Treatment method for producing sodium silicofluoride as byproduct in inorganic fluoride production process

A technology for the production process of sodium silicofluoride, which is applied in the field of treatment of sodium silicofluoride by-product in the production process of inorganic fluorides. It can solve problems such as insufficient separation and low solubility of sodium fluoride, and achieve increased economic benefits and raw material utilization. High efficiency and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

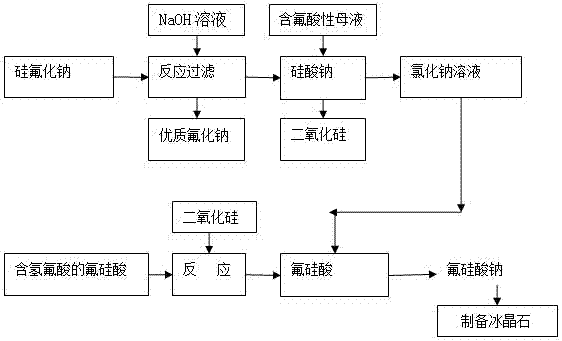

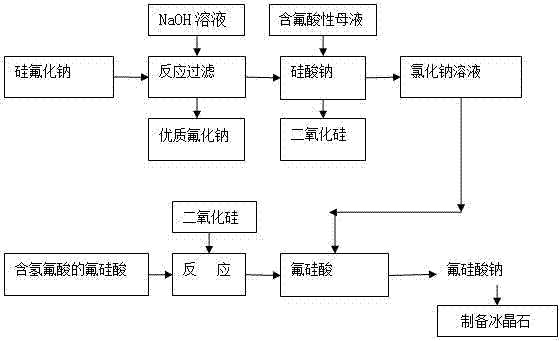

Image

Examples

Embodiment 1

[0019] Example 1 The treatment method of the by-product sodium silicofluoride in the production process of inorganic fluorides in this example is as follows:

[0020] (1) 1 ton containing 8% SiO 2 Sodium silicofluoride with 0.3 m 3 The sodium hydroxide solution with a concentration of 30% is reacted to generate sodium fluoride and sodium silicate solution, which is filtered and washed, and the filter cake is dried to obtain sodium fluoride; (2) the generated sodium silicate solution is mixed with 5 m 3 The reaction of the fluorine-containing acidic mother liquor, wherein the concentration of hydrochloric acid in the fluorine-containing acidic mother liquor is 5%, generates silicon dioxide and sodium chloride solution, and the liquid-solid separation is carried out through filtration; (3) the silicon dioxide generated in the previous step is mixed with the reaction A certain amount of fluorosilicic acid solution containing hydrofluoric acid reacts to produce fluorosilicic aci...

Embodiment 2

[0021] Embodiment 2 The treatment method of the by-product sodium silicofluoride in the production process of inorganic fluorides in this embodiment is:

[0022] (1) 1 ton containing 12% SiO 2 Sodium silicofluoride with 0.4 m 3 The sodium hydroxide solution with a concentration of 30% is reacted to generate sodium fluoride and sodium silicate solution, which is filtered and washed, and the filter cake is dried to obtain sodium fluoride; (2) the generated sodium silicate solution is mixed with 6 m 3 The reaction of the fluorine-containing acidic mother liquor, wherein the concentration of hydrochloric acid in the fluorine-containing acidic mother liquor is 10%, generates silicon dioxide and sodium chloride solution, and the liquid-solid separation is carried out through filtration; (3) the silicon dioxide generated in the previous step is mixed with the reaction A certain amount of fluorosilicic acid solution containing hydrofluoric acid reacts to produce fluorosilicic acid; ...

Embodiment 3

[0023] Embodiment 3 The treatment method of the by-product sodium silicofluoride in the production process of inorganic fluorides in this embodiment is:

[0024] (1) 1 ton containing 15% SiO 2 Sodium silicofluoride with 0.5 m 3 The sodium hydroxide solution with a concentration of 30% is reacted to form sodium fluoride and sodium silicate solution, which is filtered and washed, and the filter cake is dried to obtain sodium fluoride; (2) the resulting sodium silicate solution is mixed with 8 m 3 Fluorine-containing acidic mother liquor reaction, wherein the concentration of hydrochloric acid in the fluorine-containing acidic mother liquor is 15%, to generate silica and sodium chloride solution, which are separated from liquid and solid by filtration; Fluosilicic acid solution containing hydrofluoric acid is reacted to produce fluosilicic acid; (4) Fluosilicic acid solution is reacted with a reaction amount of sodium chloride solution, and part of the sodium chloride solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com