High-inflaming-retarding modified phenolic resin foamed plastic and preparation method thereof

A technology of phenolic resin and foam plastics, applied in the field of foam plastics, can solve problems such as poor processing performance, uneven dispersion, and unstable performance, and achieve the effects of improving flexibility, excellent comprehensive performance, and similar cell sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

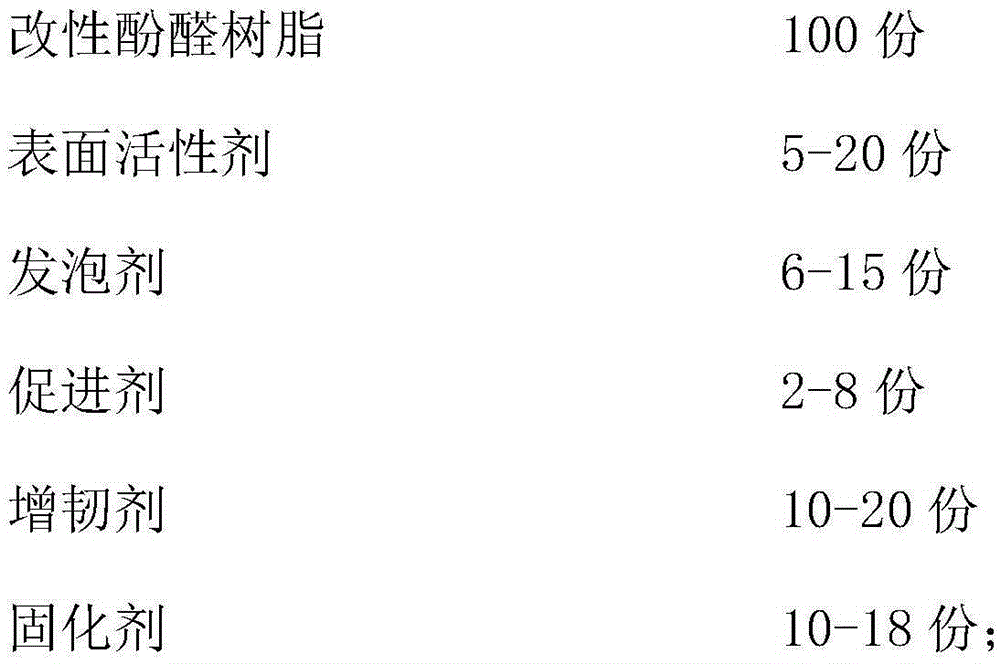

[0020] The present invention proposes a highly flame-retardant modified phenolic resin foam, which includes the following raw materials in parts by weight: 100 parts of modified phenolic resin, 5 parts of polysiloxane, 15 parts of methylene chloride, 2 parts of accelerator, and nitrile rubber 20 parts, 10 parts of curing agent;

[0021] The preparation process of the modified phenolic resin comprises: after mixing 100 parts of phenol and 180 parts of 30wt% formaldehyde solution by weight, the temperature is raised to 40°C, and 25wt% sodium hydroxide solution is added to adjust the pH value to 9- 10. Raise the temperature to 60°C, stir and react for 1.5h, add KH-5602 parts, raise the temperature to 90°C at a heating rate of 3°C / min, stir and react for 3h, cool to room temperature, and obtain a colloidal solution; to the colloidal solution Add melamine formaldehyde prepolymer to the mixture, heat up to 80°C, stir and react for 3 hours under nitrogen, add acid to adjust the pH to...

Embodiment 2

[0024] The present invention proposes a highly flame-retardant modified phenolic resin foam, which includes the following raw materials in parts by weight: 100 parts of modified phenolic resin, 20 parts of polyoxyethylene ether, 6 parts of isopentane, 8 parts of accelerator, polyurethane prepolymerized 10 parts of body, 18 parts of curing agent;

[0025] The preparation process of the modified phenolic resin comprises: after mixing 100 parts of phenol and 150 parts of 37wt% formaldehyde solution by weight, the temperature is raised to 50°C, and 15wt% sodium hydroxide solution is added to adjust the pH value to 9- 10. Raise the temperature to 80°C, stir and react for 0.5h, add KH-5606 parts, raise the temperature to 100°C at a heating rate of 2°C / min, stir and react for 1h, and cool to room temperature to obtain a colloidal solution; to the colloidal solution Add melamine formaldehyde prepolymer to the mixture, heat up to 100°C, stir and react under nitrogen for 3 hours, add ac...

Embodiment 3

[0028] The present invention proposes a highly flame-retardant modified phenolic resin foam, which comprises the following raw materials in parts by weight: 100 parts of modified phenolic resin, 12 parts of sorbitan fatty acid ester, 10 parts of n-pentane, 5 parts of accelerator, 15 parts of epoxy resin, 14 parts of curing agent;

[0029]The preparation process of the modified phenolic resin comprises: after mixing 100 parts of phenol and 165 parts of 33wt% formaldehyde solution by weight, the temperature is raised to 42°C, and 20wt% sodium hydroxide solution is added to adjust the pH value to 9- 10. Raise the temperature to 75°C, stir and react for 0.5h, add KH-5604 parts, raise the temperature to 98°C at a heating rate of 2.5°C / min, stir and react for 1h, cool to room temperature, and obtain a colloidal liquid; Add melamine-formaldehyde prepolymer to the mixture, raise the temperature to 98°C, stir and react for 2 hours under nitrogen, add acid to adjust the pH to 7-8, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com