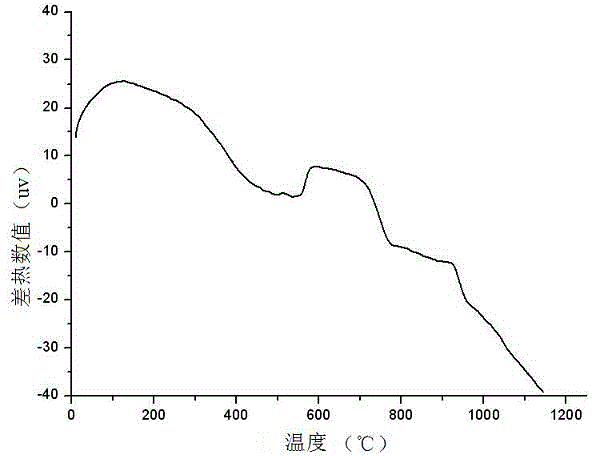

Silicate fireproof thermal insulation material and preparation method thereof

ActiveCN104876629ALight weightLow thermal conductivityCeramicwareThermal insulationEnergy consumption

The invention provides a silicate fireproof thermal insulation material composition. The silicate fireproof thermal insulation material composition is prepared from 100 parts by weight of water glass, 30-40 parts by weight of hollow glass microbeads, 0.5-1 part by weight of chemical foaming agent, 0.5-2 parts by weight of binder, 0.5-2 parts by weight of curing agent, 0.5-1 part by weight of polyether polyol and 0.5-1 part by weight of polyisocyanate; the fireproof thermal insulation material has the advantages of small volume weight, low heat conductivity coefficient and high compressive strength. The invention also provides a preparation method of the silicate fireproof thermal insulation material; the preparation method is simple in process, low in energy consumption and short in time.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Method for low temperature production of foam glass product

InactiveCN103332853ALower the foaming temperatureReduce manufacturing costGlass shaping apparatusGlass productionFiberFlat glass

The invention discloses a method for low temperature production of a foam glass product. The method includes: placing the raw material flat glass powder, the foaming agent manganese dioxide, the fluxing agent sodium silicofluoride and sodium carbonate, the foam stabilizer sodium phosphate and carbon fiber into a ball mill to undergo ball milling, preheating the ball milled particles at 430DEG C for 10-20min, controlling the foaming temperature at 750-780DEG C, the heat preservation time at 7-15min, and keeping the annealing temperature at 550DEG C, and the heat preservation time at 30min, and finally conducting cooling to room temperature. Specifically, in terms of the mass of the flat glass powder, the manganese dioxide accounts for 1-5%, the sodium silicofluoride accounts for 3-5%, the sodium carbonate accounts for 3-5%, the sodium phosphate accounts for 5-10%, and the carbon fiber accounts for 1-5%. The foam glass prepared by the invention has a uniform aperture, most of the holes are closed, the performance is excellent, and reaches the use standard. Low temperature firing of foam glass not only can reduce the production cost, but also can greatly improve the production efficiency at the same time.

Owner:YANGZHOU UNIV

Preparation method of environment-friendly porous rock granular material

ActiveCN104261688ALower the foaming temperatureImprove water absorptionGlass shaping apparatusGlass productionPorosityManganese

The invention relates to a preparation method of an environment-friendly porous rock granular material, which comprises the following steps: carrying out crushing and ball milling on screen glass to obtain CRT (cathode ray tube) screen glass powder; putting the CRT screen glass powder, manganese peroxide, sodium nitrate, lithium nitrate and antimony trisulfide in a ball mill, and carrying out ball milling to form a mixture; adding the mixture into a mold, sending into a roller hearth kiln, keeping the temperature for 5-10 minutes, and heating to 770-780 DEG C at the rate of 4-8 DEG C / minute; heating to 780-790 DEG C at the rate of 0.2-1 DEG C / minute; and cooling to 50-80 DEG C below at the rate of 80-200 DEG C / minute, crushing and screening to obtain the environment-friendly porous rock granular material. The environment-friendly porous rock granular material has the advantages of high strength, high water absorptivity, high aeration porosity, low foaming temperature and low use cost, and can not generate environment pollution in the production and use process. The environment-friendly porous rock granular material can be stored underground as excellent rain water, is a water purification material of rivers, lakes, reservoirs, fish ponds and the like, and can also be used as a heat-insulation fireproof construction material and other novel materials.

Owner:天津仁新玻璃材料有限公司

Process for preparing printing artificial flocking paper

InactiveCN103352399AFeel goodTo achieve the effect of flockingSpecial visual effect coatingsSpecial paperFoaming agentPolyethylene terephthalate

The invention discloses a process for preparing printing artificial flocking paper. The process comprises the following steps: mixing self-drying color ink, polyethylene terephthalate (PET) gloss oil and a low-temperature expansive type microsphere foaming agent and stirring uniformly to obtain a mixed material; and printing the mixed material on paper through silk screen and curing at 80 to 100 DEG C for 3 to 5 seconds to obtain the printing artificial flocking paper, wherein the mass ratio of the self-drying color ink to the PET gloss oil is from 3:4 to 3:1, and the weight of the low-temperature foaming agent is 1 to 80 percent of the total weight of the self-drying color ink and the PET gloss oil. By the process, a medium-and-low-temperature foaming material is adopted, the foaming temperature is low and the foaming time is short, a foaming effect can be realized through one-step heating of an infrared or ultraviolet drying channel of a common screen printer, and the processing requirement of paper packaging is met. Compared with a static flocking process, the process has high production efficiency, low cost and good adhesive force of a finished product, and can prepare the printing artificial flocking paper with different colors by adjusting the color of the color ink. Colorless and transparent bubbles are densely distributed on the surface of the printing artificial flocking paper prepared by the process, and an anti-counterfeit effect is achieved.

Owner:SHENZHEN NINE STARS PRINTING & PACKAGING GRP

High-toughness and high-elasticity expandable polystyrene and preparation method thereof

The invention discloses high-toughness and high-elasticity expandable polystyrene which comprises the following raw materials in parts by weight: 100 parts of styrene, 20-30 parts of an ethylene-vinyl acetate copolymer, 10-15 parts of high-density polyethylene, 150-170 parts of water, 0.2-0.5 parts of dibenzoyl peroxide, 0.05-0.1 parts of tert-butyl peroxybenzoate, 0.05-0.15 parts of activated calcium phosphate, 0.2-0.5 parts of modified titanium dioxide, 0.1-0.2 parts of hydroxyethyl cellulose, 2-8 parts of nekal, 0.05-0.15 parts of a defoamer and 7-12 parts of a foamer. The invention further discloses a preparation method for the high-toughness and high-elasticity expandable polystyrene. The high-toughness and high-elasticity expandable polystyrene is high in toughness, high in resilience, excellent in heat-retaining property, corrosion resistance, hardness, tensile strength and creep property, and good in water resistance, wear resistance and cold resistance.

Owner:芜湖市京桥精密智造有限公司

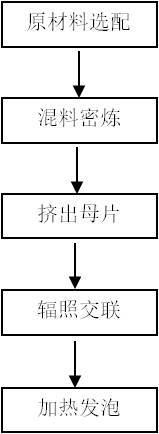

Anti-static irradiation crosslinked polyethylene foam material and preparation method thereof

PendingCN113527790AReduced granulation re-extrusion processIncrease productivityLow-density polyethylenePolymer science

The invention discloses an anti-static irradiation crosslinked polyethylene foam material. The foam material comprises, by weight, 25-35 parts of low-density polyethylene, 10-15 parts of an olefin block copolymer, 5-8 parts of a foaming agent, 5-8 parts of a foaming aid, 1-5 parts of a cross-linking agent, 0.5-3 parts of a sensitizing aid, 2-5 parts of polyethylene wax, 3-10 parts of conductive carbon black, 0.1-0.5 part of an antioxidant and 4-8 parts of a filler, wherein the melt index MI of the low-density polyethylene under the condition of 190 DEG C * 2.16 kg is equal to 1-3 g / 10 min; and the olefin block copolymer is an ethylene-octylene copolymer, the octylene content is 20-30%, and the density is 0.865-0.895 g / cm<3>. The invention also discloses a preparation method of the antistatic irradiation crosslinked polyethylene foam material. According to the anti-static irradiation crosslinked polyethylene foam material, master slices to be cross-linked can be prepared through one-step forming, the technological process is greatly simplified, and the obtained product is stable in conductivity, light in weight, free of toxicity and peculiar smell and excellent in mechanical property.

Owner:中广核高新核材科技(苏州)有限公司 +1

High-flame-retardance and high-toughness expandable polystyrene

The invention discloses high-flame-retardance and high-toughness expandable polystyrene which comprises the following raw materials in parts by weight: 95-105 parts of styrene, 20-30 parts of ethylene-propylene-diene monomer rubber, 25-35 parts of polyethylene, 150-170 parts of water, 0.3-0.4 parts of dibenzoyl peroxide, 0.05-0.1 parts of tert-butyl peroxybenzoate, 0.2-0.3 parts of dicumyl peroxide, 2-5 parts of nano calcium silicate, 0.02-0.04 part of a silane coupling agent KH560, 2-4 parts of polyvinyl alcohol, 1-3 parts of cellulose ether, 2-8 parts of nekal, 0.05-0.15 parts of a defoamer, 0.2-0.5 parts of an antioxidant, 0.4-1.2 parts of a flame retardant and 7-12 parts of a foamer. The high-flame-retardance and high-toughness expandable polystyrene disclosed by the invention is excellent in flame-retardant and heat-resistant performance, good in toughness and excellent in impact resistance.

Owner:芜湖市京桥精密智造有限公司

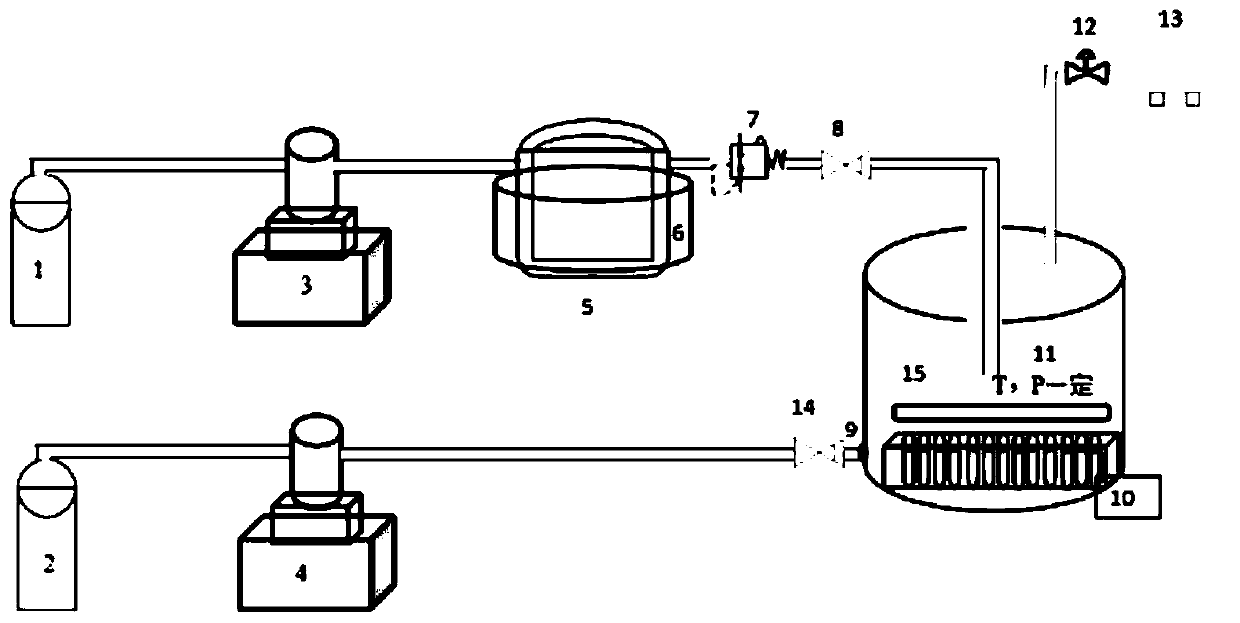

Self-balancing supercritical foaming method and self-balancing supercritical foaming device for multicomponent multiphase complex system

ActiveCN110480913ASolve for uniformityFix stability issuesBulk chemical productionFoaming agentInstability

The invention relates to a foaming and molding process and a foaming and molding device for a non-viscous polymer matrix by adopting mixed swelling of supercritical fluid and a blowing promotor. In the supercritical foaming field, the blowing promotor can promote the diffusion of the supercritical fluid in the non-viscous polymer matrix, reduce the foaming temperature of the supercritical fluid and improve the foaming rate of a foaming product. However, the supercritical fluid, the blowing promotor and a non-viscous polymer lead to extreme instability of a foaming process of a mixed foaming agent and extreme instability of cellular structures of the foaming products under a multicomponent multiphase complex system at high temperature and high pressure. For sufficiently realizing the synergistic effect of the blowing promotor and the supercritical fluid in promoting the supercritical foaming, the invention provides a self-adjusting foaming and molding process and a self-adjusting foaming and molding device for supercritical mixed fluid containing the blowing promotor under the multicomponent multiphase complex system, and thereby the self-balancing aim of the multicomponent multiphase complex system under the supercritical foaming condition is achieved, finally a foaming technology is stabilized, the cellular structure is improved and the performance of the products is improved.

Owner:SICHUAN UNIV

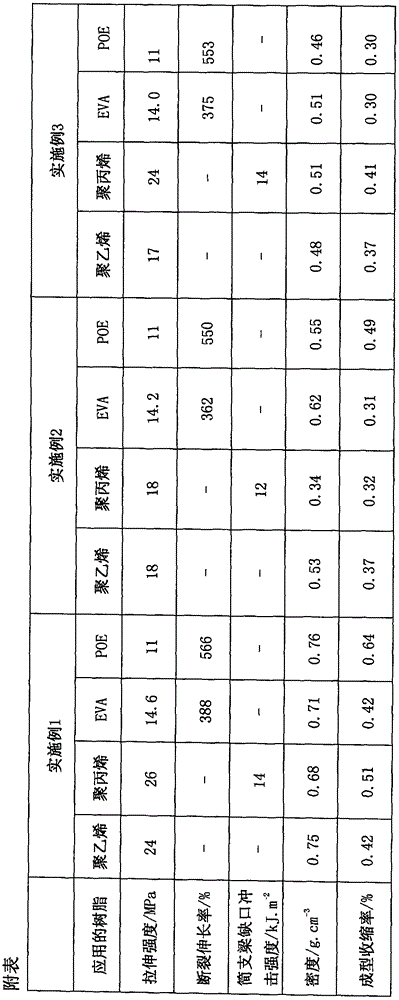

Polyolefin foaming masterbatch composition and preparation method and application

The invention belongs to the technical field of polymer function materials, and relates to a polyolefin foaming masterbatch composition and preparation method and application. The foaming masterbatch is prepared from, by weight, 50-80 parts of POE resin, 1-10 parts of a surface active agent, 10-40 parts of a foaming agent, 1-10 parts of a nucleating agent and 0.1-0.3 part of an initiator. The preparation method of the foaming masterbatch comprises the steps that the components are premixed in a mixer for 2-10 min, the mixing temperature is not higher than 40 DEG C, melt mixing is performed through an extruder, modular surface air cooling pelletizing is performed to obtain the foaming masterbatch. The foaming masterbatch has the advantages that the manufacturing cost is low, the foaming gas is safe and environmentally friendly, the foaming temperature is low, and the using range and the technological range are wide. The obtained foaming masterbatch is applied to the extrusion and injection molding processes of polyethylene, polypropylene, EVA resin and POE resin, and the obtained foaming masterbatch is safe, environmentally friendly, small in density, small in molding shrinkage and good in mechanical property.

Owner:上海睿麒塑业有限公司

Novel foam glass and preparation method thereof

InactiveCN107188422AAdd lessSolving the Refractory Titanium Containing Blast Furnace SlagGlass shaping apparatusFiberSlag

The invention discloses a novel foam glass which is prepared from the following raw materials in parts by weight: 12 to 27 parts of blast furnace slag, 5 to 22 parts of silica raw material, 20 to 40 parts of modified waste glass, 10 to 25 ceramic polishing waste, 8 to 13 parts of calcite, 9 to 21 perlite, 1.3 to 2.8 parts of aluminum oxide, 2 to 4 parts of sodium carbonate, 3 to 12 parts of borax, 0.8 to 1.4 parts of manganese dioxide, 0.7 to 1.3 parts of ferric oxide, 0.05 to 0.16 part of sodium hexametaphosphate, 1 to 5 parts of refractory fiber, 0.9 to 1.7 parts of nano medical stone powder, 0.3 to 0.7 part of nano zinc oxide, 1.1 to 2.2 parts of acetylated di-sodium starch and 0.8 to 2.4 parts of calcium carbonate. According to the novel foam glass, the blast furnace slag, the silica raw material, the modified waste glass and the ceramic polishing waste are utilized as raw materials, waste is turned into wealth, raw material source is wide, and cost is reduced; meanwhile, the refractory fiber and the nano zinc dioxide are added to serve as additives, so that performance of the foam glass is effectively improved, and strength of the foam glass is improved.

Owner:合肥钢骨玻璃制品有限公司

Method for preparing basalt porous heat-preserving material

A method for preparing a basalt porous heat-preserving material includes the steps that basalt, screen glass, calcium carbonate, silicon carbide, manganese oxide, magnesium carbonate and sodium silicate are ball-milled to obtain batch; then the batch is contained in a mould and heated, foamed, cooled and annealed to room temperature, and the basalt porous heat-preserving material is obtained. By means of the method, waste can be used easily, the environment is protected, the prepared high-strength porous material is low in foaming temperature, basalt directly serves as the main material, the preparation process is simple, and the prepared porous heat-preserving material is high in structural strength, low in water absorbing rate, small in density and low in heat conductive coefficient. Production cost of the foaming porous material can be effectively reduced, the environment is protected, waste is turned into wealth, and economic benefits and environment protection benefits are obvious.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com