Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Sodium silicofluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

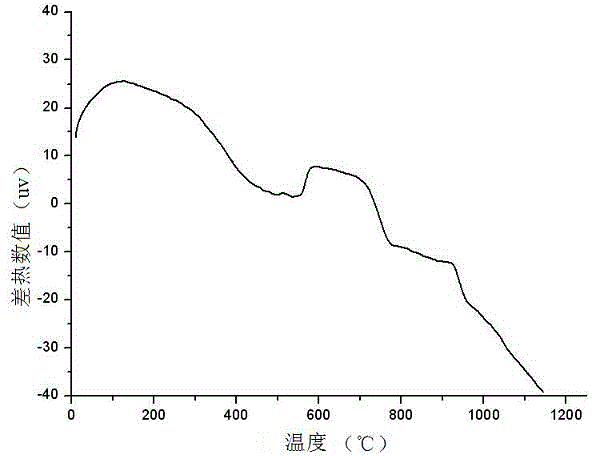

Low-temperature burning method for sludge glass ultra-light haydite

InactiveCN101215149AHigh cylinder compressive strengthLow water absorptionClaywaresHigh energySludge

A process for preparing super lightweight ceramsite of baking sludge glass at low temperature belongs to the field of architectural materials. The baking temperature of the ceramsite employing the sludge as main raw material is more than 1100DEG C with high baking temperature and high energy consumption. The invention employs waste glass power and sludge as main raw materials in the ceramsite formula, and one of sodium silicofluoride and borax as auxiliary raw material, then super lightweight ceramsite of baking sludge glass is baked at low temperature, the invention has the advantage of energy conservation. The mass mixing ratio for dispensing of the formula comprises urban domestic dry sludge of 20%-70%, waste glass powder of 25%-75% and auxiliary raw material of 2%-6%, discharging carbon at a low temperature of 300DEG C-600DEG C and baking at a temperature of 850DEG C-950DEG C to obtain ceramsite, the property of which meets the Lightweight Aggregates and its Test Methods GB / T 17431.1-1998 Standards.

Owner:BEIJING UNIV OF TECH

Positive temperature coefficient material and thermistor containing the material and preparation method therefore

ActiveCN101465185AImprove stabilityGood resistance stability at room temperaturePositive temperature coefficient thermistorsRoom temperatureHeat sensitive

Disclosed are a positive temperature coefficient material, a preparation method thereof, a positive temperature coefficient thermistor including the positive temperature coefficient material and a preparation method thereof. The material is a product formed by a mixture through melting; the mixture comprises resin, conductive filling, non-conductive filling, promoter and cross-linking agent, wherein, the mixture also comprises additives; and the additives are selected from silicon dichloride, sodium fluoride and carbon tetrachloride. The positive temperature coefficient material is provided with good stability and the output power of the positive temperature coefficient material is slowly attenuated along with the increase of the switching movement times, so that the thermistor prepared with the positive temperature coefficient material is provided with good room temperature resistance stability and PTC intensity stability after the thermistor is frequently used.

Owner:BYD CO LTD

Antibacterial and mildewproof latex foam material and preparation method thereof

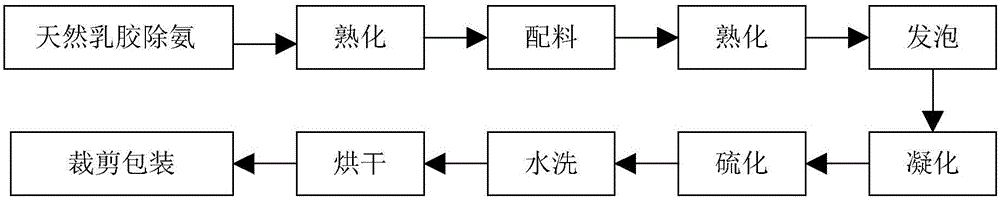

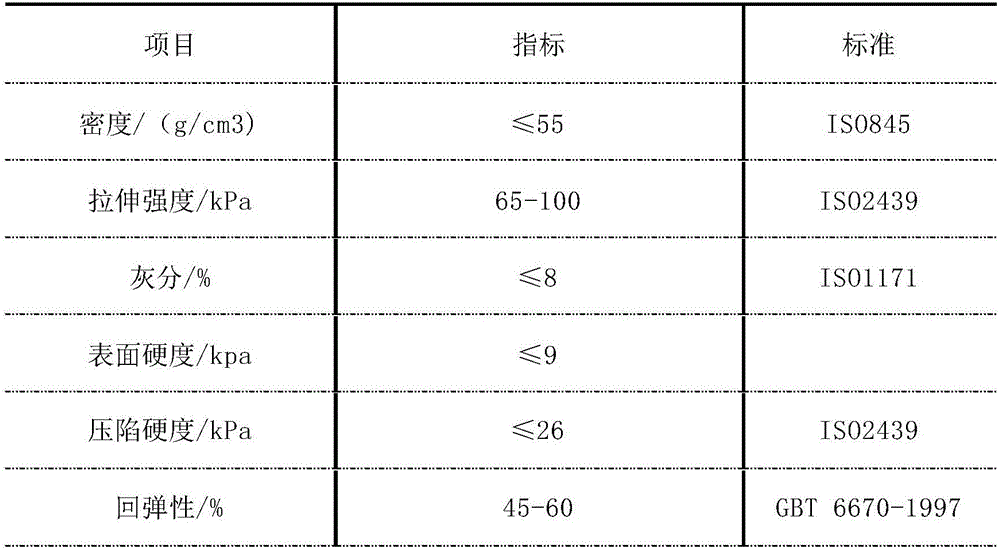

The invention provides an antibacterial and mildewproof latex foam material and a preparation method thereof. The foaming material comprises, by weight, 100 parts of latex (based on dry weight), 0.58 parts of potassium hydroxide, 2-5 parts of potassium vegetable oleate, 1-2 parts of potassium ricinate, 4-6 parts of sulfur, 1-2 parts of an antiager, 1-2 parts of sodium silicofluoride, 1-1.5 parts of bentonite, 4-6 parts of a vulcanization accelerator nanometer zinc oxide, and 0.5-1 part of an inorganic silver-carrying zinc-carrying antibacterial agent. The preparation method comprises removing ammonia, stirring ingredients, aging the mixture, and carrying out foaming, material filling, setting, vulcanization, cleaning and drying setting. The antimicrobial efficiency of the antibacterial and mildewproof latex foam material is 99% or more. The anti-mildew performance of the antibacterial and mildewproof latex foam material reaches the level 0-1. The elasticity, rebound resilience, strength and hardness of the foam material are excellent.

Owner:福家汇(北京)电子商务有限公司

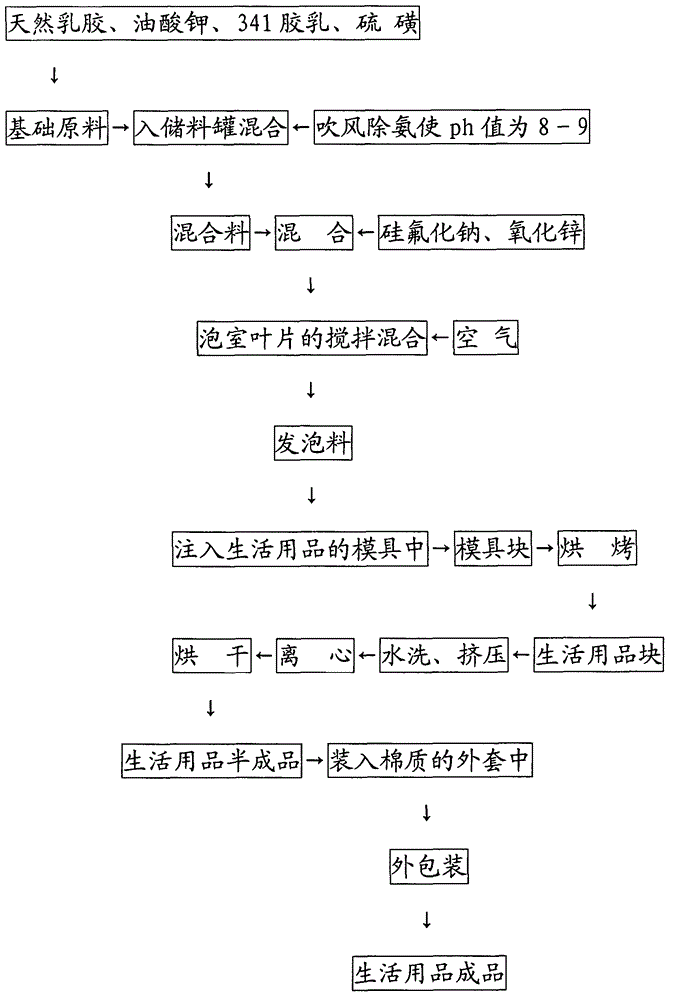

Method for manufacturing articles for daily use

The invention discloses a method for manufacturing articles for daily use and relates to the technical field of articles for daily use. The method comprises the following steps: by employing the daily article formula key technology, taking natural emulsion, potassium oleate, 341 latex and sulfur as basic raw materials, mixing and blowing air to make the pH value be 8-9, manufacturing a mixture, adding sodium silicofluoride and zinc oxide into a foaming chamber, pressing air, stirring and mixing to manufacture a foamed material to be injected into a daily article mold to manufacture a mold block, baking and manufacturing a daily article block, performing mold stripping, washing, extruding, centrifuging, drying and dehumidifying, manufacturing a daily article semi-finished product and packaging in a cover for performing external packing, and manufacturing the daily article finished product. The method is used for manufacturing pillows, mattresses, sofa cushions, chair cushions, backrests, automobile cushions, automobile neck-pillows and the like. The product is simple in process, high in quality and low in cost and contributes to popularization.

Owner:黄俊彬

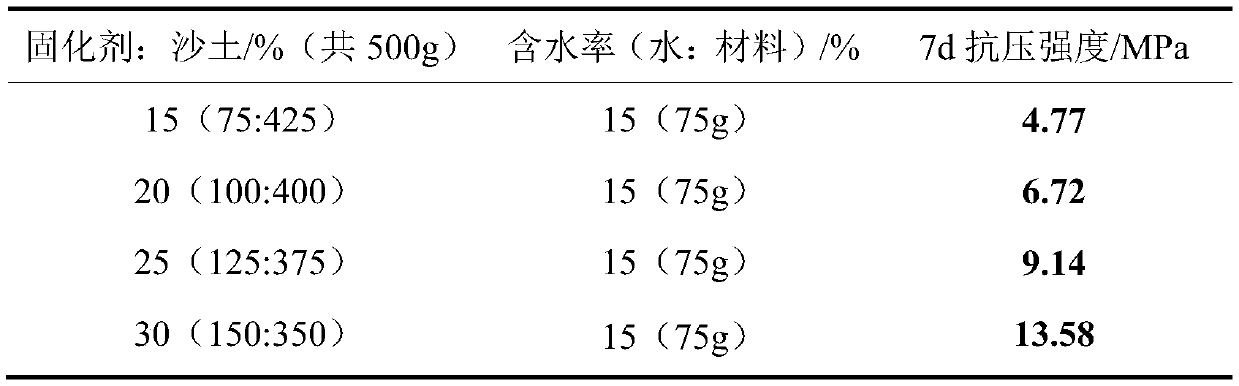

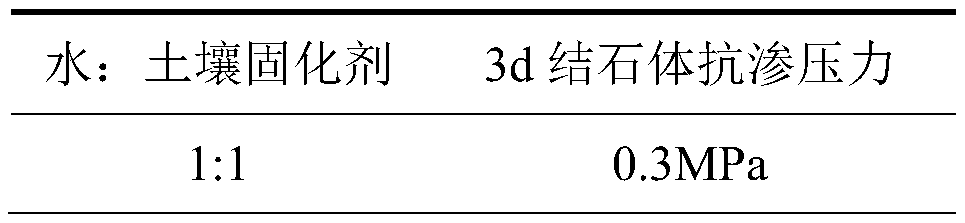

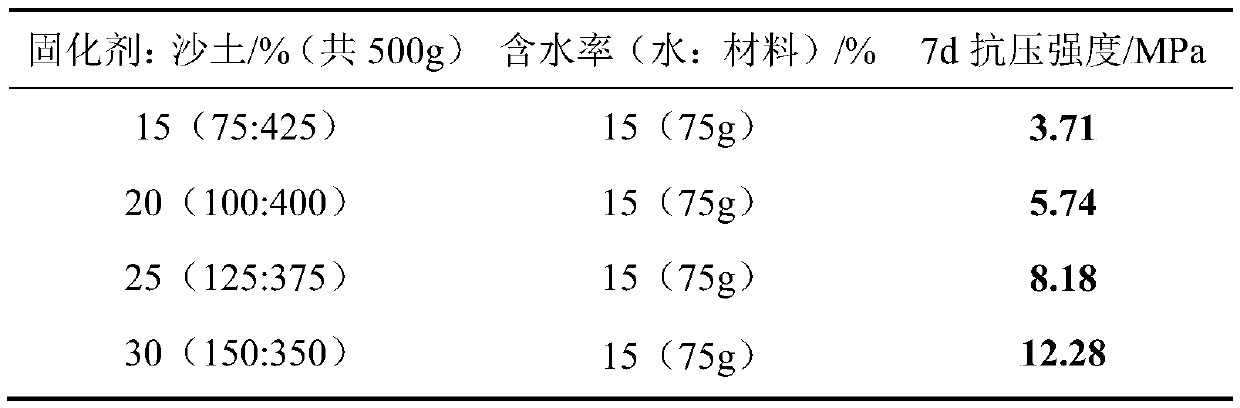

TRD continuous wall curing agent, and use method and application thereof

ActiveCN109761575AShorten the construction periodImprove efficiencyProtective foundationMarine site engineeringSlagPhosphogypsum

The invention belongs to the technical field of a soil curing agent, and particularly relates to a TRD continuous wall curing agent. The curing agent is prepared from the following ingredients including 15 to 55 parts of sodium dodecyl polyoxyethylene ether sulfate, 20 to 30 parts of sulfonated oil, 2 to 8 parts of polyanionic cellulose, 10 to 50 parts of polyhydric alcohols, 10 to 20 parts of high-molecular polymer anionic surfactants, 10 to 20 parts of water, 15 to 30 parts of fly ash, 5 to 20 parts of water glass, 3 to 9 parts of sodium silicofluoride, 10 to 40 parts of cement, 10 to 20 parts of phosphogypsum, 2 to 6 parts of sulfuric acid, 5 to 20 parts of polyacrylamide, 10 to 15 parts of epoxy resin and 3 to 5 parts of hydramine. The curing agent has the advantages of high pressure-resistant intensity and excellent waterproof and dampproof performance; waste soil, slag soil and building waste soil can be effectively modified to be reused as road building materials; the soil curing time is prolonged; the pressure-resistant intensity is improved, so that the TRD continuous wall construction work period is shortened; the efficiency is improved.

Owner:SHANDONG UNIV +1

One-step method for making colour oxide film on surface of aluminium and aluminum alloy

InactiveCN1873059AUniform and dense surfaceImprove wear resistanceSurface reaction electrolytic coatingAlloySodium silicofluoride

This invention discloses a technique for forming a color oxide film on the surface of aluminum and aluminum alloy products. The technique comprises: oxidizing aluminum or aluminum alloy in an aqueous solution of sodium silicate 2-10 g / L, sodium hydroxide 0.5-3 g / L, sodium molybdate 0.2-4 g / L, sodium silicofluoride 0.1-9 g / L, sodium tungstate 0.2-10 g / L, and potassium permanganate 0.5-4 g / L at 10-50 deg.C and current density of 0.08-2 A / cm2 for 0.5-3 h to obtain a yellow / brown / black oxide film. The oxide film is uniform and compact, and has a thickness of 20-200 mum. Besides, the oxide film also has good wear and corrosion resistance. The technique has such advantages as simple process, and no pollution.

Owner:YANSHAN UNIV

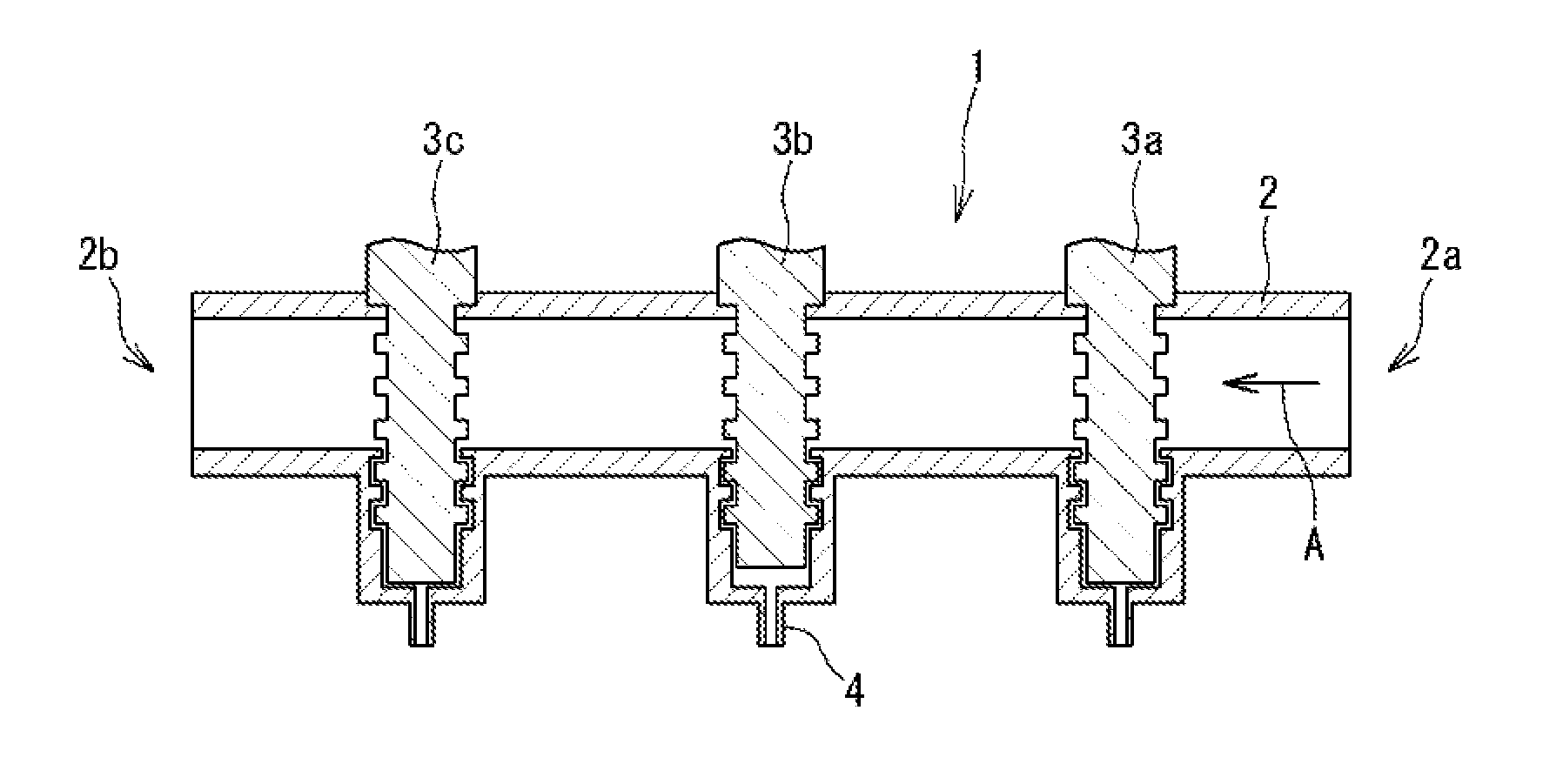

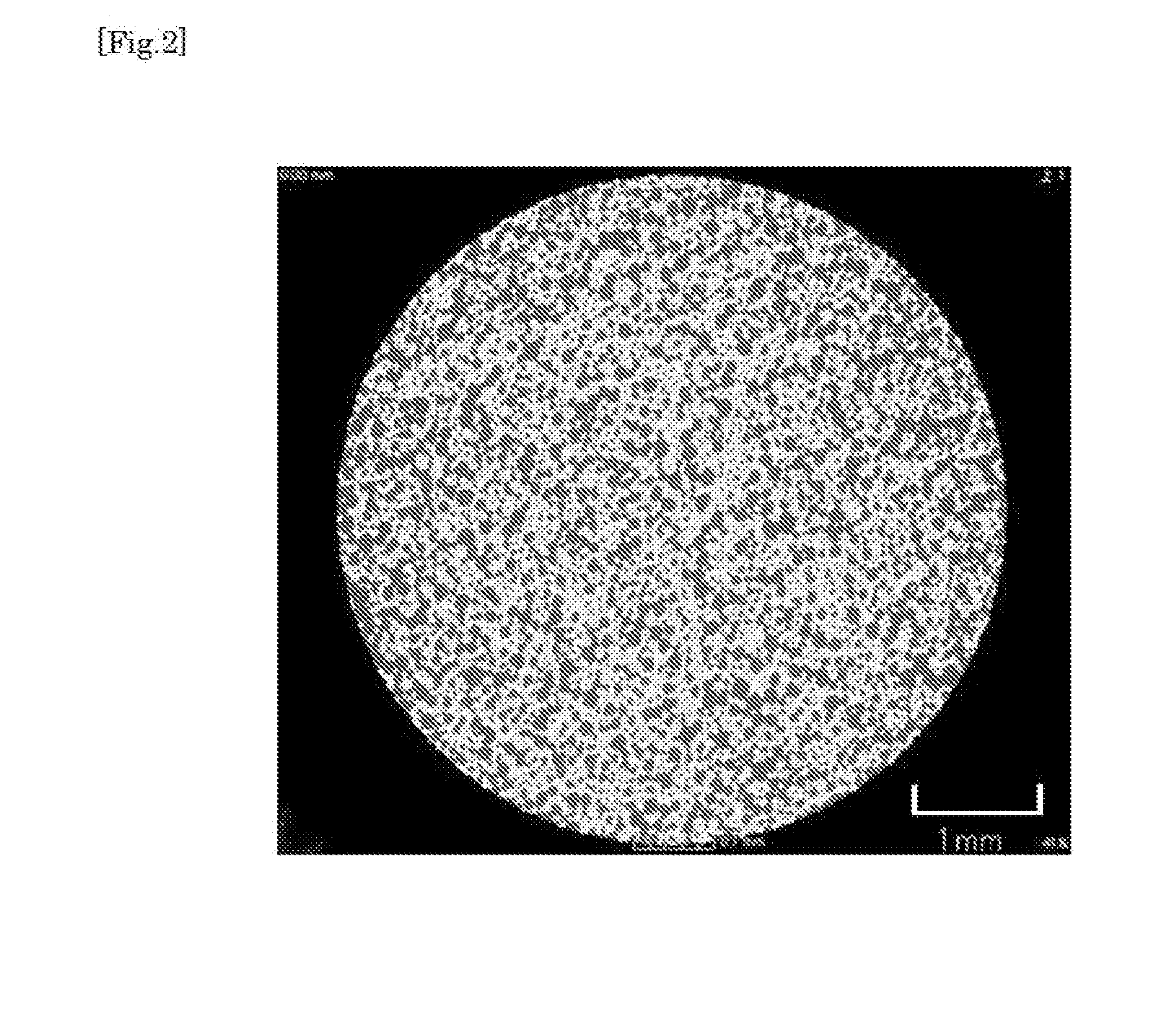

Rubber latex elastic foamed body

ActiveUS20160333158A1Rich textureExcellent in fitting property to skin propertyHair equipmentsPolymer scienceSodium silicofluoride

A rubber latex elastic foam body produced using as the raw material therefor rubber latex and sodium silicofluoride, having an average radius for the cellular foam configuring the foam body of 10-200 μm, a bulk density of 0.10-0.20 g / cm3, and stress at 50% compression of 0.1-1 N / cm2. This rubber latex elastic foam body has a rich texture, good adhesiveness to a skin, excellent powder adhesion, and excellent even powder application.

Owner:KK TAIKI

Method for preparing microcrystalline glass water washing ball

InactiveCN101239839ASimple processImprove wear resistanceCeramicwareSodium silicofluoridePore diameter

The present invention provides a method which is used for preparing a nucleated glass flush sphere and comprises the procedures of batching, molding and baking, and the method has the following characters: 50-94% powdered glass with granularity 5 mu m to 300 mu m, 2-15wt% sodium silicofluoride, 2-15wt% diborate and 1-10wt% nucleating agent and 1-10wt% foaming agent is mixed according to the proportion and is grinded to prepare the homogeneous nucleated glass powder, then the nucleated glass powder is prepared to flush sphere base substrate, the base substrate is baked for 1-4 hours at the temperature 600-950 DEG C after drying, and the nucleated glass powder sphere is prepared. The technique of the invention is simple, the nucleating agent is added to promote the crystal growth in the baking process, the kind of the nucleating agent, adding amount, temperature and baking time are controlled thereby controlling the volume content of the crystal and the crystal size in the product thereby obtaining the purpose of improving the product strength, the pore diameter of the product can be controlled between 0.1 and 0.5mm, and the inside and outside arrangement is uniform, the cost is low and the performance is excellent, the cubic effect of the washed cloth decorative pattern is excellent and the appearance is beautiful.

Owner:SHANDONG UNIV OF TECH

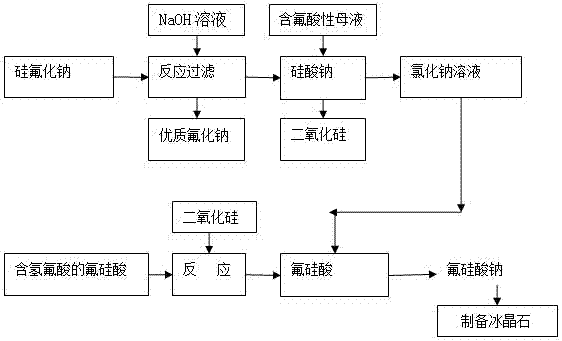

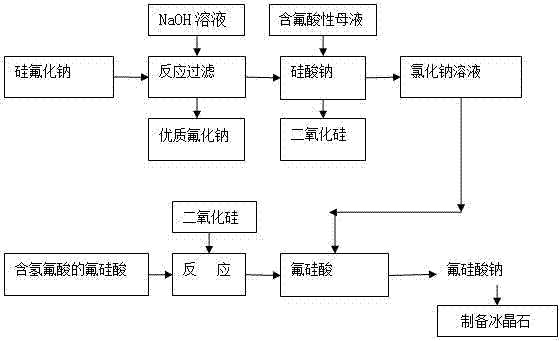

Treatment method for producing sodium silicofluoride as byproduct in inorganic fluoride production process

ActiveCN102211782AIncrease profitLow costAlkali metal fluoridesHexafluorosilicic acidSilicon dioxide

The invention relates to a treatment method for producing sodium silicofluoride as a byproduct in an inorganic fluoride production process. The technical scheme comprises the following steps: reacting the sodium silicofluoride with a sodium hydroxide solution, filtering, and drying a filter cake so as to obtain sodium fluoride; reacting a filtrate with a fluoride-containing acidic mother liquid so as to generate silica and a sodium chloride solution, filtering, and adding the generated silica in a fluosilicic acid solution containing hydrofluoric acid for reacting the silica with the hydrofluoric acid so as to prepare fluosilicic acid; and reacting the fluosilicic acid with the sodium chloride solution so as to prepare the sodium silicofluoride. The sodium silicofluoride can be used for producing cryolite, and the generated hydrochloric acid solution can be circularly used for producing the cryolite with a clay bittern method. In the method, the used raw materials are fluoride-containing solids and liquids which are byproducts in the fluoride production process, the production process is simple, and the raw material utilization is high; the content of the produced inorganic fluoride salt impurity is low, which meets the national standard; and by using the method, waste is turned into wealth, and the production idea of resource comprehensive utilization as well as energy conservation and environmental protection is achieved.

Owner:BAIYIN ZHONGTIAN CHEM

LED lamp cooling fin convenient for cooling

The invention relates to an LED lamp cooling fin convenient for cooling. The LED lamp cooling fin is prepared by raw materials comprising, by weight, 20-30 parts of silicon carbide, 10-20 parts of aluminium nitride, 8-10 parts of graphite, 6-10 parts of paraffin wax, 6-10 parts of glass fibers, 6-8 parts of polycarbonate, 4-6 parts of polyglycolic acid, 2-4 parts of sodium silicofluoride, 2-5 parts of chlorine vinegar resin, 1-3 parts of modifiers, 2-4 parts of ferrous chloride, 1-3 parts of alums and 1-3 parts of silicon nitride powder. Heat-conducting property, flame retardant property and mechanical property are greatly improved by adding the raw materials of the modified silicon carbide, the glass fibers, the polycarbonate, the alums, the silicon nitride powder and the like in a composite material; modification is performed through the silicon carbide, dispersion effect of the silicon carbide is improved, and accumulation of the silicon carbide is avoided; an LED lamp is heat resistant, aging resistant and long in service life.

Owner:WUHU SHENLONG NEW ENERGY TECH

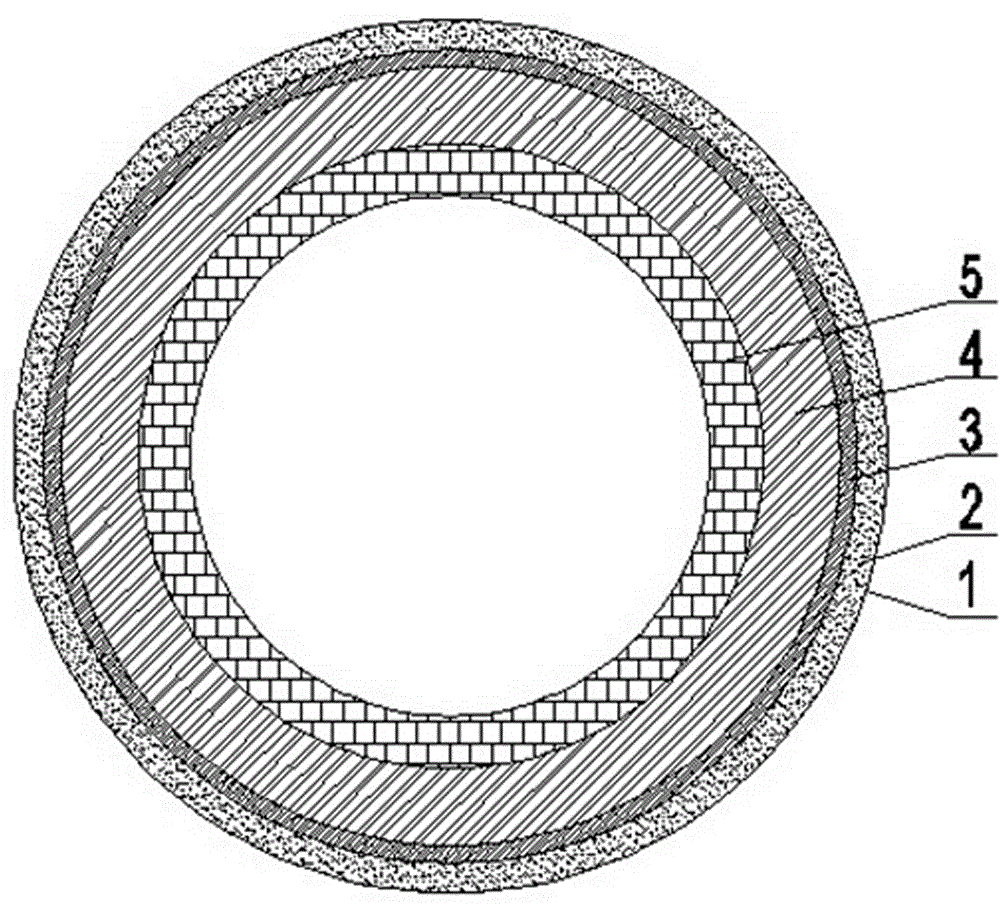

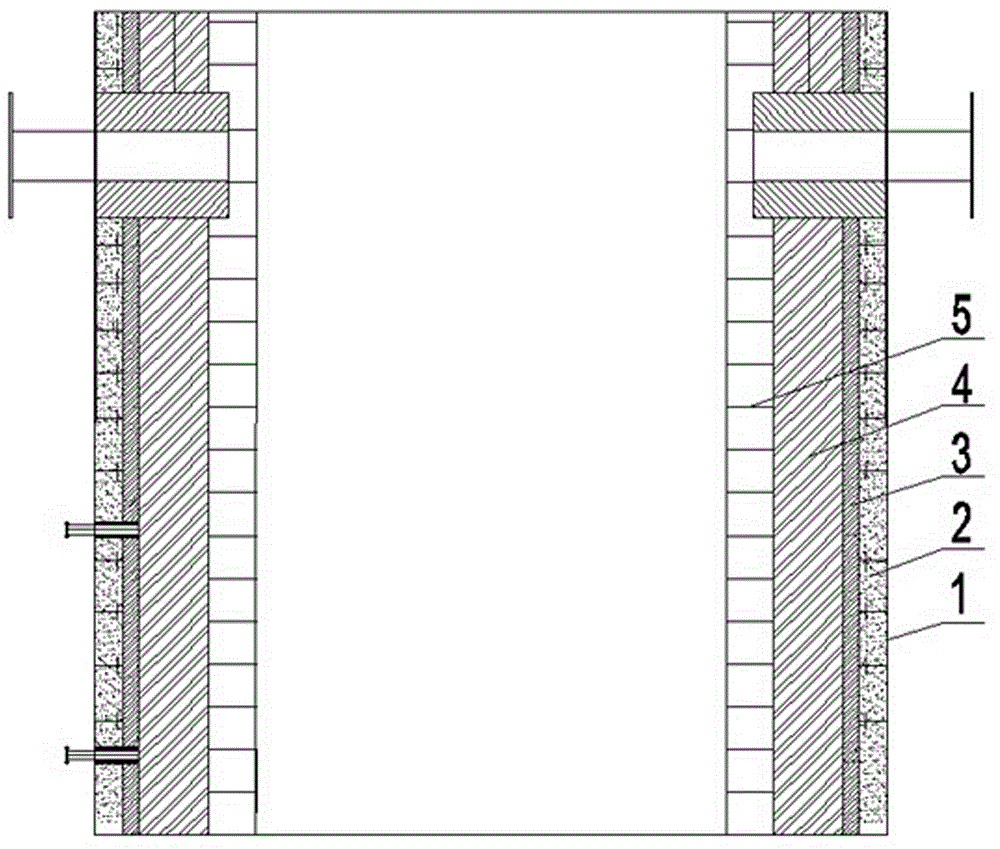

High-temperature-resistant corrosion-resistant furnace body for fluidizing chlorination furnace and manufacturing method of high-temperature-resistant corrosion-resistant furnace body

The invention provides a high-temperature-resistant corrosion-resistant furnace body for a fluidizing chlorination furnace and a manufacturing method of the high-temperature-resistant corrosion-resistant furnace body. On the inner wall of a shell, a plurality of installation assemblies are arranged along the axial direction of the shell; an anticorrosive coating made from sodium silicate, diabase powder and sodium silicofluoride is coated on the inner wall of the shell and the installation assemblies; a heat-insulation thermal-insulation casting layer is arranged on the anticorrosive coating; all installation assemblies are fixedly connected to the heat-insulation thermal-insulation casting layer; a heat-insulation thermal-insulation wall built by diatomite bricks is adhered on the surface of the heat-insulation thermal-insulation casting layer; a fire-resistant corrosion-resistant casting layer is adhered on the inner wall of the heat-insulation thermal-insulation wall; and a fire-resistant corrosion-resistant wall built by baking-free bricks is adhered on the surface of the fire-resistant corrosion-resistant casting layer. The high-temperature-resistant corrosion-resistant furnace body disclosed by the invention can be used for prolonging the service life and the repair cycle of the furnace body, lowering the production cost, preventing the flue gas from leaking to pollute the environment, and guaranteeing the safety of the working environment and the workers of the plant.

Owner:JINCHUAN GROUP LIMITED

Method for low temperature production of foam glass product

InactiveCN103332853ALower the foaming temperatureReduce manufacturing costGlass shaping apparatusGlass productionFiberFlat glass

The invention discloses a method for low temperature production of a foam glass product. The method includes: placing the raw material flat glass powder, the foaming agent manganese dioxide, the fluxing agent sodium silicofluoride and sodium carbonate, the foam stabilizer sodium phosphate and carbon fiber into a ball mill to undergo ball milling, preheating the ball milled particles at 430DEG C for 10-20min, controlling the foaming temperature at 750-780DEG C, the heat preservation time at 7-15min, and keeping the annealing temperature at 550DEG C, and the heat preservation time at 30min, and finally conducting cooling to room temperature. Specifically, in terms of the mass of the flat glass powder, the manganese dioxide accounts for 1-5%, the sodium silicofluoride accounts for 3-5%, the sodium carbonate accounts for 3-5%, the sodium phosphate accounts for 5-10%, and the carbon fiber accounts for 1-5%. The foam glass prepared by the invention has a uniform aperture, most of the holes are closed, the performance is excellent, and reaches the use standard. Low temperature firing of foam glass not only can reduce the production cost, but also can greatly improve the production efficiency at the same time.

Owner:YANGZHOU UNIV

Heat-preservation thermal-insulating building cementing material

ActiveCN106186757AImprove thermal insulation performanceLow thermal conductivitySlagSodium silicofluoride

The invention discloses a heat-preservation thermal-insulating building cementing material which is prepared from the following raw materials: plant fiber, gypsum, ferrous sulfate, lime, sodium silicate, sodium silicofluoride, glass fiber, sodium alginate, slag, silica fume, zeolite powder, nano clay, citric acid, polypropylene fiber, cellulose ether, vitrified micro bubbles, diatomite, a water reducing agent, latex powder and potassium sorbate. The heat-preservation thermal-insulating building cementing material disclosed by the invention is reasonable in formula; due to interaction of the components, and addition of the plant fiber, the vitrified micro bubbles and the like in the raw materials, the heat-preservation thermal-insulating properties of the material are improved; as waste slag is taken as a raw material, waste of energy in the building use process can be reduced. By adopting the heat-preservation thermal-insulating building cementing material disclosed by the invention, the dry density of a system is reduced, the heat conduction coefficient is reduced, and the heat-preservation property of the material is improved.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Titanium dioxide doped concrete and preparation method thereof

InactiveCN103979905AImprove toughnessImprove radiation protection performanceSolid waste managementFiberEpoxy

The invention discloses a titanium dioxide doped concrete. The titanium dioxide doped concrete is prepared by using the following raw materials, by weight, 90-120 parts of cement, 80-100 parts of gravel, 30-40 parts of desulfurized gypsum, 10-13 parts of rubber particles, 9-11 parts of epoxy resin, 8-10 parts of isocyanate, 5-8 parts of titanium dioxide, 2-4 parts of sodium silicofluoride, 95-125 parts of waste concrete, 80-100 parts of fly ash, 2-4 parts of sodium nitrate, 40-50 parts of waste clothes, 4-8 parts of an assistant and a proper amount of water. The aggregate of the titanium dioxide doped concrete prepared in the invention contains waste concrete and fly ash, so the consumption of natural sandstones is reduced, the utilization rate of the natural sandstones is improved, and the production cost is reduced; and the addition of titanium dioxide and waste cloth fibers to the raw materials for preparing the titanium dioxide doped concrete increases the toughness and the radiation resistance of the concrete, and makes the prepared concrete have the advantages of unlikely cracking, good workability, high compressive strength, high temperature resistance and the like.

Owner:江门市志广水泥制品有限公司

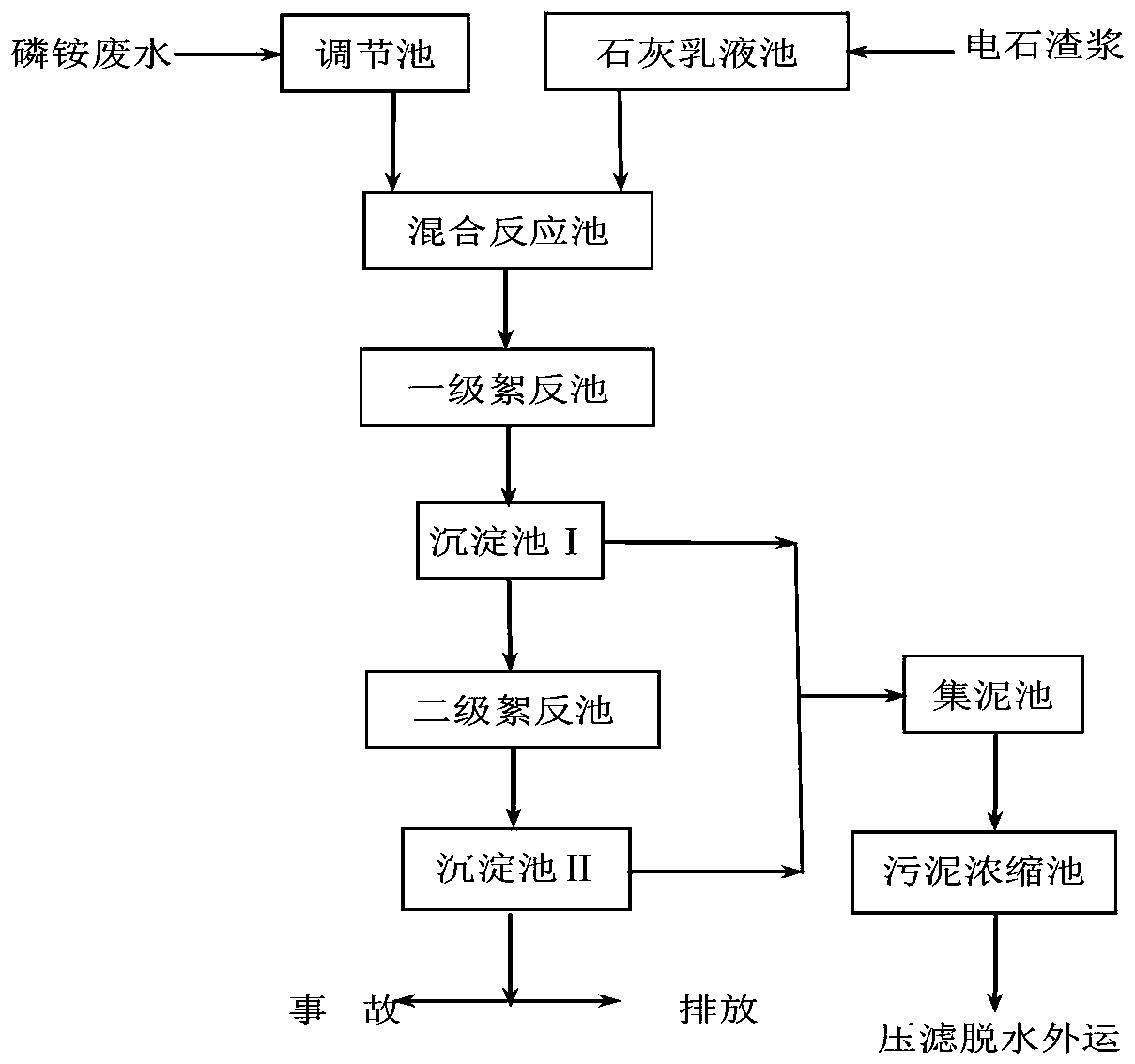

Physicochemical treatment method for mixed type chemical fertilizer production wastewater

ActiveCN105502730AMultistage water/sewage treatmentWater/sewage treatment by neutralisationSlagEvaporation

The invention provides a physicochemical treatment method for mixed type chemical fertilizer production wastewater. The method comprises specific steps as follows: ammonium phosphate reaction tail washing wastewater, sodium silicofluoride wastewater, concentrated geosyncline wastewater and tailing backwater are added to a sewage physical-chemical regulation pool, carbide-slag slurry enters a lime slurry pool, acetylene alkali waste, catalyst pumping agent wastewater and alkali evaporation wastewater enters a mixed reaction pool, acid wastewater entering the regulation pool and the carbide-slag slurry entering the lime slurry pool are conveyed to the mixed reaction pool through a pump, and a PAC (polyaluminium chloride) and PAM (polyacrylamide) mixed liquid is added; the mixed liquid is conveyed to a primary flocculation reaction pool through the pump and is stirred to have the neutralization and sedimentation reaction, a formed precipitate mixed liquid is subjected to sedimentation through a sedimentation tank I, a supernatant liquid enters a secondary flocculation reaction pool, the PAC and PAM mixed liquid is added again, pH value is regulated, the mixture has the neutralization and sedimentation reaction, a product enters a sedimentation tank II after reaction, and water treated by the secondary flocculation reaction pool can be used. The wastewater after treatment is recycled to a circulating water system of a factory, the recycling rate is higher than 90%, and the environmental and economic benefits are remarkable.

Owner:HUBEI YIHUA GRP CO LTD +2

Novel environment protective adhesives free of formaldehyde and its manufacturing process

InactiveCN1730591AImprove adhesionEasy to produceAmide/imide polymer adhesivesUnsaturated alcohol polymer adhesivesAluminium sulfateAdhesive

The invention relates to a novel environment protective adhesive free of formaldehyde and its manufacturing process, wherein the adhesive comprises main agent and auxiliary agent, the main agent comprises sodium silicate, polyvinyl alcohol, polyacrylamide, urea and aluminium sulphate, the auxiliary agent comprises sodium silicofluoride and alta-mud. The preparing process comprises the steps of mixing, heating, agitating, dissolving, mixing and stirring.

Owner:忻健存 +1

Latex silk floss quilt and production process thereof

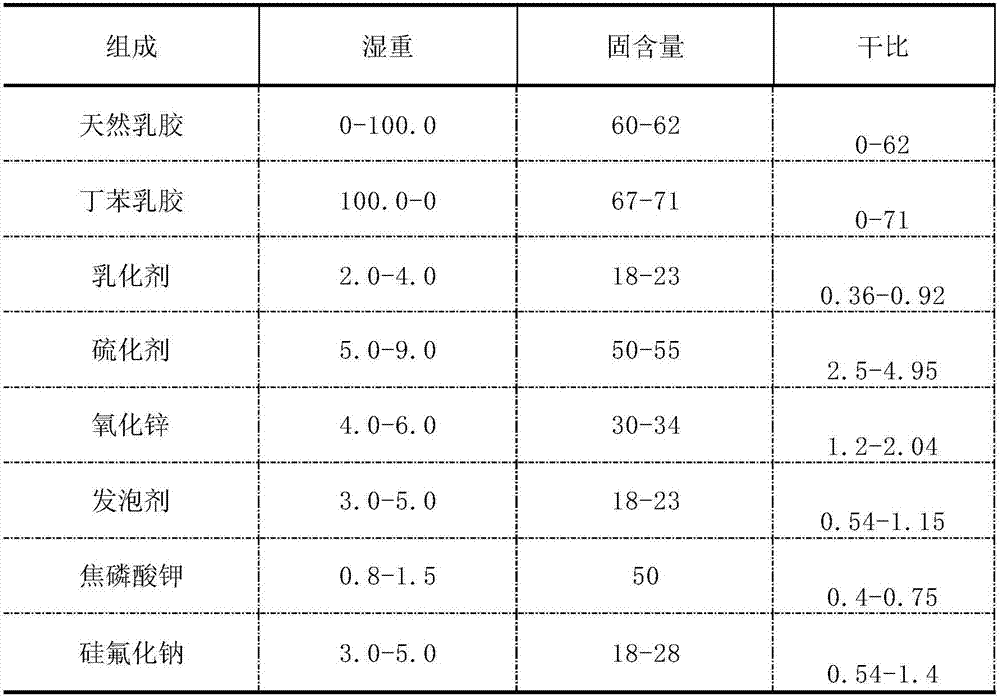

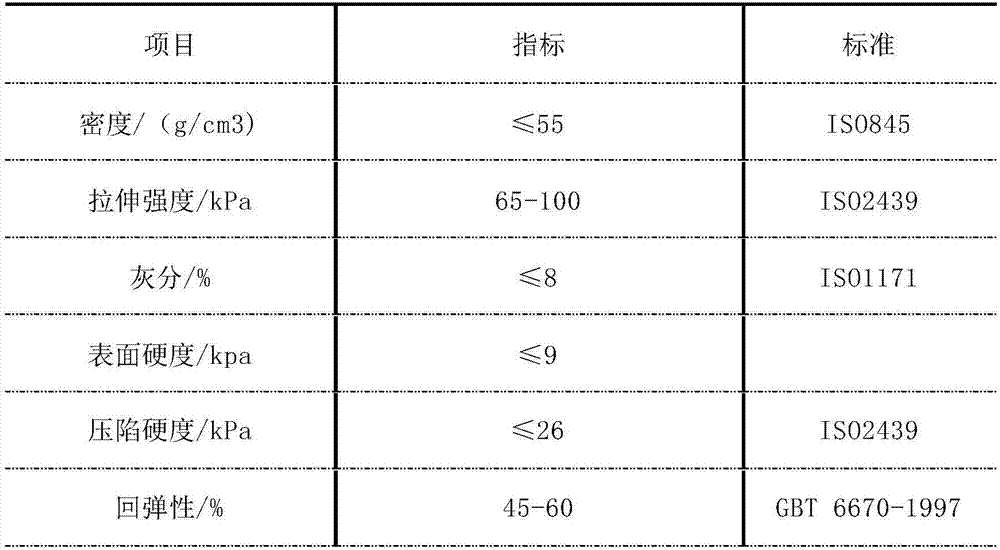

The invention discloses a production process of a latex silk floss quilt. The production process comprises the following steps: preparing raw materials in parts by weight: 0-100 parts of natural latex, 100-0 part of styrene-butadiene latex, 2-4 parts of an emulsifier, 5-9 parts of a vulcanizing agent, 4-6 parts of zinc oxide, 3-5 parts of a foaming agent, 0.8-1.5 parts of potassium pyrophosphate and 3-5 parts of sodium silicofluoride, wherein at least one of natural latex and styrene-butadiene latex is contained; dosing to form a lax raw material; curing the latex raw material at 26-30 DEG C for 2-6 hours; foaming the cured latex raw material; filling silk cotton materials into a mold; injecting the foamed latex raw material into the mold, and mixing and condensing the latex raw material and the silk cotton materials; vulcanizing the condensed latex raw material; washing the vulcanized latex raw material with water; and drying the latex raw material washed with water. The production process of the latex silk floss quilt provided by the invention can solve the problems of poor softness and air permeability of the latex silk floss quilt.

Owner:江苏江盈家居用品有限公司

Slag removing agent used for smelting aluminum alloy

The invention provides a slag removing agent used for smelting an aluminum alloy. The slag removing agent is characterized in that components of the slag removing agent comprise, by mass, 6-12% of sodium fluoride, 8-16% of calcium fluoride, 6-16% of sodium fluoroaluminate, 16-24% of potassium chloride, 5-10% of potassium nitrate, 12-18% of potassium fluorosilicate, 14-20% of sodium silicofluoride,4-10% of carbon powder, 5-10% of cryolite, and the rest sodium chloride added to 100%. The slag removing agent is adopted and has the beneficial effects that the heating effect is good, slag and aluminum separation is benefitted, the aluminum amount in slag is extremely low, the slag is dry slag, the slag removing effect is excellent, and moreover, the slag removing agent is easy to clear and convenient to use. Compared with the prior art, energy sources are saved, and labor hours are shortened.

Owner:徐州轩辕铝业有限公司

Domestic sewage treatment agent and preparation method thereof

InactiveCN109650481AImprove adsorption efficiencyImprove processing efficiencyWater/sewage treatment by sorptionSlagTreatments water

The invention discloses a domestic sewage treatment agent. The domestic sewage treatment agent is prepared by the following raw materials, by weight: 55-70 parts of a nano-magnetic ceramic matieral, 6-9 parts of montmorillonite, 0.5-1.5 parts of active alpha-alumina, 8-11 parts of calcium silicon slag, 4-6 parts of polymerized aluminum trichloride, 4-9 parts of basic iron chloride, 2-3 parts of sodium silicofluoride, 15-25 parts of polyacrylamide, 0.5-1 part of magnesium aluminosilicate, 11-14 parts of sponge rock, and 5-10 parts of activated carbon. The invention also discloses a preparationmethod of the domestic sewage treatment agent. Compared with the prior art, the domestic sewage treatment agent of the invention can be fabricated into a general fast filter tank according to treatment water quantity and discharge requiremtns. The sewage treatment agent has high adsorption efficiency for total phosphorus in pollutants, is simple in operation, good in treatment effect and low in operation cost, the used raw materials are cheap and easily available, a part of the raw materials are waste residues, and the process has the advantages of universality, simple operation and high wastewater treatment efficiency and is suitable for large-scale industrial utilization.

Owner:WUHAN FUND ENVIRONMENT PROTECTION

Titanium dioxide cover glaze used on gold smelting bucket and production method of titanium dioxide cover glaze

The invention discloses titanium dioxide cover glaze used on a gold smelting bucket. The titanium dioxide cover glaze comprises the following raw materials in parts by weight: 9-9.5 parts of feldspar, 22.5-23.5 parts of quartz, 30-32 parts of borax, 3-4 parts of sodium nitrate, 14-15 parts of titanium oxide, 1-1.5 parts of zinc oxide, 1-1.5 parts of magnesium oxide, 8.5-9 parts of trisodium phosphate and 7-8 parts of sodium silicofluoride. The preparation method of the titanium dioxide cover glaze comprises the following steps: rapidly cooling the above components into a granular or flaky borosilicate vitric material after being molten at high temperature, so as to obtain cover glaze blocks; adding the following components by weight into every 100kg of the cover glaze blocks: 6.00 percent of Xuyong china clay, 3.0 percent of cadmium red with the purity of 95 percent, 0.01 percent of cadmium yellow, 45.00 percent of water and 110.00 percent of high boehmite spheres, uniformly mixing, and ball-milling, thereby obtaining the cover glaze with the granularity of 100 meshes. The titanium dioxide cover glaze is attractive in color, stable in hue and good in properties such as acid resistance, alkali resistance, thermal resistance, wearing resistance and the like.

Owner:GUIZHOU XINGREN COUNTY RONGKAI HARDWARE ENAMEL PROD

Latex quilt production process

The invention discloses a latex quilt production process. The latex quilt production process includes: preparing a latex quilt material from, by weight, 0-100 parts of natural latex and / or 100-0 part of styrene butadiene latex, 2-4 parts of an emulsifying agent, 5-9 parts of a vulcanizing agent, 4-6 parts of zinc oxide, 3-5 parts of a foaming agent, 0.8-1.5 parts of potassium pyrophosphate and 3-5 parts of sodium silicofluoride; subjecting the latex quilt material to ageing for 2-6h at 26-30 DEG C; subjecting the aged latex quilt material to foaming treatment; injecting the foamed latex quilt material into a mould plate to realize coagulation; vulcanizing the coagulated latex quilt material; washing the vulcanized latex quilt material; drying the washed latex quilt material. By the latex quilt production process, problems of poor flexibility and breathability of latex quilts can be effectively solved.

Owner:江苏江盈家居用品有限公司

Mute heat-insulating slow-rebound rubber and plastic and preparation method thereof

The invention relates to mute heat-insulation slow-rebound rubber and plastic, which comprises the following raw materials: low-density polypropylene, an ethylene-octene copolymer, natural latex, a vulcanizing agent, a filler talcum powder, a reinforcing agent, an accelerant, an active agent, a dispersing agent, a foaming agent, an anti-aging agent, sodium silicofluoride and paraffin. By adding the latex raw material, the latex has the characteristics of excellent resilience, supporting property, shock absorption and compression fatigue resistance, so that the prepared plastic foamed sponge has the characteristics of the rubber, and the toughness, the flexing resistance and the tearing strength of the plastic, and also has the advantages of good softness, ultrahigh resilience and creep resistance.

Owner:WINCELL INSULATION CO LTD

Organic and inorganic fertilizers prepared from waste mash of alcohol and used for litchi planting and method

InactiveCN104591885AOvercome the problems of high nitrogen and phosphorus dosageReduce inputFertilizer mixturesPotassium fluorideBiological activation

The invention discloses organic and inorganic fertilizers prepared from waste mash of alcohol and used for litchi planting and a method, belonging to the technical field of fertilizers used in agriculture and forestry. The organic and inorganic fertilizers comprise the following raw materials: biomass materials, waste mash of alcohol, polyvinyl alcohol, magnesium sulfate, copper sulfate, calcium chloride, potassium fluoride, sodium silicofluoride and trisodium phosphate. The method comprises the following steps: mixing the biomass materials with the waste mash of alcohol, adding polyvinyl alcohol after airtight soaking and carrying out alcoholysis while stirring, then adding magnesium sulfate and copper sulfate, then introducing nitrogen and carrying out microwave heating activation, finally adding calcium chloride, potassium fluoride and sodium silicofluoride and mixing the materials uniformly, thus obtaining the organic and inorganic fertilizers used for litchi planting. By using the organic and inorganic fertilizers, healthy growth of litchis can be obviously promoted and the photosynthesis capacities of the litchis can be improved, thus increasing the yield, improving the quality and increasing the economic benefits; meanwhile, the fertilizer input can be also reduced, and the risk of environmental pollution caused by improper application of the fertilizers can be reduced.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

Vulcanization accelerator, environment-friendly latex sponge, preparation method and application

The invention discloses a vulcanization accelerator, environment-friendly latex sponge, a preparation method and application. The vulcanization accelerator comprises 100 parts of silicon dioxide; 40-100 parts of strong base; 1-20 parts of cerium salt; and 40-100 parts of carbon disulfide. The preparation method comprises the step of loading xanthate on silicon dioxide. The environment-friendly latex sponge comprises 100 parts of latex, 1-2 parts of an anti-aging agent, 1-3 parts of sodium silicofluoride, 0.5-2 parts of a foaming agent, 4-25 parts of the vulcanization accelerator and the like. The preparation method comprises the following steps: preparing the auxiliary agents into dispersoid, mixing, stirring, injecting into a mold, gelling, vulcanizing, demolding, washing with water and drying. The prepared environment-friendly latex sponge can be used in the fields of furniture, automobiles or sanitation. The vulcanization accelerator provided by the invention is good in thermal stability, does not decompose after being stored for a long time at room temperature, does not release pungent smell, and is environment-friendly. The environment-friendly latex sponge is good in buffering effect and has excellent stretch resistance and rebound resilience.

Owner:中胶永生东南亚乳胶制品股份有限公司

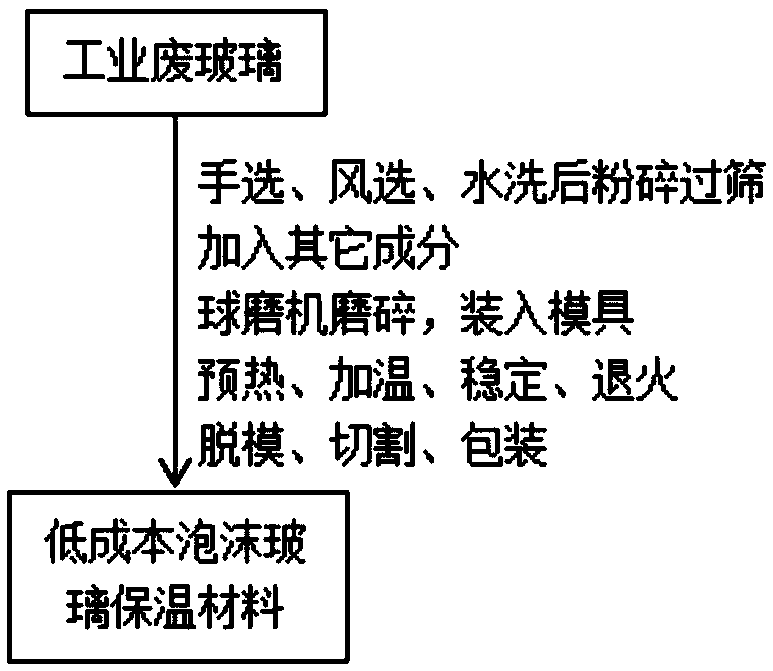

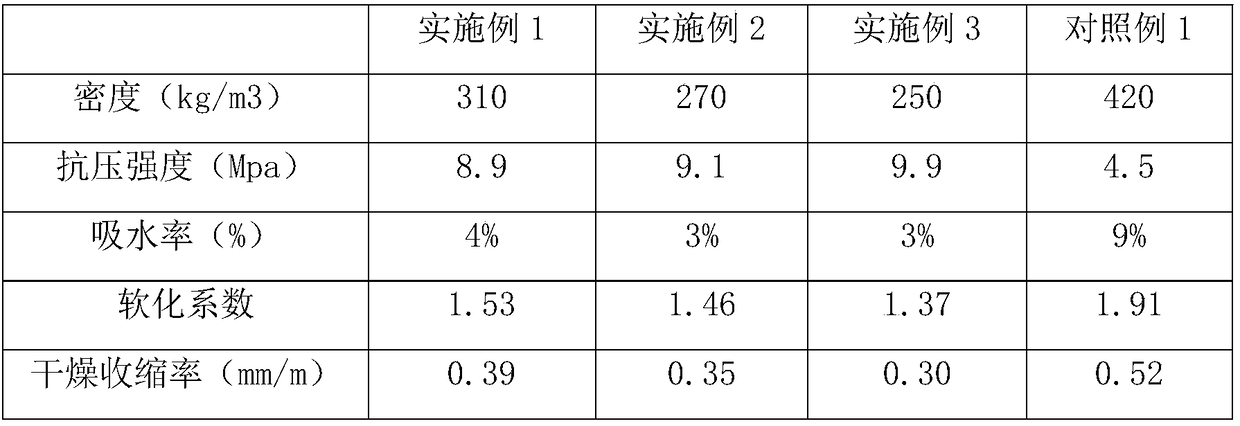

Low-cost foam glass heat insulating material, preparation and application thereof

InactiveCN108840572AImprove firing resultsImprove performanceGlass shaping apparatusGlass productionDichlorodifluoromethaneSolvent

The invention provides a low-cost foam glass heat insulating material. The low-cost foam glass heat insulating material comprises the following raw materials: industrial waste glass, porcelainized powder, a foaming agent, a cosolvent, graphene oxide, borax, antimonous oxide and a foaming accelerator, wherein the porcelainized powder comprises low-temperature porcelainized powder, medium-temperature porcelainized powder and high-temperature porcelainized powder; the foaming agent is selected from one in carbon black, silicon carbide, calcium carbonate, dolomite dust, flogopite, graphite, manganese dioxide, sodium silicate, trichlorofluoromethane and dichlorodifluoromethane; the cosolvent is selected from one or more in sodium carbonate, sodium silicofluoride, sodium benzoate, sodium salicylate, para aminobenzoic acid and Tween; the foaming agent is selected from one in lithium stearate and zinc stearate. The low-cost foam glass heat insulating material greatly improves the performance of foam glass, reduces the foaming temperature, increases the foaming range, reduces communicating holes, and improves the yield.

Owner:江苏省苏安能节能建材科技有限公司

High-strength quick-solidifying plugging agent

The invention discloses a high-strength quick-solidifying plugging agent. The high-strength quick-solidifying plugging agent is technically characterized by being prepared from, by weight, 30-50 partsof sulphate aluminum cement, 1-2 parts of polyacrylamide, 6-15 parts of hemihydrate gypsum, 26-30 parts of filler, 0.5-1 part of nonionic surface active agent and 0.5-1 part of sodium silicofluoride.The high-strength quick-solidifying plugging agent has the advantages that a high-strength solid is formed after mixture solidification, and impact resistance of a plugging layer is improved; after mixture solidification, the high-hardness solid is formed, and the abrasion resistance of the plugging layer is improved. Lithium salt and quick lime low in heat producing capability serve as auxiliaries in the mixture solidification process, so that the formed material is more dense, and the permeation resistance of the plugging material is improved. The prepared plugging material overcomes the cracking problem of a plugging material made from quick lime, the cost of the hemihydrate gypsum is far lower than that of the lithium salt, and the cost of the plugging material is remarkably reduced.

Owner:徐波

A method for producing foam glass products at low temperature

InactiveCN103332853BLower the foaming temperatureReduce manufacturing costGlass shaping apparatusGlass productionFiberFlat glass

The invention discloses a method for low temperature production of a foam glass product. The method includes: placing the raw material flat glass powder, the foaming agent manganese dioxide, the fluxing agent sodium silicofluoride and sodium carbonate, the foam stabilizer sodium phosphate and carbon fiber into a ball mill to undergo ball milling, preheating the ball milled particles at 430DEG C for 10-20min, controlling the foaming temperature at 750-780DEG C, the heat preservation time at 7-15min, and keeping the annealing temperature at 550DEG C, and the heat preservation time at 30min, and finally conducting cooling to room temperature. Specifically, in terms of the mass of the flat glass powder, the manganese dioxide accounts for 1-5%, the sodium silicofluoride accounts for 3-5%, the sodium carbonate accounts for 3-5%, the sodium phosphate accounts for 5-10%, and the carbon fiber accounts for 1-5%. The foam glass prepared by the invention has a uniform aperture, most of the holes are closed, the performance is excellent, and reaches the use standard. Low temperature firing of foam glass not only can reduce the production cost, but also can greatly improve the production efficiency at the same time.

Owner:YANGZHOU UNIV

A physical and chemical treatment method for mixed fertilizer production wastewater

Owner:HUBEI YIHUA GRP CO LTD +2

Aseptic technique of normal-pressure reaction kettle for producing poly-aluminum

InactiveCN101491753AImprove anti-corrosion performanceExtended service lifeAluminium chloridesChemical/physical/physico-chemical processesAluminium chlorohydrateAdhesive

The invention discloses an anti-corrosion technique for a normal-pressure reaction kettle for producing polyaluminium chloride, relates to an anti-corrosion technique, in particular to an anti-corrosion technique for a normal-pressure reaction kettle for producing polyaluminium chloride, and aims to provide an anti-corrosion technique for a normal-pressure reaction kettle for producing polyaluminium chloride with high anti-corrosion performance and long service life. The invention adopts a technical proposal that the normal-pressure reaction kettle for producing the polyaluminium chloride by the anti-corrosion technique comprises a kettle body and industrial acid-resistant magnetic plates, wherein the kettle body is made of bauxite, kaolin or calcium aluminate or mixture thereof, an adhesive for adhering the industrial acid-resistant magnetic plates is slurry of acid-resistant cement and calcium chloride or sodium silicofluoride and water, and the calcium chloride or the sodium silicofluoride accounts for 5 to 30 percent of the acid-resistant cement. The anti-corrosion technique is used for the normal-pressure reaction kettle for producing the polyaluminium chloride.

Owner:乔占印

Quartz sand tailing mud recycling method

The invention discloses a quartz sand tailing mud recycling method which comprises the following steps: removing metal impurities in clay mud through water washing, removing magnetic metal impurities and strong magnetic ores in the quartz sand tailing mud through magnetic separation, breaking fluid inclusion and quartz crystal lattices through low-temperature crushing, exposing aluminum impurities in the fluid inclusion and the quartz crystal lattices, and removing the aluminum impurities through acid pickling. And for impurities such as aluminum and the like which are not removed in the feldspar, performing flotation on the feldspar by adopting a cation collecting agent through a flotation method, activating the feldspar and inhibiting the quartz by adopting sodium silicofluoride, and finally obtaining high-purity and high-yield quartz. The method can be applied to production of high-end products such as monocrystalline silicon, polycrystalline silicon, quartz glass, optical fibers, solar cells, integrated circuit substrates and aerospace materials.

Owner:海南绿峰资源开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com