Method for controlling planeness during chemically mechanical polishing for ULSI multiple-layered copper wiring

A technology of chemical mechanics and control methods, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, polishing compositions containing abrasives, etc., can solve problems such as poor flatness and edge collapse, and achieve high flatness and reduce The problem of edge collapse, the effect of good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of polishing liquid: choose 25L silica sol with a particle size of 15nm as the abrasive, the concentration is 20%, and the ratio with deionized water is 1:1; choose FA / O chelating agent to adjust the pH value to 10; choose FA / OI type The active agent is used as a surfactant, the content is 10ml / l; select H 2 o 2 It is an oxidant with an oxidant content of 10ml / l. The polishing process conditions are: flow rate 1L / min, temperature 20°C, speed 60rpm / min, pressure 100g / cm 2 .

[0030] The polishing machine used in the experiment is C6382 type, and the polishing cloth is the fine throwing cloth of Taiwan Weiying Company.

Embodiment 2

[0032] Preparation of polishing solution: choose 35L silica sol with a particle size of 20nm as abrasive, the concentration is 50%, and the ratio of deionized water is 1:3; choose FA / O chelating agent to adjust the pH value to 13; choose JFC as surface active agent, the content is 100ml / l; choose H 2 o 2 It is an oxidant with an oxidant content of 10ml / l. The polishing process conditions are: flow rate 5L / min, temperature 30°C, speed 120rpm / min, pressure 250g / cm 2 .

Embodiment 3

[0034]Preparation of polishing liquid: choose 30L silica sol with a particle size of 15nm as abrasive, the concentration is 20%, and the ratio of deionized water is 1:2; select FA / O chelating agent to adjust the pH value to 12.5; select FA / O activity A kind of surfactant, JFC, fatty alcohol polyoxyethylene ether, polyoxyethylene alkylamine, alkyl alcohol amide, the content is 50ml / l; choose H 2 o 2 It is an oxidizing agent with an oxidizing agent content of 20ml / l. The polishing process conditions are: flow rate 3L / min, temperature 25°C, speed 90rpm / min, pressure 200g / cm 2 .

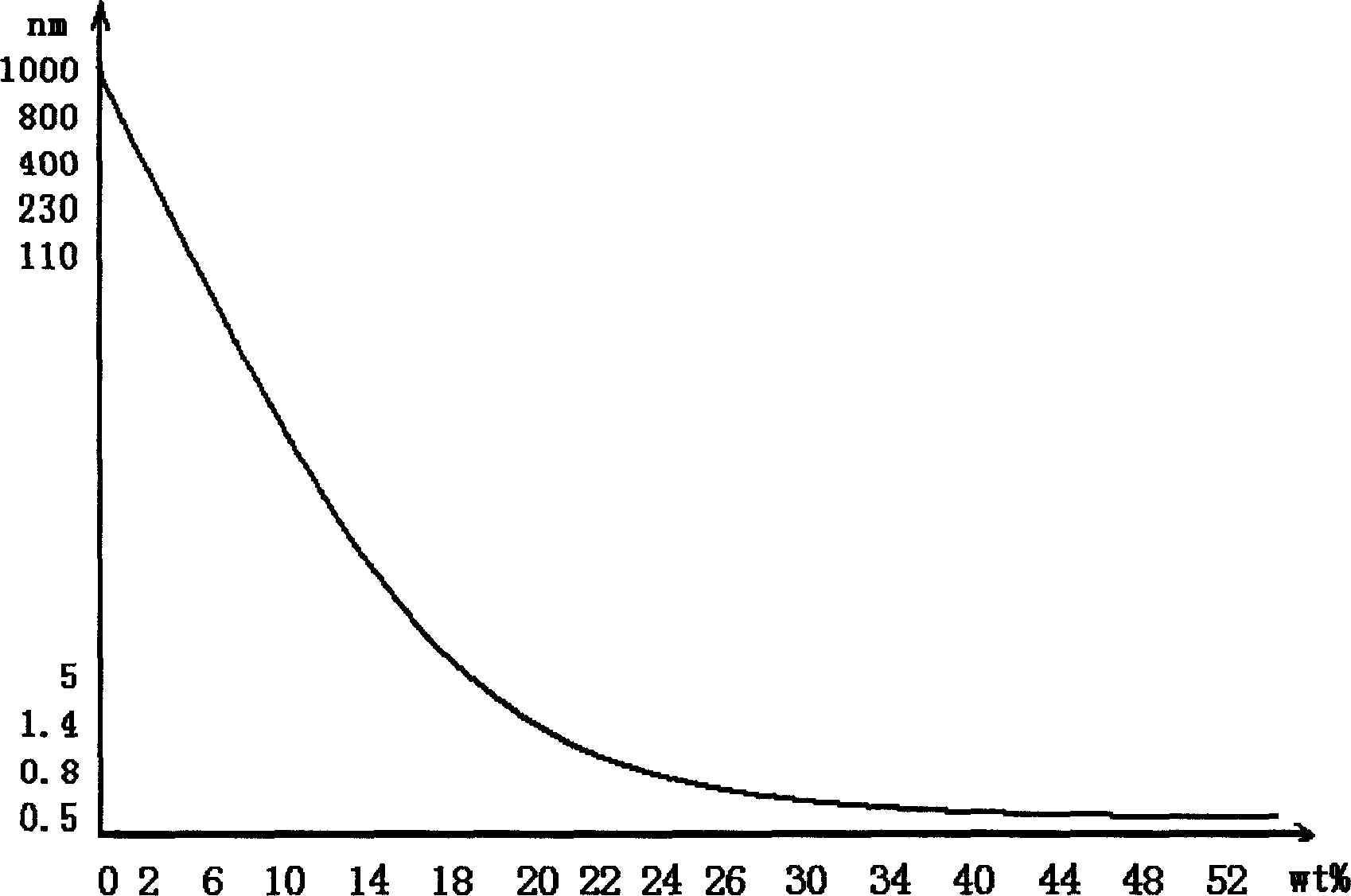

[0035] After measurement, the flatness of the surface of the copper wire after polishing by the method of the present invention is less than 0.5nm. see figure 1 , when the abrasive concentration>20wt%, the number of sags decreased significantly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com