Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Low surface roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

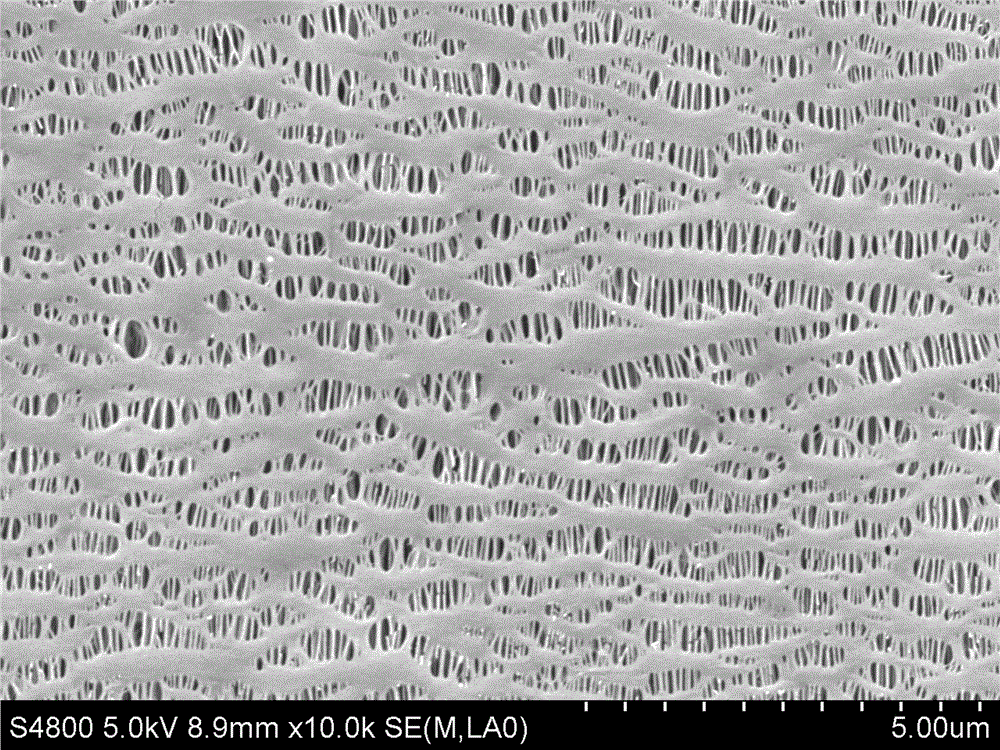

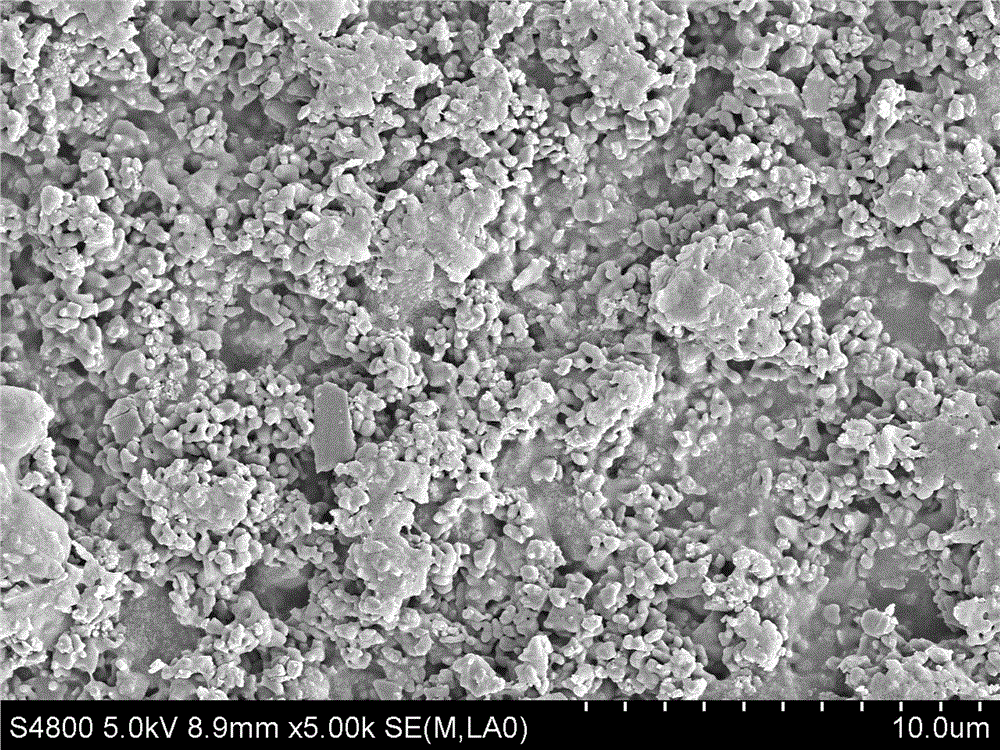

Composite ceramic membrane for lithium ion batteries and preparation method thereof

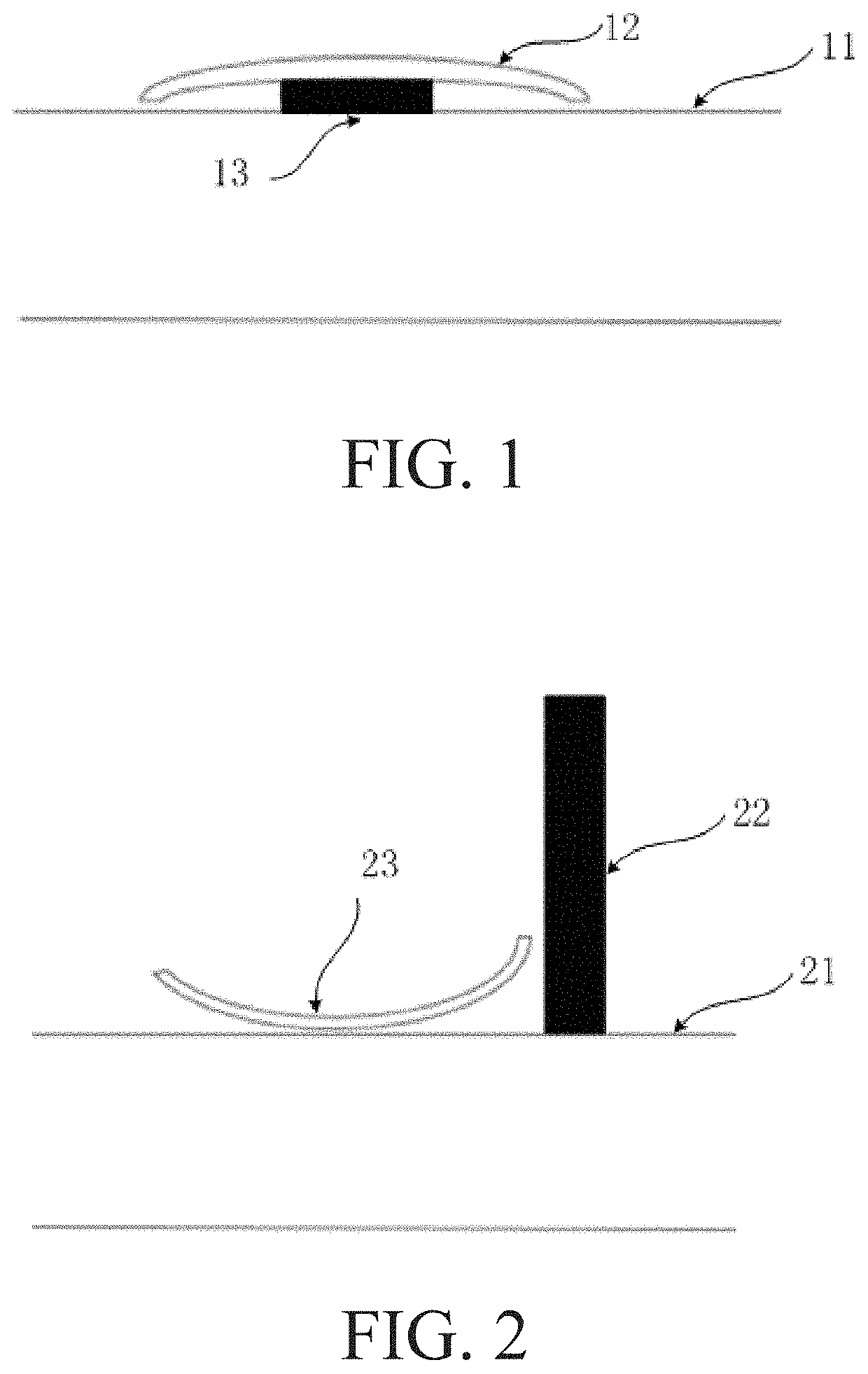

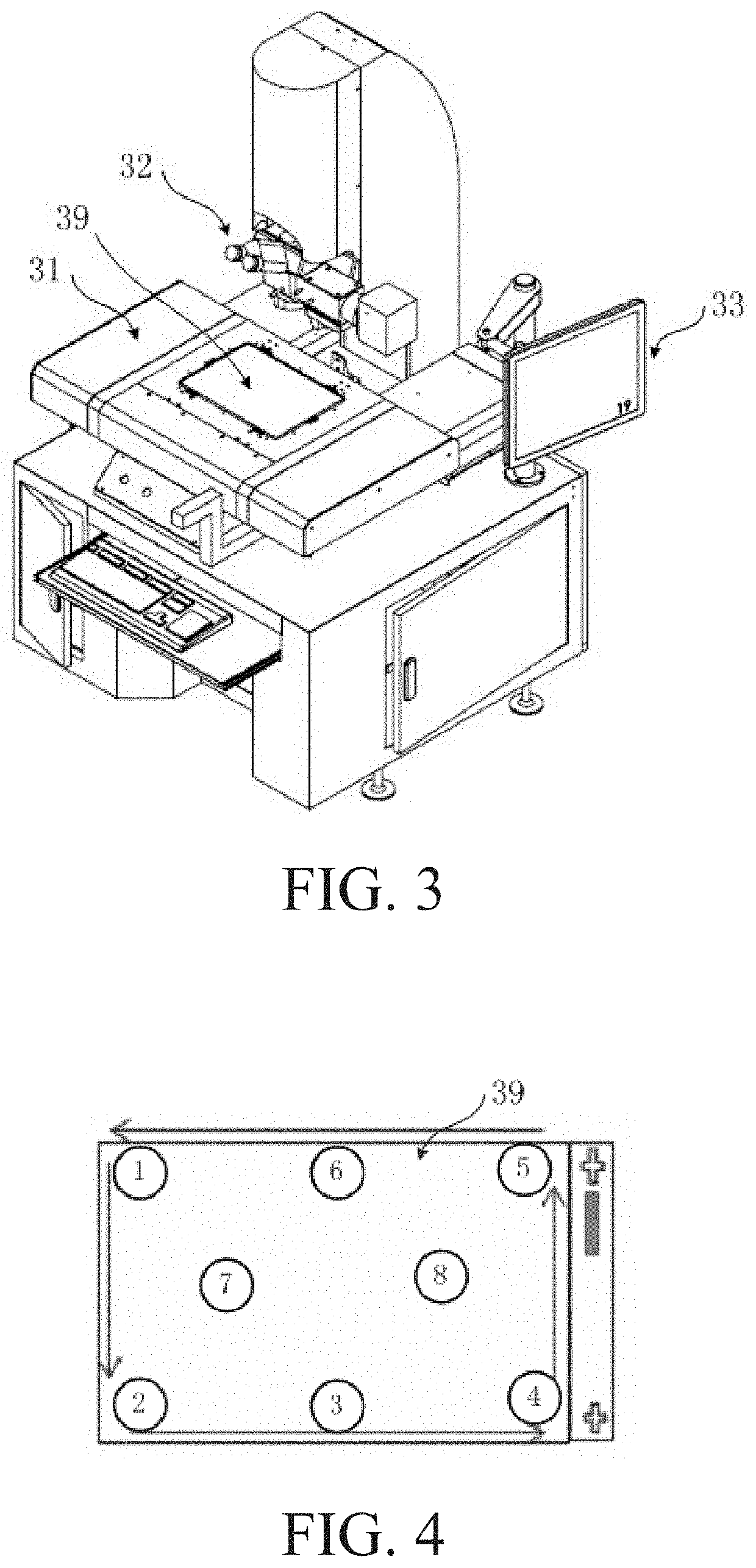

ActiveCN103956451AAvoid thermal runawayImprove high temperature thermal stabilityCell component detailsElectrolytic agentCeramic coating

The invention discloses a composite ceramic membrane for lithium ion batteries and a preparation method thereof, including a ceramic coating modification method and a ceramic lithium battery membrane. The ceramic protective layer is mainly prepared from a ceramic-adhesive mixture subjected to graft modification by a sodium-sulfonate / sodium-carboxylate-group-containing anionic surfactant. The grafting is completed by using a grafting-on process under the action of a coupling agent; the grafting ratio of the ceramic is higher; the high-temperature-resistant large-surface-area nano ceramic is introduced to the conventional PP (polypropylene) membrane surface, the insulativity and electrolyte wettability of the modified ceramic membrane are greatly enhanced; and the membrane has excellent high-temperature heat stability especially at the high temperature of 130 DEG C, 150 DEG C and 180 DEG C. The lithium battery composite membrane avoids the thermal shrinkage of the convention membrane, thereby avoids the thermorunaway in the battery due to thermal shrinkage, and further enhancing the safe reliability of the lithium ion battery.

Owner:中国东方电气集团有限公司

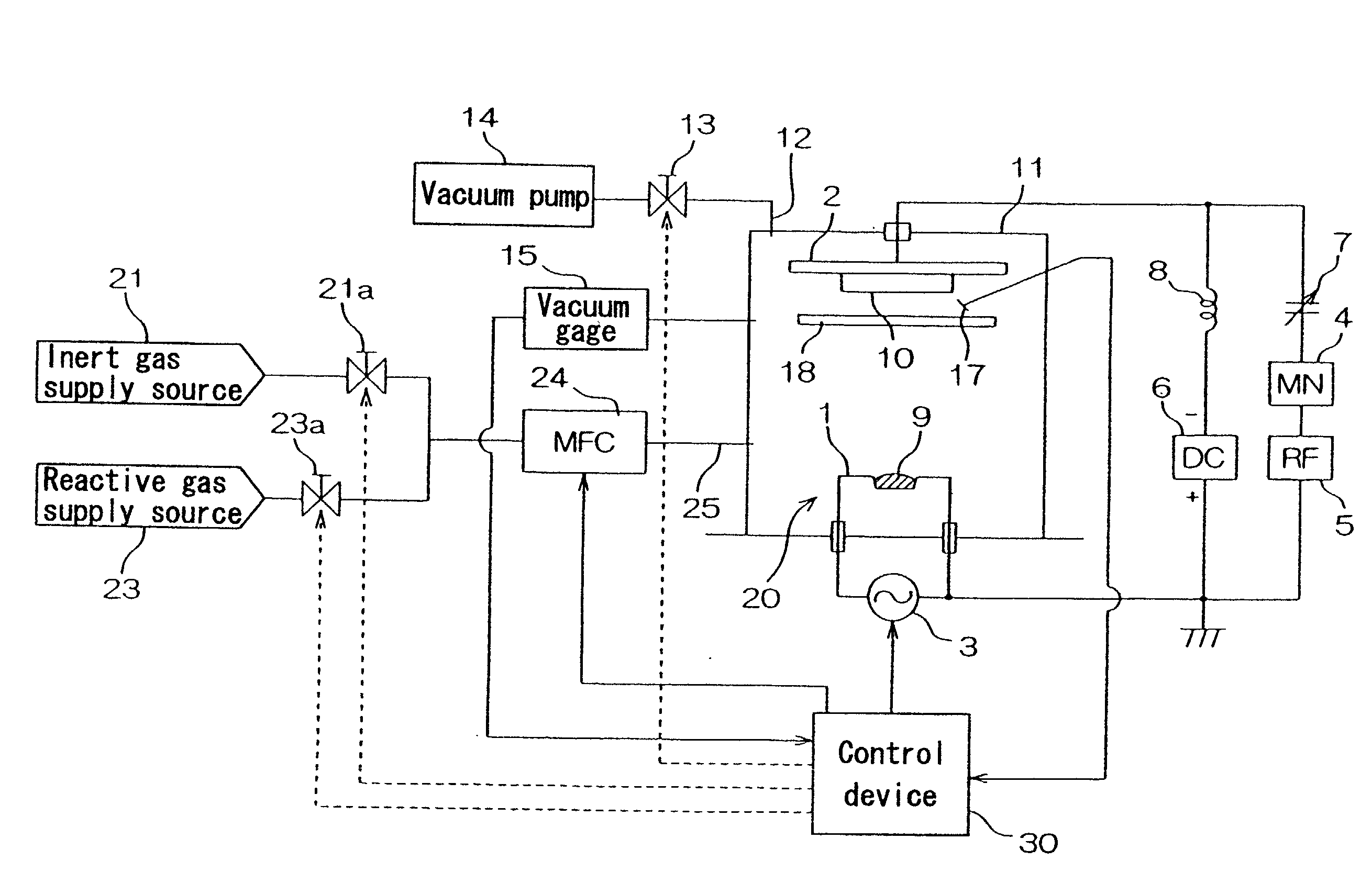

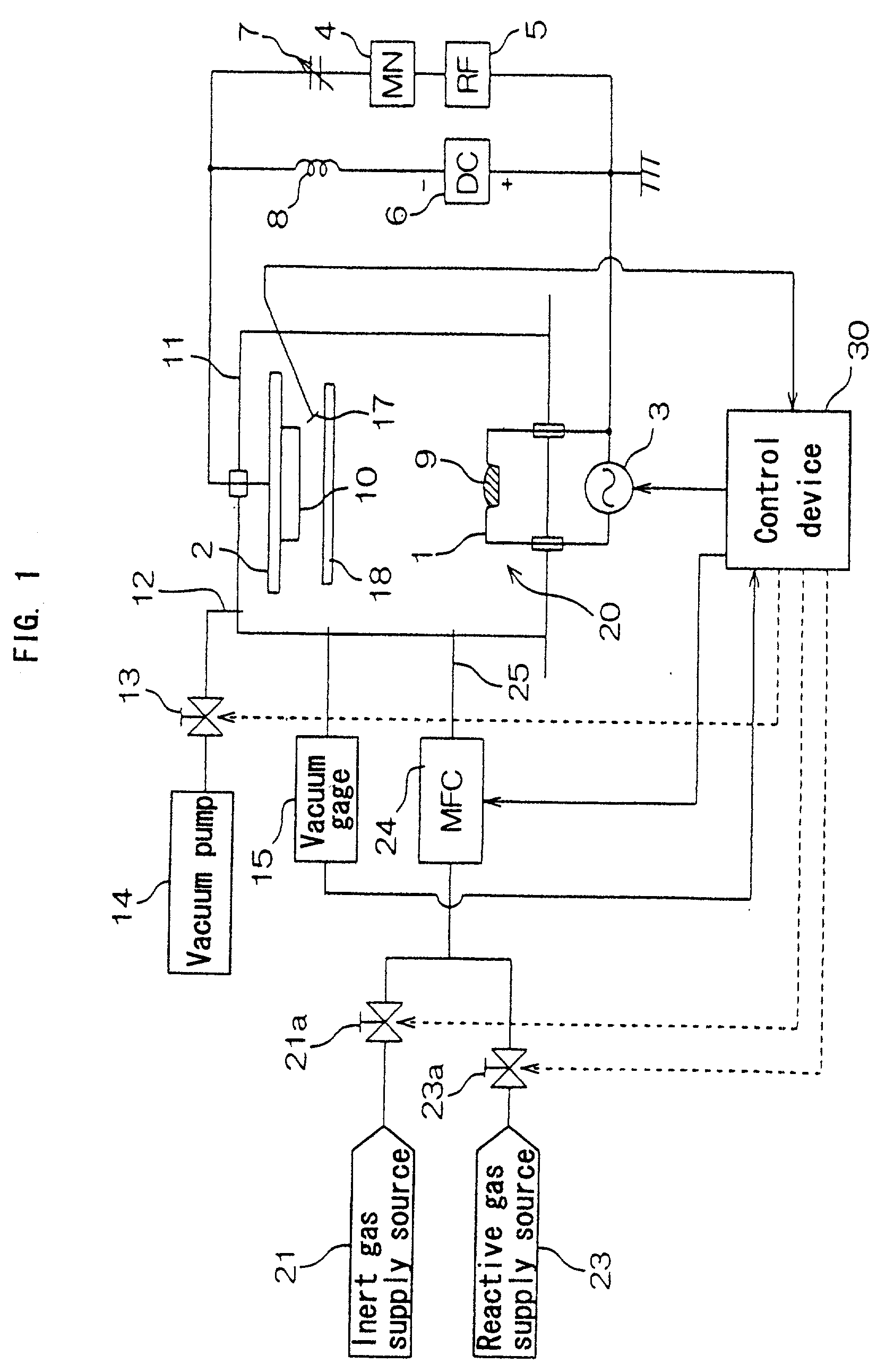

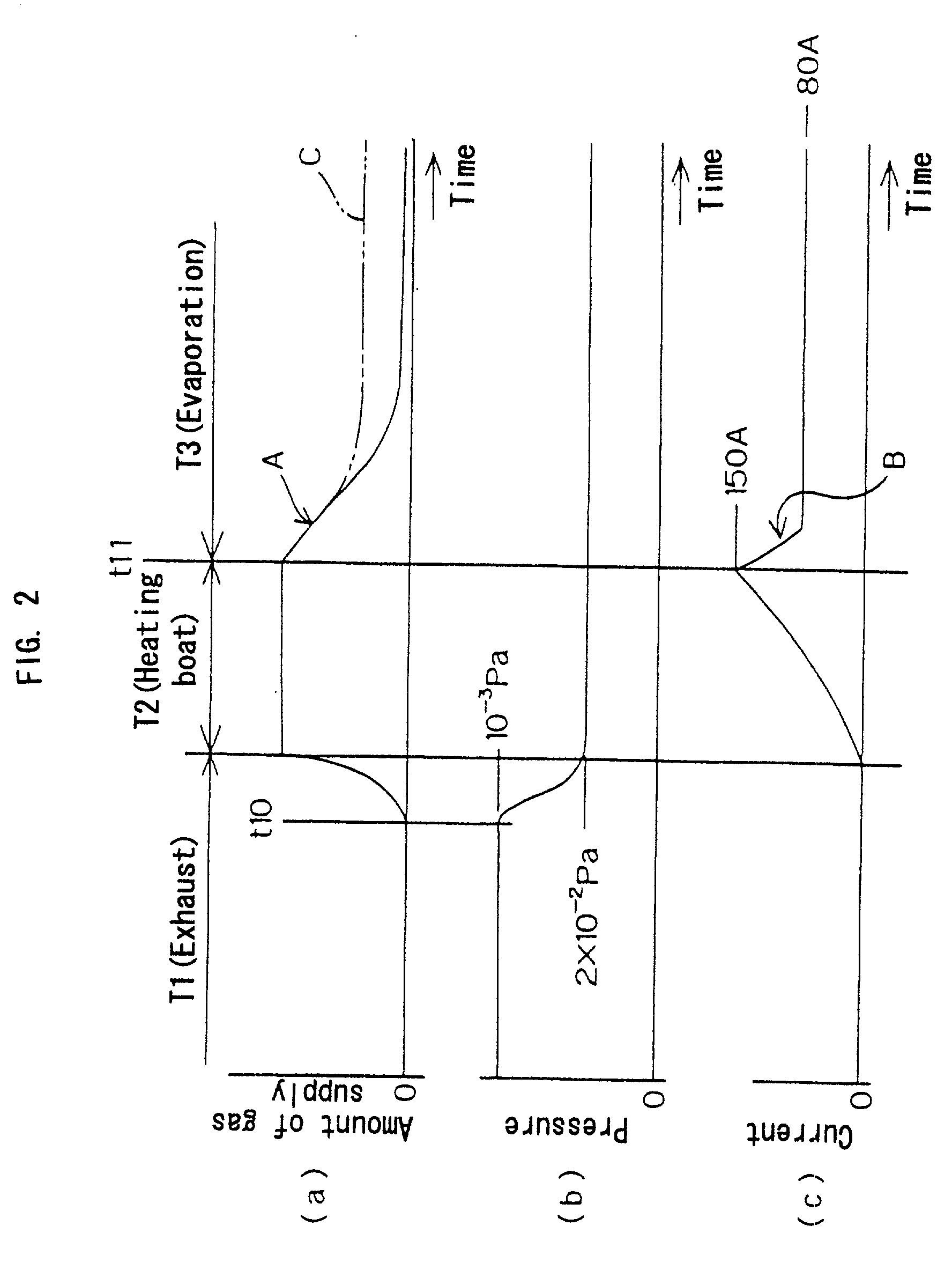

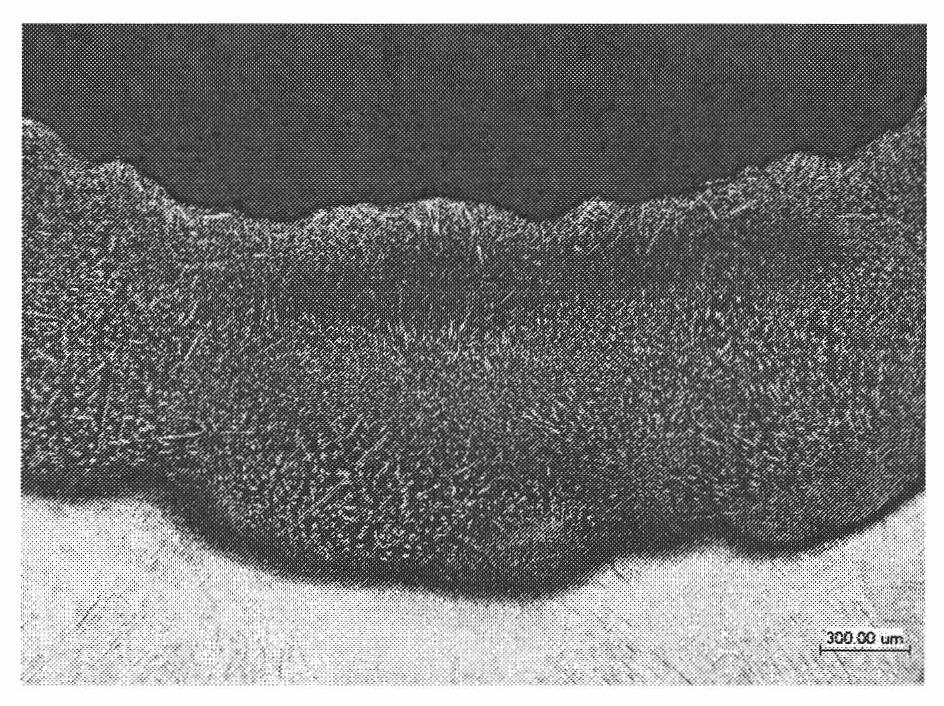

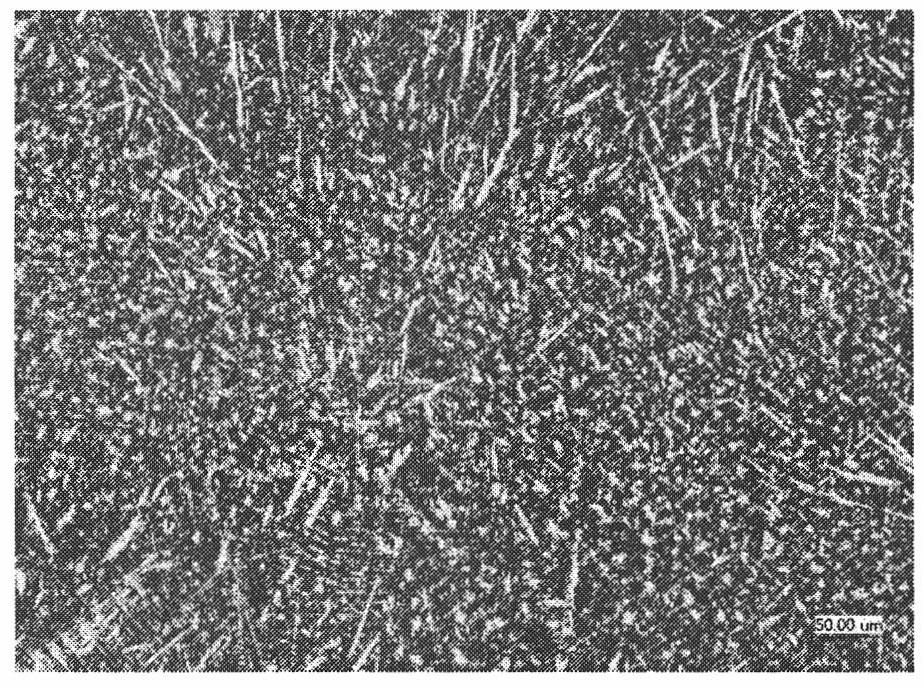

Metal film and metal film-coated member, metal oxide film and metal oxide film-coated member , thin film forming apparatus and thin film forming method for producing metal film and metal oxide film

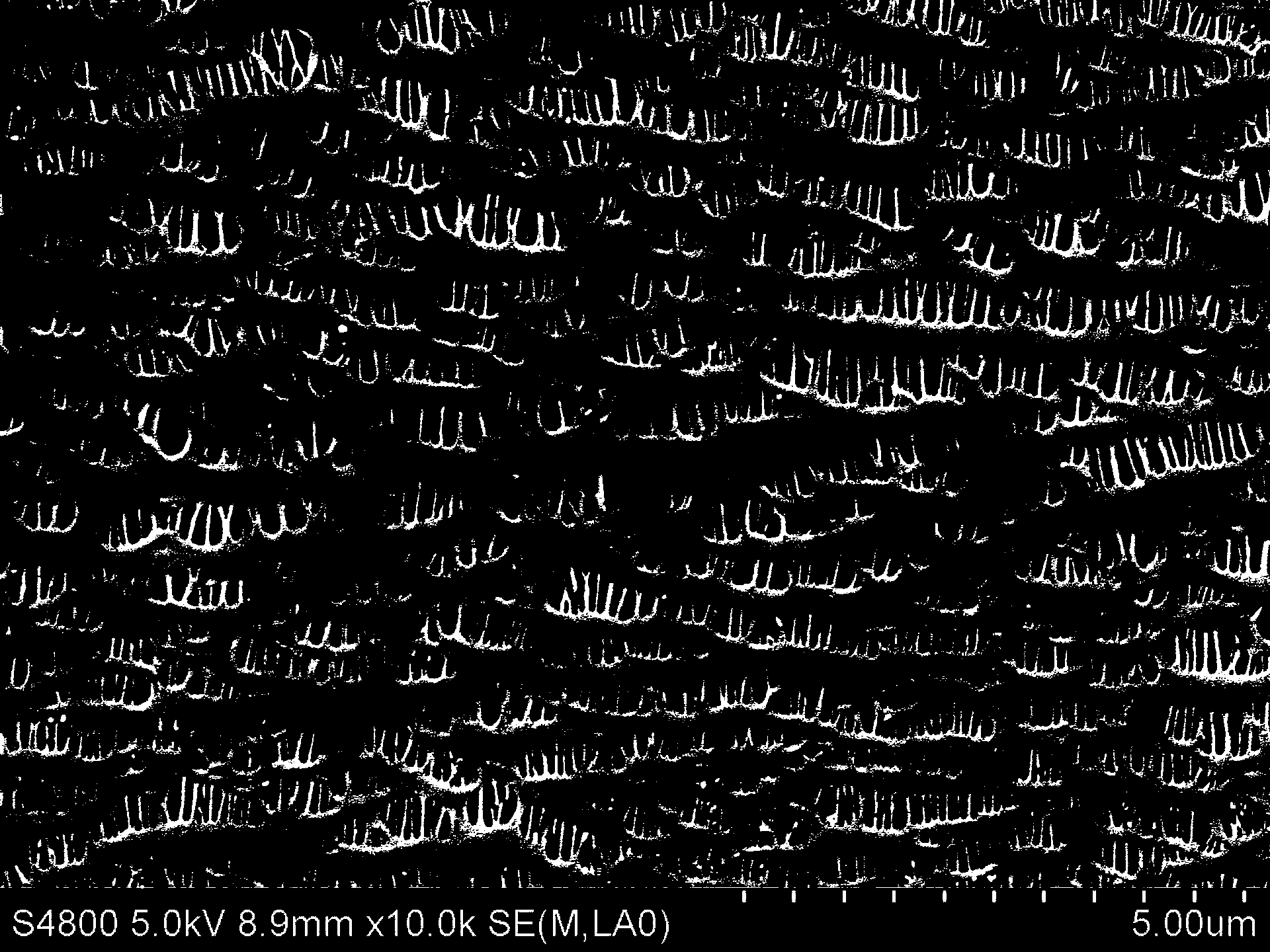

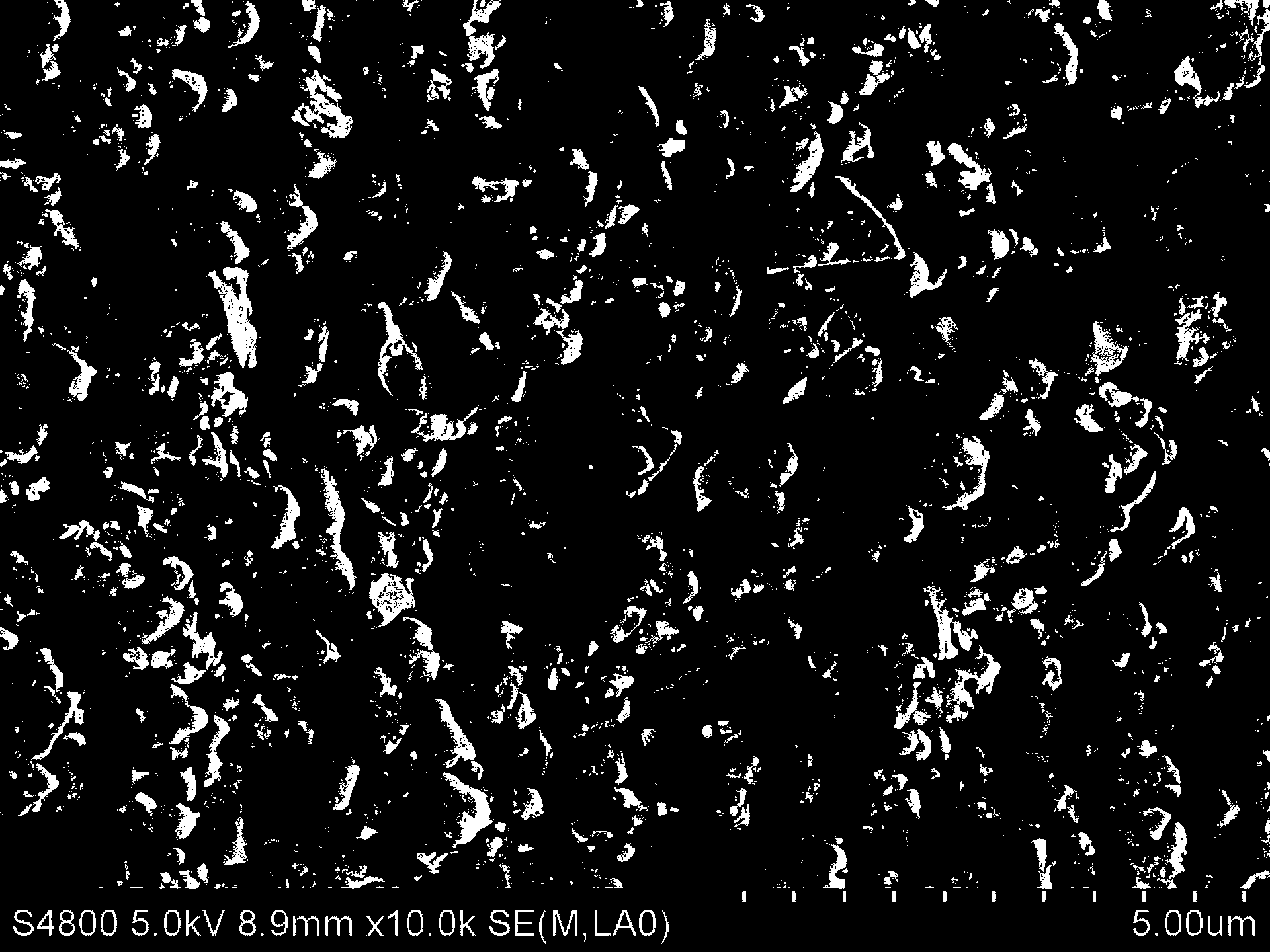

ActiveUS20020126265A1Low surface roughnessGood crystal orientationVacuum evaporation coatingSputtering coatingCrystal orientationSingle crystal

The metal film of the present invention is a dense film of a single crystal that has very low surface roughness and very good crystal orientation because an arithmetic mean roughness of the surface is not larger than 2 nm and a (111) peak intensity of X-ray diffraction is not less than 20 times the sum of all other peaks. Also the metal oxide film of the present invention is a dense film that includes less oxygen defects and almost no voids therein because a content of a non-oxidized metal is not higher than 1 mole % of a metal component that constitutes the metal oxide and a packing density is 0.98 or higher.

Owner:KYOCERA OPTEC

Large-area TiB-TiC reinforced titanium-based composite coating and preparation method thereof

The invention discloses a large-area TiB-TiC reinforced titanium-based composite coating prepared from the following components in percentage by weight: 83-88 percent of Ti, 5-7 percent of B4C, 2-4 percent of Al, 1-3 percent of nano TiC and 3-5 percent of rare-earth oxide. The invention adopts a new method for preparing a pre-coating layer which has the advantages of smooth surface, controllable thickness, less adhesive and relatively simple process. In addition, the invention optimally selects the proportioning of a cladding material system so that the coating after cladding has reinforcing phases of TiB and TiC; in addition, since a base body and a base body material Ti6Al4V are both titanium alloy, the coating and the base body have favorable physical compatibility. The invention also remarkably lowers the intensity degree of reaction for generating TiB and TiC by adding a little amount of thinner nanoTiC.

Owner:SHANGHAI UNIV OF ENG SCI

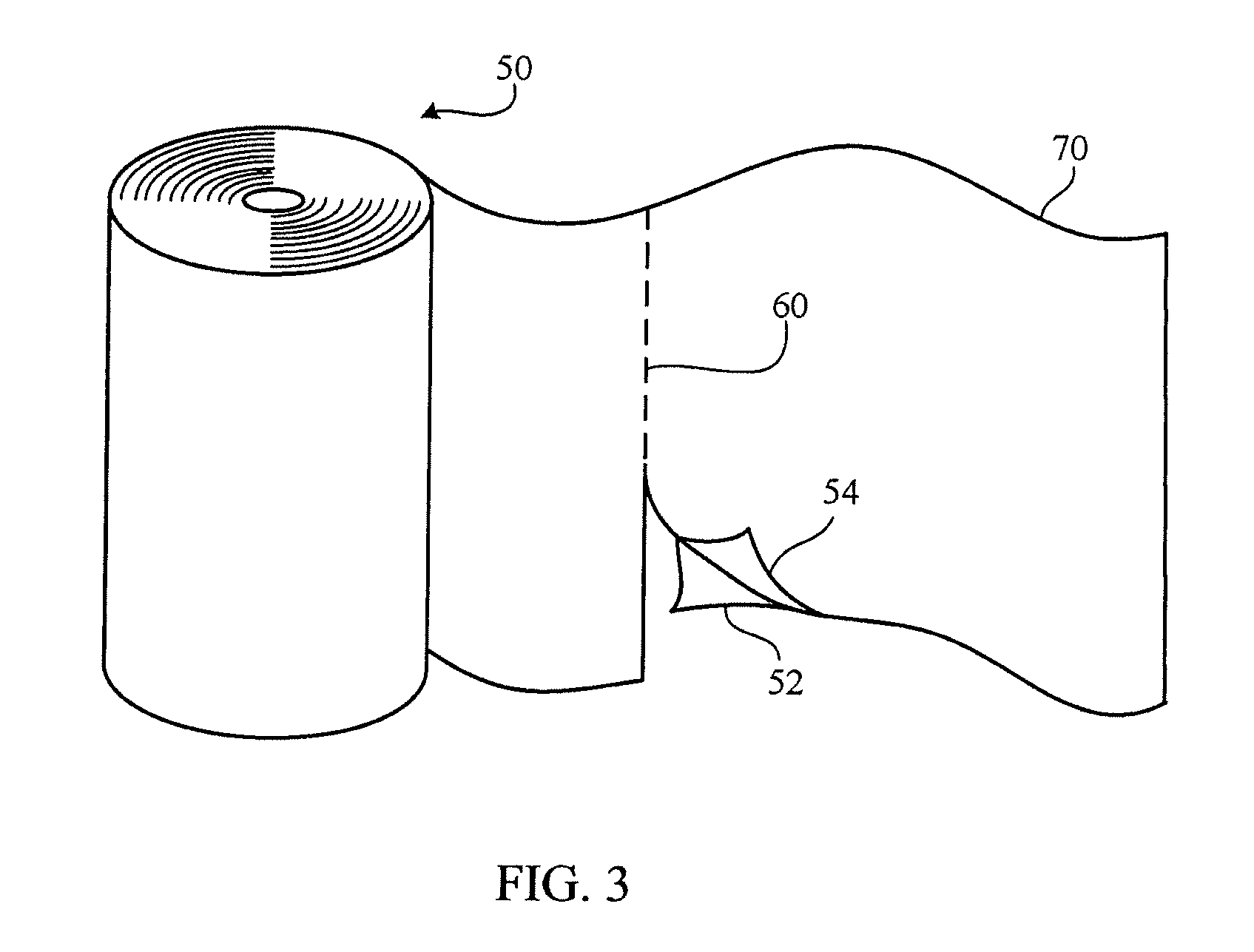

Writable-erasable surfaces

InactiveUS20110300294A1Low porosityLow surface roughnessWriting boardsPretreated surfacesRadiationMetallurgy

Writable-erasable surfaces prepared by a powder coating process are provided. The coatings have many desirable attributes. For example, the coatings (e.g., powder compositions) cure rapidly at elevated temperatures or under radiation, have low VOC emissions, and have reduced tendency to form ghost images, even after prolonged and repeated normal use.

Owner:ICP CONSTR INC

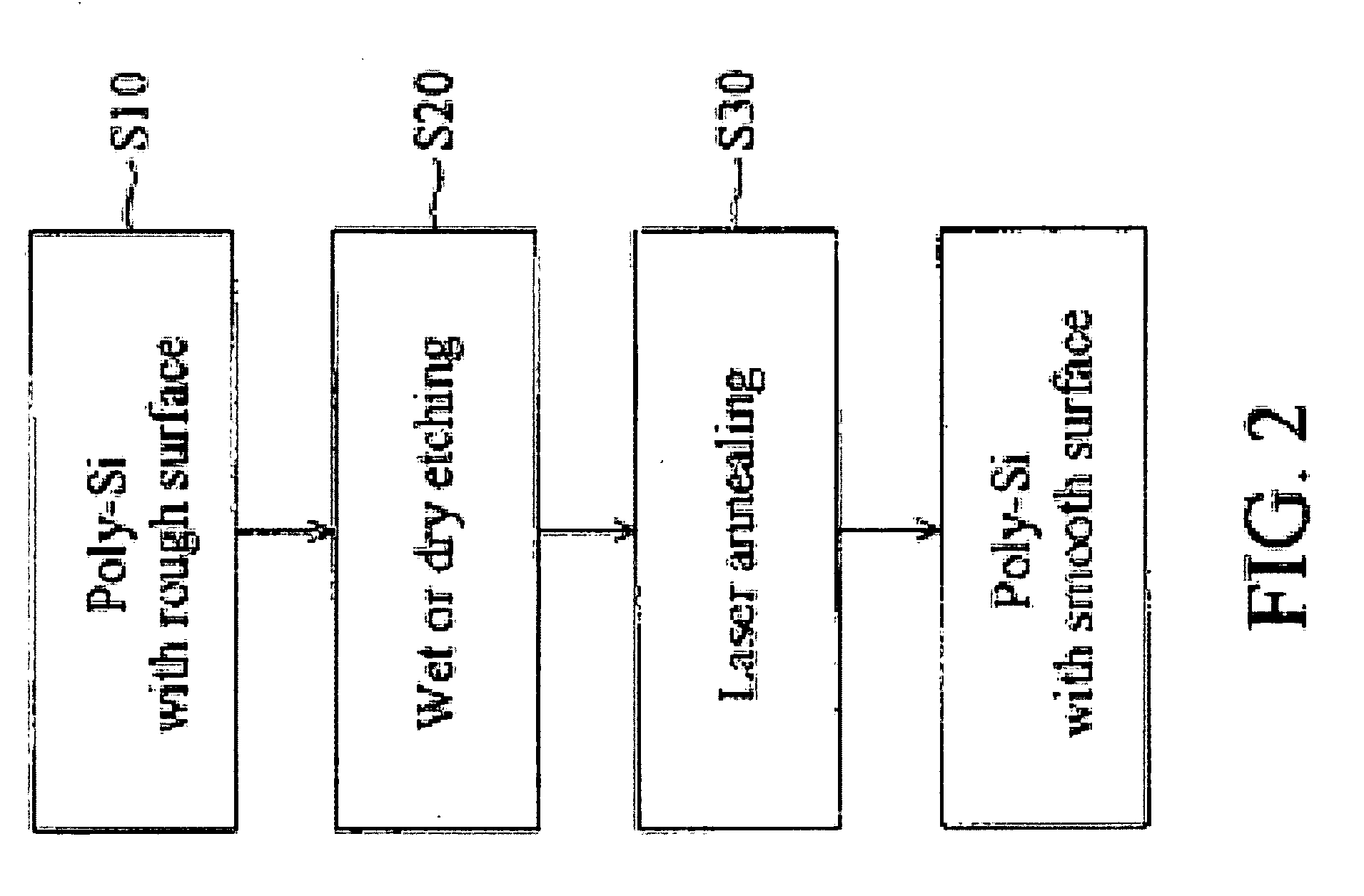

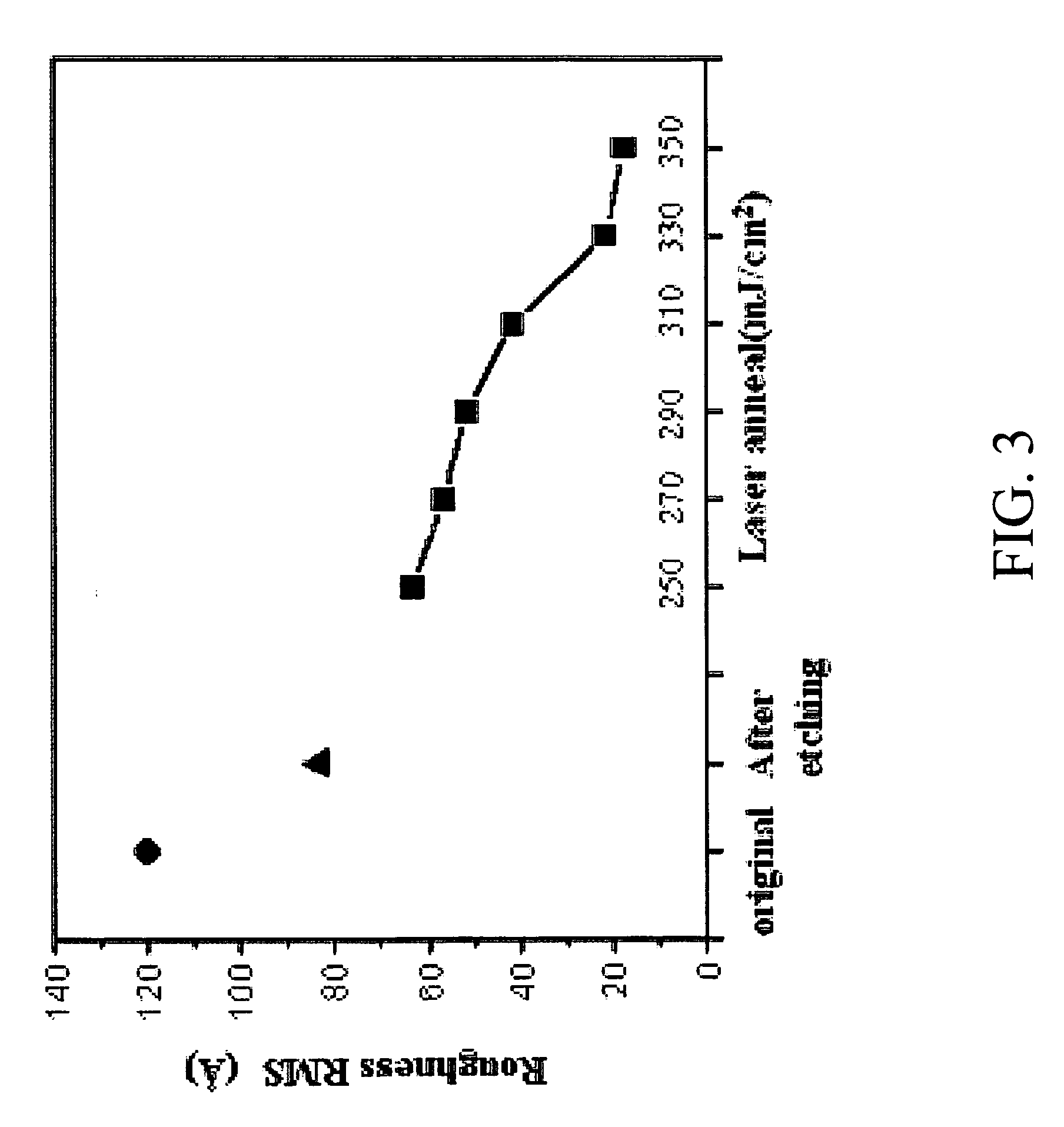

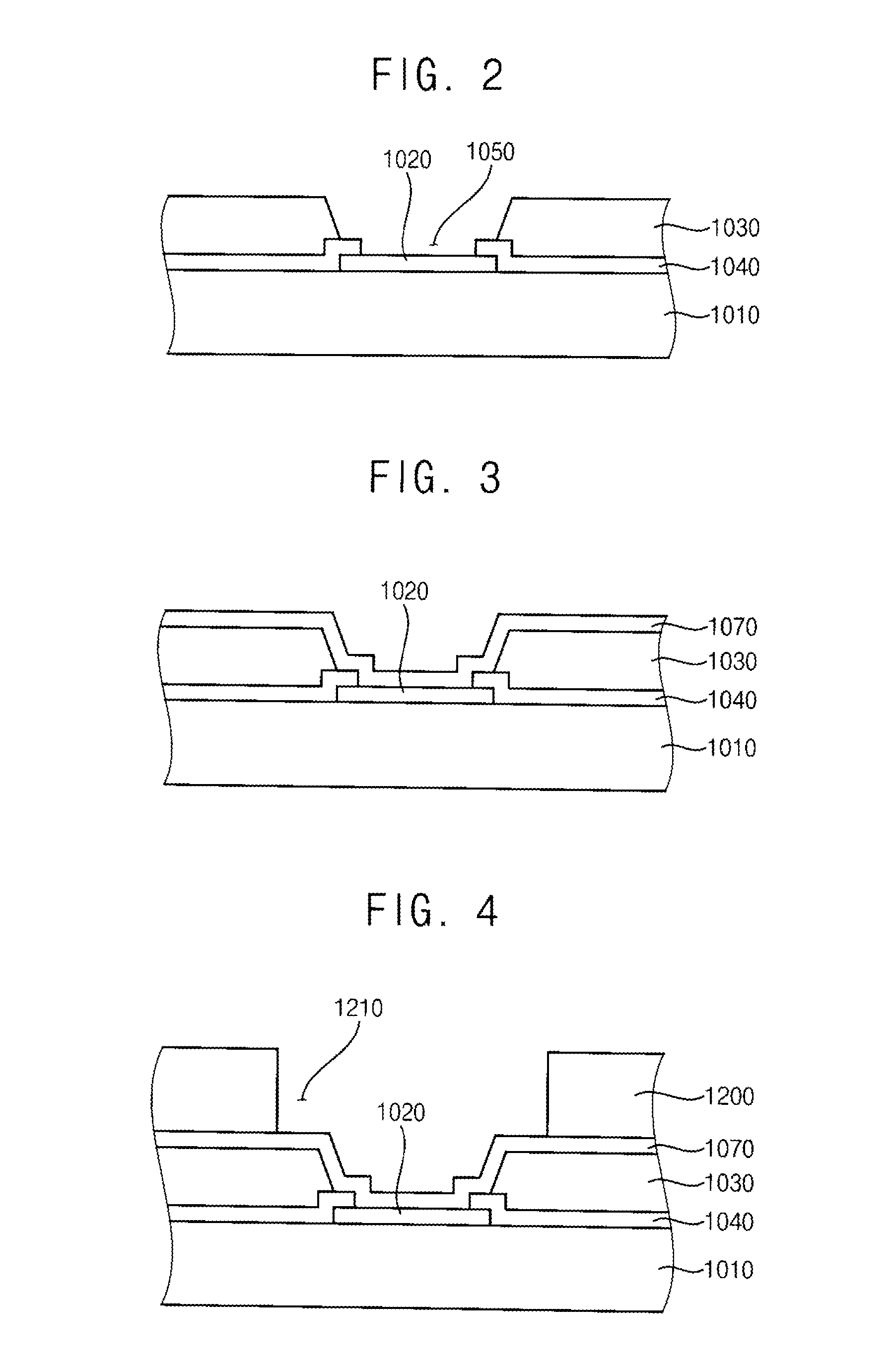

Method for planarizing polysilicon

InactiveUS20060043072A1Smooth surfaceLow surface roughnessDecorative surface effectsSemiconductor/solid-state device manufacturingOptoelectronicsOxide

A method for planarizing polysilicon comprises providing a substrate, forming a dielectric layer on the substrate, forming an amorphous silicon film on the dielectric layer, etching the amorphous silicon film to remove native oxide formed on a surface of the amorphous silicon film, exposing the surface of the amorphous silicon film to a first radiation source to polycrystallize the amorphous silicon film into a polysilicon film, etching the polysilicon film to remove weak bonded silicon formed on a surface of the polysilicon film, and exposing the surface of the polysilicon film to a second radiation source to reflow the polysilicon film.

Owner:IND TECH RES INST

Method for controlling planeness during chemically mechanical polishing for ULSI multiple-layered copper wiring

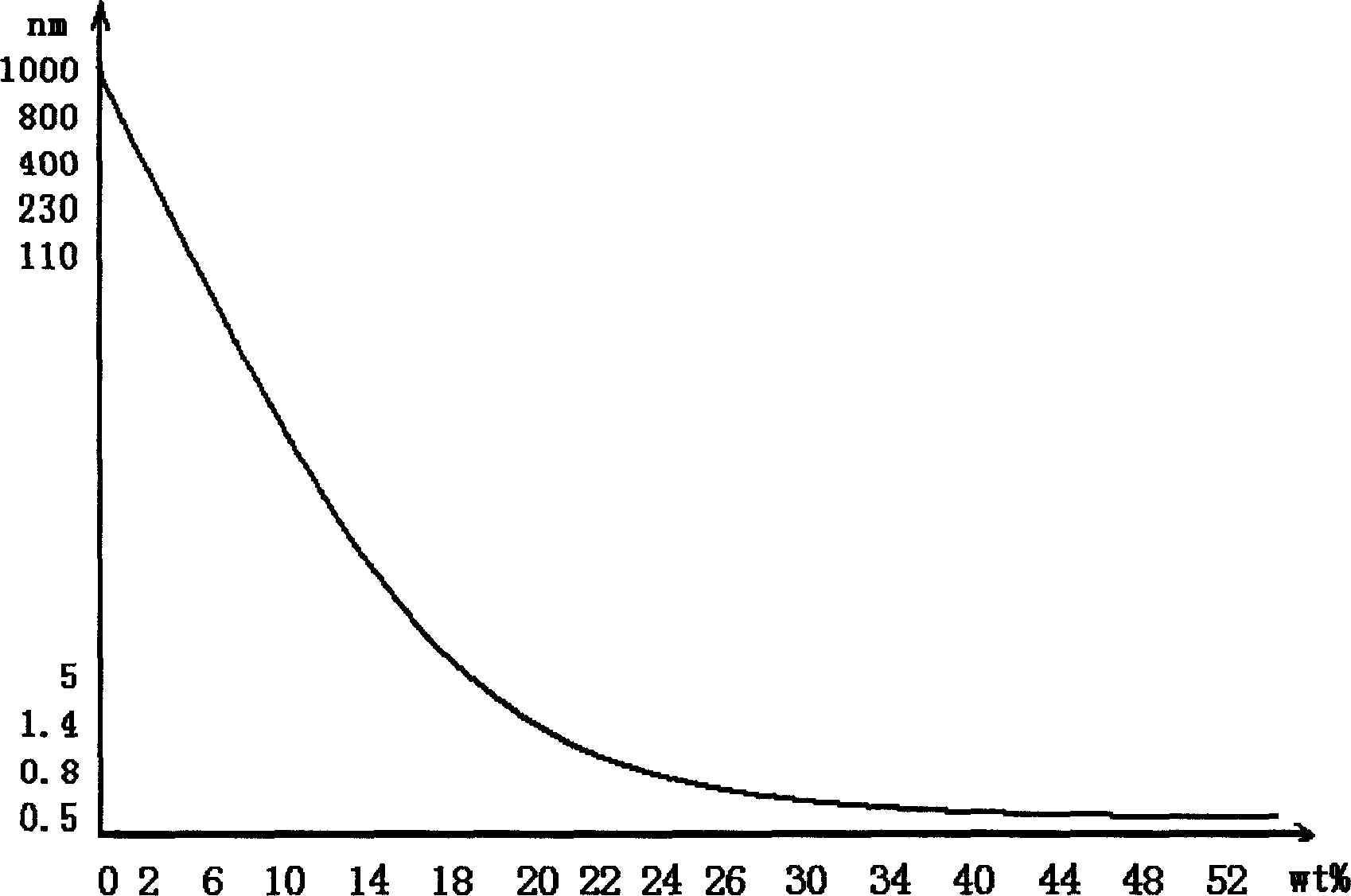

InactiveCN1861321ASolve the problem of selectivitySolve many disadvantages such as copper wire collapse after polishingPolishing machinesAqueous dispersionsCopper-wiringMultiple layer

A method for controlling the level degree on the ULSI multi-layer wiring in chamico-mechanical polishing includes such steps as diluting SiO2 hydrosol by deionized water, adding metal ion chelating agent to regulate pH=10-13, adding alcohol-ether kind of surfactant and oxidant while stirring to obtain polishing liquid, and polishing at 20-40 deg.C and 60-120 rpm under 100-250 g / sq.cm.

Owner:天津河北工业大学资产经营有限责任公司

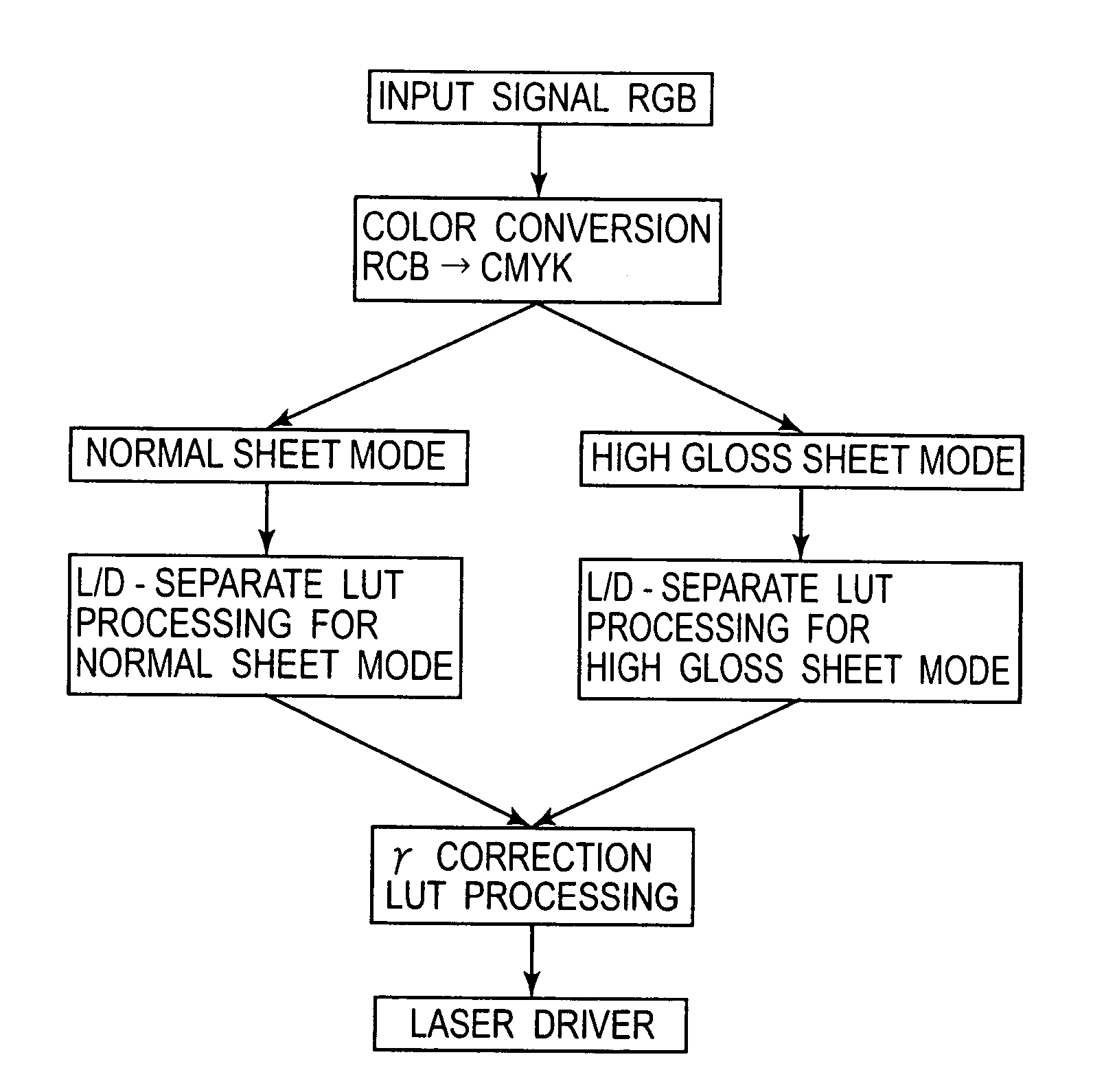

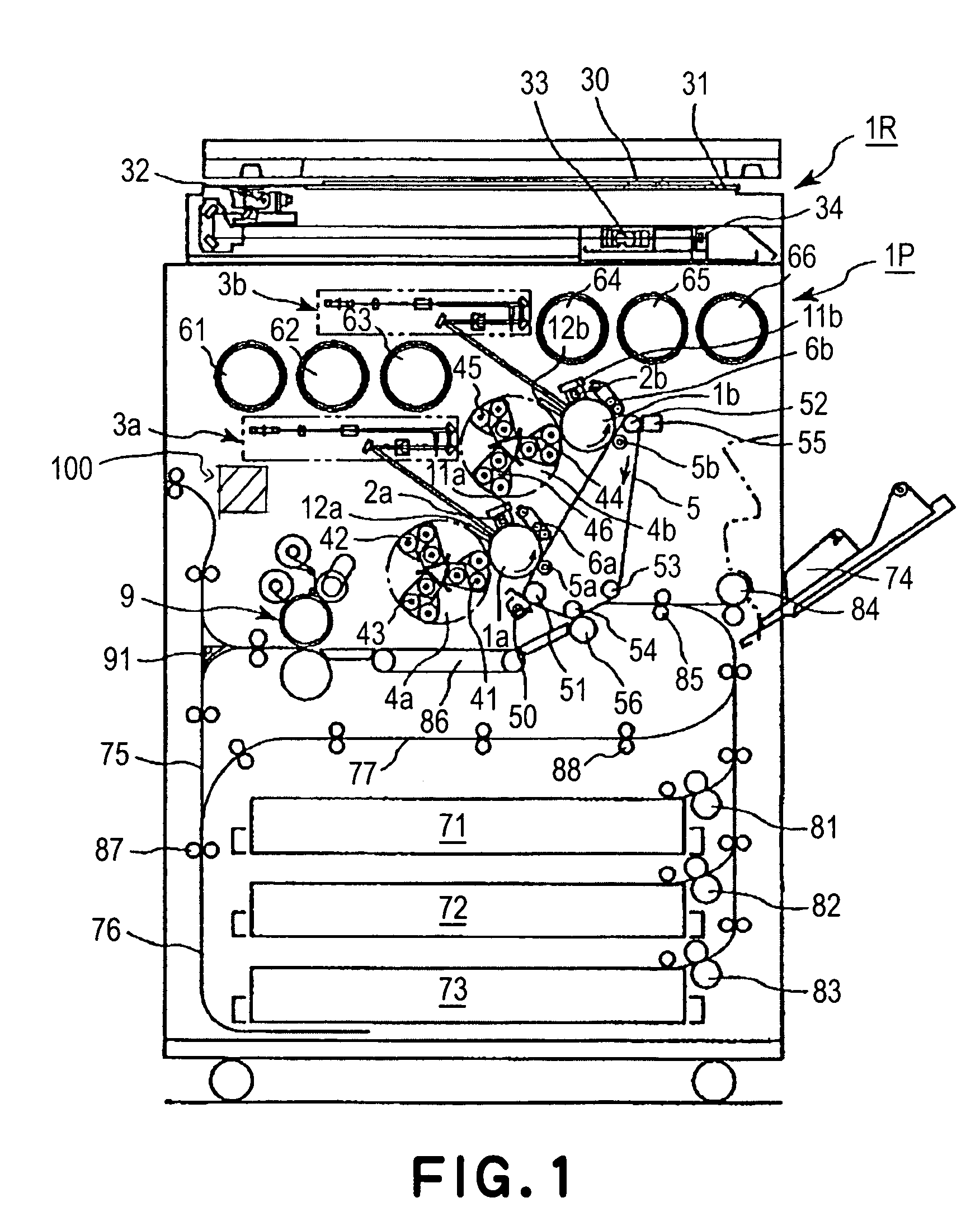

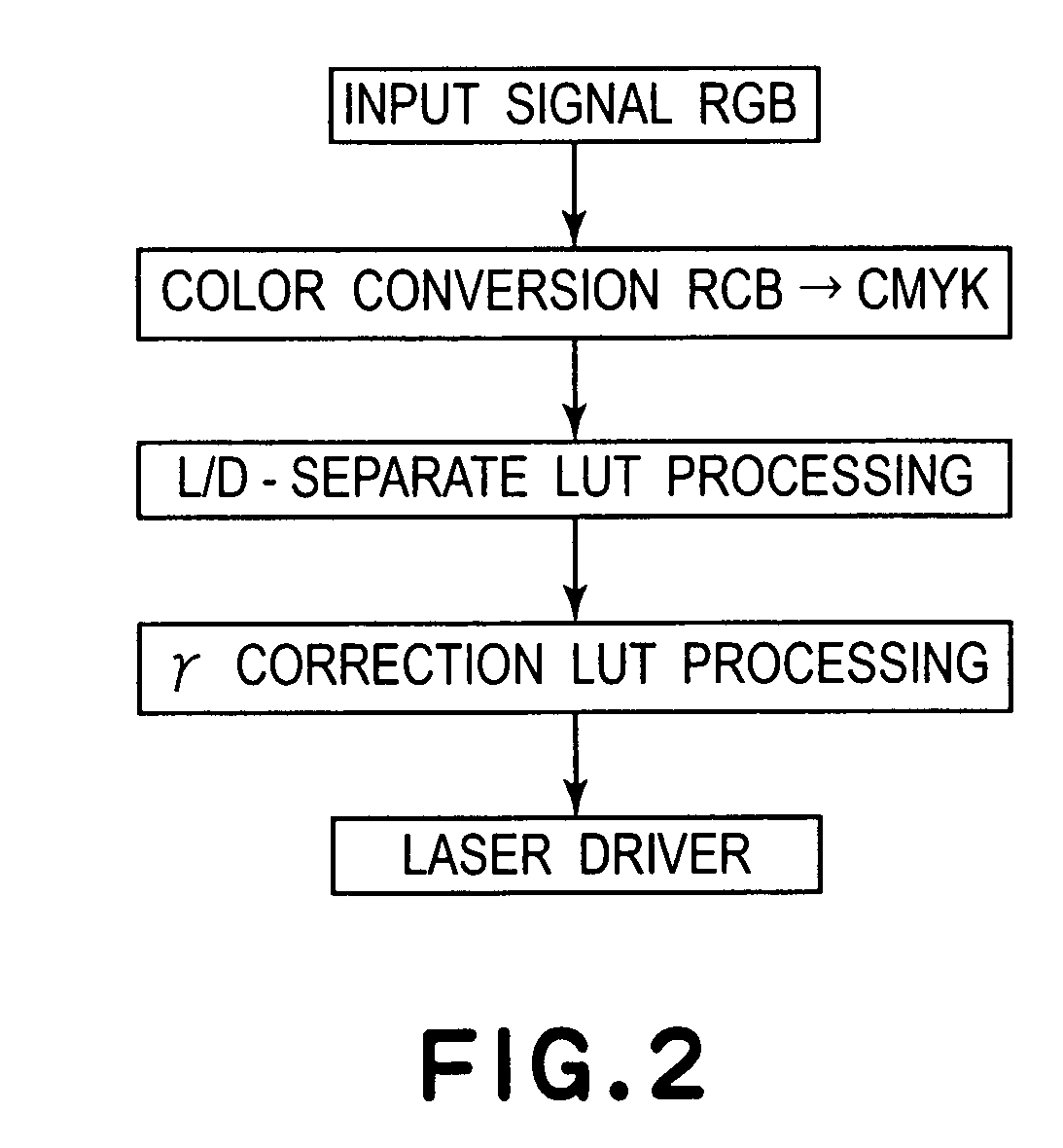

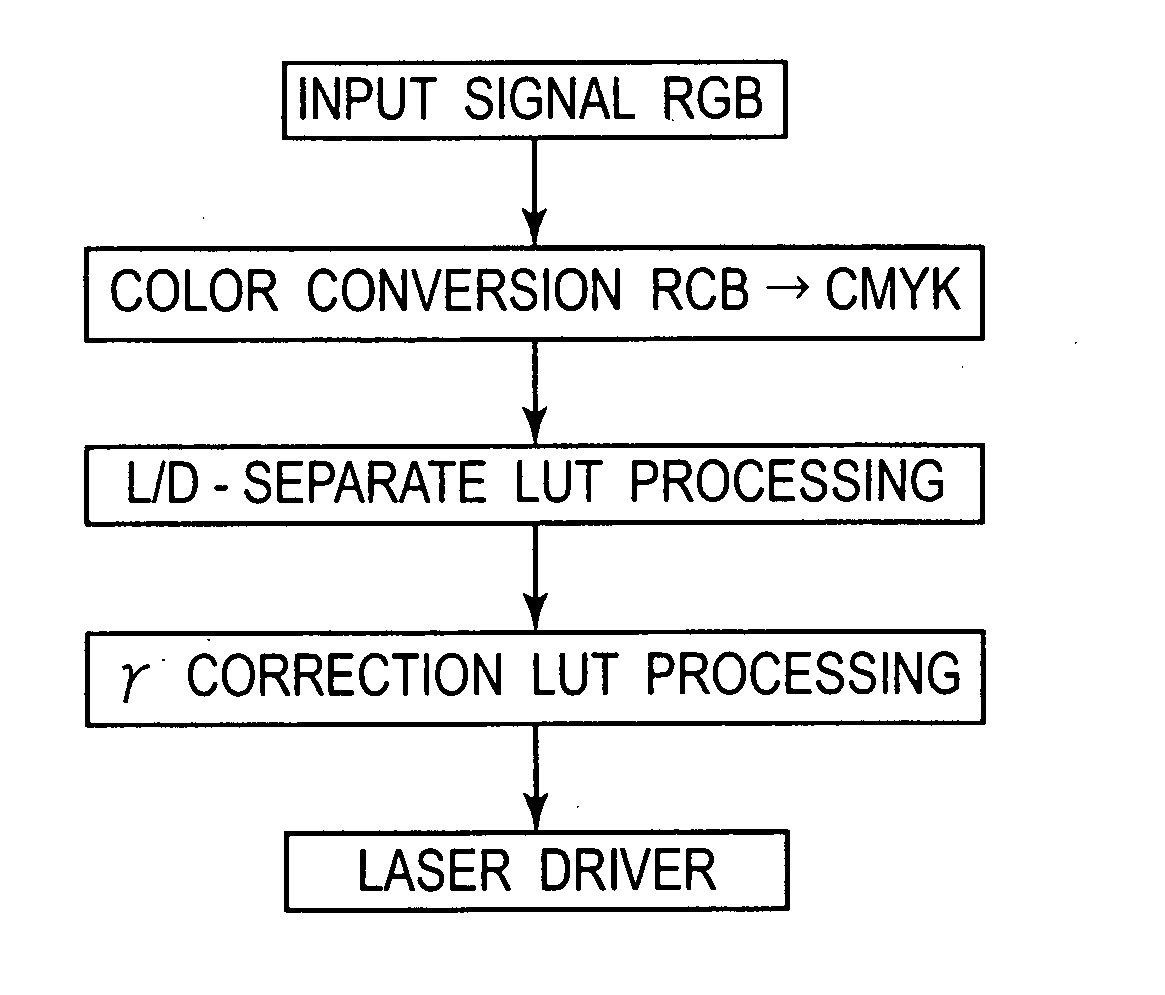

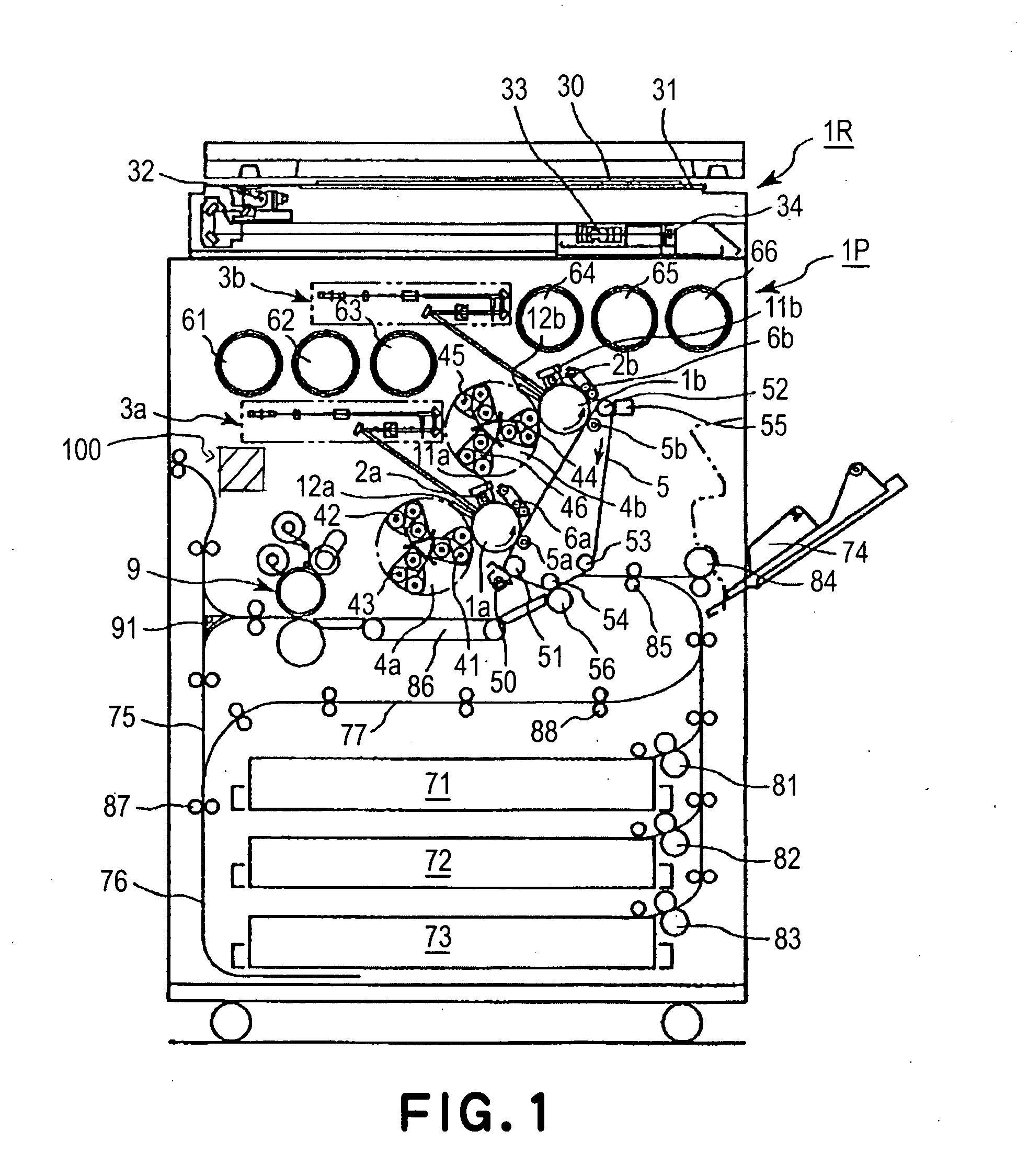

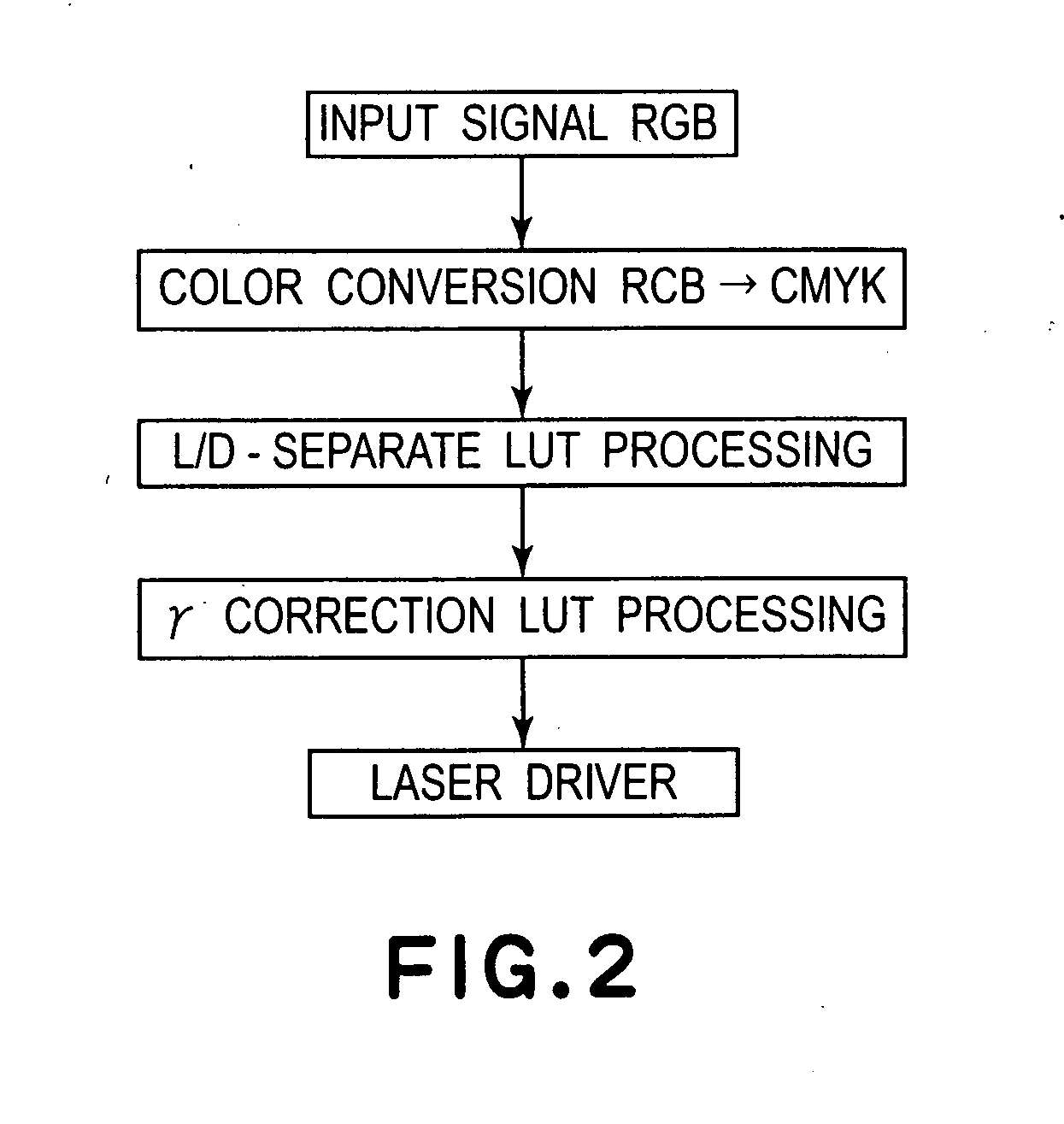

Image forming apparatus capable of accomplishing uniformity in glossiness

InactiveUS7113729B2Extended service lifeLow densityElectrographic process apparatusImage formationHue

An image forming apparatus includes an image bearing member for carrying an electrostatic image; a developing device for developing the electrostatic image with a plurality of toners having the same hue and having different densities; a toner image formation device for forming on a recording material a toner image constituted by the toner having the same hue and different densities; and a fixing device for fixing the toner image on the recording material, wherein a total of amounts per unit area of the toners which have the same hue and different densities and which constitute a part of the toner image, is substantially the same as a total of amounts per unit area of the toners which have the same hue and different densities and which constitute another part of the toner image having a different density.

Owner:CANON KK

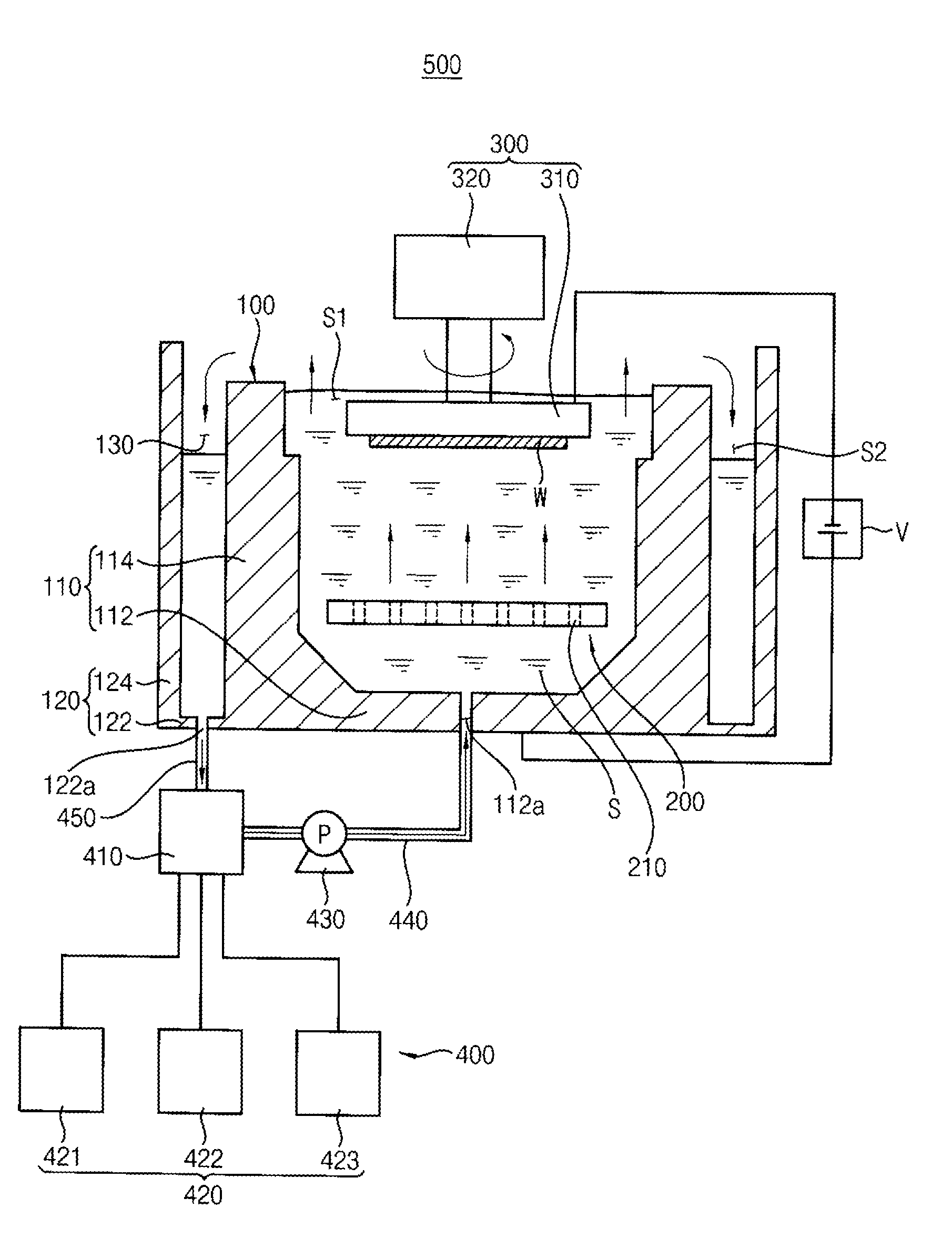

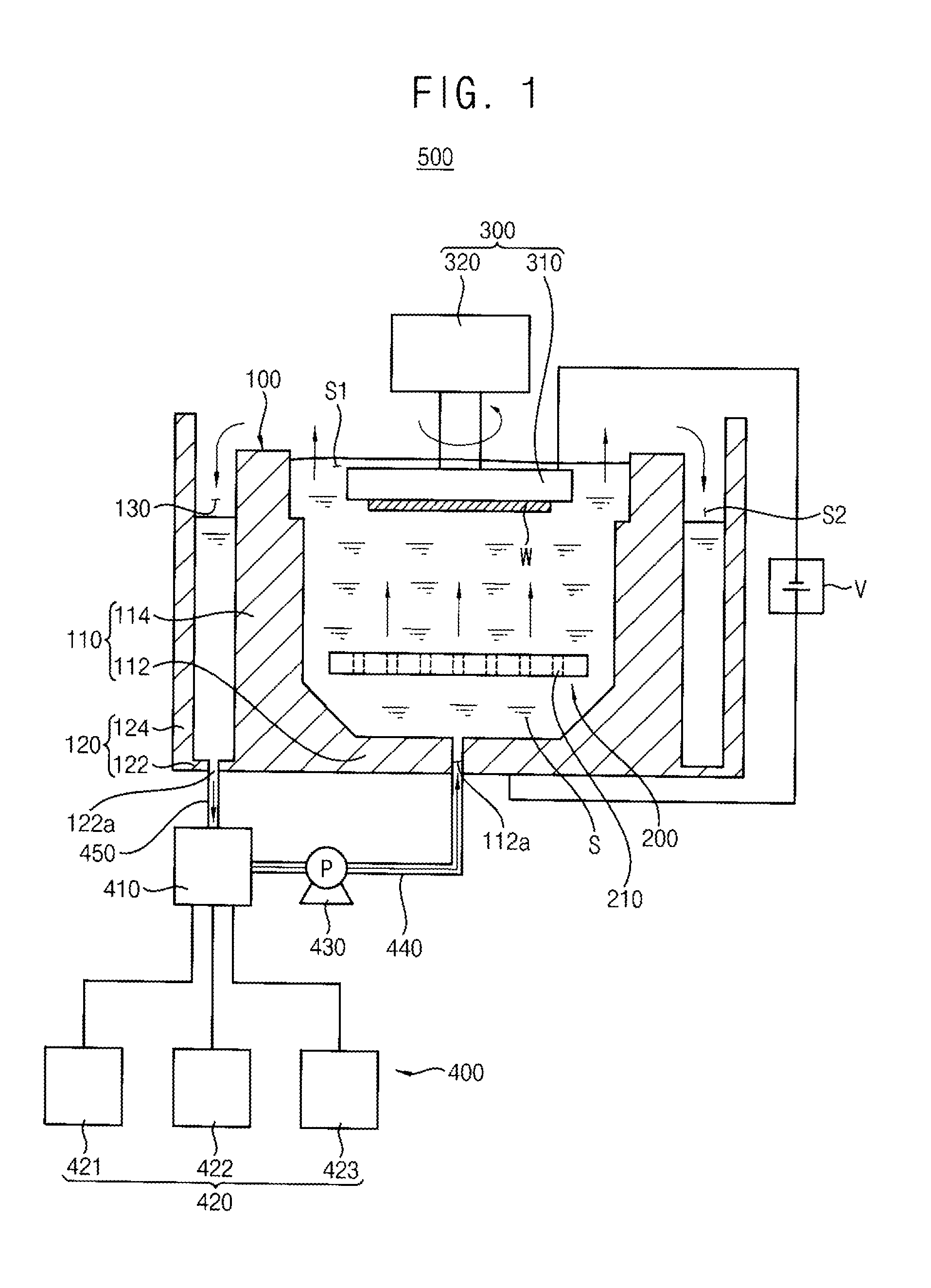

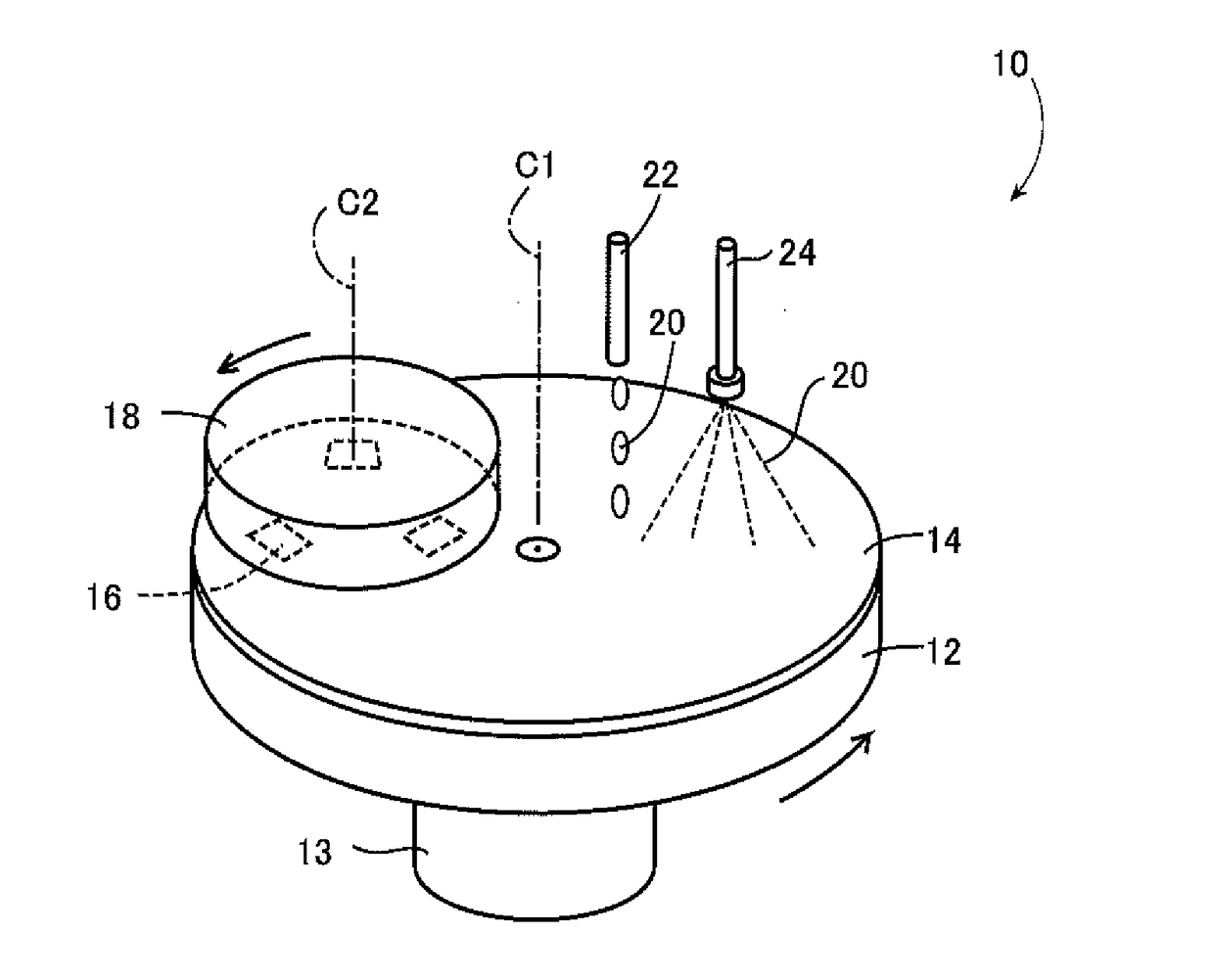

Copper electroplating solution and copper electroplating apparatus

ActiveUS20140197038A1Increasing overall electroplating processImprove processing efficiencyCellsSemiconductor devicesNitrogenAqueous electrolyte

An electroplating solution includes an aqueous electrolyte solution including water soluble copper salts, sulfide ions and chloride ions, an accelerator including an organic material having sulfur (S), the accelerator accelerating copper (Cu) reduction, a suppressor including a polyether compound, the suppressor selectively suppressing the copper reduction, and a leveler including a water soluble polymer having nitrogen that is dissolved into positive ions in the aqueous electrolyte solution.

Owner:SAMSUNG ELECTRONICS CO LTD

Image forming apparatus capable of accomplishing uniformity in glossiness

InactiveUS20050031379A1Extended service lifeLow densityElectrographic process apparatusImage formationEngineering

An image forming apparatus includes an image bearing member for carrying an electrostatic image; developing means for developing the electrostatic image with a plurality of toners having the same hue and having different densities; toner image formation means for forming on a recording material a toner image constituted by the toner having the same hue and different densities; and fixing means for fixing the toner image on the recording material, wherein a total of amounts per unit area of the toners which have the same hue and different densities and which constitute a part of the toner image, is substantially the same as a total of amounts per unit area of the toners which have the same hue and different densities and which constitute another part of the toner image having a different density.

Owner:CANON KK

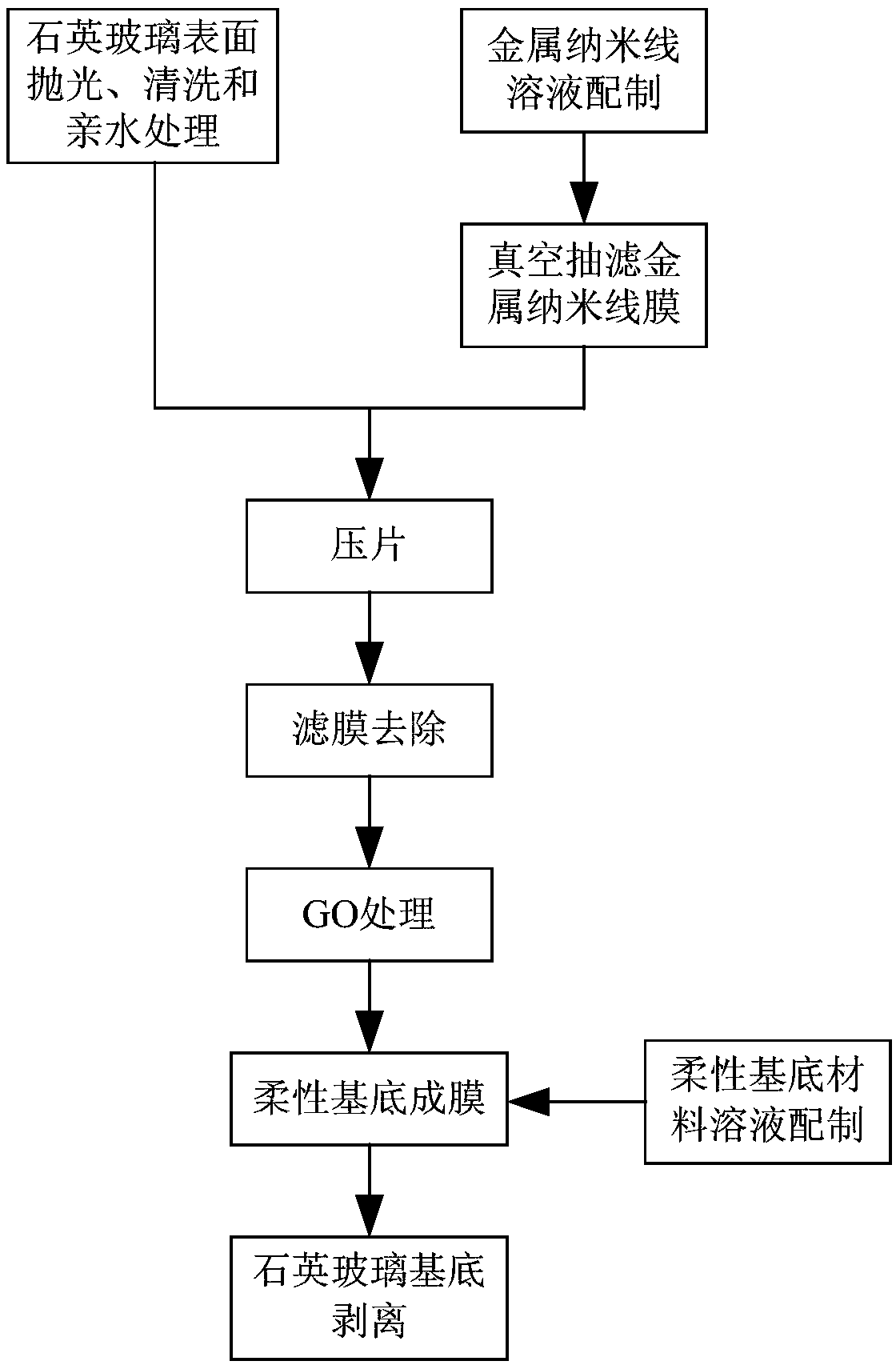

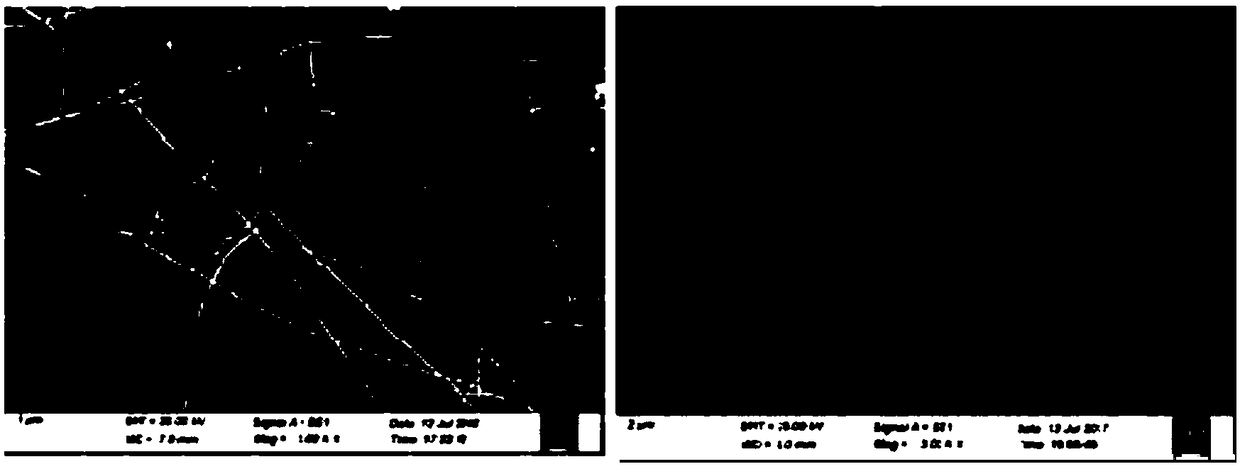

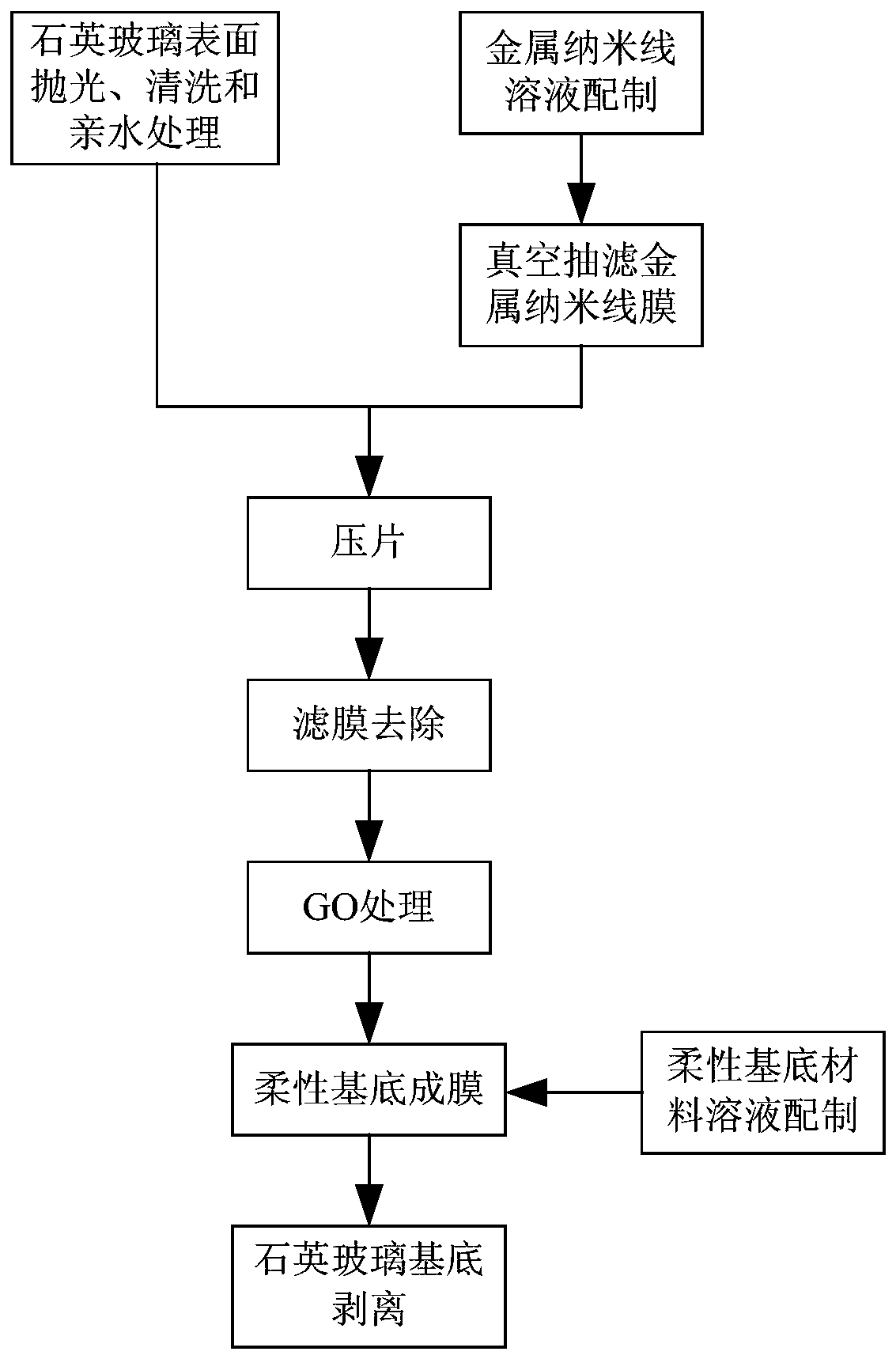

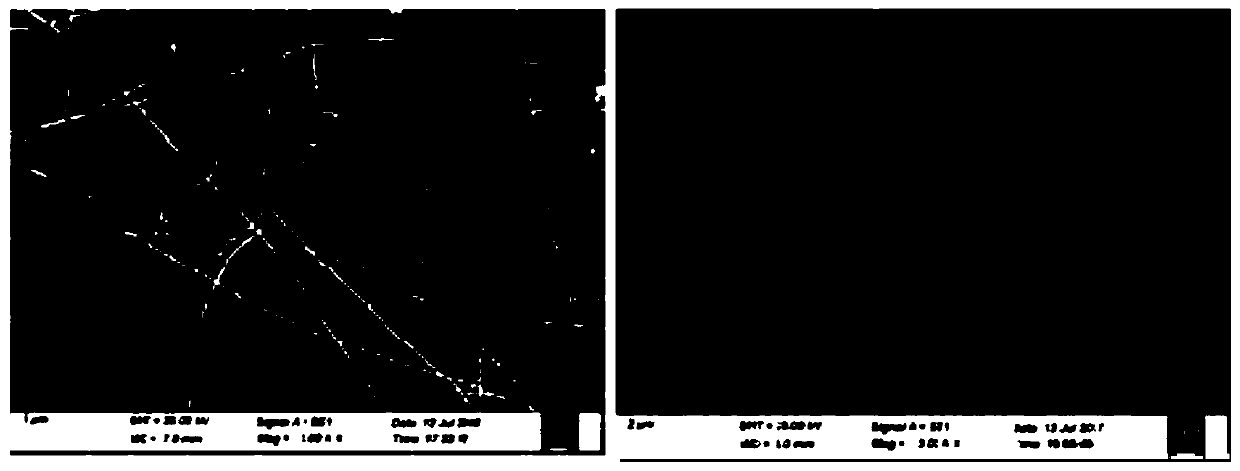

Flexible substrate-GO-metal nanowire composite transparent conductive thin film and preparation method thereof

InactiveCN108806885ACoated evenlyUniform adhesionConductive layers on insulating-supportsCable/conductor manufactureSurface roughnessOptical transmittance

The invention provides a preparation method of a flexible substrate-GO-metal nanowire composite transparent conductive thin film. The preparation method comprises the steps of quartz glass substrate surface processing, metal nanowire solution preparation, vacuum filtering metal nanowire film, lamination, filtering film removal, GO processing, flexible substrate material solution preparation, flexible substrate film formation and quartz glass substrate stripping. The invention also provides the flexible substrate-GO-metal nanowire composite transparent conductive thin film prepared by the method. The composite transparent conductive thin film prepared by the method has the advantages of low surface peak valley roughness and surface average roughness, good conductivity, high optical transmittance, good mechanical flexibility and good thermal stability, the metal nanowire is firmly attached onto the flexible substrate, the application demand of a device can be achieved, particularly, therequirement of a flexible thin film electronic device on electrode surface roughness can be met, and the reliability and the stability of the metal nanowire electrode in application of the thin film electronic device are improved.

Owner:CHONGQING UNIV

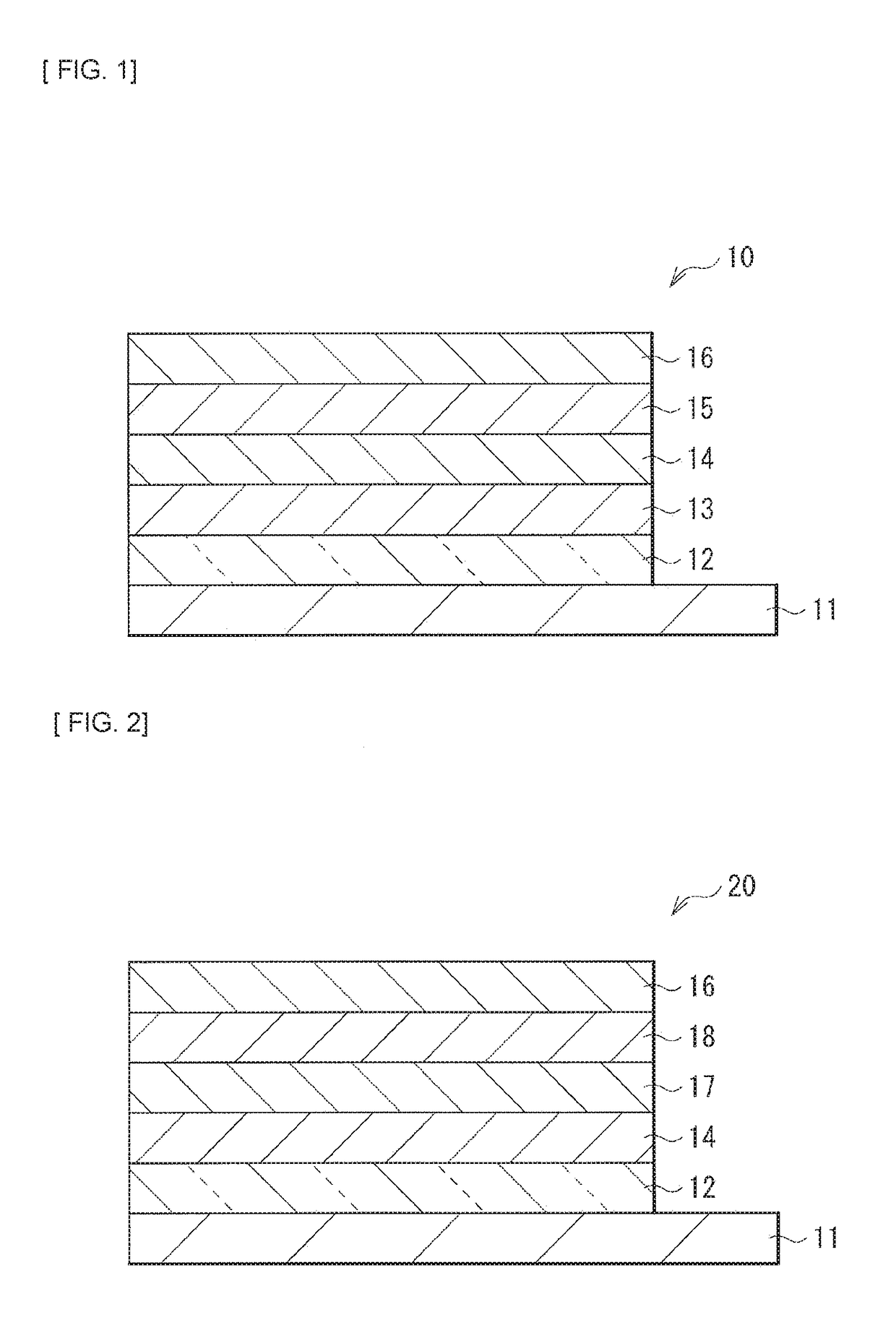

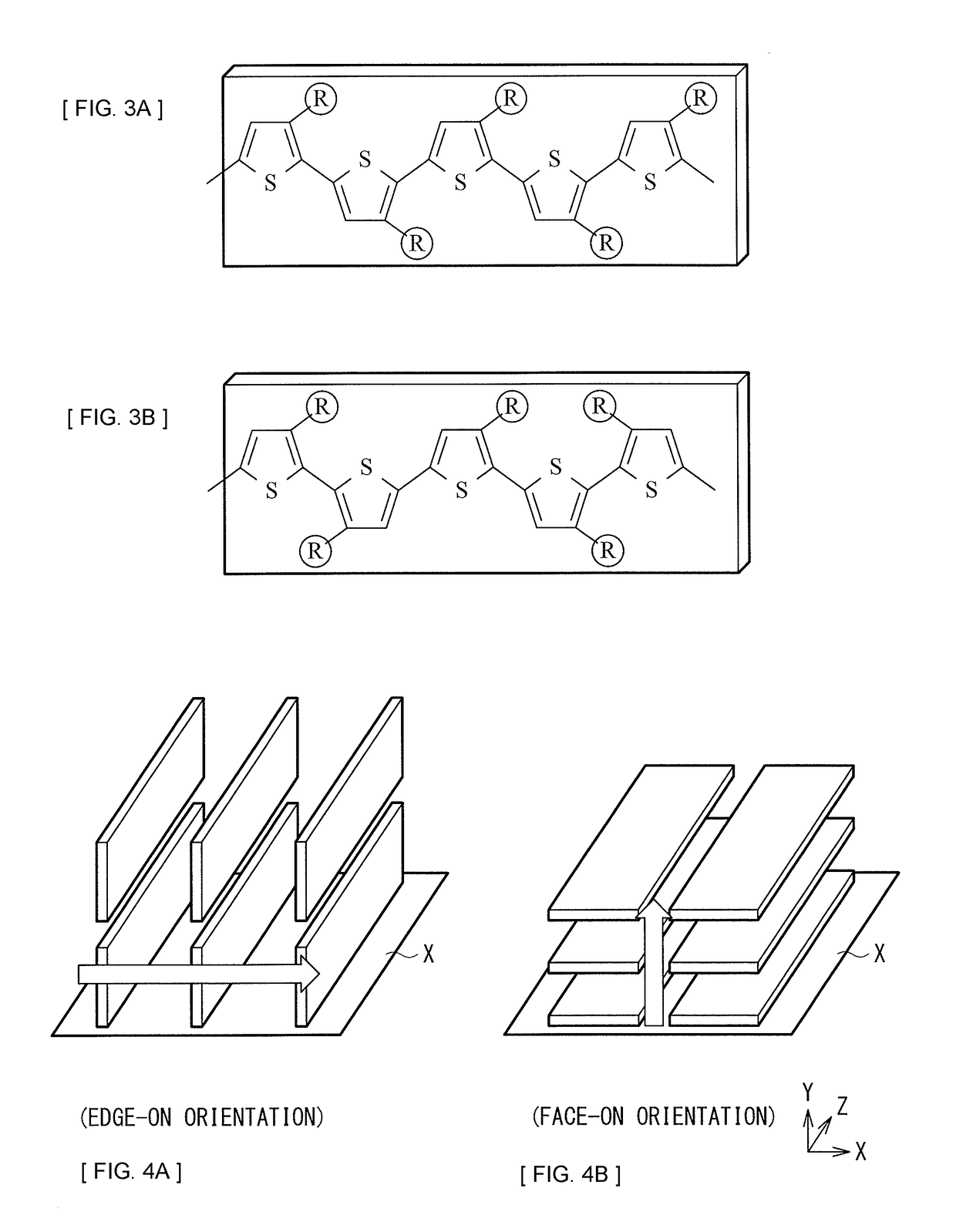

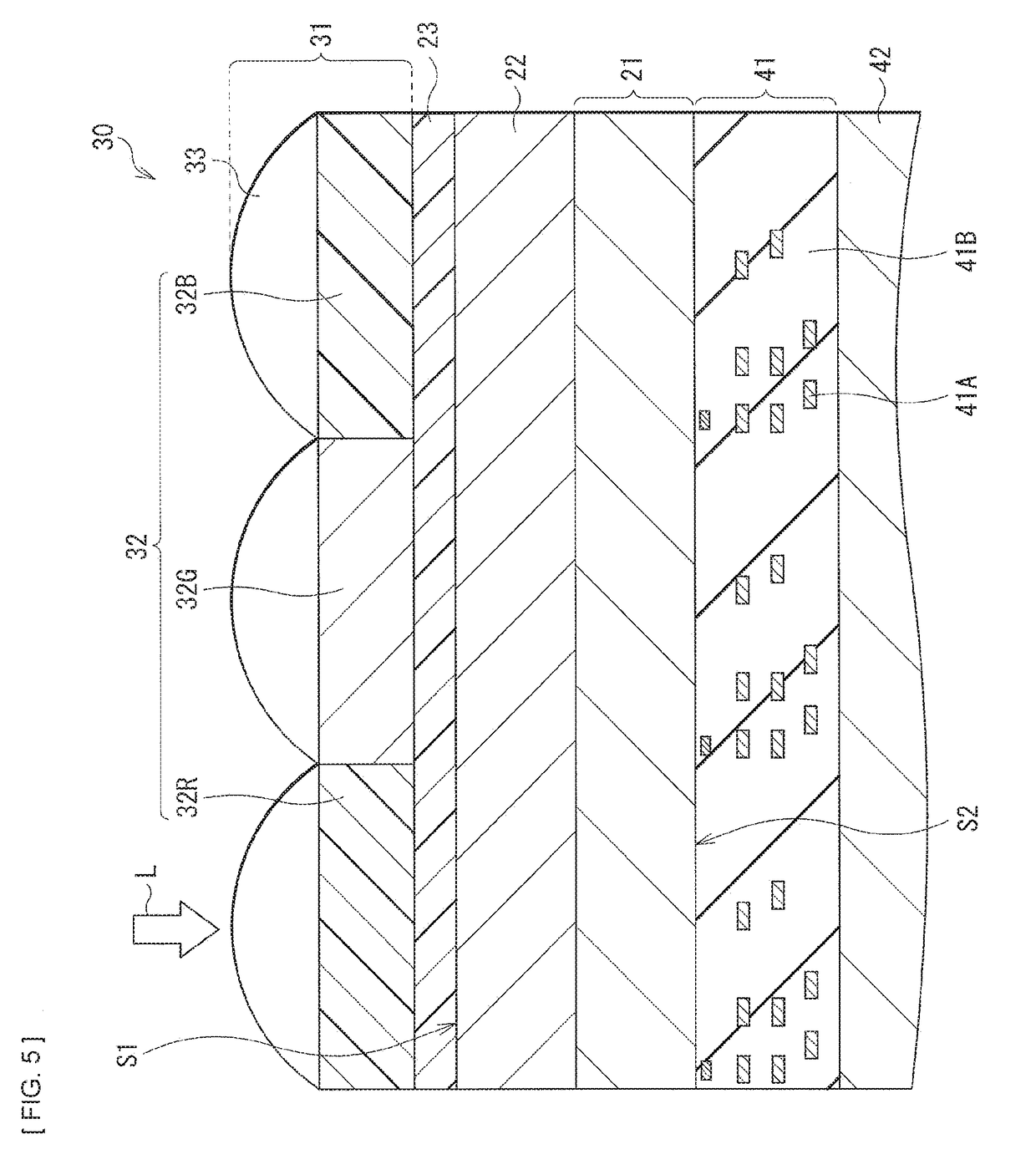

Photoelectric conversion device and imaging unit

InactiveUS20180366519A1Raise the ratioHigh carrier mobilityFinal product manufactureSolid-state devicesCouplingPhotoelectric conversion

A photoelectric conversion device according to an embodiment of the present disclosure includes: a first electrode and a second electrode facing each other; and a photoelectric conversion layer provided between the first electrode and the second electrode, and including a first organic semiconductor having head (Head)-to-tail (Tail) coupling regioregularity of 95% or more represented by a formula (1) and a second organic semiconductor having head-to-tail coupling regioregularity of 75% or more but less than 95% represented by the formula (1),

Owner:SONY CORP

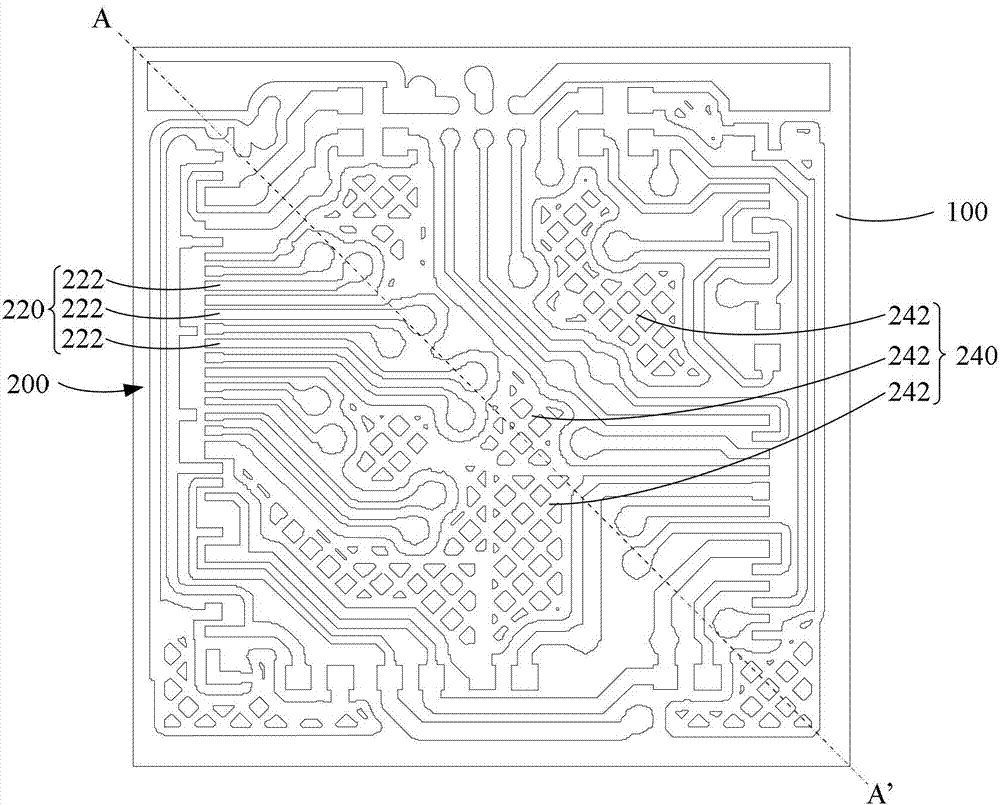

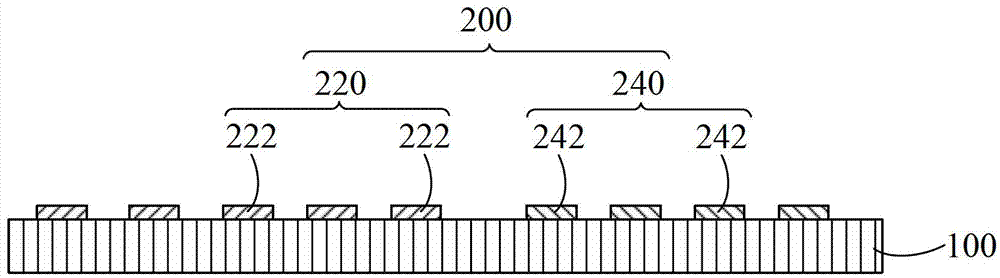

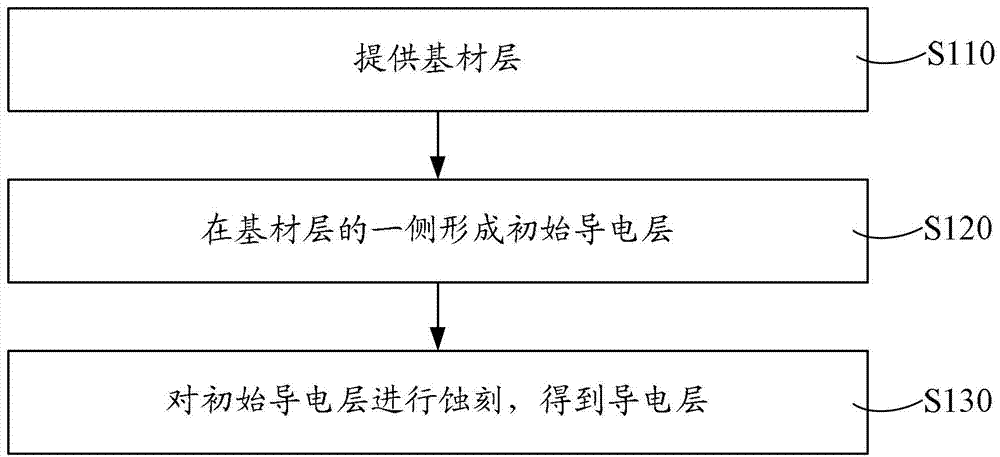

Flexible printed circuit board and manufacturing method thereof

InactiveCN103402303AConsistent deformationLow surface roughnessPrinted circuit manufactureElectrical connection printed elementsManufacturing technologyEngineering

The invention discloses a flexible printed circuit board and a manufacturing method thereof. A routing part of a conductive layer comprises a plurality of conductive traces which are arranged at intervals; and a non-routing part is formed by intercrossing conductive wires which are arranged at intervals. The non-routing part is designed to be formed by intercrossing the conductive wires which are arranged at intervals, so that the phenomenon that a region, which is used for holding the non-routing part, of a base material layer is completely covered by the non-routing part is avoided. In a subsequent manufacturing technology, when the flexible printed circuit board is baked or passes through a furnace after being erected with other components and is then deformed, stress produced in the flexible printed circuit board is uniformly distributed, and parts of the flexible printed circuit board are deformed consistently; and the reduction of the surface flatness of the flexible printed circuit board is avoided.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD +3

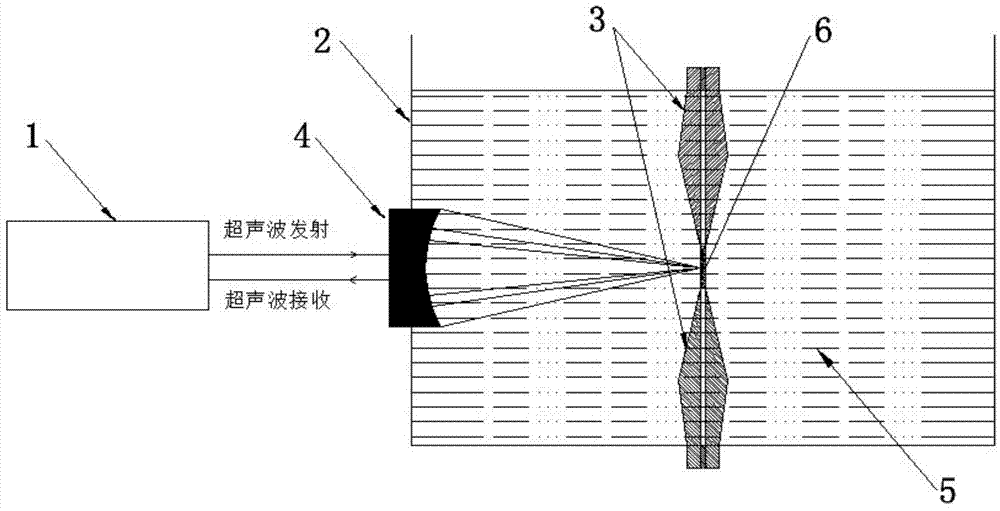

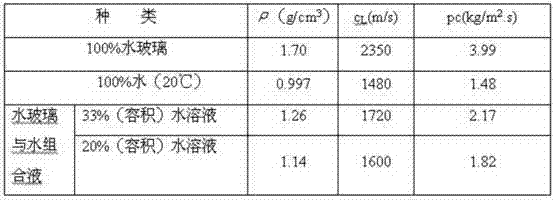

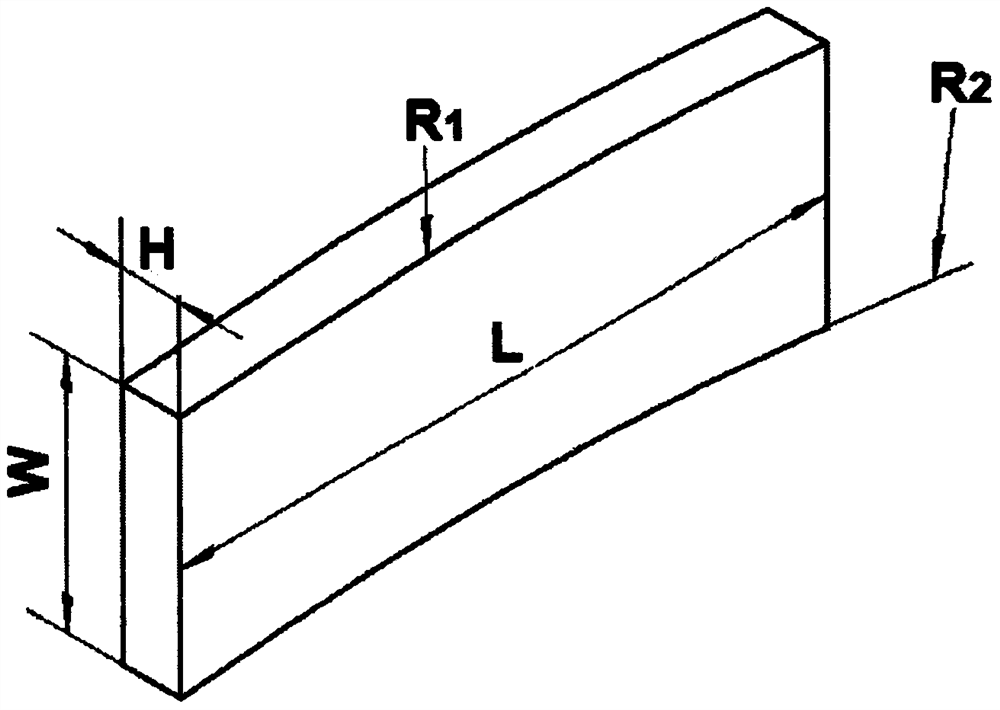

Method and device for testing acoustic performance of ultrathin polyethylene test sample

ActiveCN103698402ASmall geometryLow surface roughnessAnalysing solids using sonic/ultrasonic/infrasonic wavesTest sampleAcoustic impedance

The invention relates to the test of acoustic performance of polyethylene test samples and provides a method and a device for testing acoustic performance of an ultrathin polyethylene test sample. An impulse reflection device based on immersion focusing technology comprises an ultrasonic detector, a test container, a clamping device and a focusing probe. The method for testing acoustic performance of ultrathin polyethylene test sample comprises the following steps: preparing an ultrathin polyethylene test sample to be tested; immersing the ultrathin polyethylene test sample in coupling liquid, and blending the coupling liquid until the ultrasonic detector receives no echo signal; calculating the sound velocity and acoustic impedance of the coupling liquid, wherein the acoustic impedance of the coupling liquid is the acoustic impedance of the ultrathin polyethylene test sample; and calculating the sound velocity of the ultrathin polyethylene test sample. The contact interface coupling problem of ultrasonic and test sample does not need to be considered in the method disclosed by the invention, so that the method is suitable for measuring the acoustic impedance of ultrathin test samples with irregular surfaces, and the precision of the test result is high.

Owner:ZHEJIANG UNIV

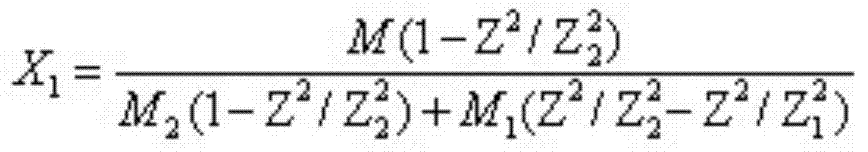

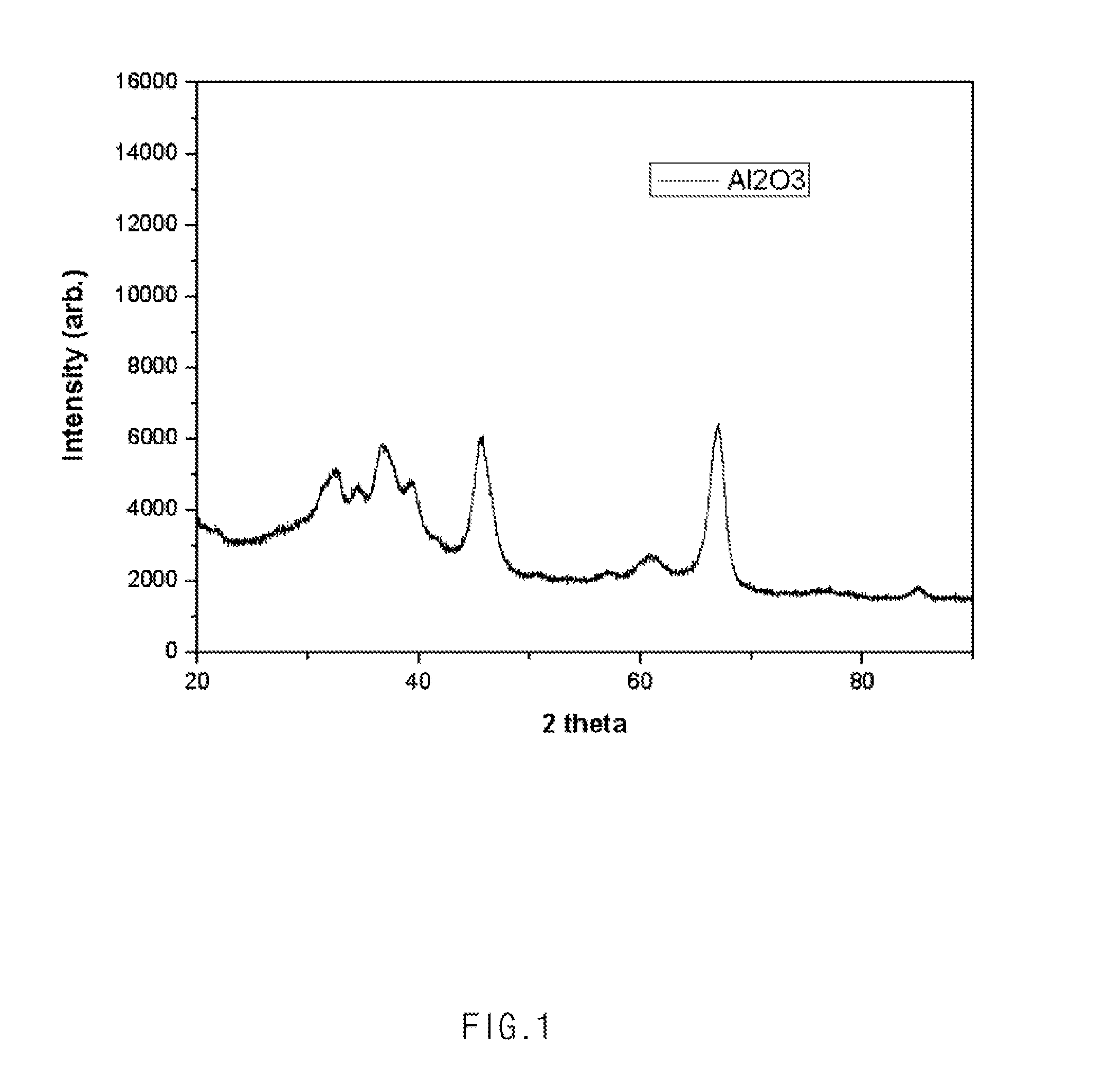

Method of preparing positive electrode material for lithium secondary battery, positive electrode material for lithium secondary battery, and lithium secondary battery including the positive electrode material

ActiveUS20160254546A1Low surface roughnessExcellent coating performanceMaterial nanotechnologyElectrode thermal treatmentOxideAluminium oxide

The present invention relates to a method of preparing a positive electrode material for a lithium secondary battery including a first step of synthesizing a lithium transition metal oxide represented by Chemical Formula 1, a second step of preparing lithium transition metal oxide powder by grinding the lithium transition metal oxide, a third step of preparing a positive electrode material including an alumina coating layer by mixing as well as dispersing the lithium transition metal oxide powder in an alumina nanosol, and a fourth step of drying the positive electrode material, a positive electrode material for a lithium secondary battery prepared by the above method, and a lithium secondary battery including the positive electrode material,Li(1+a)(Ni(1−a−b−c)MnbCoc)On [Chemical Formula 1]where 0≦a≦0.1, 0≦b≦1, 0<c≦1, and n is an integer of 2 or 4.

Owner:LG CHEM LTD

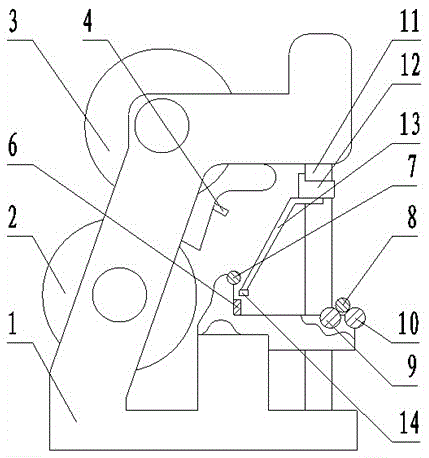

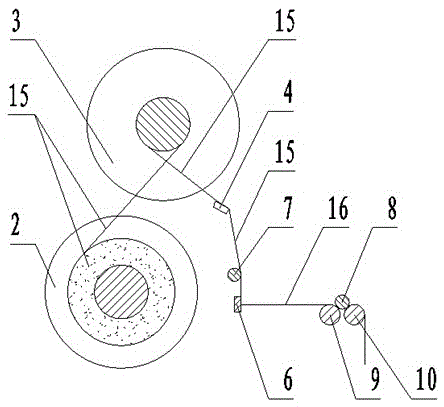

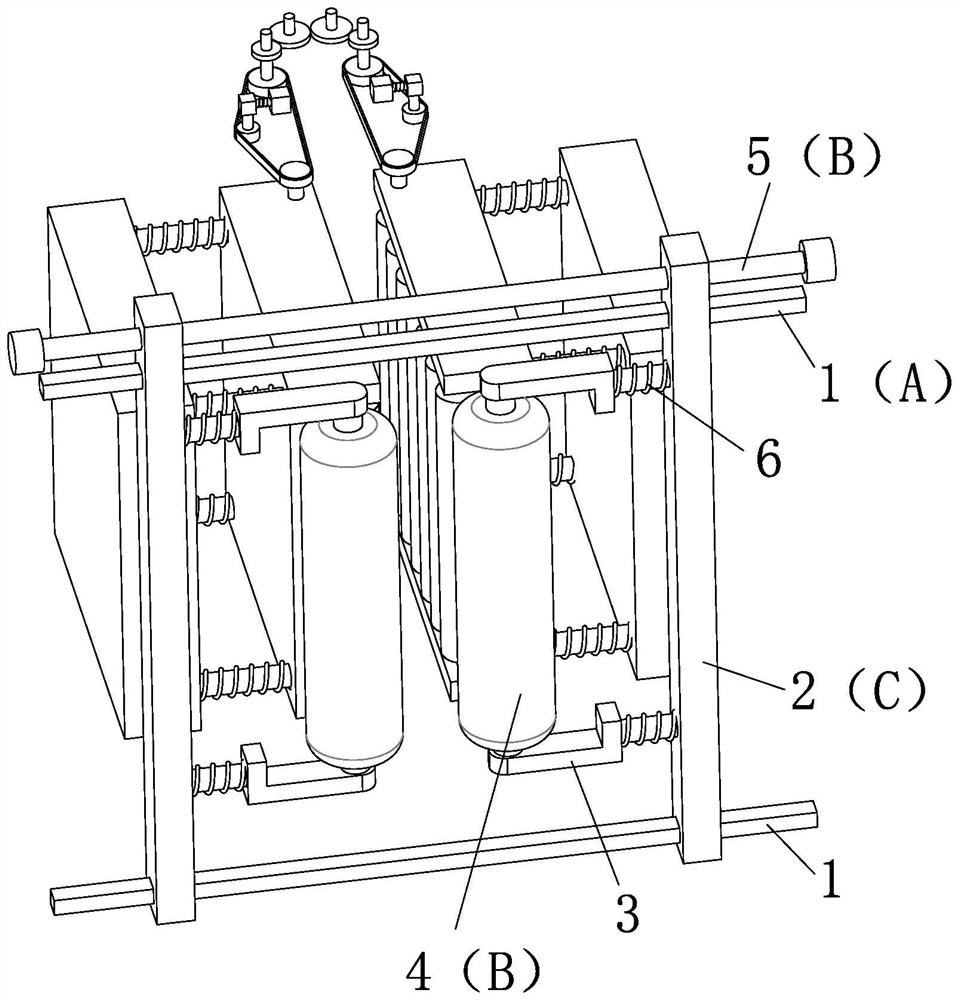

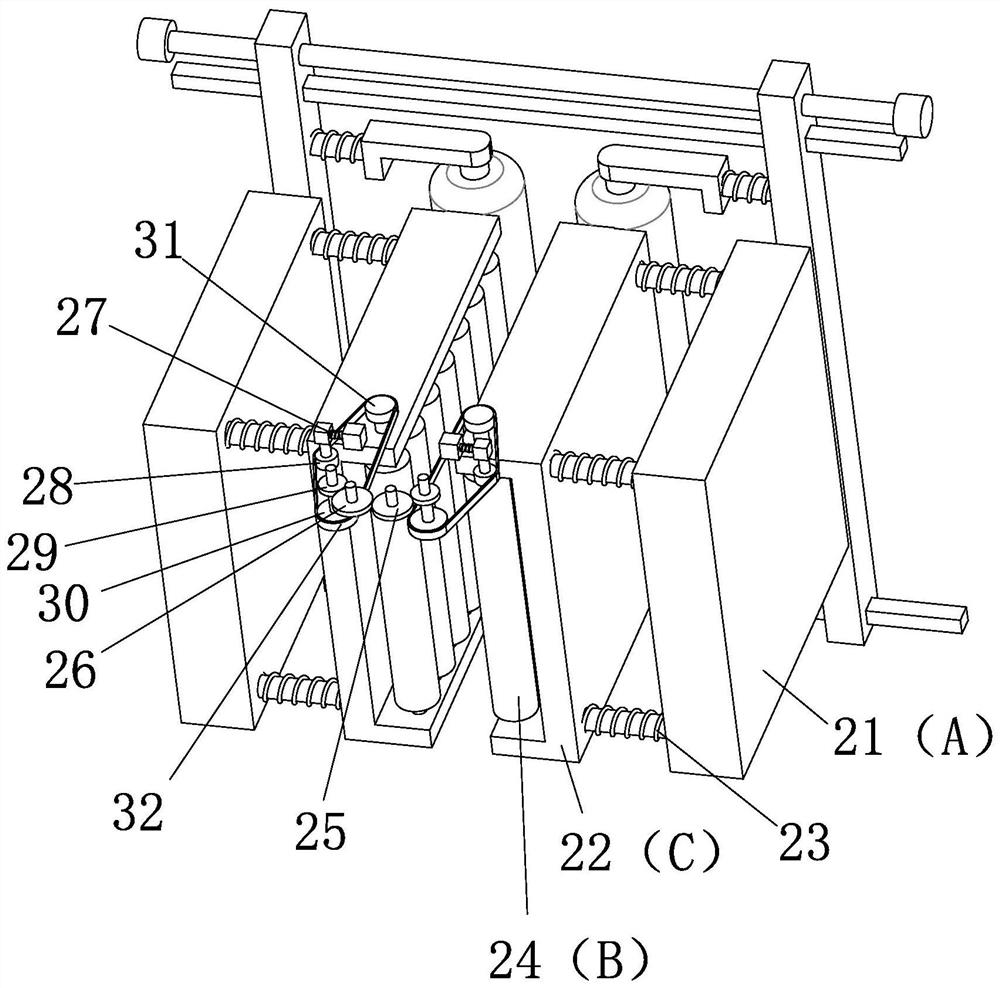

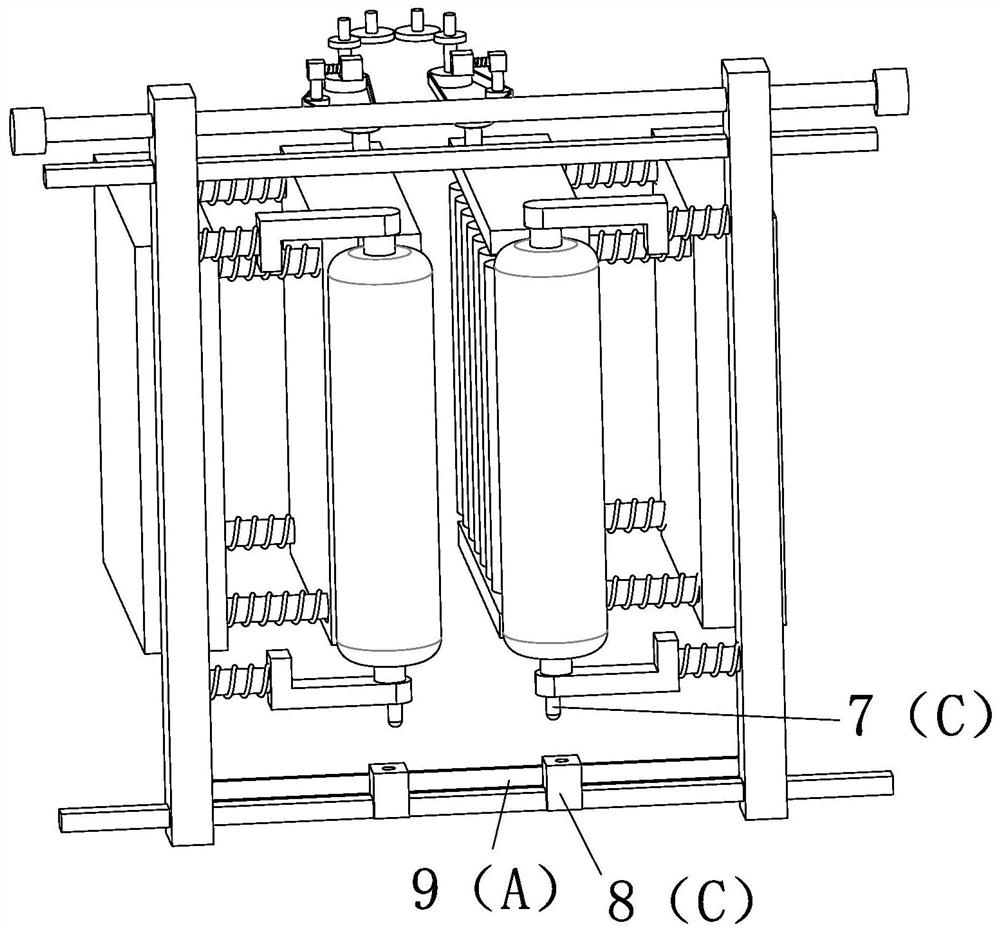

Method for lowering defective rate of woven fabric and loom

InactiveCN104947297AAvoid wrinklesEliminate wrinklesLoomsHeating/cooling textile fabricsYarnStructural engineering

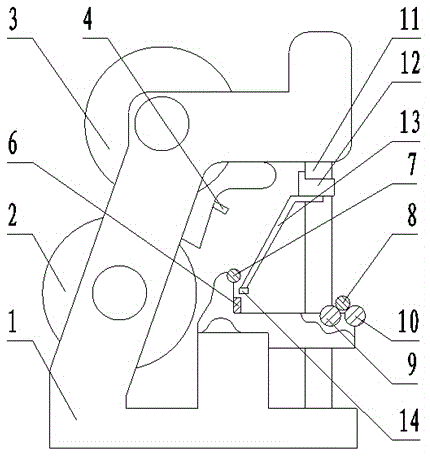

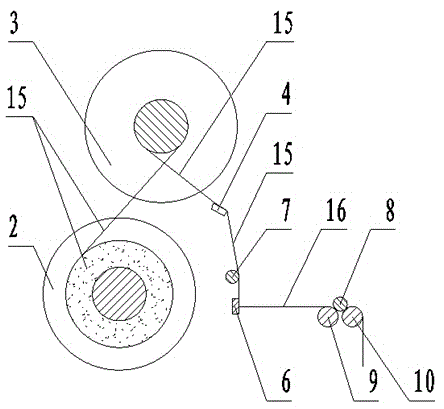

The invention discloses a method for lowering the defective rate of woven fabric and a loom. According to the method, an infrared probe is used for scanning, a motor is controlled by a controller to stop suddenly, secondary tensioning is conducted on yarn through a tensioning wheel and a tensioning roller, and woven fabric is heated through a heating roller so that wrinkles can be eliminated. The loom manufactured through the method comprises a machine frame (1), wherein a yarn wheel (2) and the tensioning wheel (3) are arranged on the machine frame (1), a distributor plate (4) and a working table (5) are arranged below the tensioning wheel (3), knitting needles (6) and the tensioning roller (7) are arranged at one end of the working table (5), a limiting roller (8), the heating roller (9) and a guiding roller (10) are arranged at the other end of the working table (5), a sliding rail (11) is arranged above the working table (5), and the infrared probe (14) is connected to the sliding rail (11) through a sliding block (12) and a suspension frame (13). The method for lowering the defective rate of woven fabric and the loom can improve the quality of products and lower the defective rate and further have the advantages that the production efficiency is high and the surface smoothness is good.

Owner:HUZHOU JIESHENG GAOKE TEXTILE

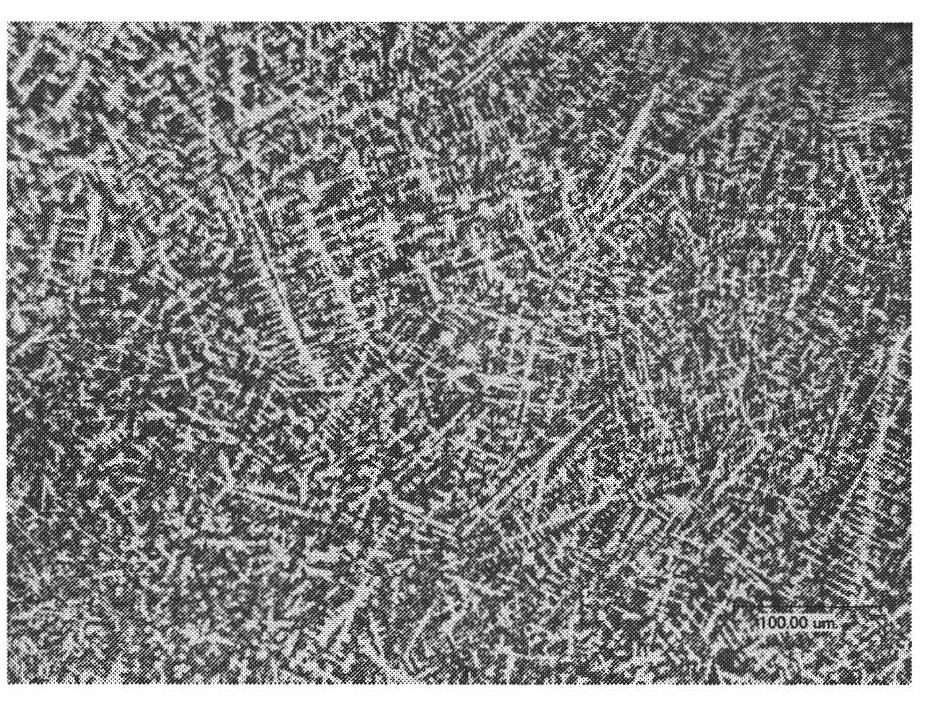

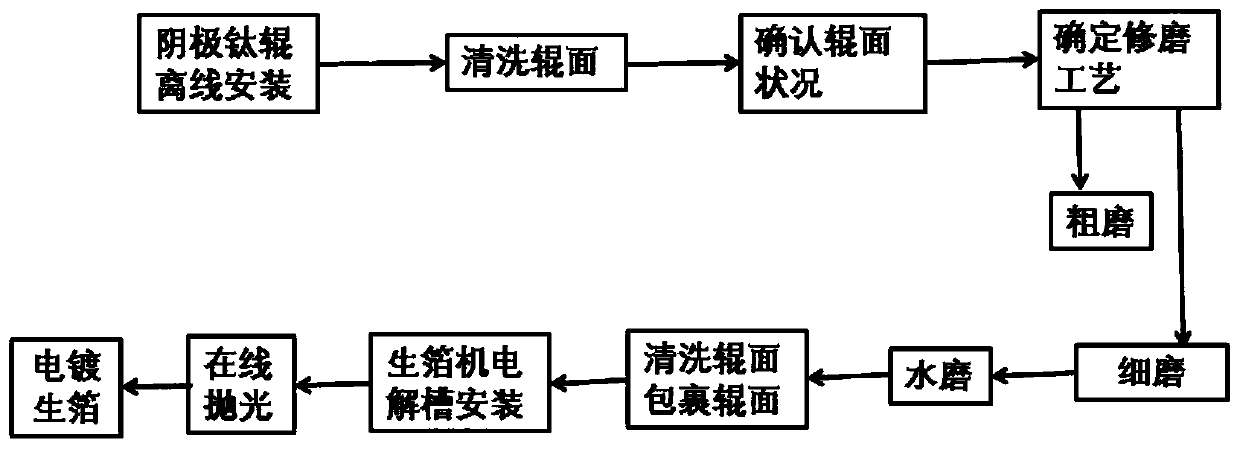

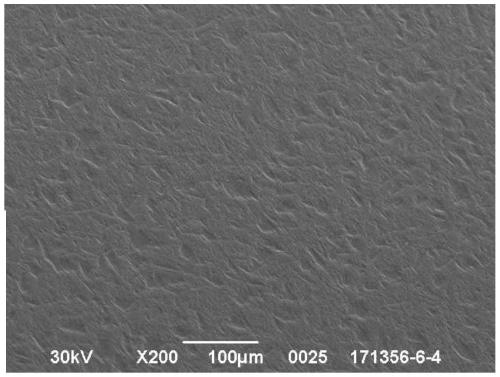

Cathode titanium roller surface grinding and polishing technology for raw foil manufacturing

ActiveCN111496646AReduce defectsLow surface roughnessPolishing machinesLapping machinesCopper foilSurface grinding

The invention discloses a cathode titanium roller surface grinding and polishing technology for raw foil manufacturing, and belongs to the field of electrolytic copper foil technology preparing. The cathode titanium roller surface grinding and polishing technology comprises the following steps that firstly, preparing is conducted, a titanium roller is installed, an offline polishing and grinding machine is started, and the titanium roller runs and is flushed; secondly, grinding is conducted, the titanium roller is sequentially subjected to rough grinding, fine grinding and water grinding or the titanium roller is sequentially subjected to fine grinding and water grinding; and thirdly, polishing is conducted, the titanium roller ground in the second step is installed online, polishing is started, the polishing strength is 20%-50%, and polishing is conducted for 2-4 circles. Multifunctional and multipurpose electrolytic copper foil produced in the ground and polished cathode titanium roller electroplating process has the characteristics of being few in defect, fine in grain, low in surface roughness, high in strength, high in ductility and thinner, and is suitable for high-fineness electrolytic copper foil manufacturing.

Owner:东强(连州)铜箔有限公司

A kind of composite diaphragm for lithium ion battery and preparation method thereof

ActiveCN103956450BAvoid thermal runawayImprove high temperature thermal stabilityCell component detailsElectrolytic agentCeramic coating

The invention discloses a composite separator for lithium ion batteries and a preparation method thereof, including a ceramic coating modification method and a ceramic lithium battery separator. The ceramic protective layer is mainly a mixture composed of ceramics graft-modified by anionic surfactants containing sodium sulfonate or sodium carboxylate groups, and a binder. The grafting is completed under the action of dehydrating agent and using the "grafting to" method. The grafting rate of ceramics is relatively high. The modified ceramic separator has greatly improved the performance of the modified ceramic separator due to the introduction of high-temperature-resistant high-specific surface area nanoceramics on the surface of the conventional PP separator. The insulation and electrolyte wettability of the separator are improved, especially at high temperatures of 130°C, 150°C and 180°C, showing excellent high-temperature thermal stability. The lithium battery composite separator avoids the heat shrinkage of conventional separators, thereby avoiding thermal runaway inside the battery caused by heat shrinkage, thereby improving the safety and reliability of lithium-ion batteries.

Owner:DONGFANG ELECTRIC CORP LTD

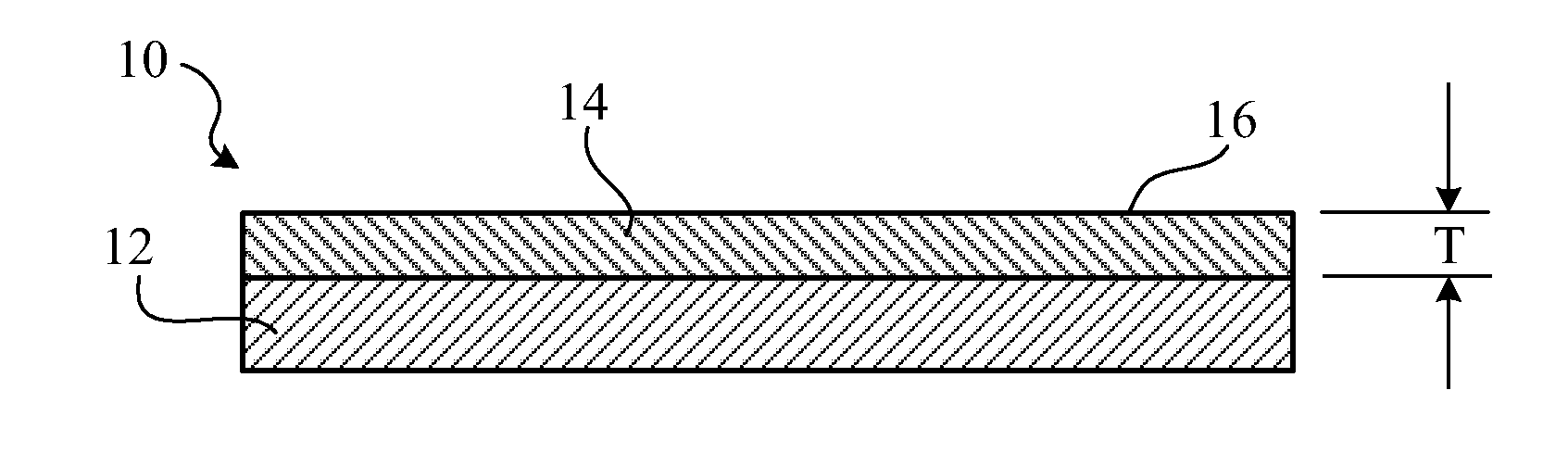

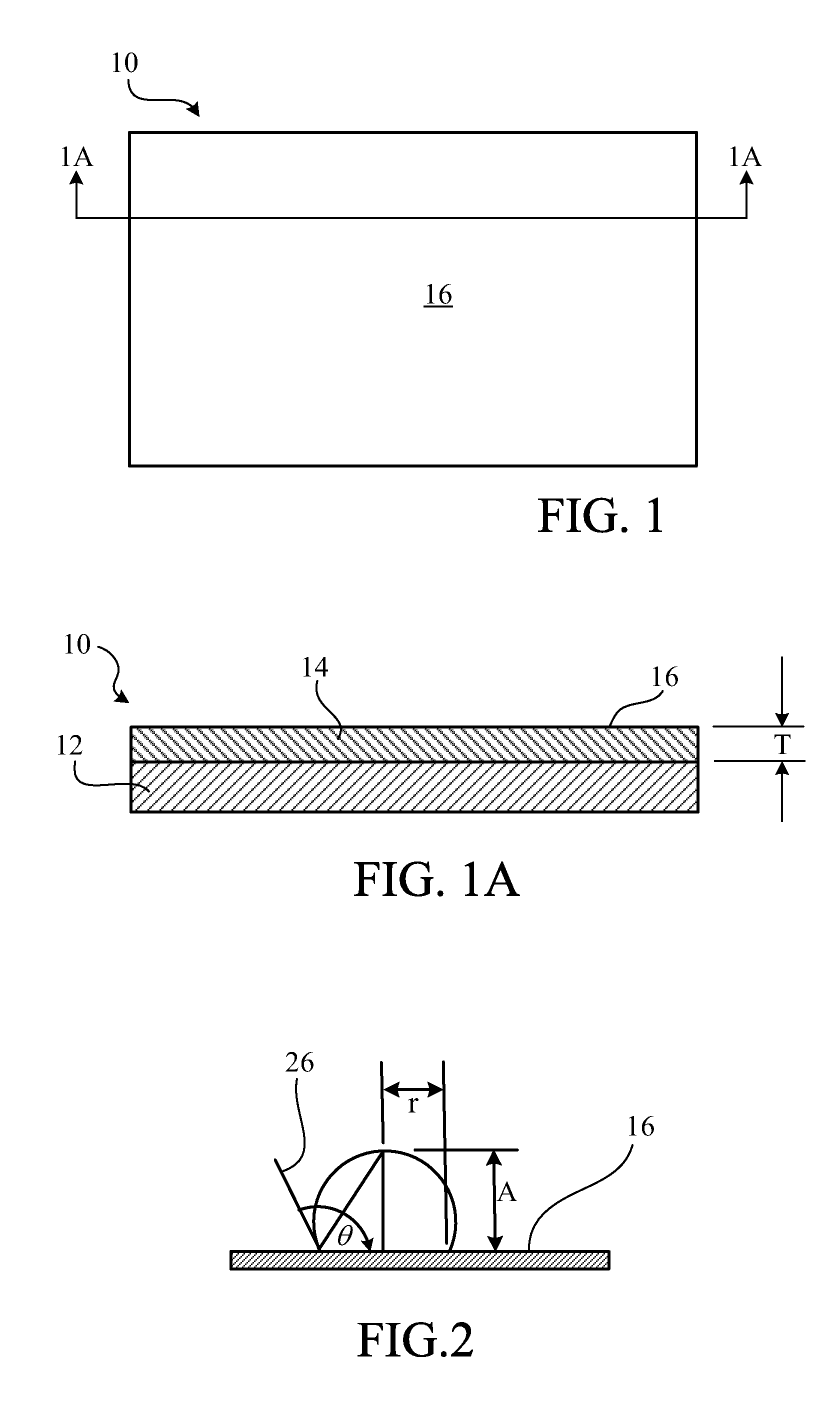

Magnetic recording medium

InactiveUS7060340B2Increase productionSuppress output fluctuationIron oxides/hydroxidesMagnetic materials for record carriersSurface roughnessComputational physics

A magnetic recording medium having a non-magnetic support, at least one primer layer on one surface of the support, a magnetic layer on the primer layer and a back coat layer on the other surface of the non-magnetic support, in which the support has a thickness of 2 to 5 μm, the surface roughness (Ra) of the support on its surface carrying the primer layer and the magnetic layer is from 2.5 nm to 20 nm, the thickness of the primer layer is 1.5 μm or less, and the primer layer contains 2 to 30% by weight, based on the weight of all inorganic powder in the primer layer, of alumina powder having a particle size of 0.01 μm to 0.1 μm.

Owner:FUJIFILM CORP

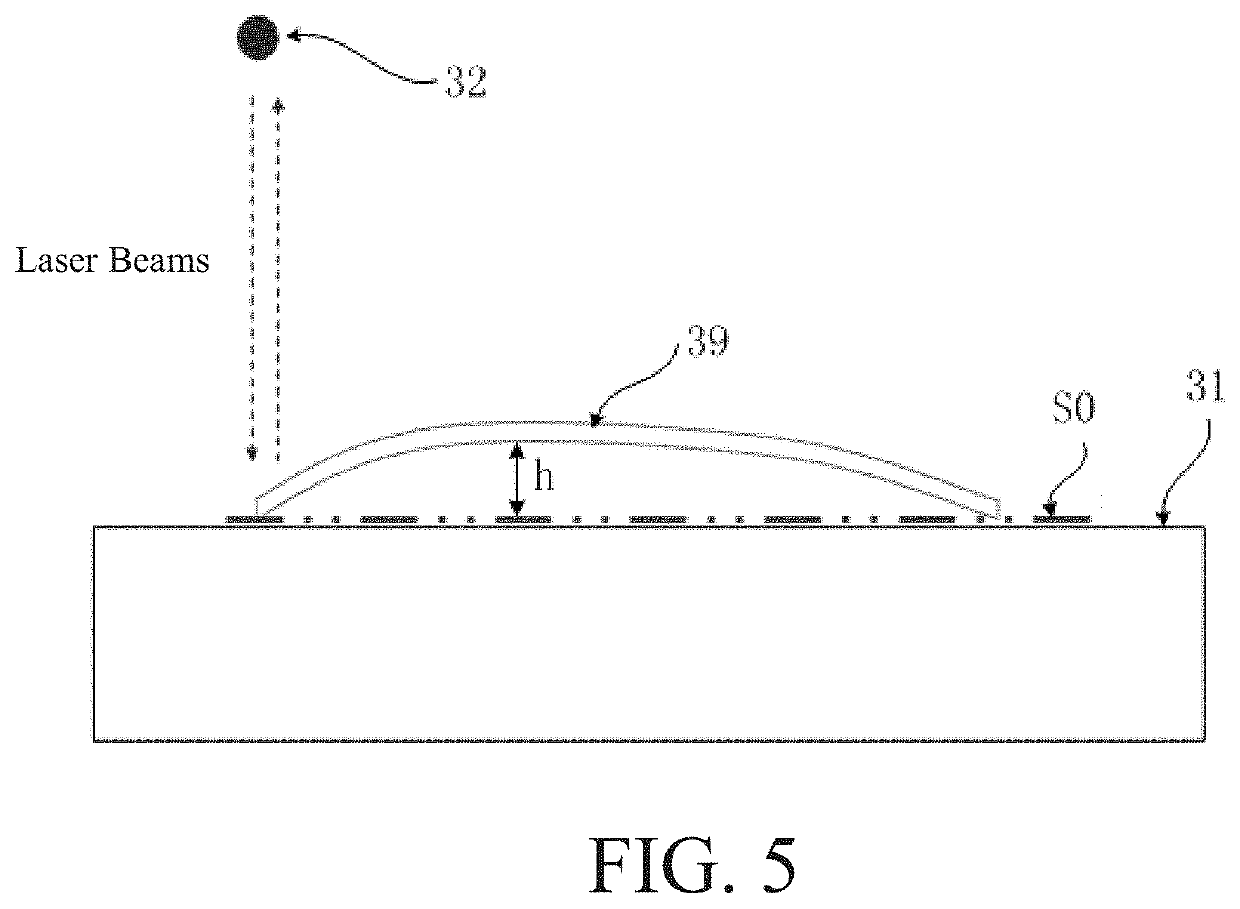

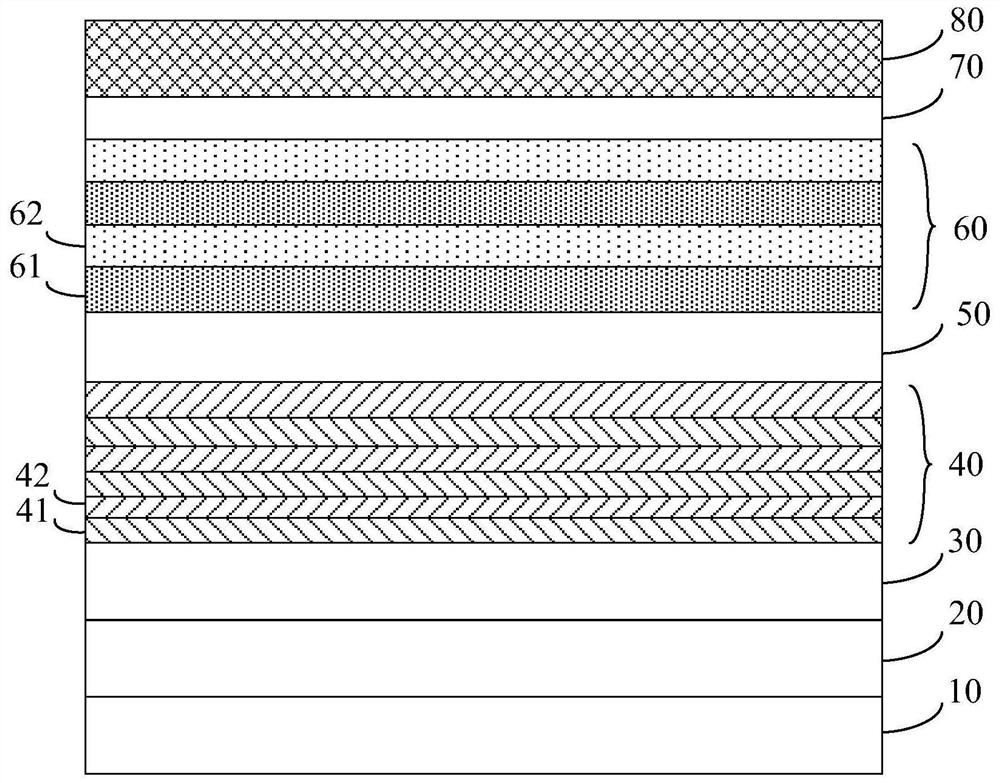

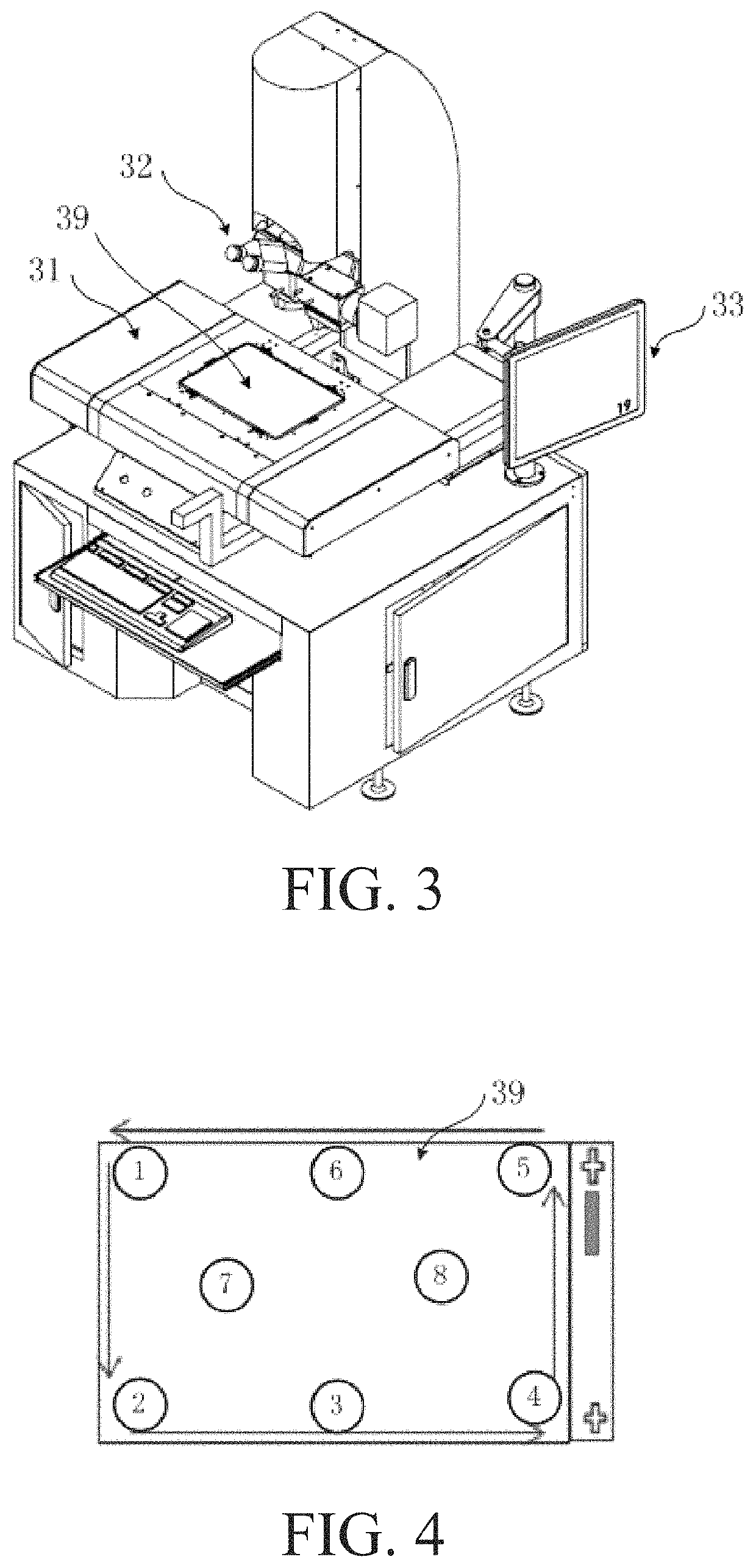

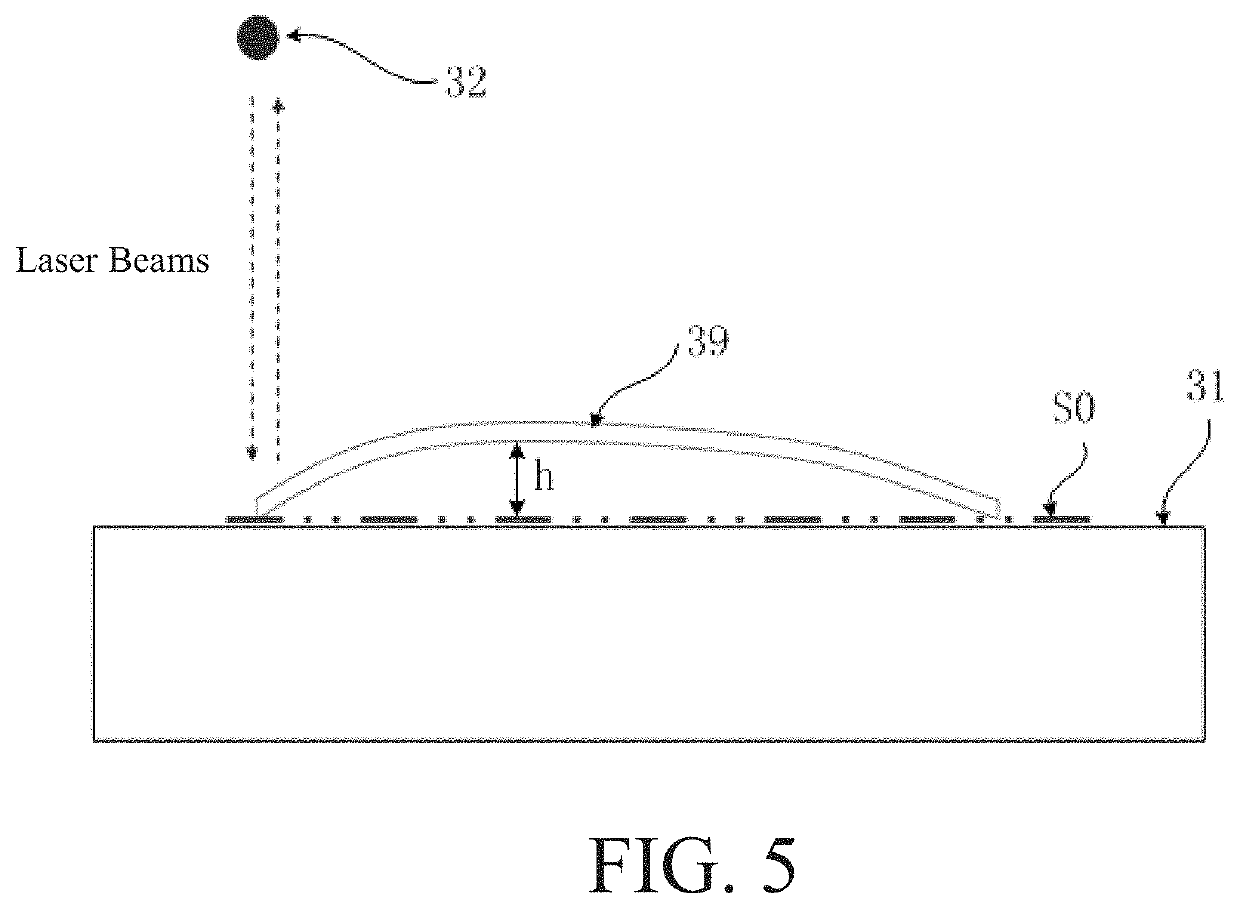

Surface flatness measuring device and surface flatness measuring method

ActiveUS20200200527A1Low measurement precisionEasy to measureUsing optical meansNon-linear opticsSoftware engineeringMonoboard

A surface flatness measuring device and a surface flatness measuring method are disclosed. By non-contacting laser measurement, measurement precision can reach 0.001 mm so the measurement precision is high. A repetitive measurement error thereof can be controlled to be within 3 um so the measurement error is tiny, which prevent issues of low measurement precision and great measurement errors due to manual measurement in prior art. At the same time, the present invention measurement data can be automatically recorded and saved, measurement for a large batch of boards under measurement can be implemented, which prevents the issues of the conventional measurement data requiring manual recording and lacking capability of uploading the measurement data.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Magnetic recording medium

InactiveUS20050100763A1Low surface roughnessSuppress fluctuationsIron oxides/hydroxidesBase layers for recording layersSurface roughnessComputational physics

A magnetic recording medium having a non-magnetic support, at least one primer layer on one surface of the support, a magnetic layer on the primer layer and a back coat layer on the other surface of the non-magnetic support, in which the support has a thickness of 2 to 5 μm, the surface roughness (Ra) of the support on its surface carrying the primer layer and the magnetic layer is from 2.5 nm to 20 nm, the thickness of the primer layer is 1.5 μm or less, and the primer layer contains 2 to 30% by weight, based on the weight of all inorganic powder in the primer layer, of alumina powder having a particle size of 0.01 μm to 0.1 μm.

Owner:FUJIFILM CORP

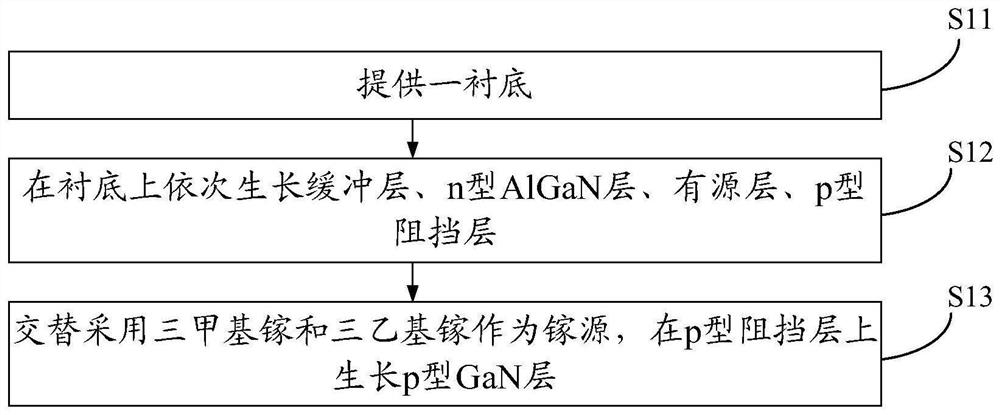

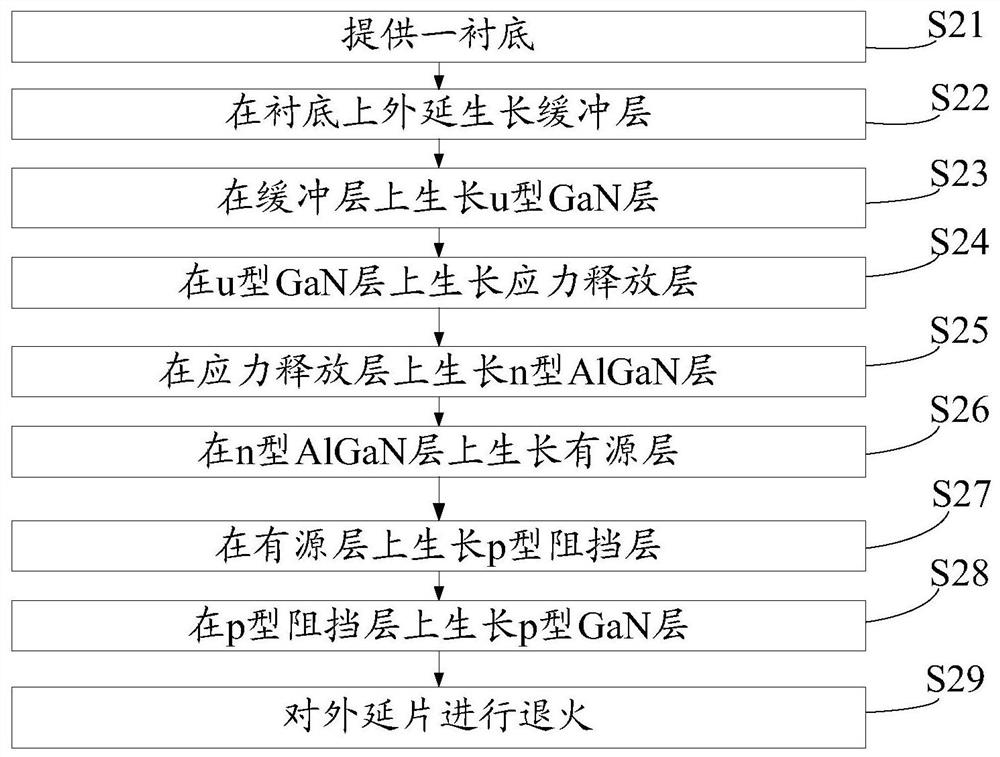

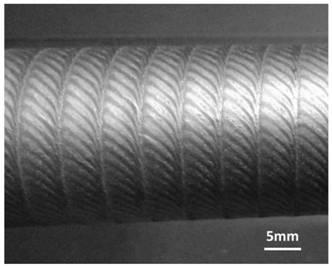

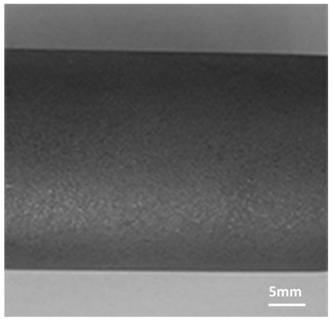

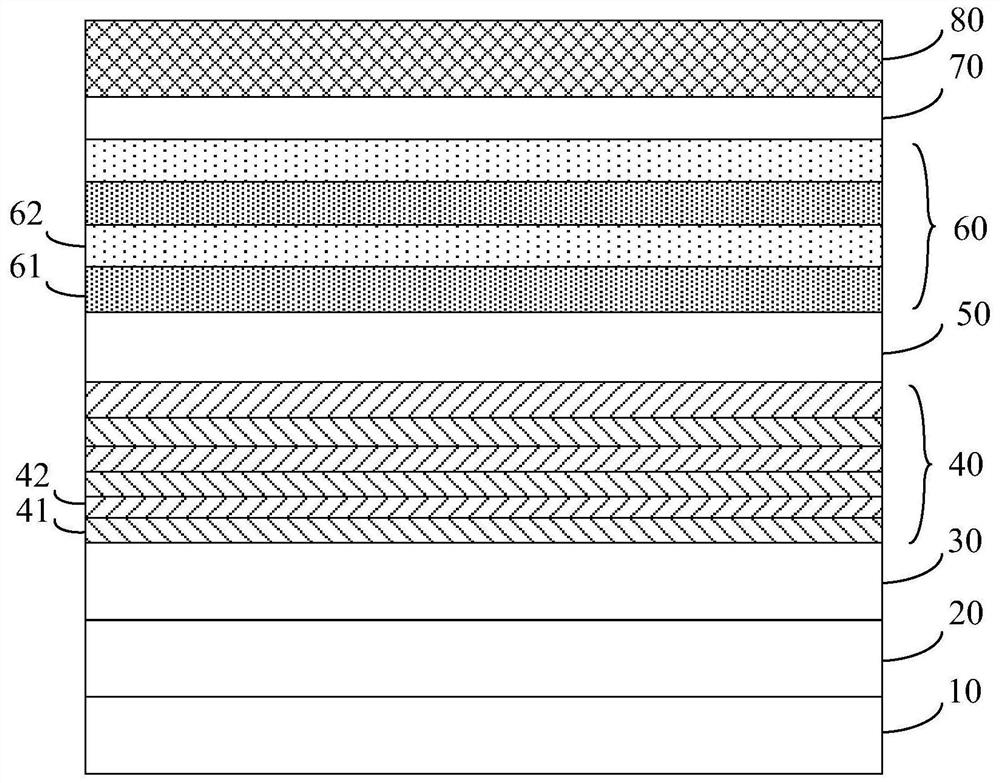

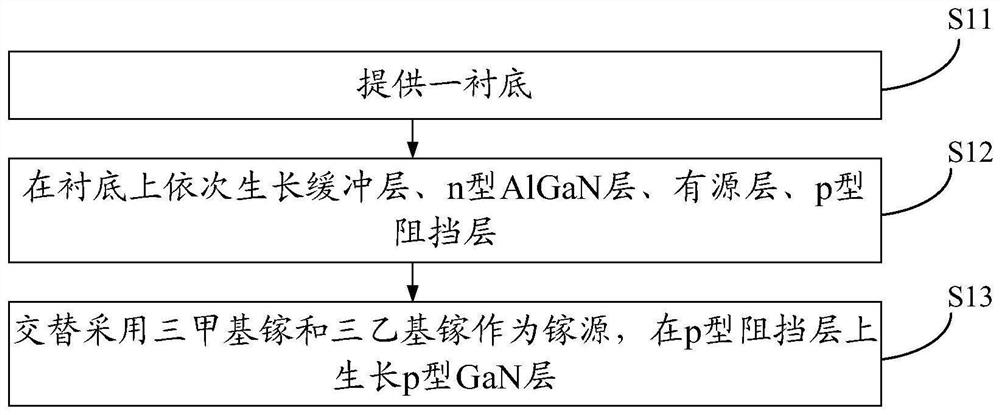

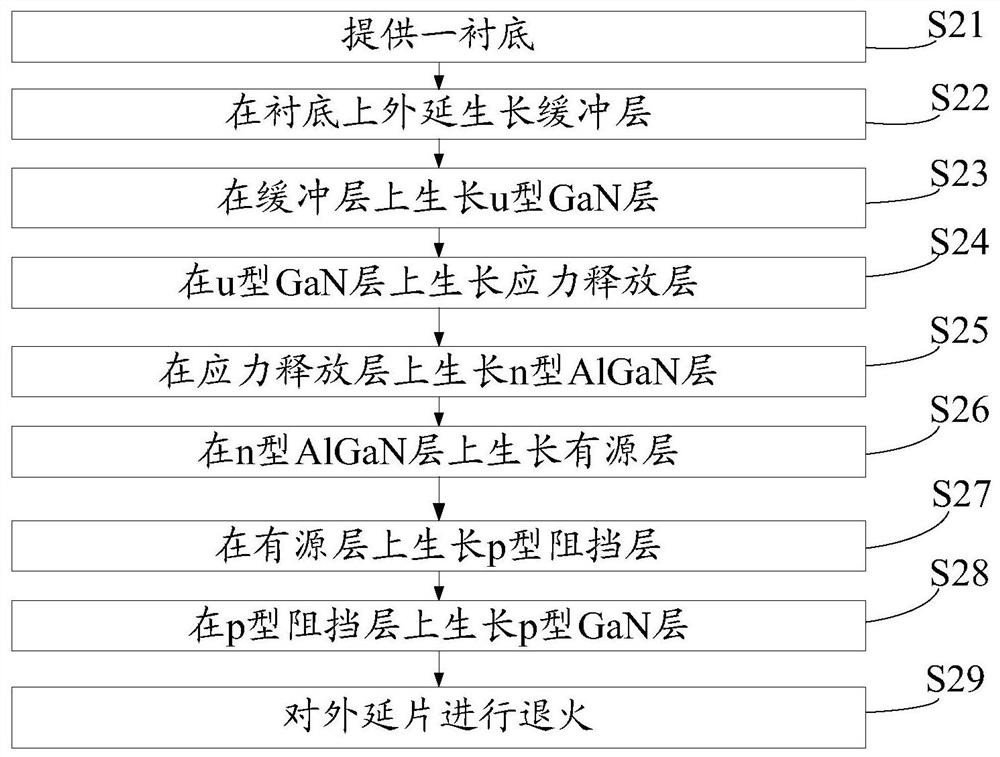

Epitaxial wafer of light emitting diode and manufacturing method thereof

ActiveCN112466999AConducive to total reflectionEasy to dopeSemiconductor devicesElectron holeUltraviolet lights

The invention discloses an epitaxial wafer of a light emitting diode and a manufacturing method thereof, and belongs to the technical field of photoelectrons. The manufacturing method comprises the following steps: providing a substrate; sequentially growing a buffer layer, an n-type AlGaN layer, an active layer and a p-type barrier layer on the substrate; and alternately adopting trimethyl gallium and triethyl gallium as a gallium source, and growing a p-type GaN layer on the p-type barrier layer. When trimethyl gallium serves as a gallium source for growth, the grown surface flatness is low,surface coarsening is facilitated, total reflection of light can be reduced, scattering of the light is improved, and when triethyl gallium serves as the gallium source for growth, a film formed through growth has high crystal quality, Mg doping is facilitated, the hole concentration can be improved, and the improvement of luminous efficiency is facilitated. By reducing the total reflection of light, improving the scattering of light and improving the concentration of holes, the light extraction efficiency of the deep ultraviolet light-emitting diode is improved on the whole.

Owner:HC SEMITEK ZHEJIANG CO LTD

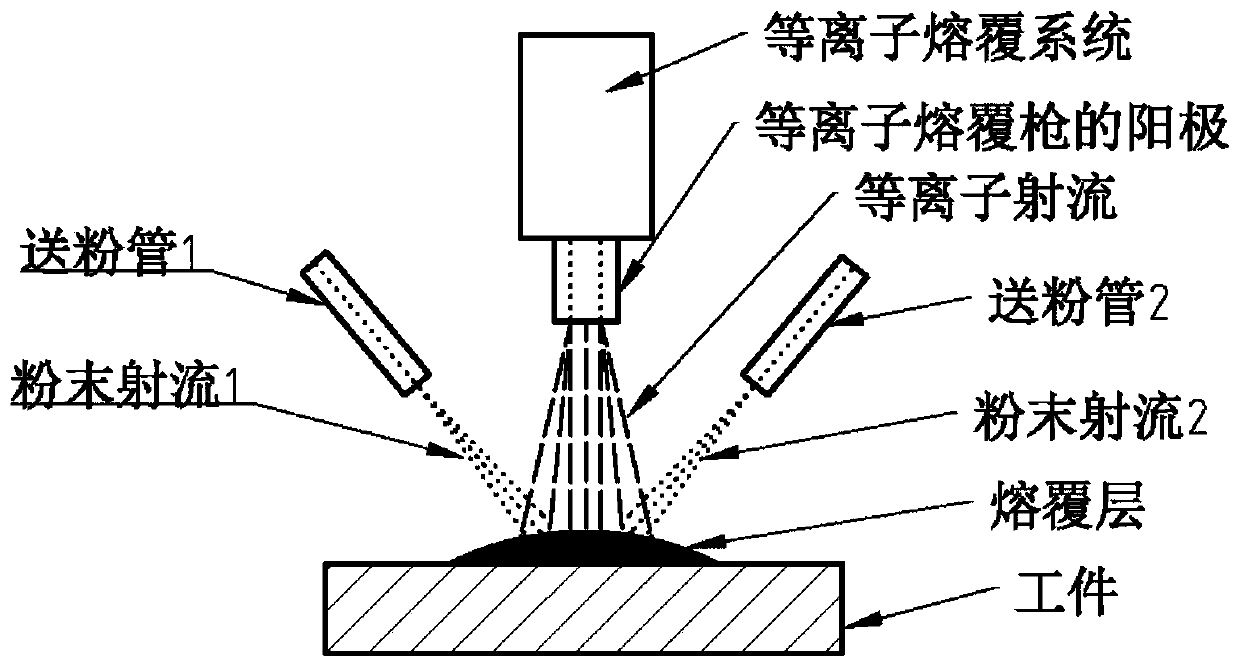

Conical powder feeding device for ultra-high-speed plasma cladding and ultra-high-speed plasma cladding method

InactiveCN111411355AHigh powder feeding rateIncrease productivityMetallic material coating processesPlasma jetUltra high speed

The invention provides a conical powder feeding device for ultra-high-speed plasma cladding and an ultra-high-speed plasma cladding method. The conical powder feeding device comprises a central cylinder, a water-cooled inner spacer, a powder guide spacer, and a protective air spacer and a water-cooled outer spacer which are assembled to the outside from a central shaft. The entrance of the centralcylinder is axially connected with the anode of a cladding gun of a plasma cladding system; the conical powder feeding device delivers the powder to a plasma jet uniformly at a high speed, under themechanical constraint of the outlet oblique conical surface of the powder guide space, a conical powder fluid with a pre-designed angle is formed, and finally the fluid focuses on the central shaft, so as to obtain the powder jet with high concentration, high speed, uniform distribution and small divergence, and under the ultra-high-speed plasma cladding condition of above 10-200m / min relative movement speed of the plasma cladding system and a workpiece, a cladding layer with thin thickness, uniform chemical composition, low surface roughness, low dilution rate and dense microstructure can beobtained.

Owner:TIANJIN UNIV

Method and loom for reducing defective rate of weaving

InactiveCN104947297BAvoid wrinklesEliminate wrinklesLoomsHeating/cooling textile fabricsYarnElectric machinery

The invention discloses a method for lowering the defective rate of woven fabric and a loom. According to the method, an infrared probe is used for scanning, a motor is controlled by a controller to stop suddenly, secondary tensioning is conducted on yarn through a tensioning wheel and a tensioning roller, and woven fabric is heated through a heating roller so that wrinkles can be eliminated. The loom manufactured through the method comprises a machine frame (1), wherein a yarn wheel (2) and the tensioning wheel (3) are arranged on the machine frame (1), a distributor plate (4) and a working table (5) are arranged below the tensioning wheel (3), knitting needles (6) and the tensioning roller (7) are arranged at one end of the working table (5), a limiting roller (8), the heating roller (9) and a guiding roller (10) are arranged at the other end of the working table (5), a sliding rail (11) is arranged above the working table (5), and the infrared probe (14) is connected to the sliding rail (11) through a sliding block (12) and a suspension frame (13). The method for lowering the defective rate of woven fabric and the loom can improve the quality of products and lower the defective rate and further have the advantages that the production efficiency is high and the surface smoothness is good.

Owner:HUZHOU JIESHENG GAOKE TEXTILE

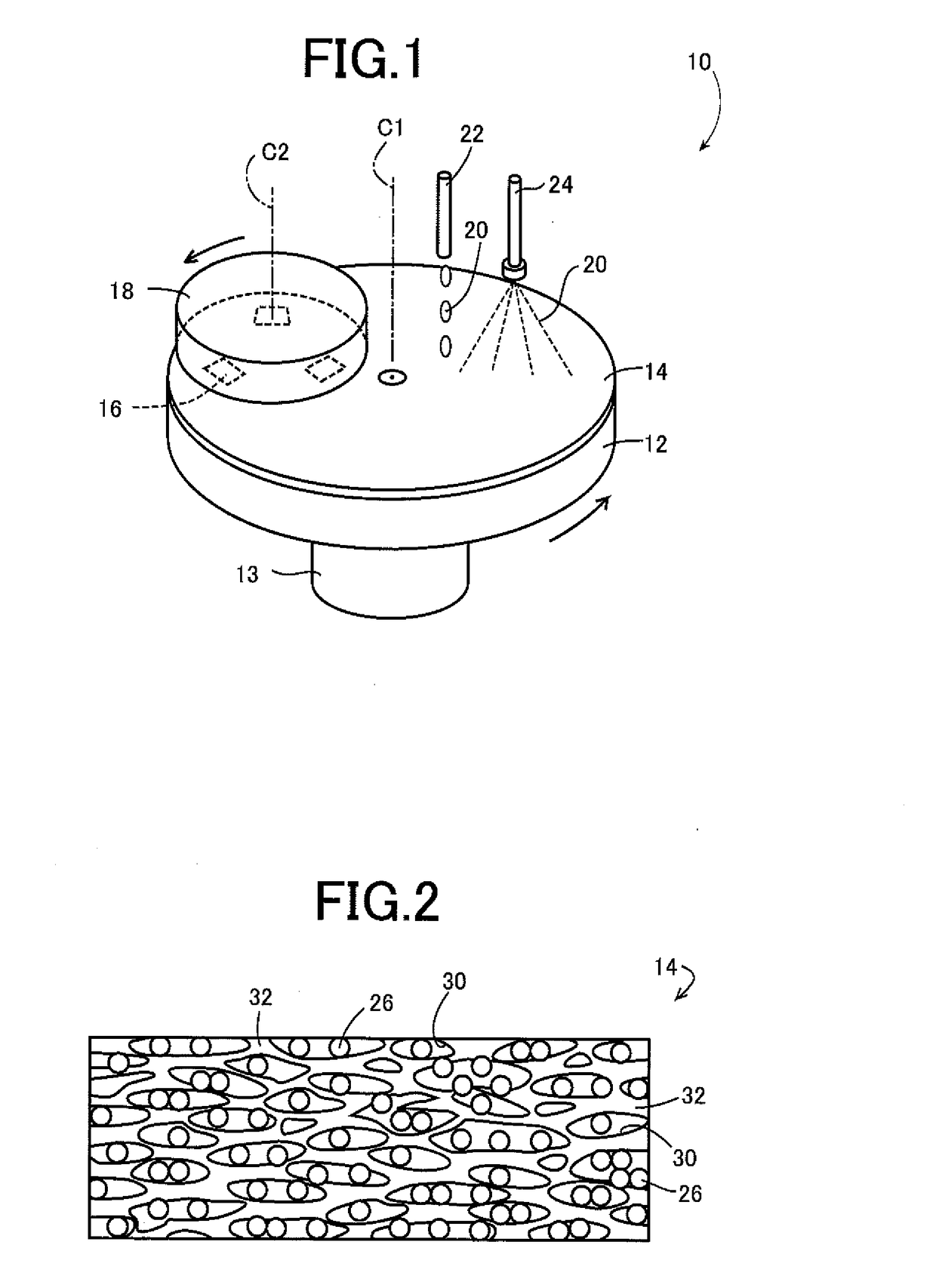

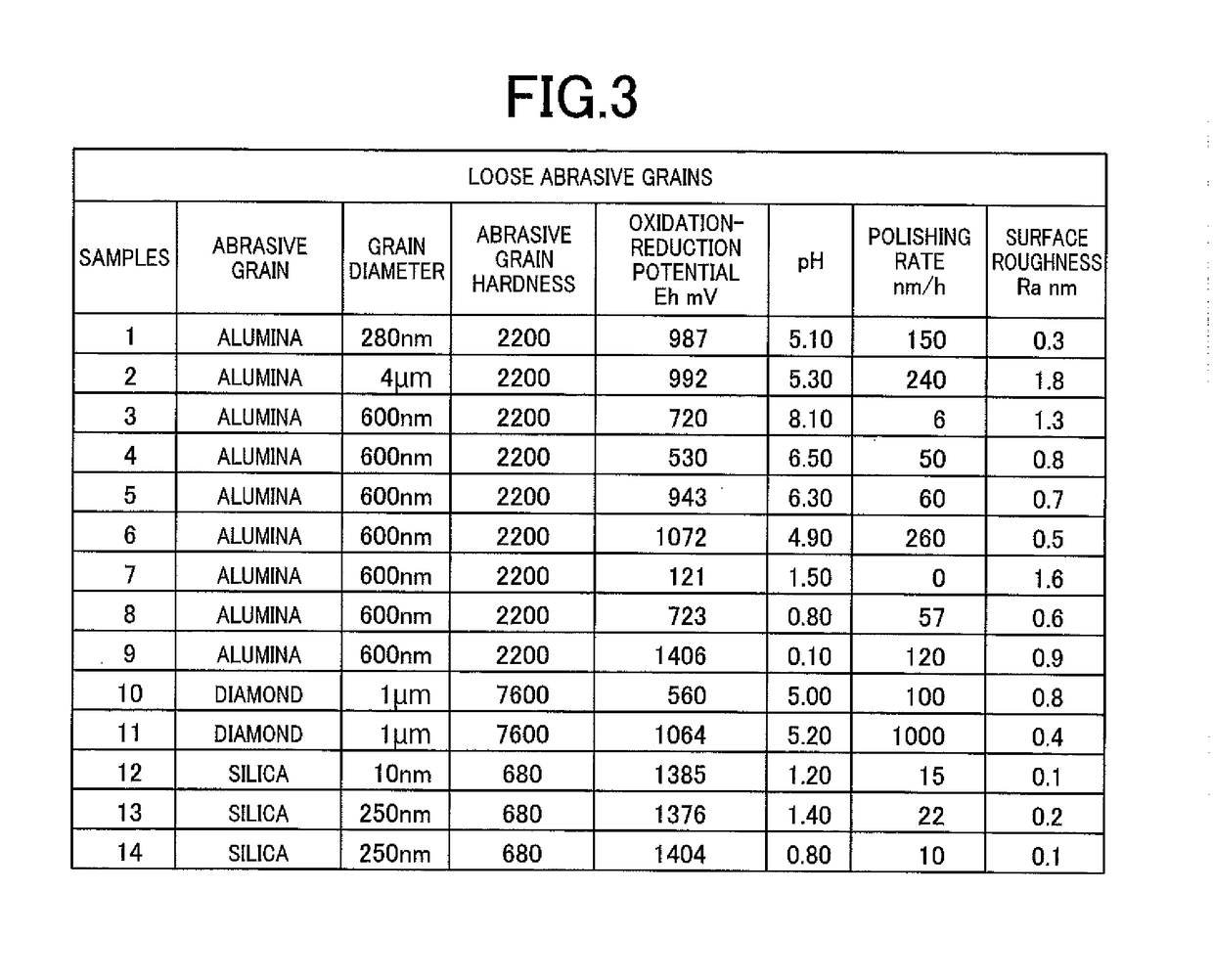

Method for polishing GAN single crystal material

ActiveUS20170100815A1High polishing efficiencyLow surface roughnessOther chemical processesSemiconductor/solid-state device manufacturingOxidation reductionSingle crystal

A polishing processing method using a CMP method for polishing a surface of a crystal material to be smooth by using a loose polishing abrasive grain type polishing pad in the presence of a polishing liquid and a plurality of polishing abrasive grains, in which the crystal material is a single crystal of GaN, and the polishing liquid is an oxidizing polishing liquid having an oxidation-reduction potential between Ehmin (determined by Eq. (1)) mV and Ehmax (determined by Eq. (2)) mV and pH between 0.1 and 6.5: Ehmin (mV)=−33.9 pH+750 . . . (1) Ehmax (mV)=−82.1 pH+1491 . . . (2).

Owner:NORITAKE CO LTD

Epitaxial wafer of light emitting diode and manufacturing method thereof

ActiveCN112466999BConducive to total reflectionEasy to dopeSemiconductor devicesTrimethylgalliumMaterials science

The disclosure discloses an epitaxial wafer of a light-emitting diode and a manufacturing method thereof, belonging to the field of optoelectronic technology. The manufacturing method includes: providing a substrate; sequentially growing a buffer layer, an n-type AlGaN layer, an active layer, and a p-type barrier layer on the substrate; alternately using trimethylgallium and triethylgallium as a gallium source, and at p A p-type GaN layer is grown on the barrier layer. When trimethylgallium is used as a gallium source for growth, the grown surface has low flatness, which is conducive to roughening the surface, which can reduce the total reflection of light and improve light scattering. When triethylgallium is used as a gallium source for growth, The film formed by growth has high crystal quality, which is beneficial to Mg doping, can increase the concentration of holes, and is beneficial to improving luminous efficiency. By reducing the total reflection of light, increasing the scattering of light and increasing the concentration of holes, the light extraction efficiency of the deep ultraviolet light-emitting diode is increased as a whole.

Owner:HC SEMITEK ZHEJIANG CO LTD

Surface flatness measuring device and surface flatness measuring method

ActiveUS10837764B2Easy to measureReduce measurement errorUsing optical meansNon-linear opticsContact laserMeasurement precision

A surface flatness measuring device and a surface flatness measuring method are disclosed. By non-contacting laser measurement, measurement precision can reach 0.001 mm so the measurement precision is high. A repetitive measurement error thereof can be controlled to be within 3 um so the measurement error is tiny, which prevent issues of low measurement precision and great measurement errors due to manual measurement in prior art. At the same time, the present invention measurement data can be automatically recorded and saved, measurement for a large batch of boards under measurement can be implemented, which prevents the issues of the conventional measurement data requiring manual recording and lacking capability of uploading the measurement data.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Flexible substrate-go-metal nanowire composite transparent conductive film and preparation method thereof

InactiveCN108806885BCoated evenlyUniform adhesionConductive layers on insulating-supportsCable/conductor manufactureSurface roughnessOptical transmittance

The invention provides a preparation method of a flexible substrate-GO-metal nanowire composite transparent conductive thin film. The preparation method comprises the steps of quartz glass substrate surface processing, metal nanowire solution preparation, vacuum filtering metal nanowire film, lamination, filtering film removal, GO processing, flexible substrate material solution preparation, flexible substrate film formation and quartz glass substrate stripping. The invention also provides the flexible substrate-GO-metal nanowire composite transparent conductive thin film prepared by the method. The composite transparent conductive thin film prepared by the method has the advantages of low surface peak valley roughness and surface average roughness, good conductivity, high optical transmittance, good mechanical flexibility and good thermal stability, the metal nanowire is firmly attached onto the flexible substrate, the application demand of a device can be achieved, particularly, therequirement of a flexible thin film electronic device on electrode surface roughness can be met, and the reliability and the stability of the metal nanowire electrode in application of the thin film electronic device are improved.

Owner:CHONGQING UNIV

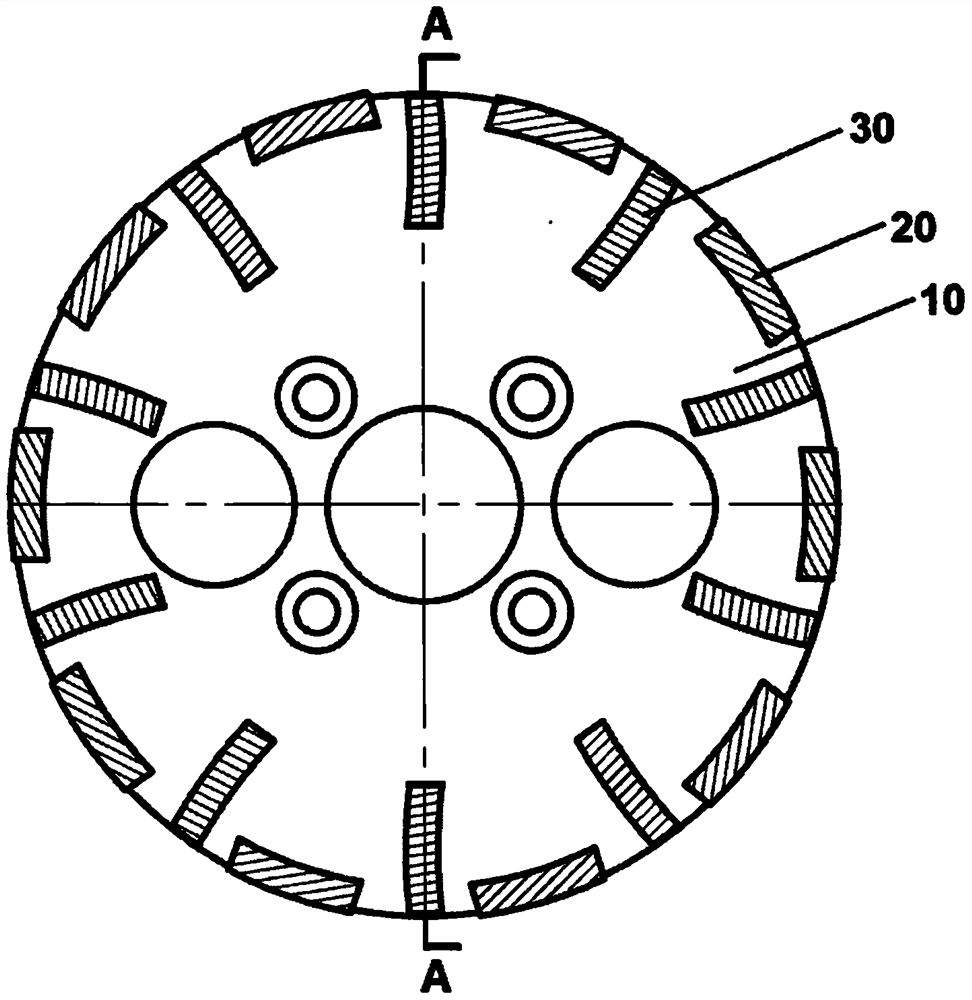

Diamond abrasive tool head and preparation method thereof

ActiveCN110026913BImprove sharpnessImprove stabilityAbrasion apparatusGrinding devicesSurface roughnessGraphite particle

Owner:江苏友美工具有限公司

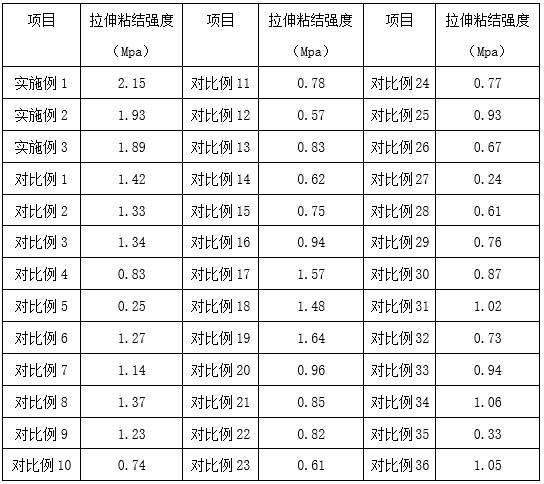

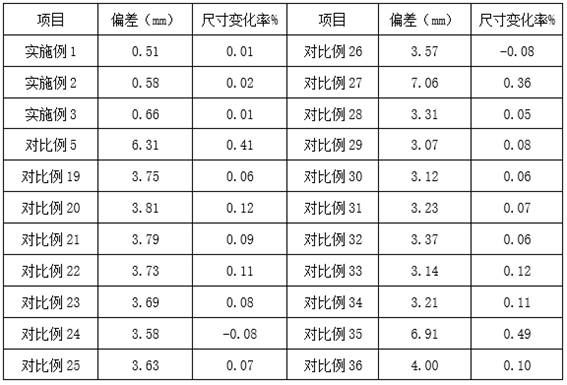

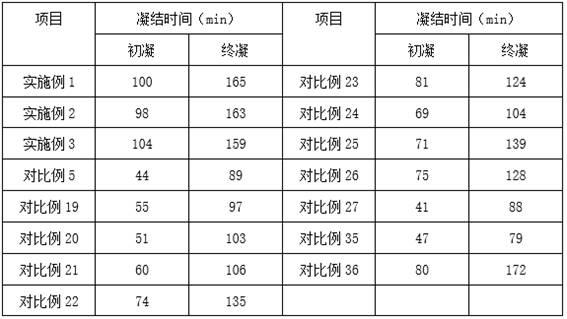

Dry-mixed self-leveling mortar

The invention provides dry-mixed self-leveling mortar and a preparation method thereof. The glass sand in the machine-made sand is fine sand made of waste glass products, resource waste is reduced, the surface of the glass sand is modified and protected, and the glass sand has good workability in mortar. Lithium-based bentonite and sepiolite powder in the surface modifier have certain expansibility, so that the shrinkage rate of the mortar can be reduced. And the modified retarder delays the coagulation time and reduces the shrinkage phenomenon in the coagulation process. In the mortar, the effect of bonding with a base plane is also achieved, and the excellent bonding performance is achieved. A modified leveling agent is added, so that the active ingredients in the mortar are effectively prevented from being flocculated and agglomerated, the mortar can be self-leveled, meanwhile, micro-pores on the surface are sealed, the surface of the mortar is not easily polluted when encountering oil stains, and the anti-pollution capability of the surface of the mortar is improved.

Owner:龙南县彩艺装饰材料厂

Intelligent thickness detection device of gear machining equipment and operation method

PendingCN114433961ALow surface roughnessMeasurement/indication equipmentsGear-cutting machinesGear wheelSurface flatness

The invention provides an intelligent thickness detection device of gear machining equipment and an operation method, and belongs to the technical field of gear manufacturing equipment. The problem that the thickness of an existing gear cannot be accurately calibrated under the high-precision requirement is solved. The intelligent thickness detection device of the gear machining equipment comprises a thickness detection part used for detecting whether the distance between the end faces of the two sides of a gear changes or not and two conveying parts. The two conveying parts are located at the front end and the rear end of the thickness detection part respectively and play a role in vertically aligning and conveying the gears into the thickness detection part and a role in conveying the gears subjected to thickness detection out of the thickness detection part respectively. Compared with the prior art, the intelligent thickness detection device can detect whether the thickness of the gear meets the standard or not in a full-coverage mode, and the gear with the low surface flatness is further screened out.

Owner:ZHEJIANG DONGFENG GEAR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com