Anti-static irradiation crosslinked polyethylene foam material and preparation method thereof

A technology of cross-linked polyethylene and foamed materials, applied in the field of foamed polyethylene products, can solve the problems of complicated preparation process of foamed sheets, and achieve the effects of reducing loss, excellent mechanical properties and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0040] Embodiment 1~3: Preparation of antistatic radiation cross-linked polyethylene foam material

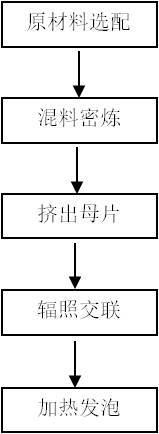

[0041] This embodiment provides an antistatic radiation cross-linked polyethylene foam material and a preparation method thereof, comprising the following steps:

[0042] Step 1: Mixing

[0043] According to the formula in Table 1, first stir low-density polyethylene, olefin block copolymer, foaming agent, foaming aid, crosslinking agent, polyethylene wax and antioxidant in an internal mixer for 1 minute, and mix well , and then add conductive carbon black and fillers, heat and banbury to 120°C.

[0044] Step 2: One-step molding to obtain the master chip

[0045] Put the materials mixed in step 1 directly into the main feeding hopper of the single-screw extruder. There is a feeding section in the middle section of the single-screw extruder. A die head that meets the requirements is installed at the end of the extruder to extrude the mother sheet.

[0046] Step 3: Irradiatio...

Embodiment 1

[0053] In embodiment 1: the melting index MI=1.5g / 10min of low-density polyethylene; Foaming auxiliary agent is zinc oxide; The particle diameter of conductive carbon black is 15-25nm, pH=6-7.5; Antioxidant is main antioxidant Oxygen 1076 + auxiliary antioxidant DSTP; cross-linking agent is a mixture of TAIC and TAC.

Embodiment 2

[0054] In embodiment 2: the melting index MI=2g / 10min of low-density polyethylene; Foaming aid is zinc oxide and stearic acid mixture, and mass ratio is 1:5; The particle diameter of conductive carbon black is 15-25nm, pH =6-7.5; antioxidant main antioxidant 1076 + auxiliary antioxidant DSTP; cross-linking agent is a mixture of TAIC and TMPTMA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com