Low-cost foam glass heat insulating material, preparation and application thereof

A technology for foam glass and thermal insulation materials, applied in the field of building thermal insulation materials, can solve the problems of high product prices, backward technology and equipment, unstable product quality, etc., and achieve improved firing results, rich economic benefits, and small thermal weight loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

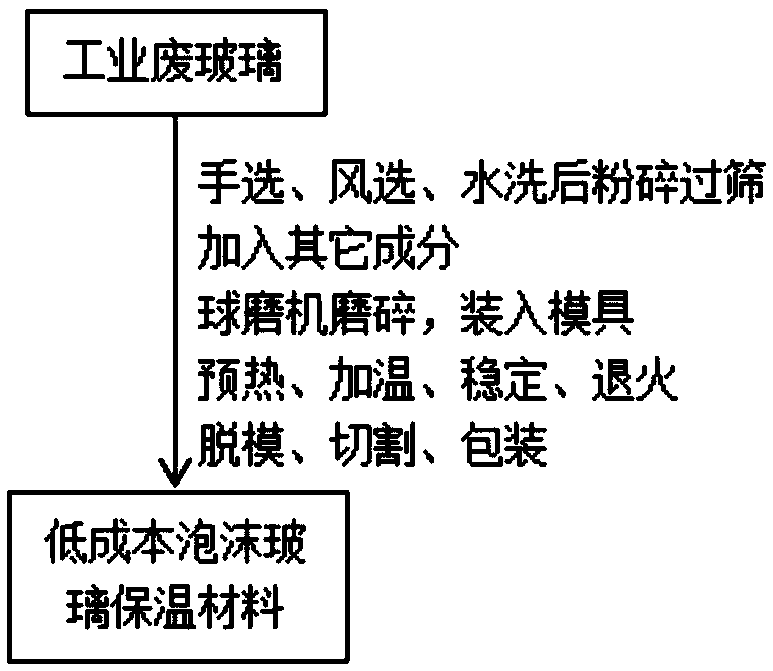

Method used

Image

Examples

Embodiment 1

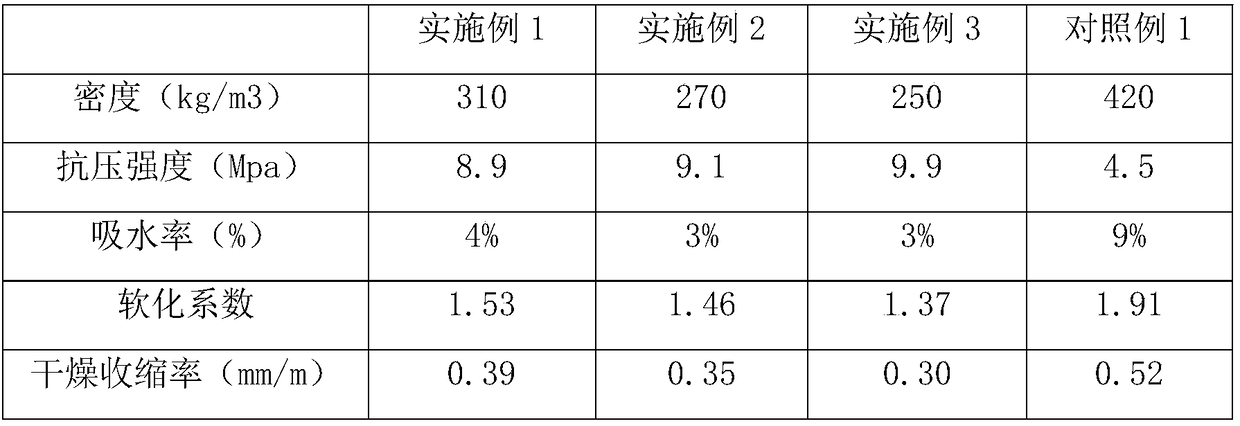

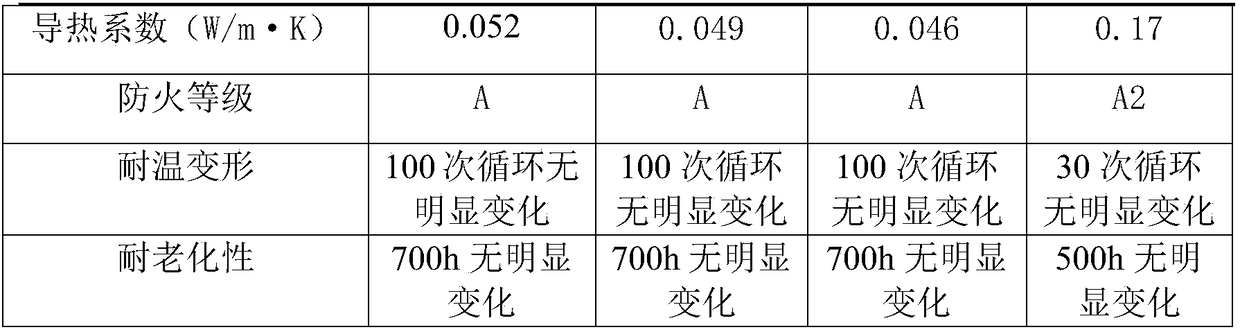

[0022] Embodiment 1 The preparation of low-cost cellular glass insulation material

[0023] Raw material composition: 70 parts of industrial waste glass, 4 parts of low-temperature glass powder, 8 parts of montmorillonite, 8 parts of magnesium oxide, 5 parts of carbon black, 5 parts of sodium fluorosilicate, 1 part of graphene oxide, 1 part of borax, trioxide 1 part of antimony and 1 part of lithium stearate;

[0024] Preparation:

[0025] The industrial waste glass is hand-selected, winnowed, washed, crushed and sieved, and low-temperature glass powder, montmorillonite, magnesium oxide, carbon black, sodium fluorosilicate, graphene oxide, borax, antimony trioxide and hard Lithium fatty acid, add ball mill to grind, put into foaming mold, preheat in heating furnace at 500°C for 1 hour, heat up at a speed of 10°C / min, heat at 800°C, keep for 2 hours, wait for foaming and stabilization Finally, cool down to 600°C at a speed of 10°C / min, anneal and cool to room temperature afte...

Embodiment 2

[0026] Embodiment 2 Preparation of low-cost cellular glass insulation material

[0027] Raw material composition: 90 parts of industrial waste glass, 3 parts of aluminum hydroxide, 12 parts of diatomite, 15 parts of kaolin, 15 parts of manganese dioxide, 10 parts of sodium benzoate, 5 parts of graphene oxide, 5 parts of borax, antimony trioxide 5 parts and 3 parts zinc stearate;

[0028] Preparation:

[0029] The industrial waste glass is hand-selected, winnowed, washed, crushed and sieved, and aluminum hydroxide, diatomaceous earth, kaolin, manganese dioxide, sodium benzoate, graphene oxide, borax, antimony trioxide and stearic acid are added in proportion Add zinc to a ball mill to grind, put it into a foaming mold, preheat in a heating furnace at 500°C for 1 hour, heat up at a speed of 15°C / min, and heat at a heating temperature of 900°C for 3 hours. After foaming and stabilization, Cool down to 600°C at a speed of 20°C / min, anneal and cool to room temperature after 24 ho...

Embodiment 3

[0030] Embodiment 3 Preparation of low-cost cellular glass insulation material

[0031] Raw material composition: 80 parts of industrial waste glass, 4 parts of magnesium hydroxide, 13 parts of mica powder, 8 parts of magnesium oxide, 10 parts of water glass, 8 parts of acetamide, 2 parts of graphene oxide, 2 parts of borax, 2 parts of antimony trioxide 1 part and 1 part of zinc stearate;

[0032] Preparation:

[0033] The industrial waste glass is hand-selected, winnowed, washed, crushed and sieved, and added in proportion to magnesium hydroxide, mica powder, magnesium oxide, water glass, acetamide, graphene oxide, borax, antimony trioxide and zinc stearate , put it into a ball mill to grind, put it into a foaming mold, preheat in a heating furnace at 500°C for 1 hour, heat up at a speed of 12°C / min, heat up at 850°C, and keep it for 2.5 hours. After foaming and stabilization, Cool down to 600°C at a speed of 15°C / min, anneal and cool to room temperature after 24 hours, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com