Polyolefin foaming masterbatch composition and preparation method and application

A polyolefin foaming and masterbatch technology, applied in the field of polymer functional materials, can solve the problems of flammability and harmfulness of foaming agent and foaming gas, achieve wide application range and process range, small molding shrinkage, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

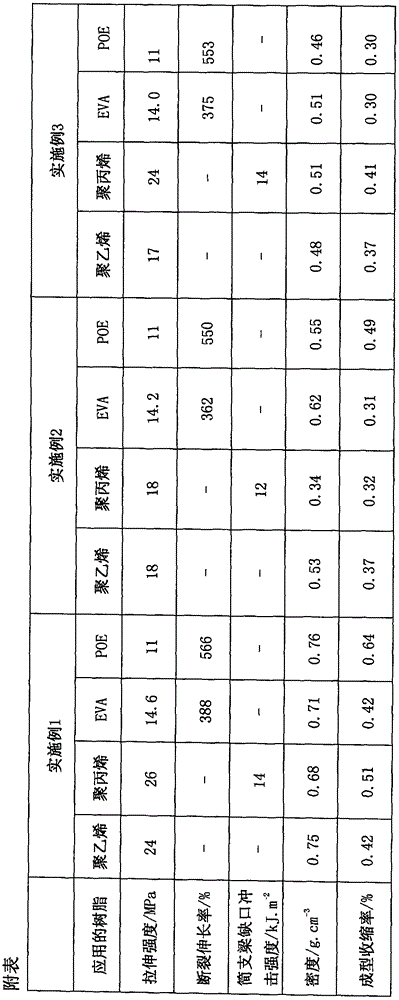

Examples

Embodiment 1

[0030] In this embodiment, a polyolefin foam masterbatch is made of the following components by weight:

[0031] POE resin 80 parts,

[0032] 2 parts sorbitan monooleate,

[0033] Potassium bicarbonate 10 parts,

[0034] 3 parts superfine talcum powder,

[0035] 0.1 part of dicumyl peroxide.

[0036] The POE resin is an ethylene-octene copolymer with a melting point of 52° C. and a melt flow rate of 2.1 g / 10 min at 190° C. under a load of 2.16 kg.

[0037] In the present embodiment, a kind of preparation method of polyolefin foam masterbatch comprises the following steps:

[0038] Step 1, taking POE resin, sorbitan monooleate, potassium bicarbonate, superfine talcum powder and dicumyl peroxide in proportion;

[0039] Step 2: Put the above raw materials into the mixer for pre-mixing in turn, the temperature of the mixer should not exceed 40°C, and the mixing time is 2 minutes;

[0040] Step 3. The above-mentioned materials are melted and mixed in a co-rotating twin-screw ...

Embodiment 2

[0044] In this embodiment, a polyolefin foam masterbatch is made of the following components by weight:

[0045] POE resin 50 parts,

[0046] 10 parts of sorbitan monooleate,

[0047] Potassium bicarbonate 30 parts,

[0048] Superfine talc powder 10 powder,

[0049] 0.1 part of dicumyl peroxide,

[0050] 0.2 parts of benzoyl peroxide.

[0051] The POE resin is an ethylene-octene copolymer with a melting point of 89° C. and a melt flow rate of 1 g / 10 min at 190° C. under a load of 2.16 kg.

[0052] In the present embodiment, a kind of preparation method of polyolefin foam masterbatch comprises the following steps:

[0053] Step 1, taking POE resin, sorbitan monooleate, potassium bicarbonate, superfine talcum powder, dicumyl peroxide and benzoyl peroxide in proportion;

[0054] Step 2. Put the above raw materials into the mixer one by one for pre-mixing. The temperature of the mixer does not exceed 40°C, and the mixing time is 10 minutes;

[0055] Step 3. The above-mentio...

Embodiment 3

[0059] In this embodiment, a polyolefin foam masterbatch is made of the following components by weight:

[0060] POE resin 55 parts,

[0061] 1 part sorbitan monooleate,

[0062] Potassium bicarbonate 40 parts,

[0063] 4 parts dibenzylidene sorbitol

[0064] 0.2 parts of benzoyl peroxide.

[0065] The POE resin is an ethylene-octene copolymer with a melting point of 66° C. and a melt flow rate of 9.8 g / 10 min at 190° C. under a load of 2.16 kg.

[0066]In the present embodiment, a kind of preparation method of polyolefin foam masterbatch comprises the following steps:

[0067] Step 1, taking POE resin, sorbitan monooleate, potassium bicarbonate, dibenzylidene sorbitol, and benzoyl peroxide in proportion;

[0068] Step 2. Put the above raw materials into the mixer for pre-mixing in turn, the temperature of the mixer should not exceed 40°C, and the mixing time is 6 minutes;

[0069] Step 3. The above-mentioned materials are melted and mixed in a co-rotating twin-screw ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com