Diamond abrasive tool head and preparation method thereof

A technology of diamond and diamond particles, used in metal processing equipment, grinding/polishing equipment, abrasives, etc., can solve problems such as failure to meet construction requirements, increase labor costs, increase abrasive tool consumption, etc., achieve good sharpness, reduce Surface flatness, the effect of reducing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

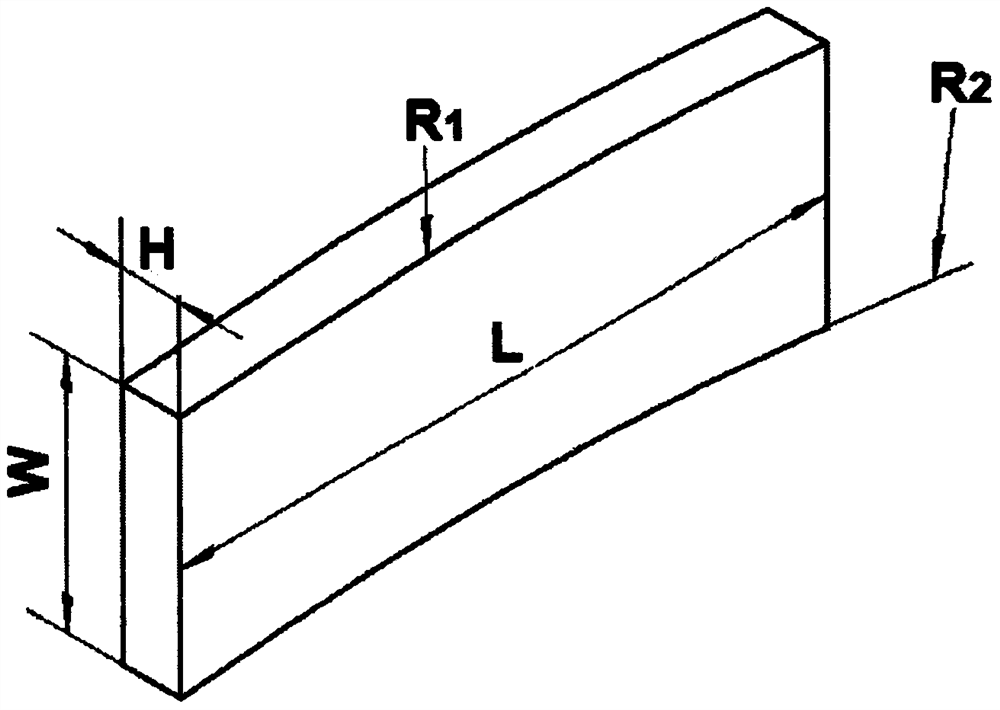

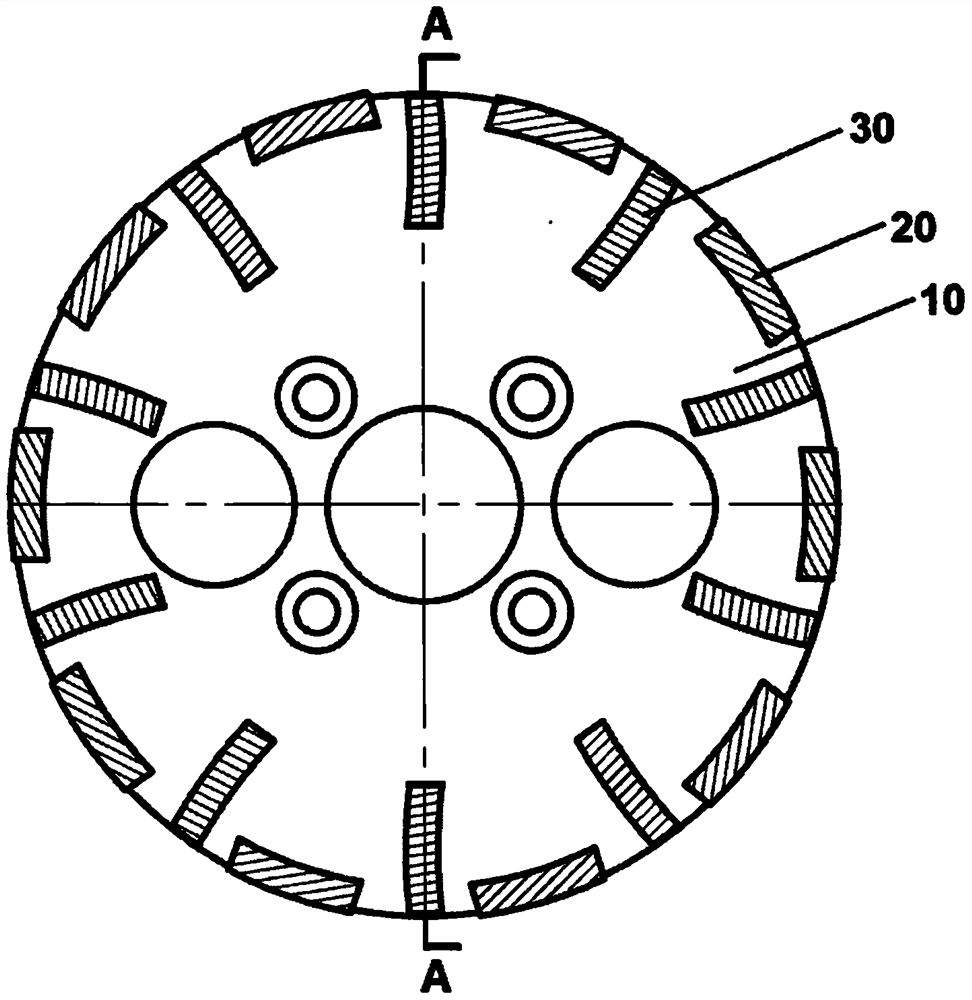

[0025] In the present invention, the abrasive tool head is formed by cold-pressing and hot-pressing sintering from a mixed powder composed of a metal bond containing tungsten carbide, diamond particles, graphite particles and metal halide additives. As an example, the preparation method may include the following steps: (1) preparing a metal bond comprising tungsten carbide, diamond particles, graphite particles and metal halide additives, and mixing to obtain a mixed powder; (2) mixing the mixed powder in Cold pressing in the mold to obtain the cutter head body; (3) hot pressing and sintering the cutter head body, the hot pressing sintering temperature is 780-850°C, and the pressure is 200-300kg / cm 2 , and the hot-press sintering was carried out in an oxygen-poor atmosphere. The oxygen-depleted atmosphere refers to an atmosphere containing 1-20v% air and the rest nitrogen. Hot press sintering is carried out in an oxygen-poor atmosphere. On the one hand, part of the graphite p...

Embodiment 1

[0031]Take 3.2kg of copper powder, 3.2kg of iron, 0.8kg of nickel, 2kg of tungsten carbide, and 0.8kg of tin, put them into the mixing tank and mix for 30 minutes, then add 0.08kg of graphite particles, CoCl 2 0.02kg, diamond 0.15kg, continue mixing for 2 hours, pour the powder into the mold for cold pressing, hot pressing sintering, hot pressing sintering temperature is 850°C, pressure 220kg / cm 2 , the holding time is 5 minutes, the sintering atmosphere includes 10v% air, and the balance is N 2 .

Embodiment 2

[0033] Take 2.5kg of copper powder, 4.1kg of iron, 1.5kg of nickel, 1.5kg of tungsten carbide, and 0.4kg of tin, put them into the mixing tank and mix for 30 minutes, then add 0.08kg of graphite particles, LaF 3 0.03kg, diamond 0.15kg, continue mixing for 2 hours, pour the powder into the mold for cold pressing, hot pressing sintering, hot pressing sintering temperature is 850°C, pressure 220kg / cm 2 , the holding time is 5 minutes, the sintering atmosphere includes 20v% air, and the balance is N 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com