Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Little environmental hazard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

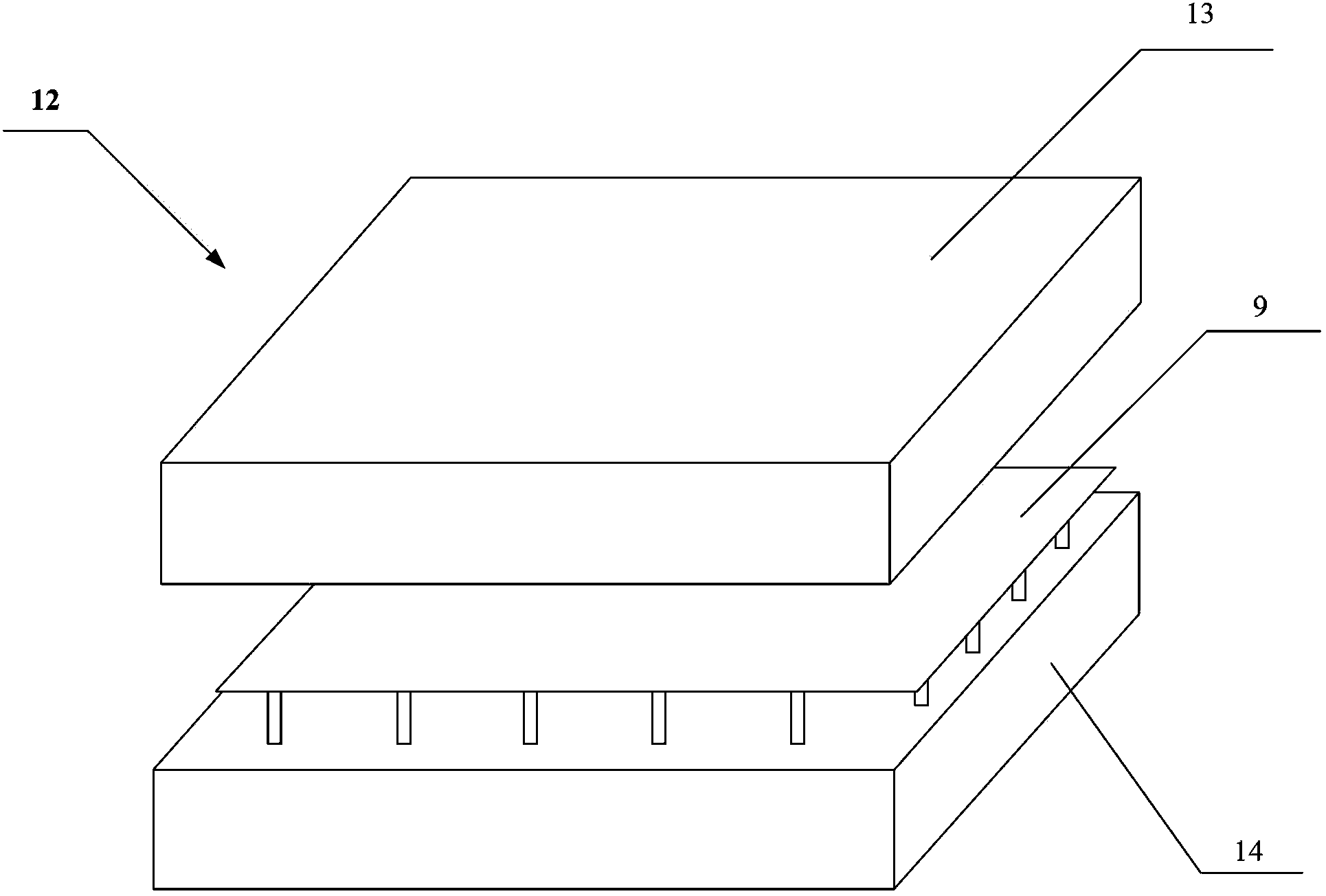

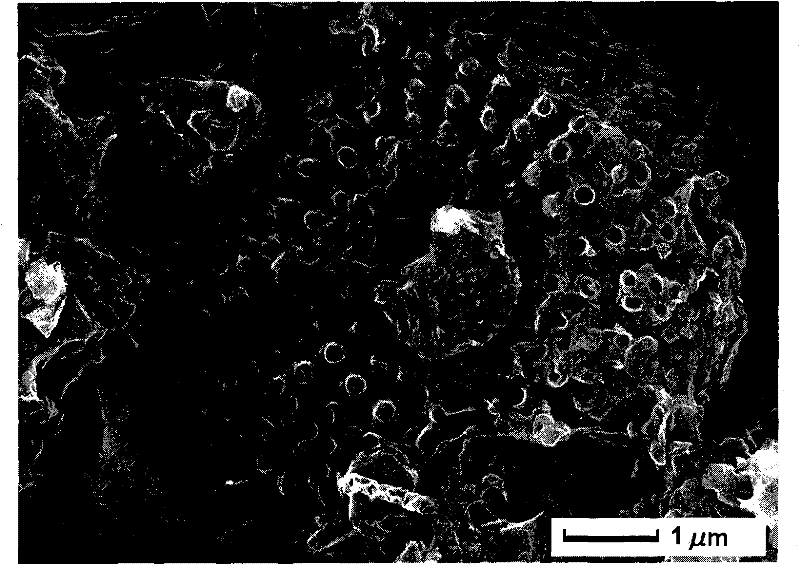

Method for preparing porous carbon and white carbon black by using diatomite

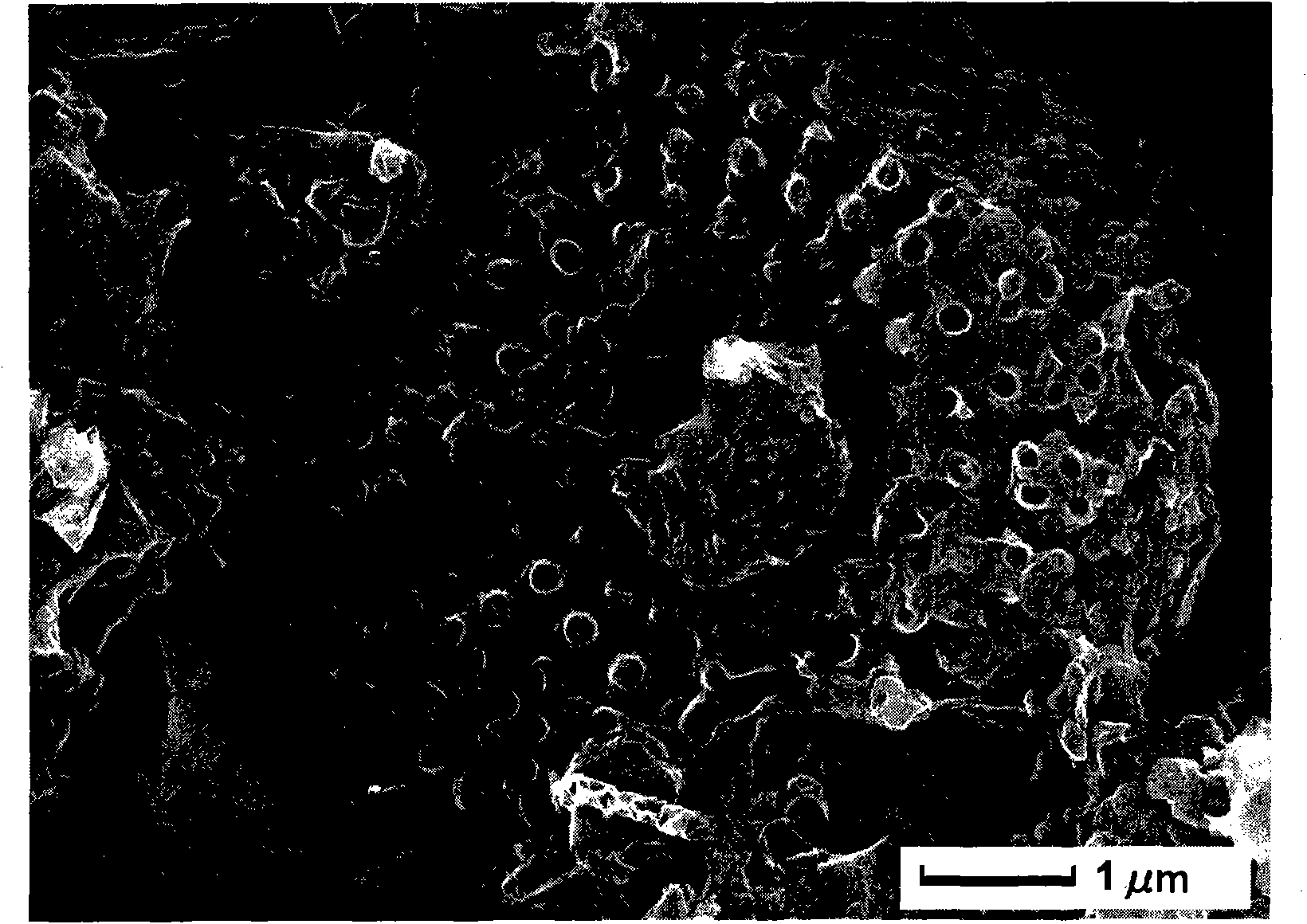

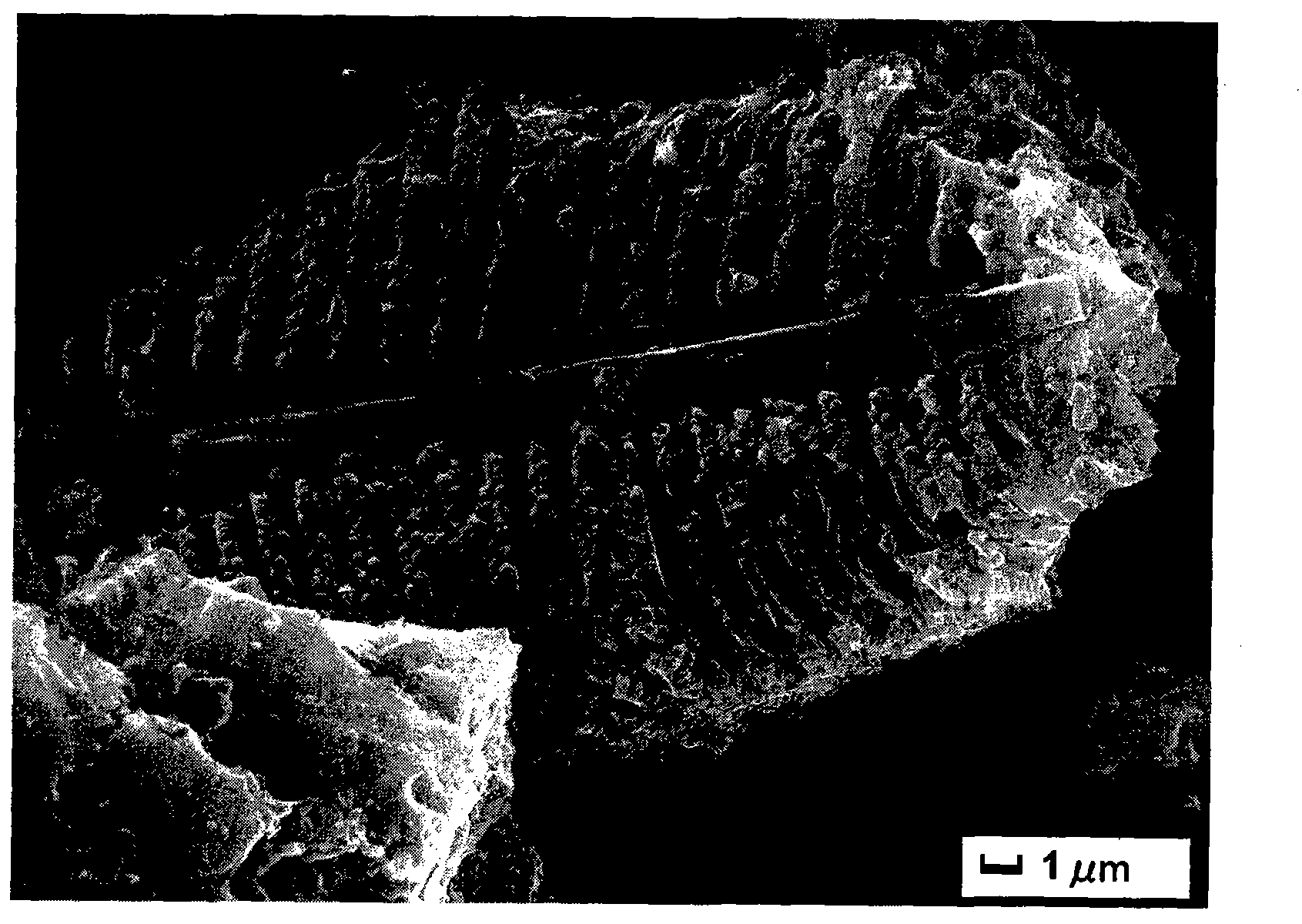

The invention relates to a method for preparing porous carbon and white carbon black by using diatomite. The method comprises the following steps of: catalyzing a carbon source with the solid acid site of the diatomite serving as a template as well as a catalyst to polymerize the carbon source and generate the porous carbon having a diatom shell shape; and removing the template with strong alkali and treating obtained waste liquor to generate the white carbon black having a large specific surface area. The obtained porous carbon has a multi-stage pore canal structure and a specific surface area of over 250 m<2> / g and is widely used in fields such as adsorption, separation, loading, capacitor preparation and the like. The obtained white carbon black has a specific surface area of over 400 m<2> / g and can be used in fields such as reinforcing agents, diluents, cementing agents, fillers, carriers and the like. The method has the advantages of simple process, low cost, light pollution, low energy consumption and the like.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

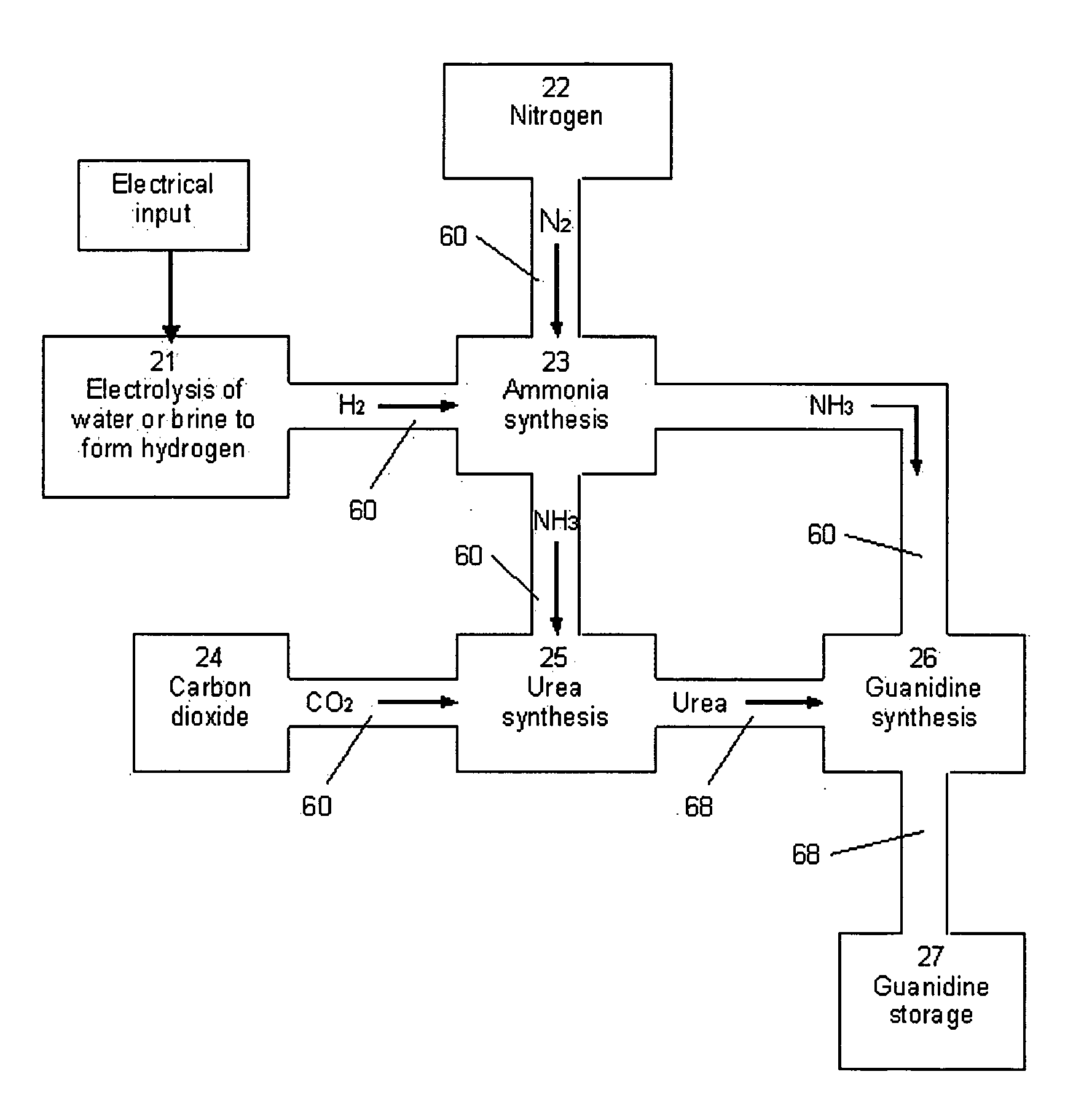

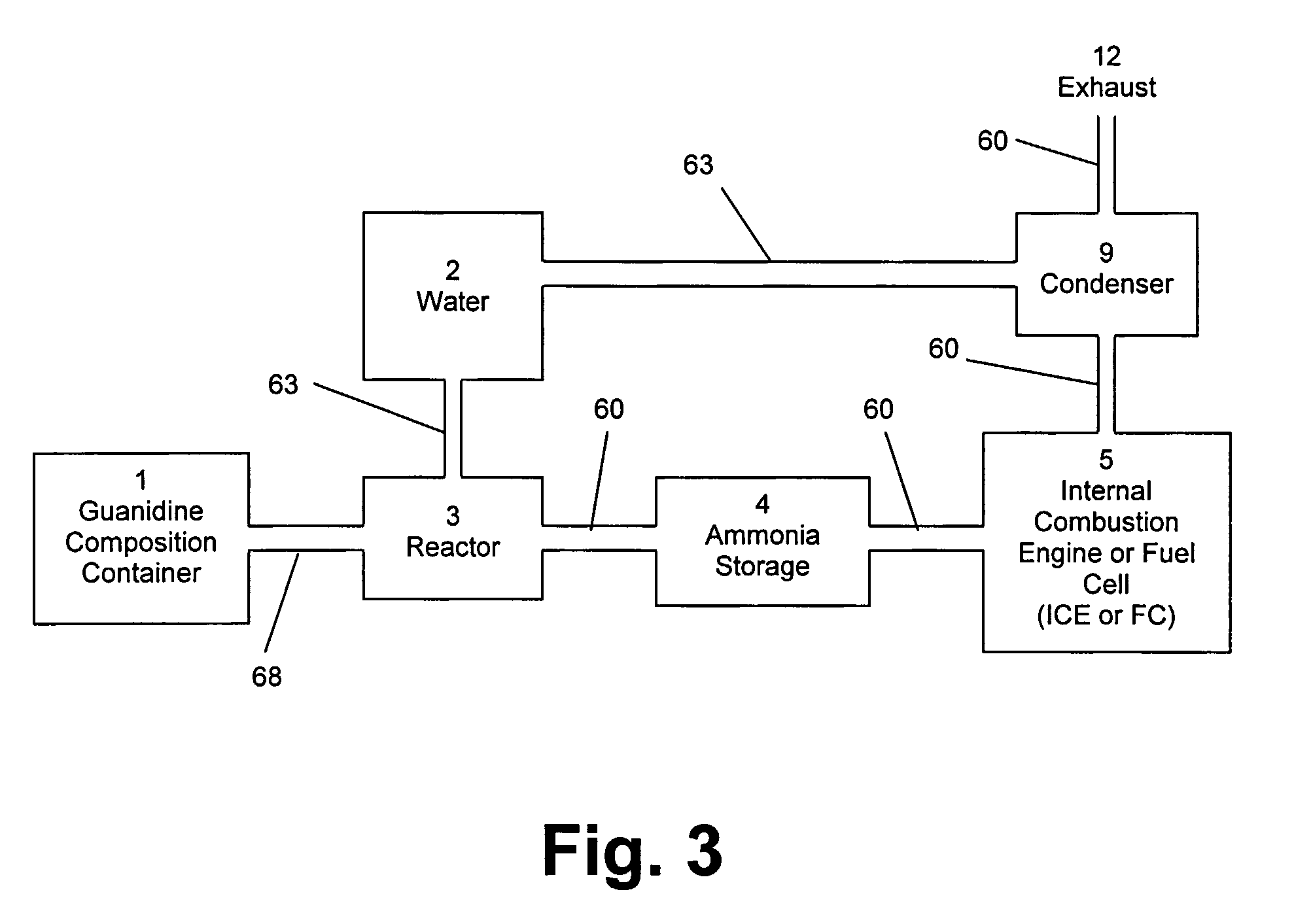

Guanidine Based Composition and System for Same

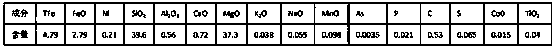

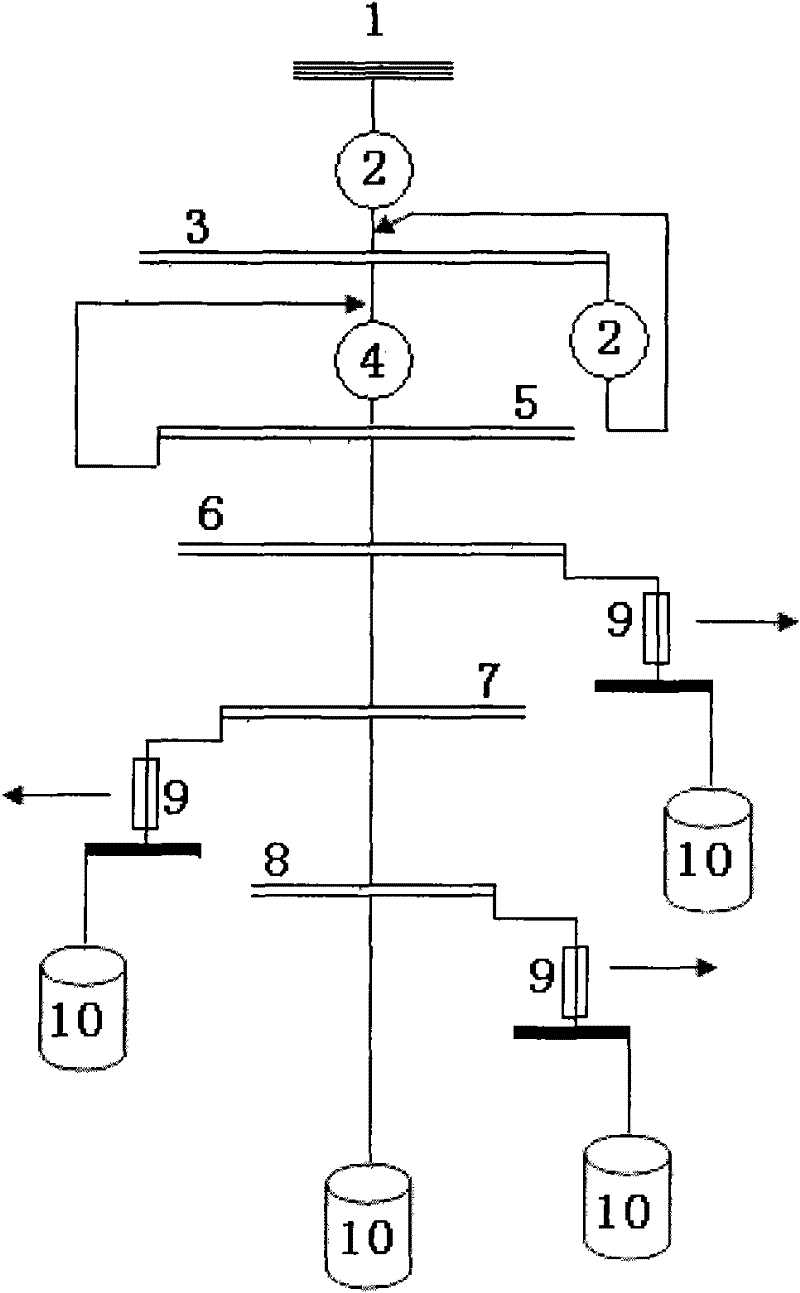

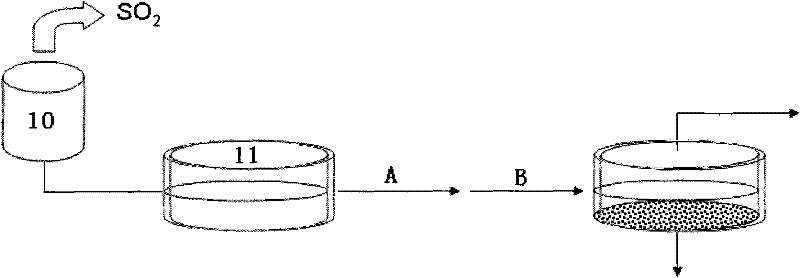

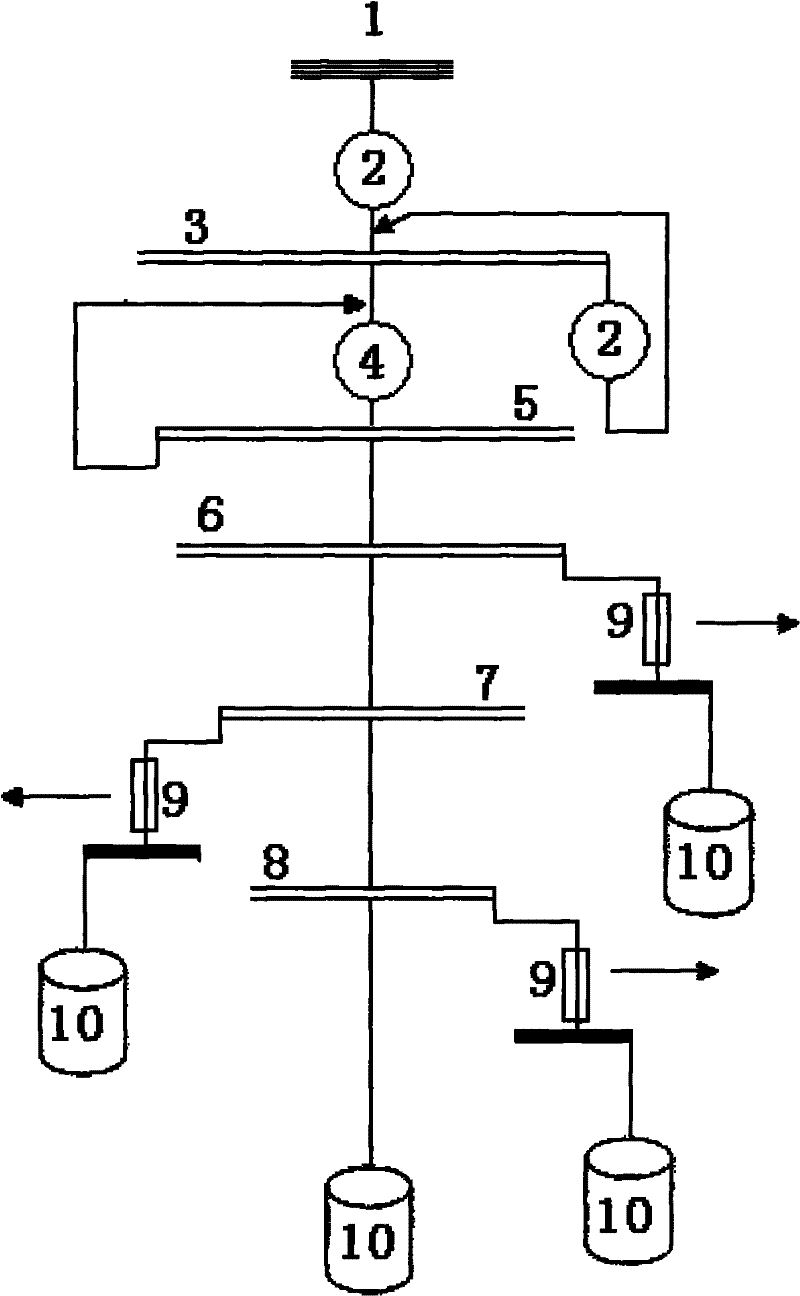

InactiveUS20080286165A1High specific energyIncrease energy densityOrganic chemistryOrganic compound preparationBuffer tankNitrogen

A method and apparatus for generating energy from a composition containing guanidine and a method for providing the composition containing guanidine. The apparatus includes a container such as tank (1) for providing the composition, and a container such as tank (2) for providing water. The composition is delivered from tank (1) to a container such as reactor (3) for reacting the guadinine composition with water, supplied from tank (2), to form ammonia. The apparatus may also include buffer tank (4) for storing the ammonia produced by the reactor. The ammonia produced from the reactor of the guadinine composition with water is delivered from the buffer tank (4) to a container such as chamber (5) for oxidizing ammonia to form water and nitrogen generating energy

Owner:GRAUPNER ROBERT K +2

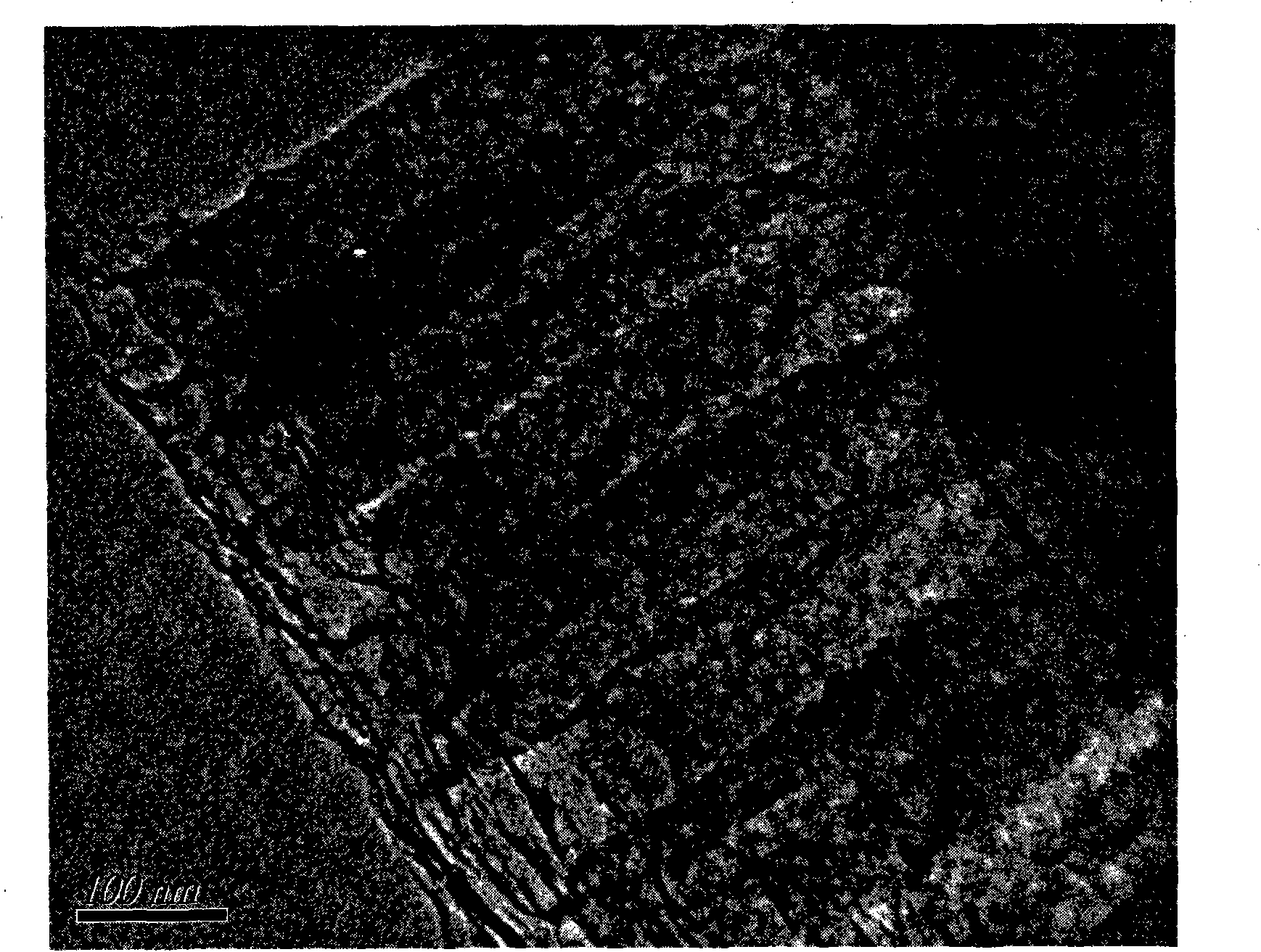

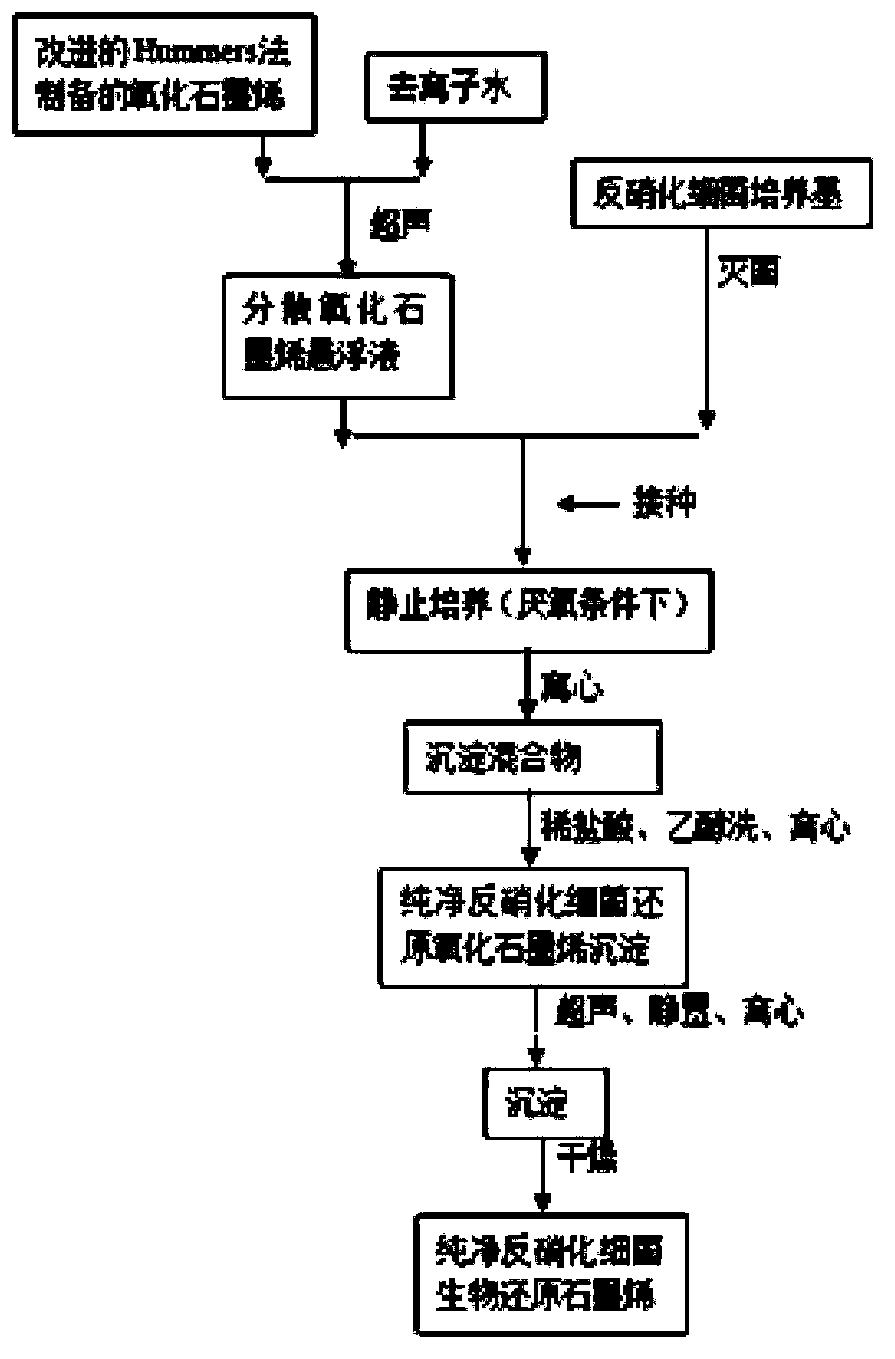

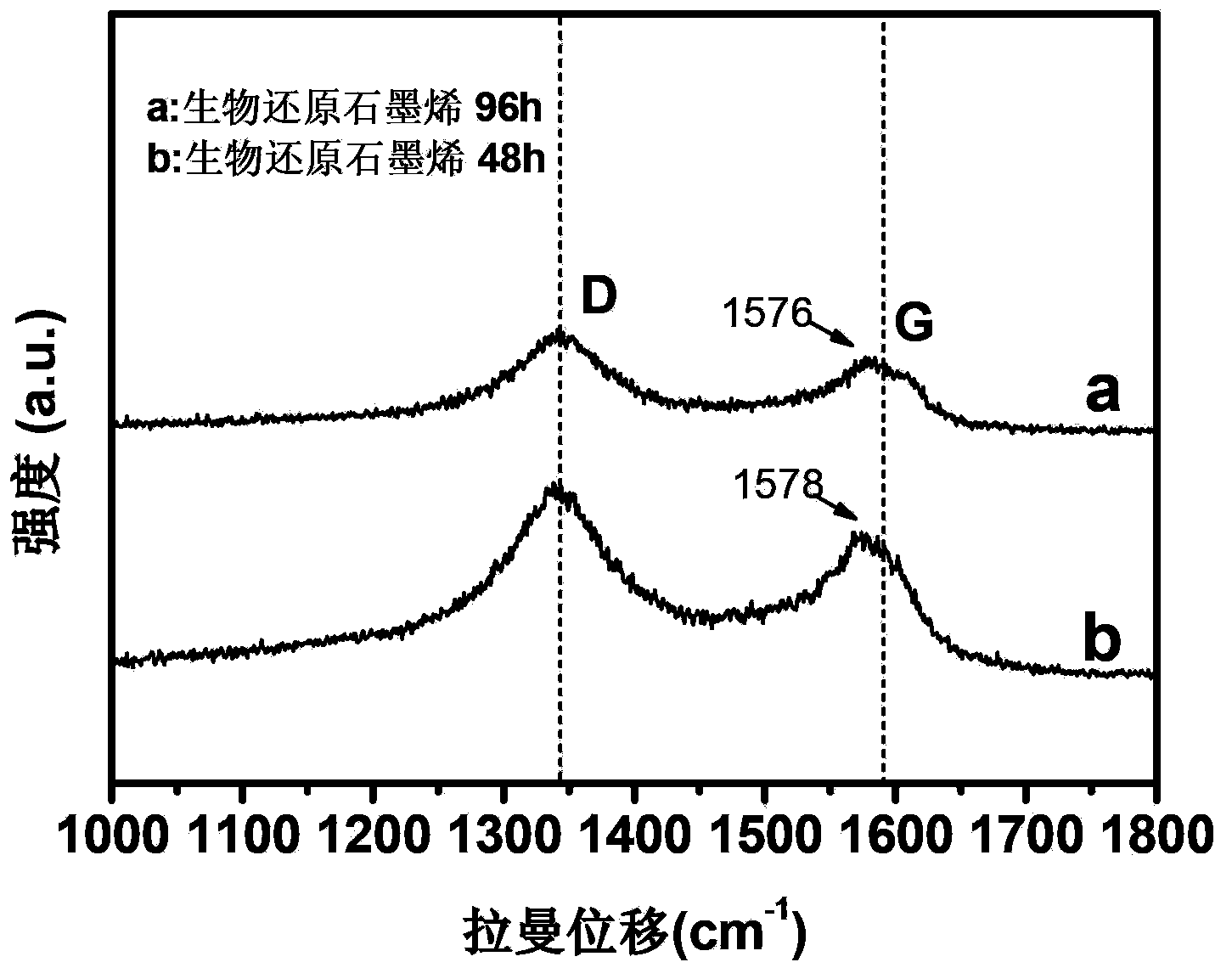

Microbial reduction of graphene oxide and preparation method for graphene

The invention discloses a microbial reduction of graphene oxide and a preparation method for graphene. The method comprises the following steps: dispersing graphene oxide in water to form a graphene oxide suspending solution with better dispersion; mixing denitrifying bacteria culture medium being subjected to sterilization and cooling with the graphene oxide suspending solution; inoculating a seed solution; culturing in still standing state in anaerobic condition for a few days, removing the oxygen-containing functional group of the dispersed graphene oxide with the effect of denitrifying bacteria to form graphene; after finishing the culturing, using hydrochloric acid, alcohol, and deionized water to remove bacterial cells, metabolite, and other ions produced in the reduction process, using water to cleaning until the water is neutral finally, and drying to obtain pure graphene. The method using microorganism denitrifying bacteria capable of reducing high valence state inorganic nitrogen and carbon as the microbial strain to conduct microbial reduction on graphene oxide; compared with similar reducing bacteria of Shewanella, the denitrifying bacteria has the advantages that the environmental safety is good, the reaction condition is mild and controllable, the medium component is simple, and the graphene obtained by preparation has less defects and layers.

Owner:NANJING UNIV OF SCI & TECH

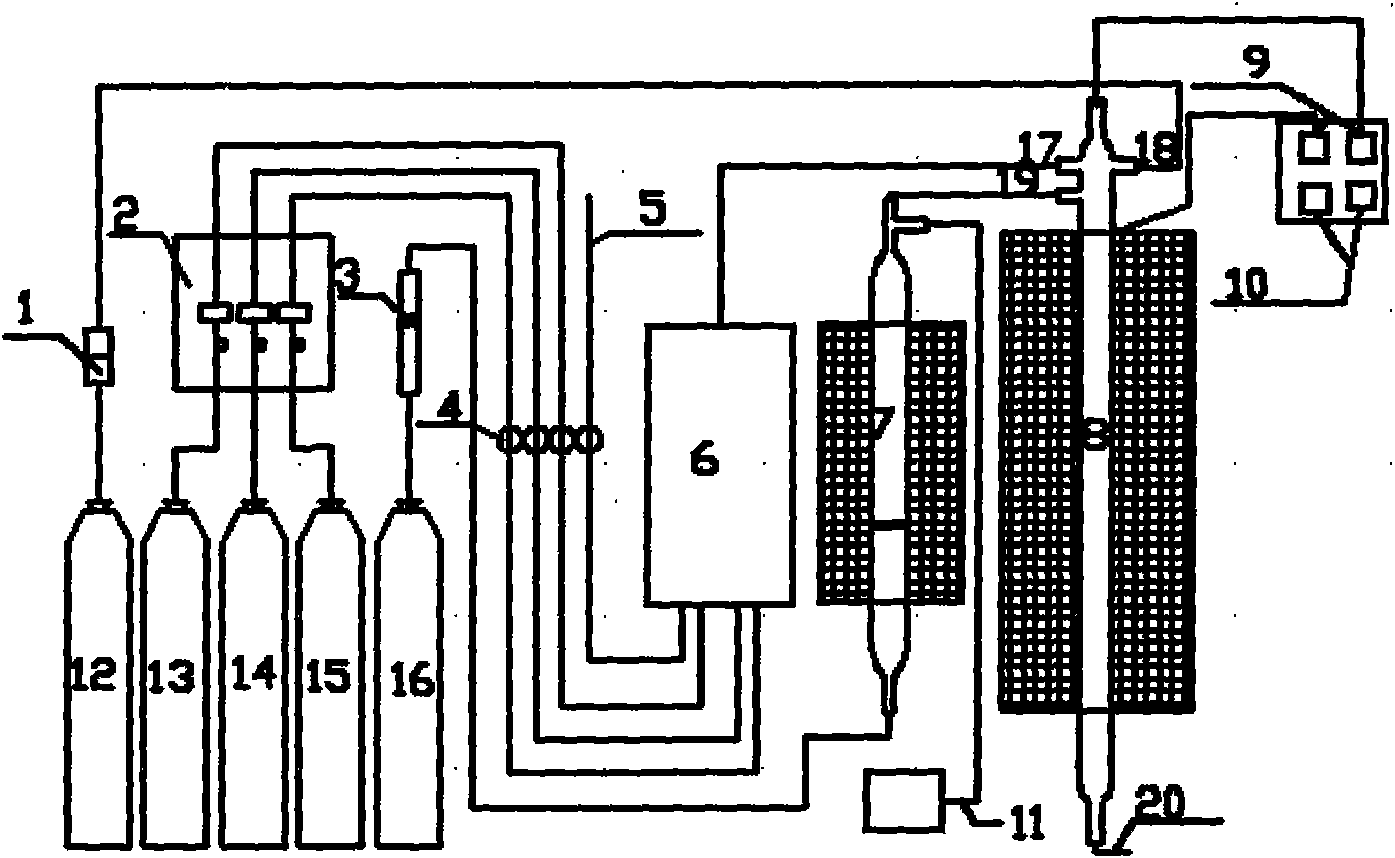

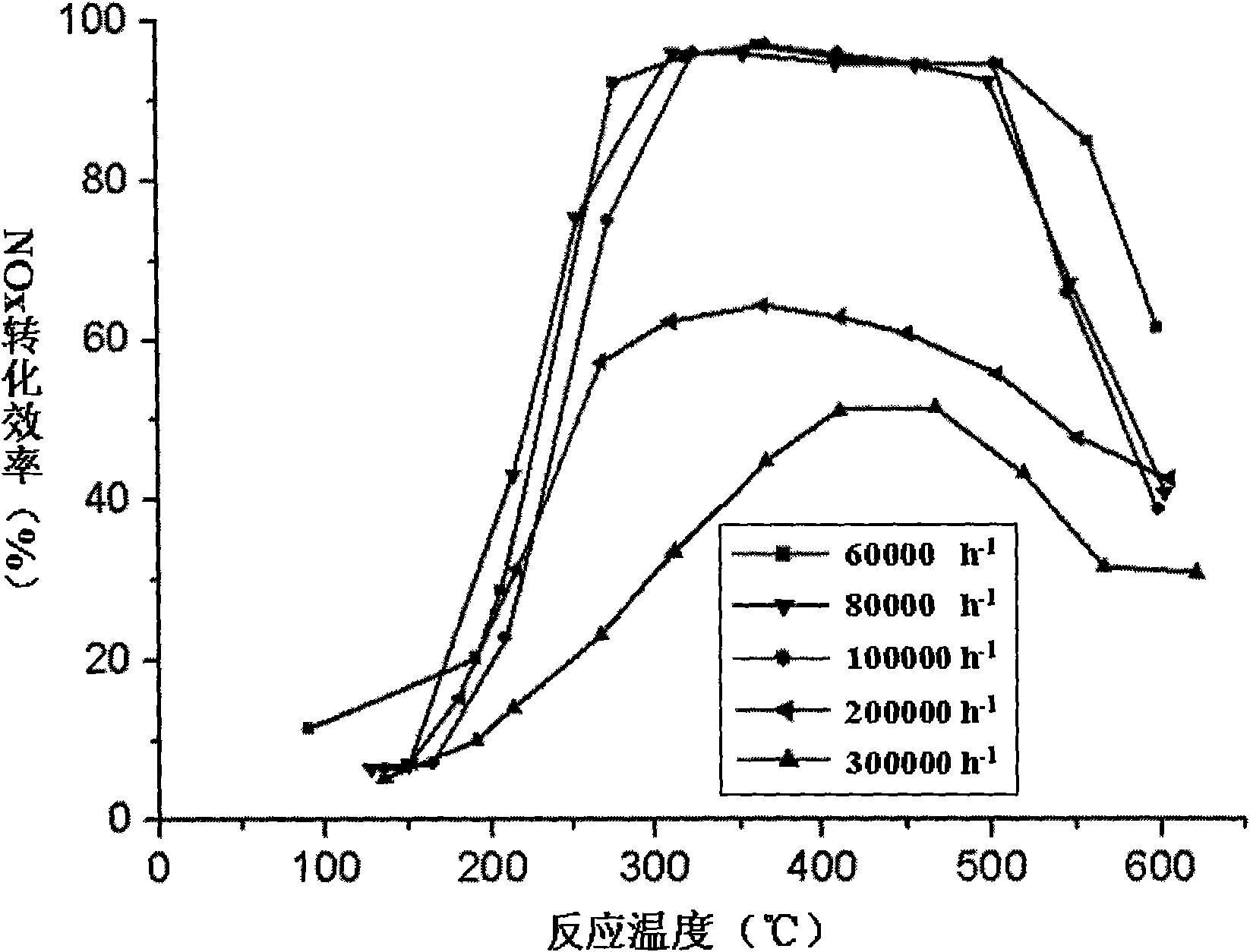

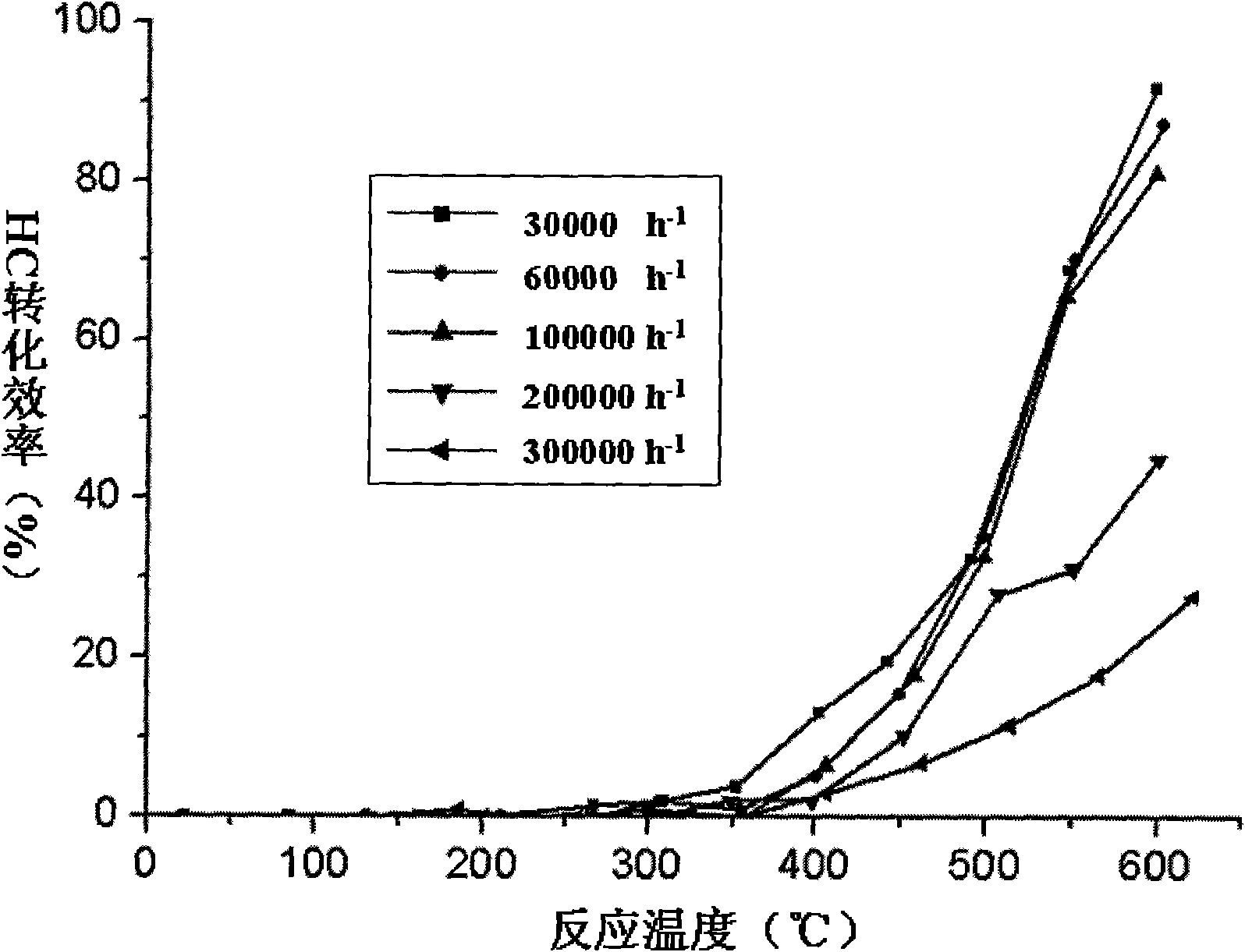

Catalyst for removing nitrogen oxide through selective catalytic reduction for Ce2O3 and V2O5 double active composition diesel truck

InactiveCN101559363ALow biological toxicityFacilitate catalytic reactionsInternal combustion piston enginesDispersed particle separationTraffic conditionsDiesel engine

The invention relates to a catalyst for removing nitrogen oxide through selective catalytic reduction for an automobile diesel engine adopting Ce2O3 and V2O5 double active compositions. The catalyst adopts scordierite honeycomb ceramics as a framework material, the Ce2O3 and the V2O5 as main active compositions, WO3 or MoO3 as an auxiliary catalyst composition, and TiO2 as a coating substrate, wherein the mass fraction of the main active compositions, namely the Ce2O3 and the V2O5, to the auxiliary catalyst composition WO3 or MoO3 to the coating substrate TiO2 is 1-3:6:12:85-93. The specific process comprises the following steps: preparing a TiO2 precursor solution; coating a TiO2 coating; coating an auxiliary catalyst; determining the loading of active compositions of oxides; and coating the main active compositions, namely the Ce2O3 and the V2O5. The catalyst replaces the V2O5 with high toxicity with the Ce2O3 with low toxicity, and reduces the environmental hazards of the catalyst, and the replaced catalyst has wider active temperature range, particularly greatly improves the low-temperature activity, and is particularly suitable for the traffic conditions of urban highways of China.

Owner:TIANJIN UNIV

Preparation method for synthesizing aniline catalyst by undergoing hydrogenation reaction on nitrobenzene

InactiveCN102553576ALow costLittle environmental hazardOrganic compound preparationCatalyst activation/preparationCitrate sodiumNitrobenzene

The invention discloses a preparation method for synthesizing an aniline catalyst by undergoing a hydrogenation reaction on nitrobenzene. The method comprises the following steps of: reducing a PdCl2 aqueous solution under the protection of sodium citrate by taking a NaBH4 aqueous solution as a reducing agent to obtain Pd nanoparticle sol; and mixing and stirring an ultrasonically-treated carbon nanotube in the aqueous solution with the Pd nanoparticle sol to form a Pd-carbon nanotube catalyst. The aniline catalyst shows very high activity in a reaction for synthesizing aniline through hydrogenation of nitrobenzene, and has long cycle life.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

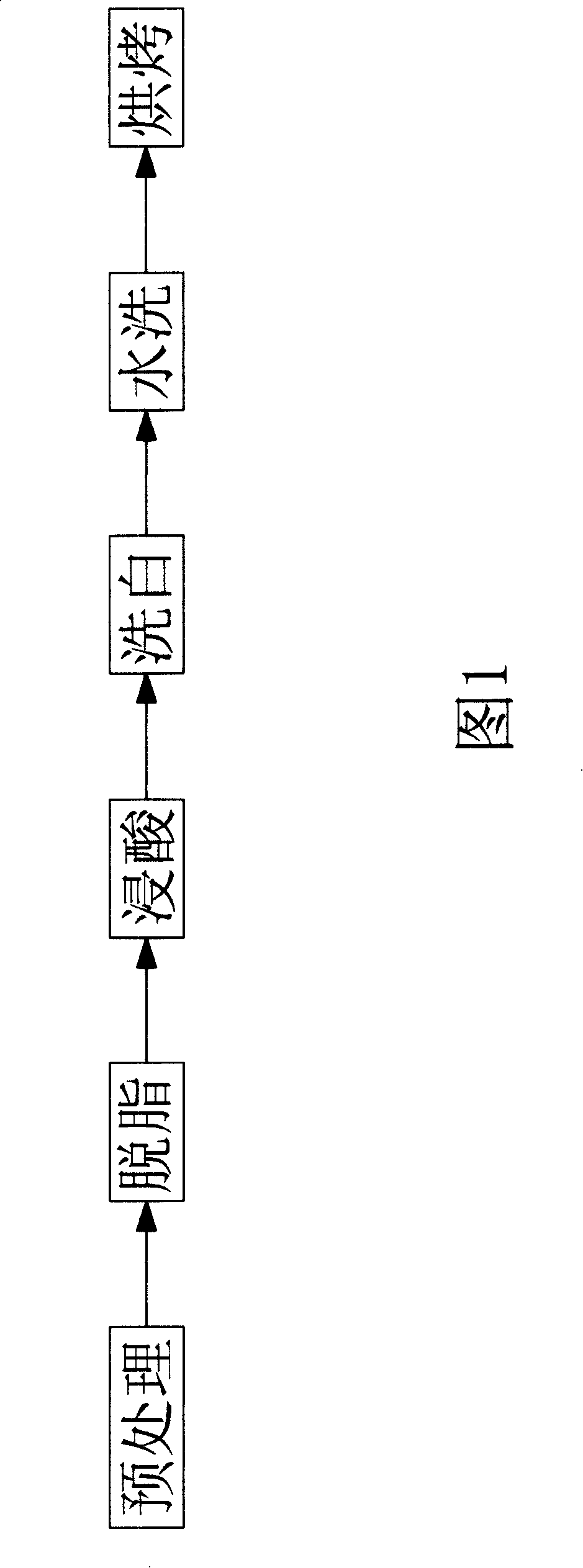

Stainless steel whitening solution and whitening technique thereof

InactiveCN101215699AReduce the risk factorLittle environmental hazardSuperimposed coating processSolventPhosphoric acid

The invention provides stainless steel washed white solution, which uses water as solvent, every one liter of the solution comprises 4-10 percent of nitric acid, 10-40g phosphoric acid, 2.5g boric acid, 5-30g acetic acid, 10-30g ammonium sulfate, 10-30g trisodium phosphate and 15-35g ammonium bifluoride. The method of using the stainless steel washed white solution to do the washed white process of the surface of stainless steel has the technological processes of pretreatment, degreasing, pickling, washing white, washing and baking, wherein after the stainless steel which is needed to be washed white is pretreated, degreased and pickled, the stainless steel which is pickled is put into the stainless steel washed white solution for 10-35 minutes in 55-85 DEG C, at last through washing and baking, the surface of the stainless steel is formed with an uniform silvery film layer which has a sand surface effect.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

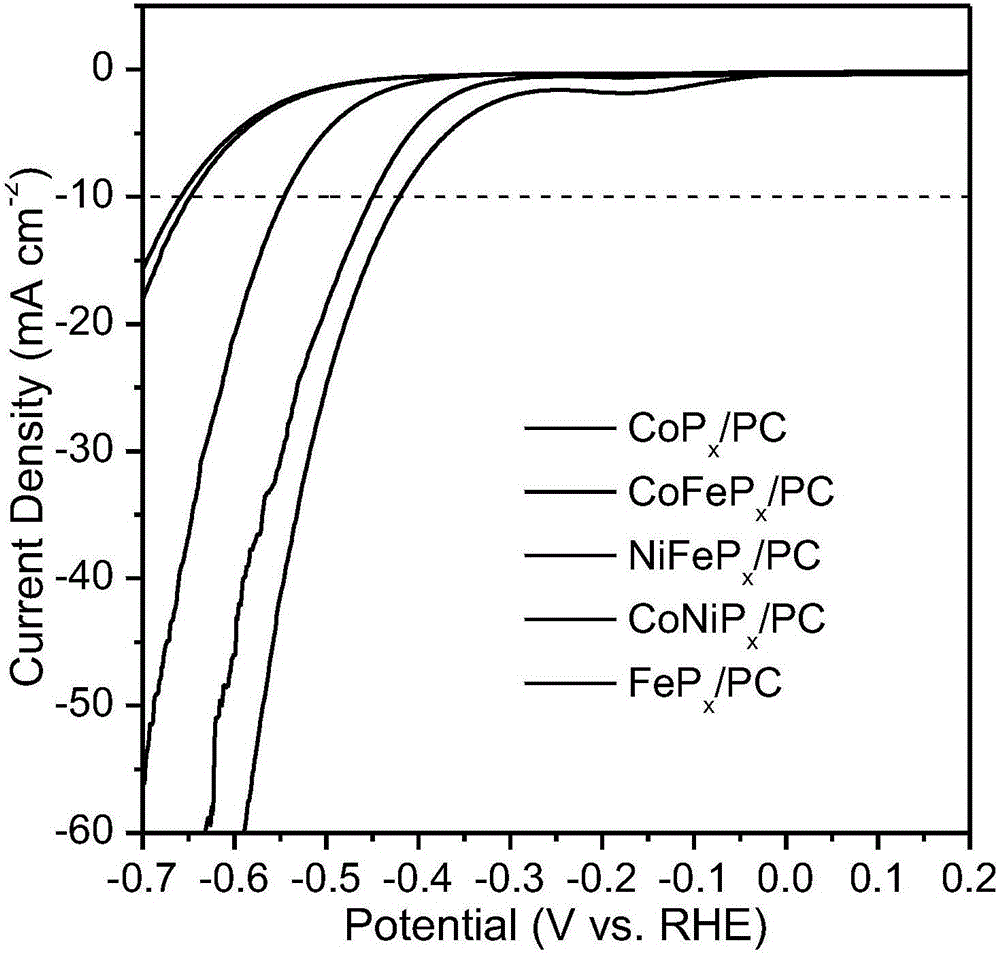

Bimetallic phosphide hydrogen evolution catalyst and preparation method

InactiveCN106694003ALow costReduce usagePhysical/chemical process catalystsElectrodesMetal chlorideNanoparticle

The invention discloses a bimetallic phosphide hydrogen evolution catalyst and a preparation method. The catalyst is prepared from phosphorus doped nano-carbon and bimetallic phosphide nanoparticles. The preparation method comprises the steps as follows: firstly, mixing a metal chloride salt solution with an organic phosphorus source solution to prepare a precursor; decomposing the precursor at a high temperature to prepare the bimetallic phosphide hydrogen evolution catalyst. The bimetallic phosphide hydrogen evolution catalyst and the preparation method have the advantages that the preparation cost is low, the method is simple, amplification is facilitated, and the electrochemical catalysis activity is higher.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

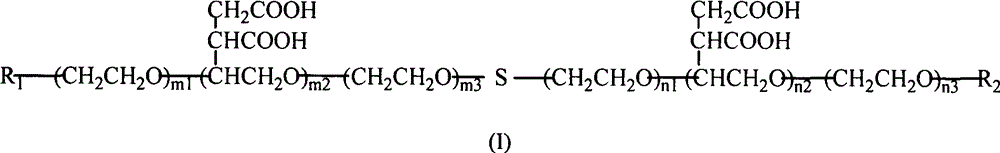

Efficient aqueous pigment dispersant

InactiveCN102974267AGood dispersion effectLittle environmental hazardTransportation and packagingInksFatty alcoholPOLYOXYETHYLENE ETHER

The invention relates to an auxiliary agent for a pigment, which is particularly suitable for dispersing the pigment, has good dispersion performance and high stability, and belongs to the field of application of a fine chemistry industry. A dispersant is prepared from fatty alcohol-polyoxyethylene ether, fatty alcohol-polyoxyethylene ether monoester, fatty alcohol-polyoxyethylene ether diester, carboxylated fatty alcohol-polyoxyethylene ether, carboxylated fatty alcohol-polyoxyethylene ether monoester and carboxylated fatty alcohol-polyoxyethylene ether diester. The dispersant is easily and biologically degraded and meets ecological and green and environment-friendly requirements; and a unique molecular chain structure can better disperse the pigment and can keep the pigment stable.

Owner:JIANGNAN UNIV

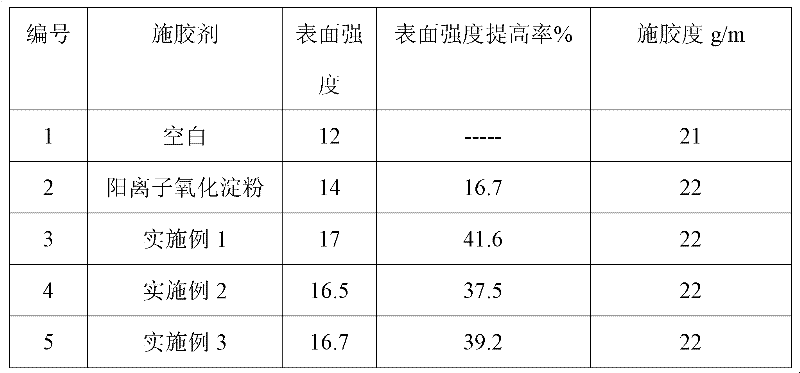

Surface sizing agent and preparation method thereof

ActiveCN102363938ALittle environmental hazardStable viscosityWater-repelling agents additionChemistrySizing

The invention discloses a surface sizing agent and a preparation method thereof. The preparation method comprises the following steps: 1, adding an aqueous solution of a cationic etherifying agent to a mixture of guar gum raw powder and an aqueous solution of a low carbon alcohol under an inert atmosphere, such as a nitrogen atmosphere, adding an alkali catalyst, and reacting to obtain a cationic guar gum product; 2, adjusting the pH value of a system of the product obtained in step 1 to 1-4 by an acidic neutralizer, adding a superacidic chemical, and reacting; and 3, adding a viscosity stabilizing agent, and simultaneously adjusting the PH value to 6-9, reacting, and collecting the surface sizing agent from reaction products. The surface sizing agent of the invention, which has the characteristics of very good fluidity, easy dispersion and usage, exquisite and stable gum solution, and rapid hydration swelling, is an ideal surface sizing agent, and simultaneously is a multifunctional wet-end additive. The surface sizing agent is suitable for sizing various surfaces of cultural paper, newspaper, art paper and special paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Technology of using asbestos tailings to produce silicon-calcium-magnesium-potassium fertilizer

ActiveCN109020629AReasonable stepsLittle environmental hazardMagnesium fertilisersPotassium fertilisersFertilizerCalcium magnesium

The invention discloses a technology of using asbestos tailings to produce a silicon-calcium-magnesium-potassium fertilizer. The technology comprises following steps: at first, grinding serpentine bya cone crusher to a size of 3 cm or so; then adding grinded serpentine into a ball milling machine, carrying out ball milling for 30 to 40 minutes, controlling the granularity of serpentine to be 250meshes or so; adding KCl particles into the ball milling machine, wherein the ratio of KCl particles to serpentine is 1:9, carrying out ball milling for 30 minutes, when the granularity of particles in the ball milling machine is greater than 300 meshes, discharging the powder to a winnowing machine, winnowing the powder under a pressure of 6 kg; after winnowing, directly packaging the powder, orusing the powder to product a fertilizer, discharging materials which are not winnowed from the rotating cylinder, and taking non-winnowed materials as a metallurgy raw material. The asbestos tailingsare processed harmlessly, the wastes are converted into valuable resources, and the environmental pollution is reduced.

Owner:北京璞域环保科技有限公司

Automatic purifying method for spherical graphite

The invention discloses a purifying method for spherical graphite. The automatic purifying method for the spherical graphite comprises the following steps: adding the spherical graphite, fluoride, a complexing agent and water into a primary reaction tank, uniformly stirring, introducing steam, heating for 3h, and carrying out reaction for 8-12h at the temperature of 80-120 DEG C; after reaction, pumping a material into a primary filter press through a pipeline at the bottom by virtue of a material conveying pump, carrying out filtration and deacidification, collecting waste acid liquid into an acid storage tank for secondary reserve, introducing soft water, and cleaning the material to be neutral; sending the material discharged by the primary filter press into a middle pulping tank by virtue of a spiral material conveying device; adding aqua regia and water into the middle pulping tank according to a certain ratio, and stirring until the material is in a gruel shape, and pumping the material into a secondary reaction tank by virtue of the material conveying pump; introducing the steam, heating, and carrying out reaction for 4-8h at the temperature of 80-120 DEG C; after reaction, discharging the material, enabling the material to enter a secondary filter press by virtue of the material conveying pump, carrying out filtration and deacidification, collecting concentrated acid liquid into an acid storage tank, introducing deionized water, cleaning the material to be neutral, and drying the discharged material to obtain the high-purity spherical graphite, wherein the purity of the spherical graphite can achieve 99.99-99.995 percent.

Owner:营口博田材料科技有限公司

Flyash tamping plug and preparation method thereof

ActiveCN103232220ALittle environmental hazardImprove plasticityCeramic materials productionClaywaresPlastic filmRaw material

The invention relates to a flyash tamping plug and a preparation method thereof and belongs to the field of water pressure blasting technology. The flyash tamping plug is prepared from the following raw materials in parts by weight: 90-110 parts of low liquid limit clay (liquid limit (50%)), 5-7 parts of coarse sand, 6-8 parts of flyash and 14-17 parts of water. The preparation method comprises the following steps of: weighing the low liquid limit clay, the coarse sand, the flyash and the water as required and uniformly mixing to form primary material; hardening the primary material for 1-2h and fianlly processing the hardened into a tamping plug rolls. According to the novel tamping plug, flyash and clay powder are used as core materials, local materials are used, and the cost is saved. The corresponding preparation method is simple, the water-retaining property of the obtained product is good, the flyash tamping plug can be stored for 12 hours after being processed into the tamping plug rolls; if coated with a plastic film, the storage time can be further prolonged, and the existing common loess tamping plug only can be stored for 5 hours under no protection.

Owner:中铁十局集团第二工程有限公司

A new environment-friendly gold ore beneficiation process under simulated natural conditions

InactiveCN102274785ALittle environmental hazardReduce governance costsWet separationEnvironmentally friendlyBeneficiation

The invention discloses a novel environment-friendly gold ore beneficiation process under simulated natural conditions, and relates to the fields of beneficiation and environmental protection. It is characterized in that the particle size distribution of gold particles in the gold ore and the components and forms of the associated ore are accurately measured, and then the gold ore is crushed, finely ground, step-by-step screened, blown, magnetized water treatment, heating, cooling , ultrasound, microwave, gravity separation and other technological procedures, simulated the geological weathering process that would take millions of years to complete under natural conditions, and quickly realized the process of gold ore transformation into alluvial gold and gold concentration, so that the grade of gold concentrate produced It can be increased from less than 100 grams / ton to 300-1000 grams / ton. This treatment process is suitable for refractory original ecological gold mines, and can effectively recycle various tailings produced in the process. Compared with traditional processes, it can greatly reduce production costs and reduce environmental pollution. It is a low-cost And environment-friendly gold ore beneficiation process.

Owner:李溪

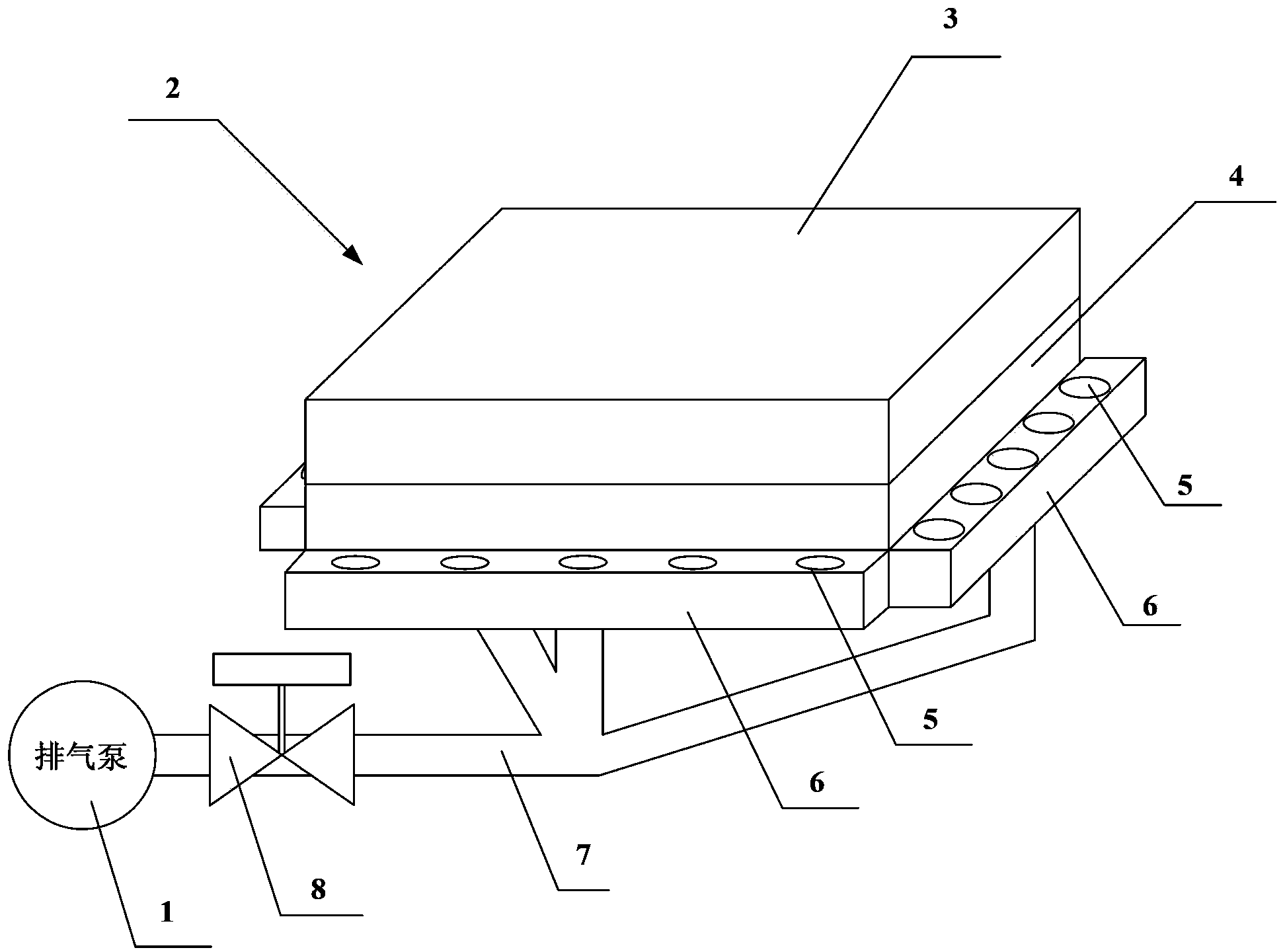

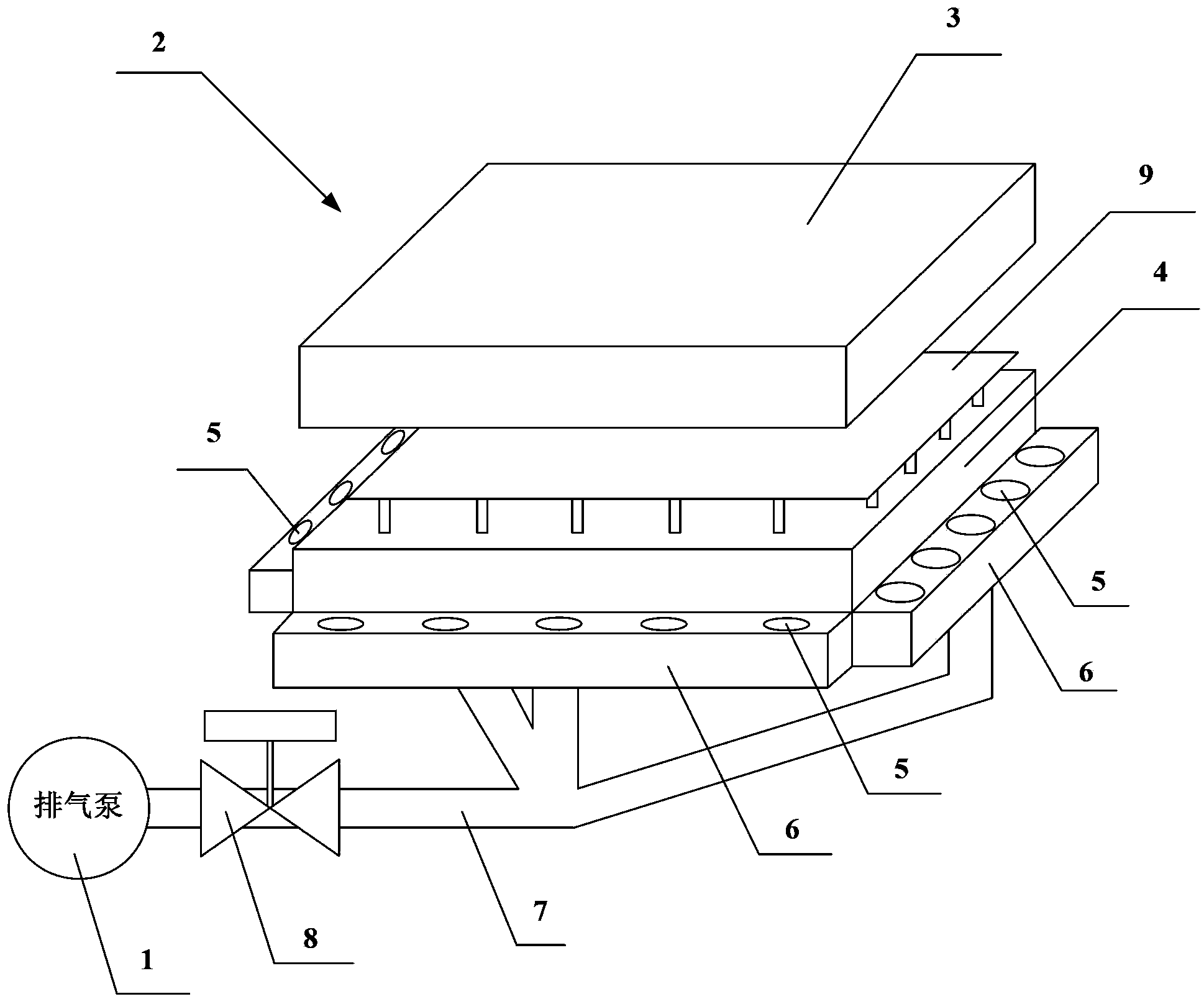

Exhaust system and method of vacuum drying chamber

InactiveCN104296520ALittle environmental hazardHarm reductionDrying solid materialsHigh concentrationAir pump

The invention discloses an exhaust system and method of a vacuum drying chamber. The exhaust system of the vacuum drying chamber comprises a plurality of exhaust openings and an exhaust pump, wherein the exhaust openings are formed outside the vacuum drying chamber; the exhaust pump is connected with the exhaust openings through exhaust pipes. The exhaust method of the vacuum drying chamber includes the steps that when a base plate to be dried is placed in the vacuum drying cavity, exhausting is conducted through the exhaust pump; when the vacuum drying chamber is closed, the exhaust pump is stopped from conducting exhausting; when the dried base plate is taken out of the vacuum drying chamber, exhausting is conducted through the exhaust pump. In conclusion, the multiple exhaust openings are formed outside the vacuum drying cavity, so that when the base plate is stored in and taken out of the cavity, the volatile gas of the dissolved matter of high concentration in the cavity can be discharged through the multiple exhaust openings formed outside the vacuum drying cavity, and the harm to the environment generated in the storing and taking process of the base plate is reduced.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Method for preparing porous carbon and white carbon black by using diatomite

The invention relates to a method for preparing porous carbon and white carbon black by using diatomite. The method comprises the following steps of: catalyzing a carbon source with the solid acid site of the diatomite serving as a template as well as a catalyst to polymerize the carbon source and generate the porous carbon having a diatom shell shape; and removing the template with strong alkaliand treating obtained waste liquor to generate the white carbon black having a large specific surface area. The obtained porous carbon has a multi-stage pore canal structure and a specific surface area of over 250 m<2> / g and is widely used in fields such as adsorption, separation, loading, capacitor preparation and the like. The obtained white carbon black has a specific surface area of over 400 m<2> / g and can be used in fields such as reinforcing agents, diluents, cementing agents, fillers, carriers and the like. The method has the advantages of simple process, low cost, light pollution, lowenergy consumption and the like.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

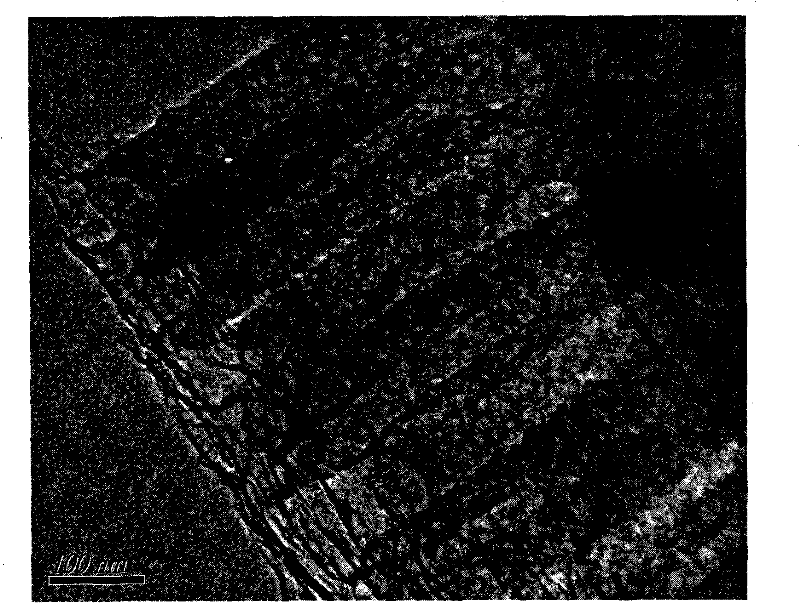

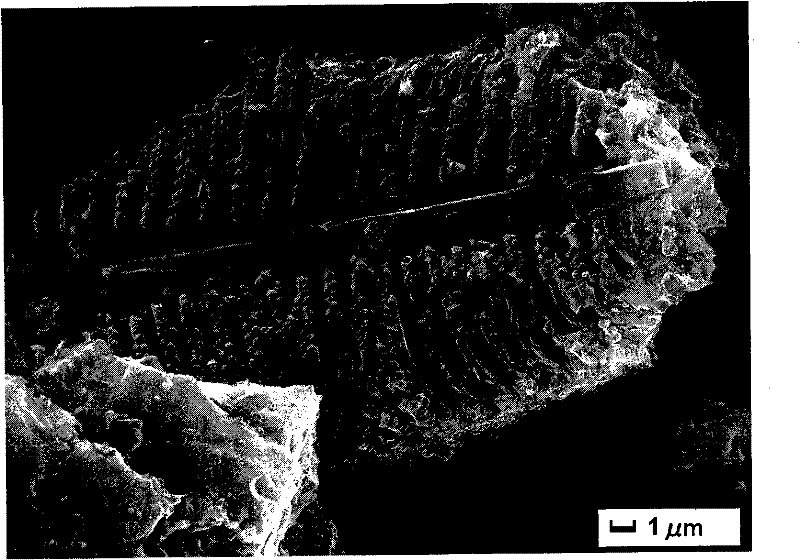

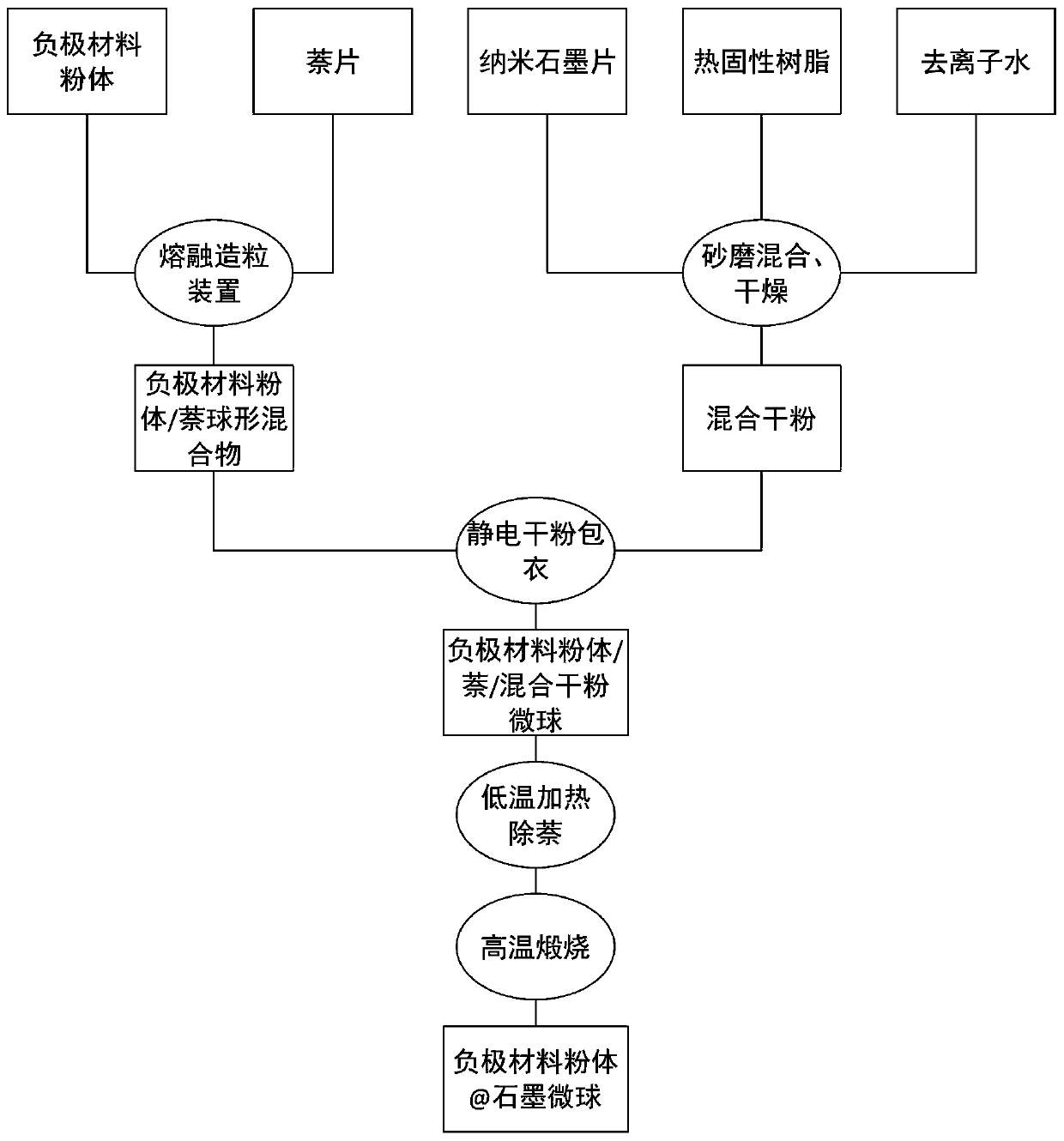

Egg yolk-egg shell structure type microsphere and preparation method thereof

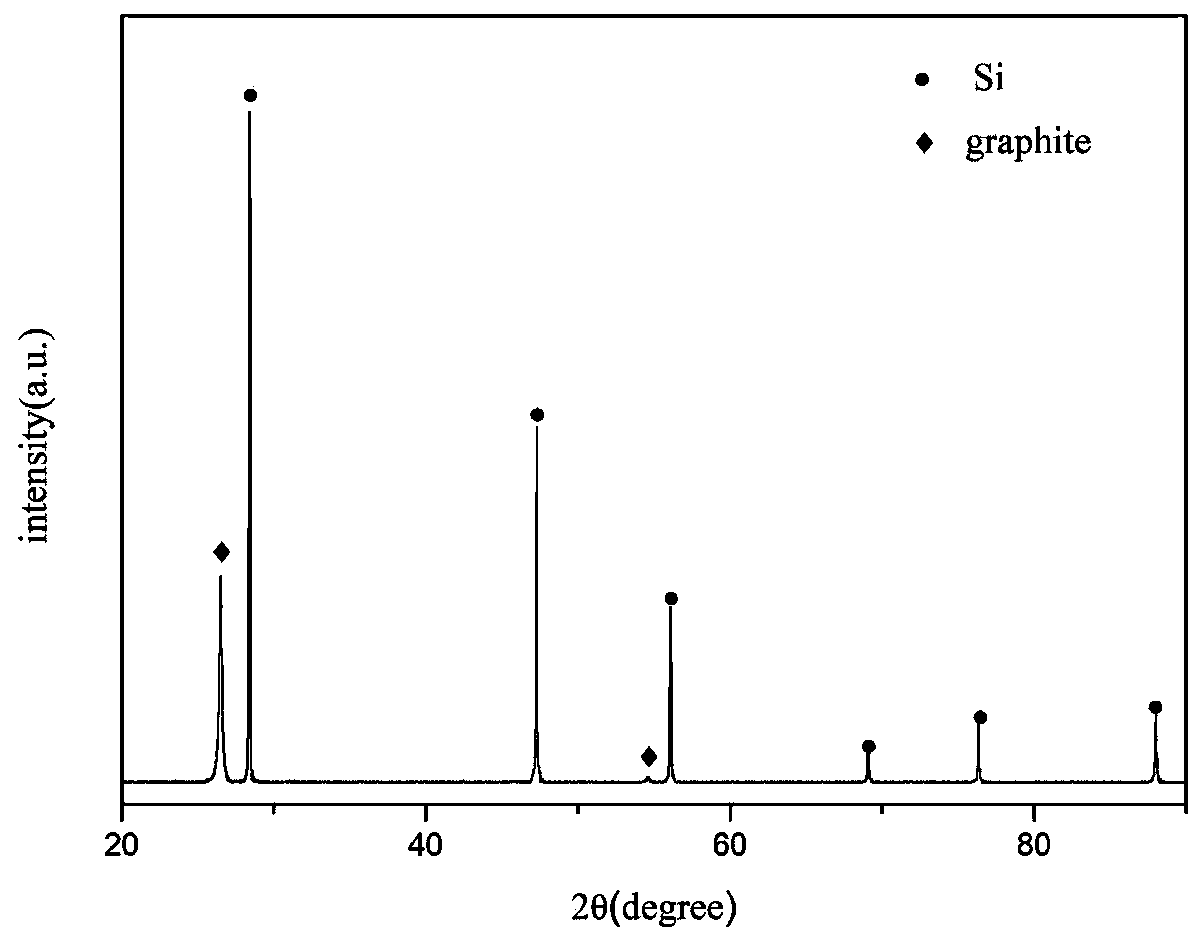

ActiveCN110350169ALittle environmental hazardSimple processCell electrodesSecondary cellsCorrosionYolk

The invention discloses an egg yolk-egg shell structure type microsphere and a preparation method thereof. The preparation method comprises the following steps: preparing a mixed dispersion material of powder and molten naphthalene, wherein a mass ratio of the powder to the naphthalene in the mixed dispersion material is 1 : (2-5); treating the mixed dispersion material by adopting a melt granulation device to obtain a powder / naphthalene spherical mixture; preparing a mixed material of a nano-graphite flake and an organic binder, and wrapping the surface of the powder / naphthalene spherical mixture with the mixed material to obtain a powder / naphthalene / mixed material microsphere, wherein a mixed material and a powder body wherein a mass ratio of the mixed material to the powder / naphthalenespherical mixture is 1 : (10-70); and carrying out low-temperature heating treatment on the powder / naphthalene / mixed material microsphere to remove a naphthalene layer to obtain an egg yolk-egg shellstructure type powder@mixed material microsphere, and carrying out high-temperature carbonization treatment on the powder@mixed material microsphere to obtain an egg yolk-egg shell structure type powder@graphite microsphere. The invention provides a preparation method of an egg yolk-egg shell structure type nuclear@graphite microsphere which is corrosion-free, simple, cheap and environment-friendly, and can be prepared on a large scale.

Owner:云南三磷科技有限公司

Corrosion-preventing treating agent for surface of alloy casting

The invention discloses a corrosion-preventing treating agent for the surface of an alloy casting. The corrosion-preventing treating agent comprises, by weight, 100 parts of oxalic acid, 20-25 parts of silane coupling agent, 20-30 parts of isopropanol, 10-15 parts of soluble aluminum salt, 6-8 parts of corrosion inhibitor and 80-120 parts of distilled water. At the room temperature, the oxalic acid and the soluble aluminum salt are sequentially added into a mixed solution of the isopropanol and the distilled water to be evenly stirred, and then the silane coupling agent and the corrosion inhibitor are added to the solution. According to the corrosion-preventing treating agent, a very good corrosion-prevention and rust-prevention protection effect can be better achieved on the metal pressure casting, cleaning of the surface of the casting can be strengthened through the adding of the oxalic acid and the soluble aluminum salt, the dispersing effect of the treating agent can be enhanced under the synergistic effect of the silane coupling agent and other components, the binding force of a corrosion-prevention film layer is improved, and coating adhesive force is improved.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

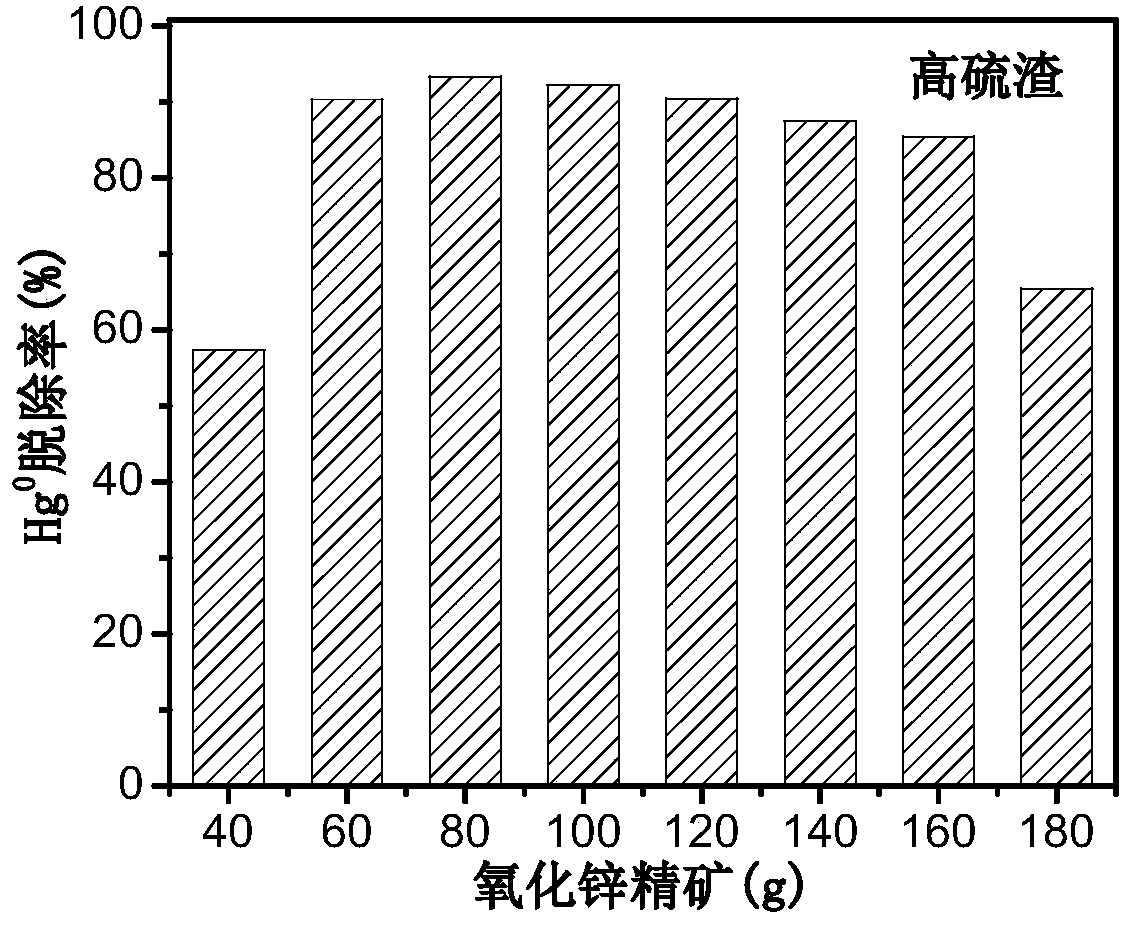

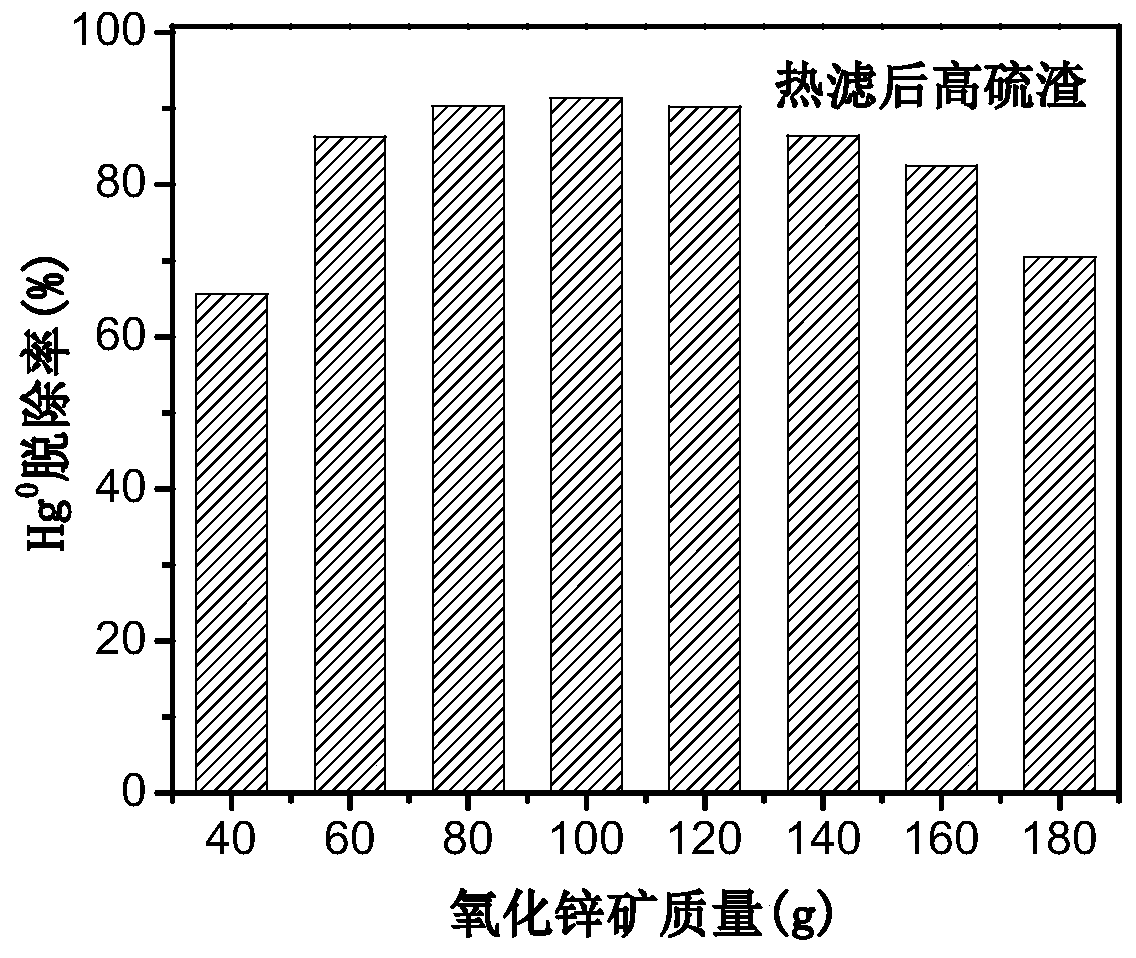

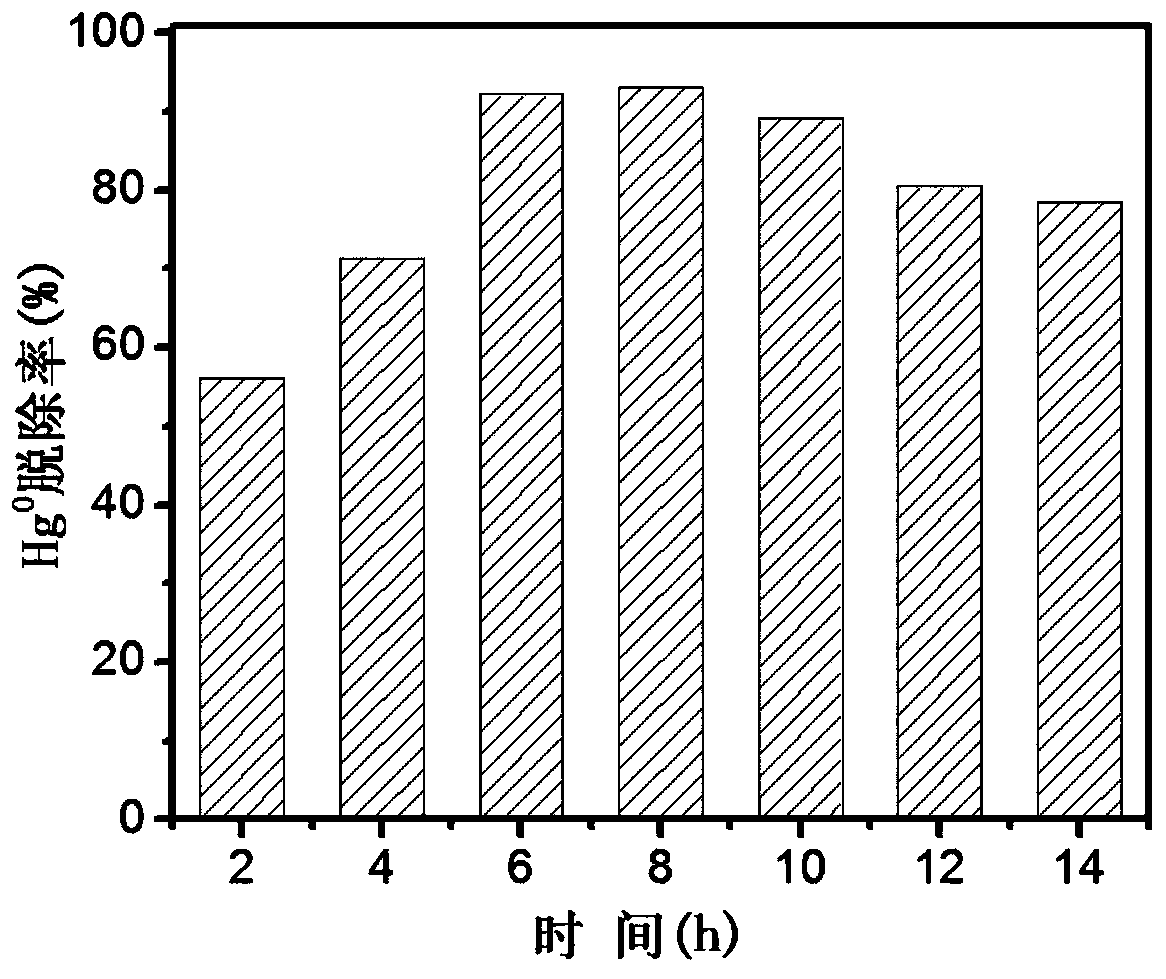

Method of utilizing zinc hydro-metallurgy oxygen pressure acid leaching slag to prepare demercuration adsorbent

ActiveCN110801803ALittle environmental hazardRealize full quantitative resource utilizationGas treatmentOther chemical processesSulfide saltChemistry

The invention discloses a method of utilizing zinc hydro-metallurgy oxygen pressure acid leaching slag to prepare a demercuration adsorbent. The method comprises following steps: (1) evenly mixing oxidized zinc ores with oxygen pressure acid leaching slag to obtain a premixed material, and dissolving soluble sulfides into an organic solution to obtain a sulfide solution; (2) mixing the premixed material and the sulfide solution obtained in the step (1), stirring the mixture under the assistance of ultrasonic waves to obtain a turbid liquid, heating the turbid liquid to carry out hydrothermal reactions, and collecting the product namely a zinc polysulfide compound; and (3) mixing the zinc polysulfide compound obtained in the step (2) with iron salts, and evenly mixing to obtain the demercuration adsorbent. The zinc hydro-metallurgy oxygen pressure acid leaching slag is taken as the raw material to prepare the demercuration adsorbent; the damage to the environment is reduced; the oxygenpressure acid leaching slag is completely converted into valuable resources; moreover, the prepared adsorbent has a high mercury removal rate, and at least 90% of mercury in various forms in flue gasand waste liquid is removed.

Owner:JIANGXI UNIV OF SCI & TECH

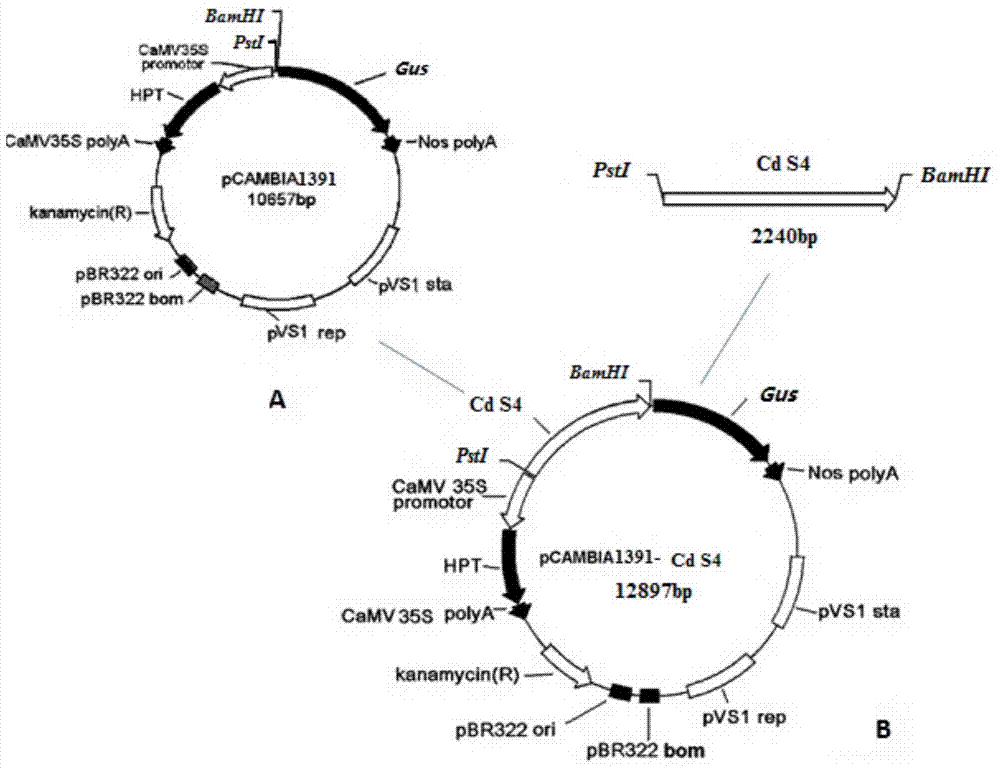

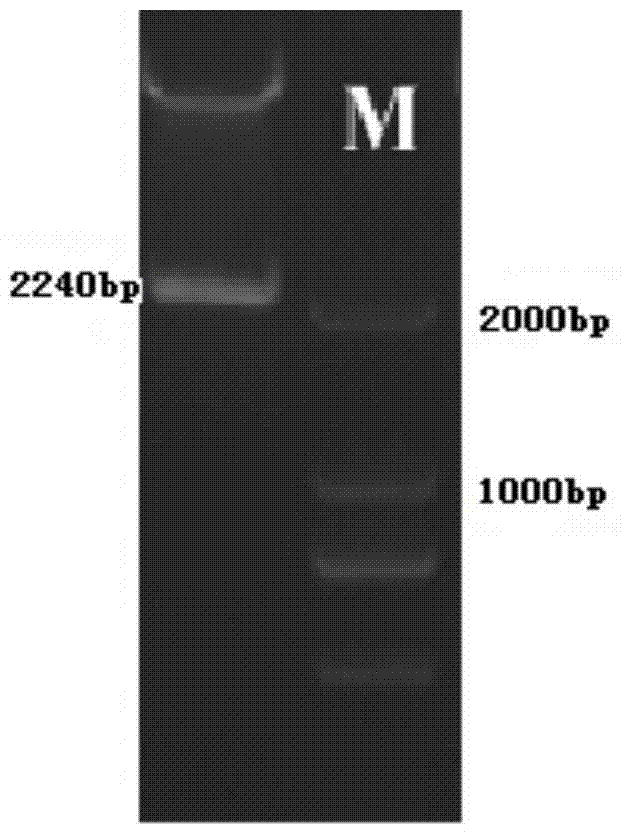

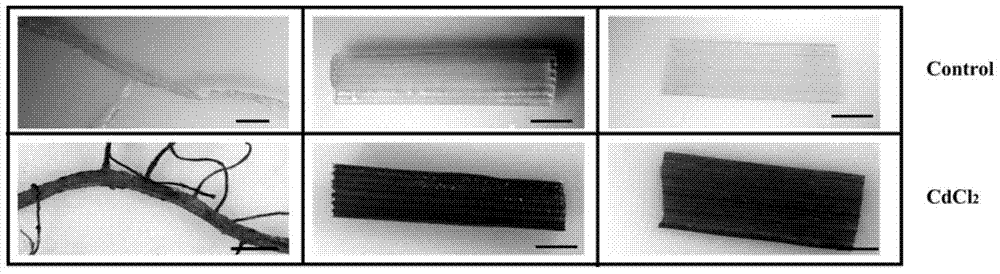

Heavy metal strongly inducible promoter cd‑s4 and its application

ActiveCN104745583BIncrease profitImprove phytoremediation effectVector-based foreign material introductionAngiosperms/flowering plantsBiotechnologyInduced demand

The present invention provides a strong induction expression promoter of heavy metals such as cadmium and nickel, and the promoter can regulate the concentrated expression of target genes under the induction condition of heavy metals such as cadmium and nickel. The strong inducible expression promoter of heavy metals such as cadmium and nickel of the present invention comprises: the nucleotide sequence as described in SEQ ID No: 1 or 2 of the sequence listing or derivatives thereof. The invention also provides a recombinant expression vector, an expression cassette constructed by using the promoter and its application in plant cultivation. By linking the promoter of the present invention to the gene to be expressed and using the vector to transfer it into the plant, it can drive the expression of the foreign gene in various parts of the plant. With the development of molecular biology and developmental biology, people have an increasingly strong demand for the specific inducible expression promoter, and the promoter provided by the present invention just meets such demand. In particular, it has very huge potential commercial value for the cultivation and breeding of heavy metal-resistant plants.

Owner:RICE RES ISTITUTE ANHUI ACAD OF AGRI SCI

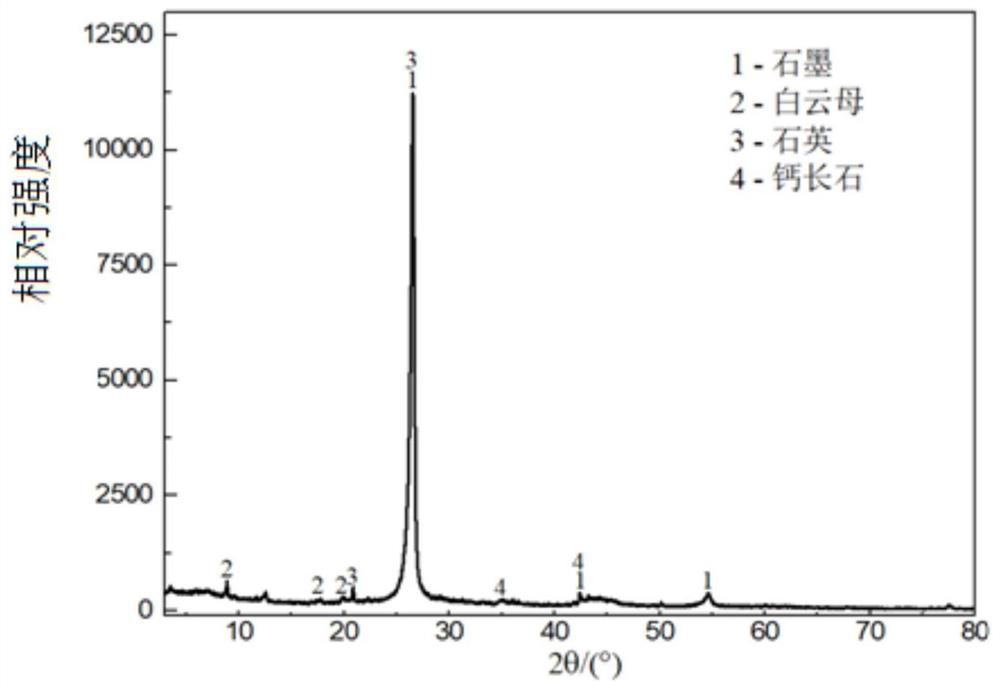

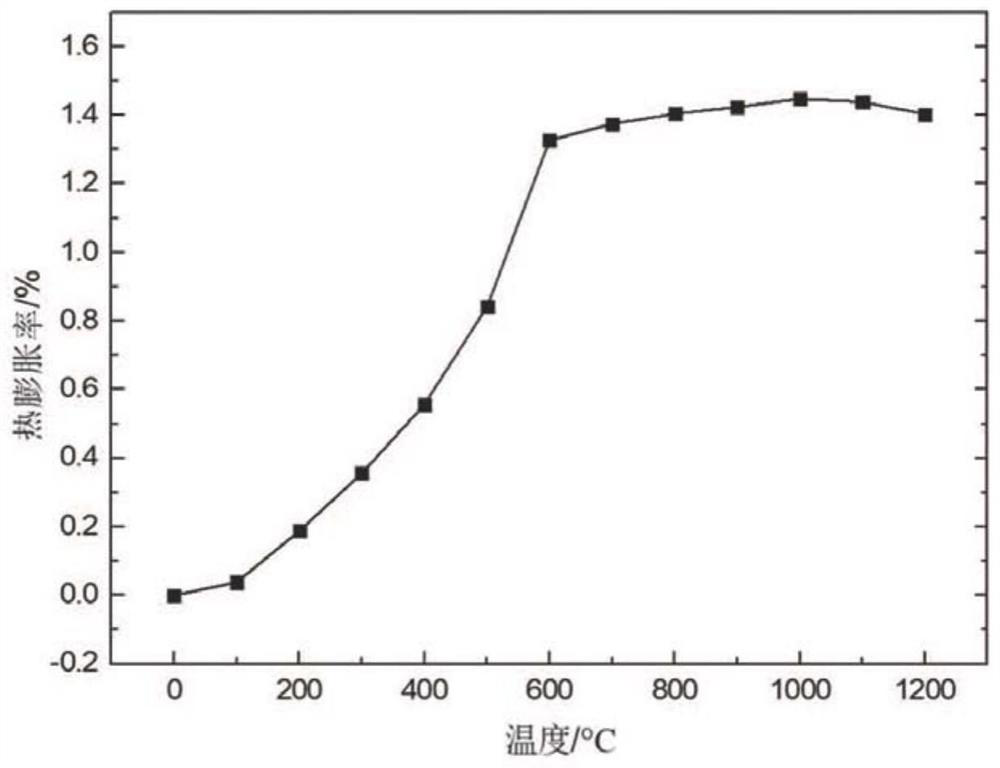

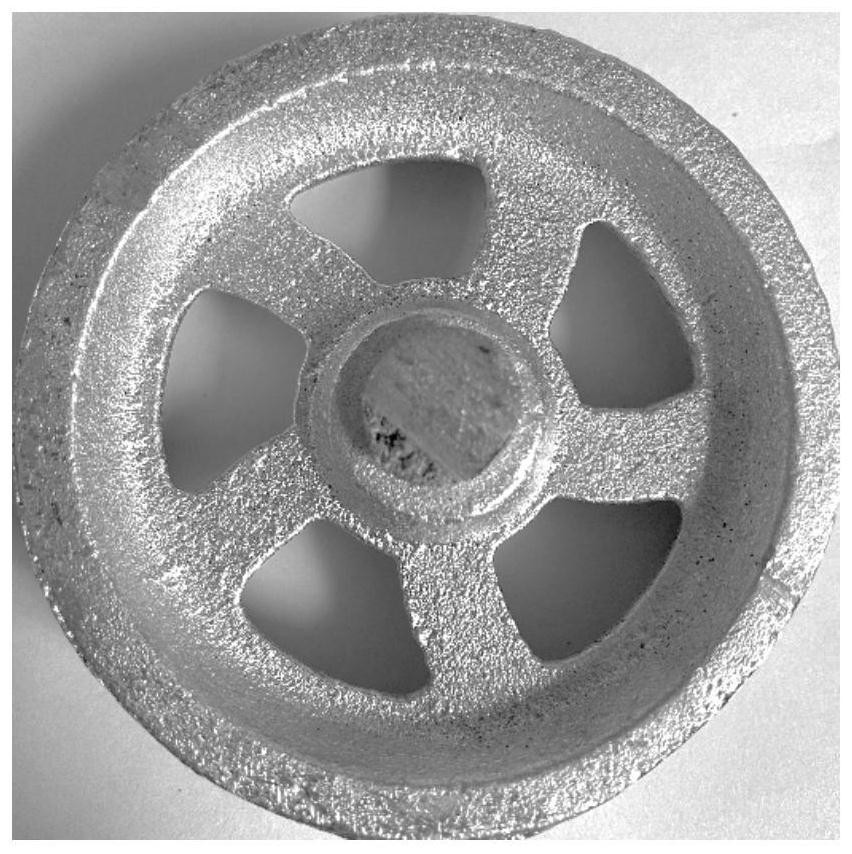

Casting green sand, environment-friendly carbonaceous additive and preparation process of environment-friendly carbonaceous additive

ActiveCN113070443AAchieve recyclingLow costFoundry mouldsProcess efficiency improvementSodium BentoniteMaterials science

The invention provides casting green sand, an environment-friendly carbonaceous additive and a preparation process of the environment-friendly carbonaceous additive. The environment-friendly additive comprises microcrystalline graphite, an extracted titanium slag extract and coal gasification slag, wherein the microcrystalline graphite accounts for 60-80% by mass, the extracted titanium slag extract accounts for 0-20% by mass, the coal gasification slag accounts for 0-20% by mass, and the extracted titanium slag extract is obtained by flotation of extracted titanium slag and contains 40-60% by mass of fixed carbon; the casting green sand comprises 100 parts by mass of quartz sand, 8-10 parts by mass of sodium bentonite and 3-7 parts by mass of the environment-friendly carbonaceous additive. The raw materials comprise the titanium extraction slag extract and the coal gasification slag, waste recycling can be achieved, and the cost is low; harmful gas released at high temperature is remarkably reduced, and environmental harm is reduced; the low thermal expansion rate is achieved, and casting deformation can be effectively reduced; the binding force between a binder and the quartz sand can be obviously improved, and the wet compression strength is improved.

Owner:杭州洁铸科技有限公司

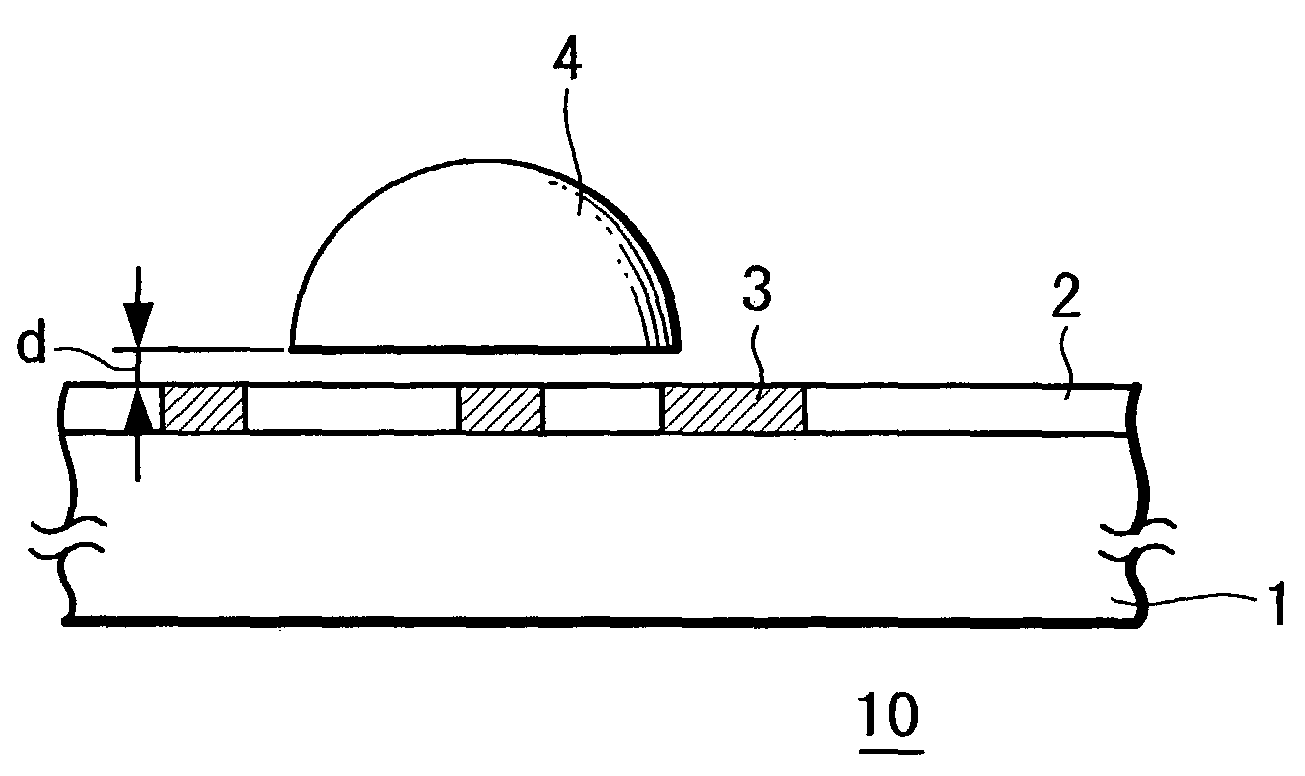

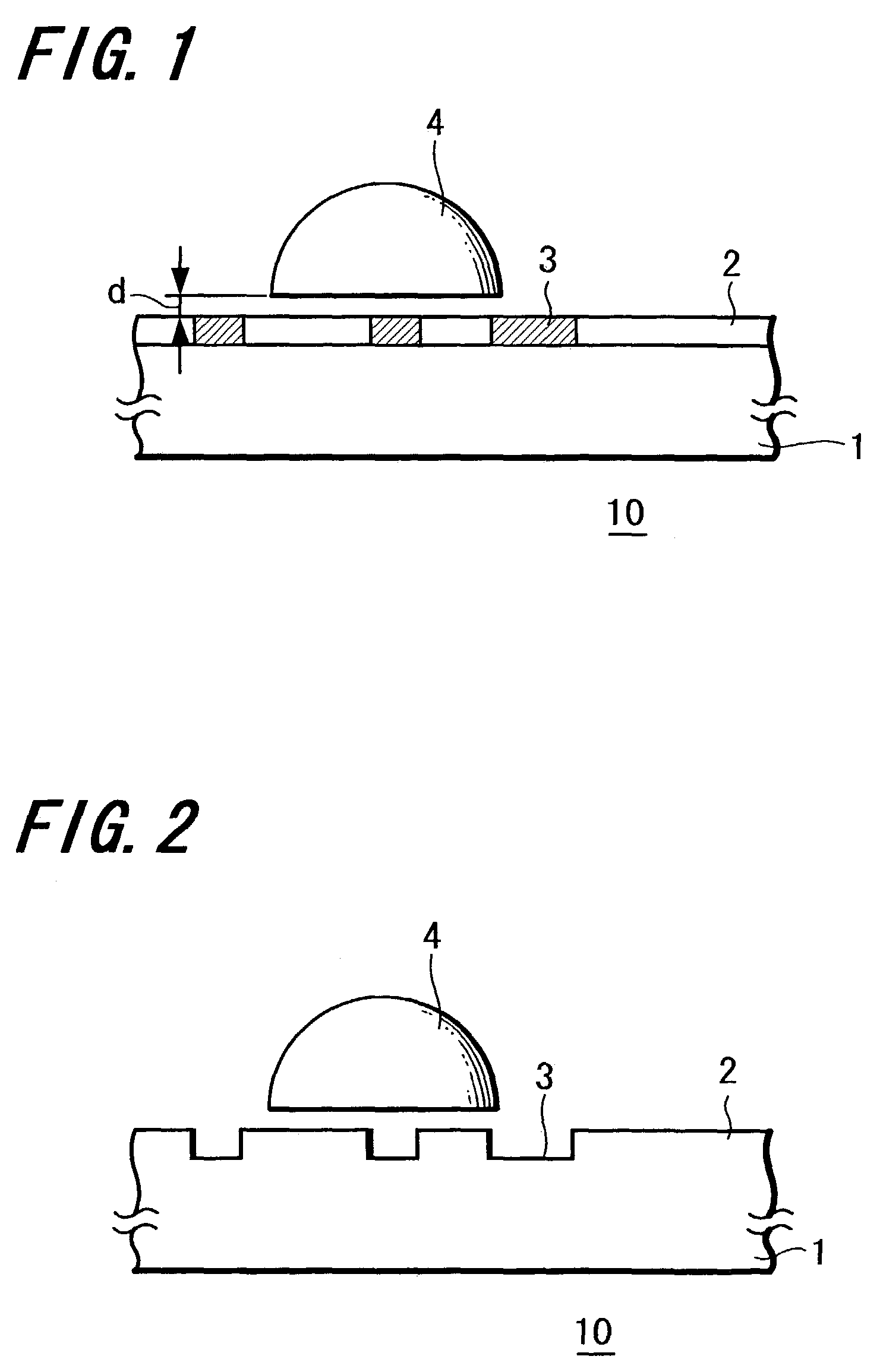

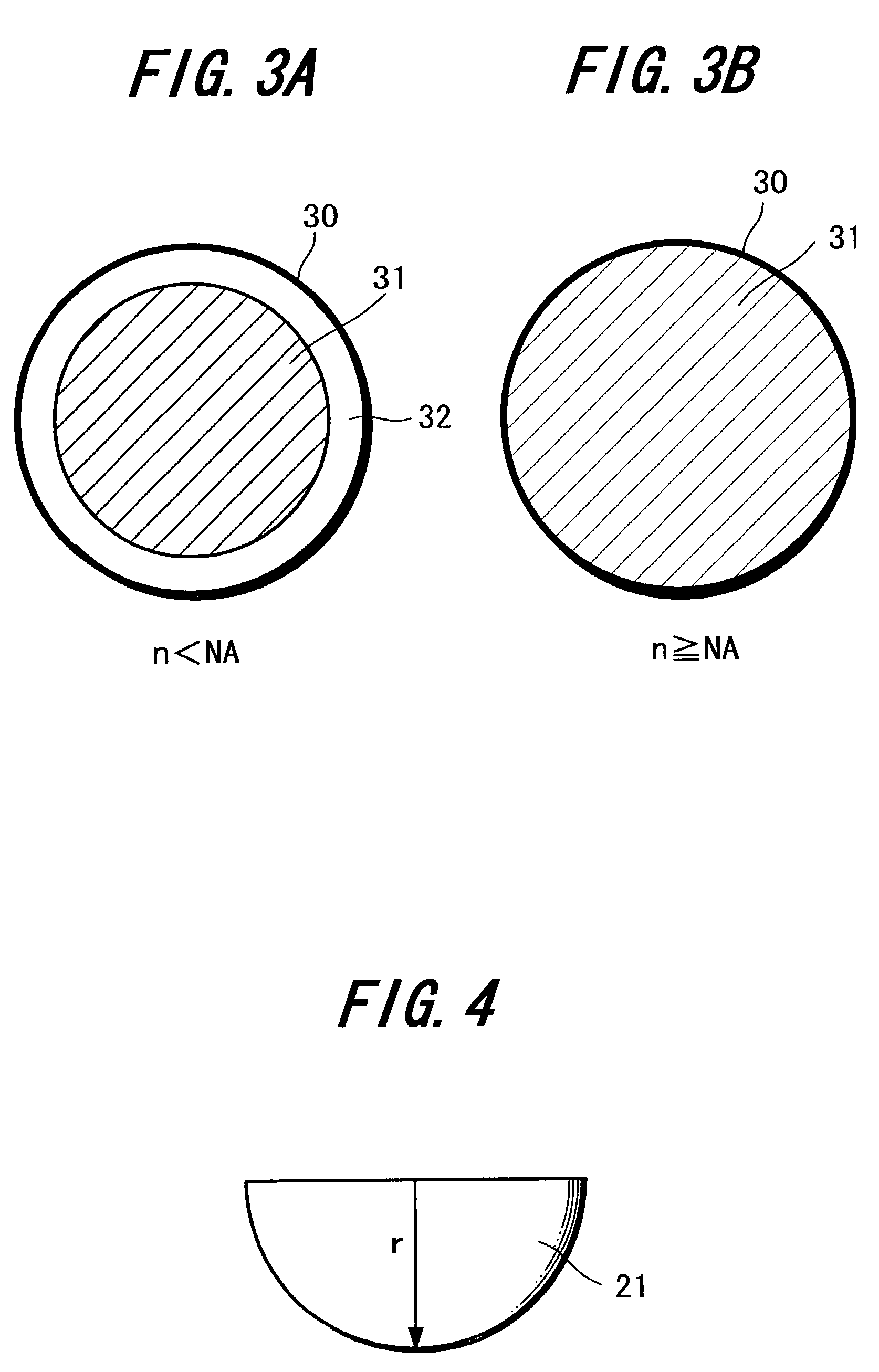

Optical recording medium and optical recording/reproducing method

InactiveUS7420888B2Improve reproductive characteristicsLittle environmental hazardCombination recordingRecord information storageRefractive indexOptical recording

An optical recording medium 10 on which recording / reproducing or reproducing is performed by irradiating a light by means of an objective lens 4 having a numerical aperture equal to or more than 1 wherein an optical recording portion 2 is provided at least at the outer most surface at the irradiation side of the optical recording medium 10 and a relation n≧NA is selected when the refractive index of the recording portion 2 is n and the numerical aperture of the objective lens 4 is NA. Accordingly, it can propose an optical recording medium and an optical recording / reproducing method suitable for a near-field optical recording method which uses an objective lens having a numerical aperture equal to or more than 1.

Owner:SONY CORP

Flyash tamping plug and preparation method thereof

ActiveCN103232220BLittle environmental hazardImprove plasticityBlastingCeramic materials productionPlastic filmMaterials science

The invention relates to a flyash tamping plug and a preparation method thereof and belongs to the field of water pressure blasting technology. The flyash tamping plug is prepared from the following raw materials in parts by weight: 90-110 parts of low liquid limit clay (liquid limit (50%)), 5-7 parts of coarse sand, 6-8 parts of flyash and 14-17 parts of water. The preparation method comprises the following steps of: weighing the low liquid limit clay, the coarse sand, the flyash and the water as required and uniformly mixing to form primary material; hardening the primary material for 1-2h and fianlly processing the hardened into a tamping plug rolls. According to the novel tamping plug, flyash and clay powder are used as core materials, local materials are used, and the cost is saved. The corresponding preparation method is simple, the water-retaining property of the obtained product is good, the flyash tamping plug can be stored for 12 hours after being processed into the tamping plug rolls; if coated with a plastic film, the storage time can be further prolonged, and the existing common loess tamping plug only can be stored for 5 hours under no protection.

Owner:中铁十局集团第二工程有限公司

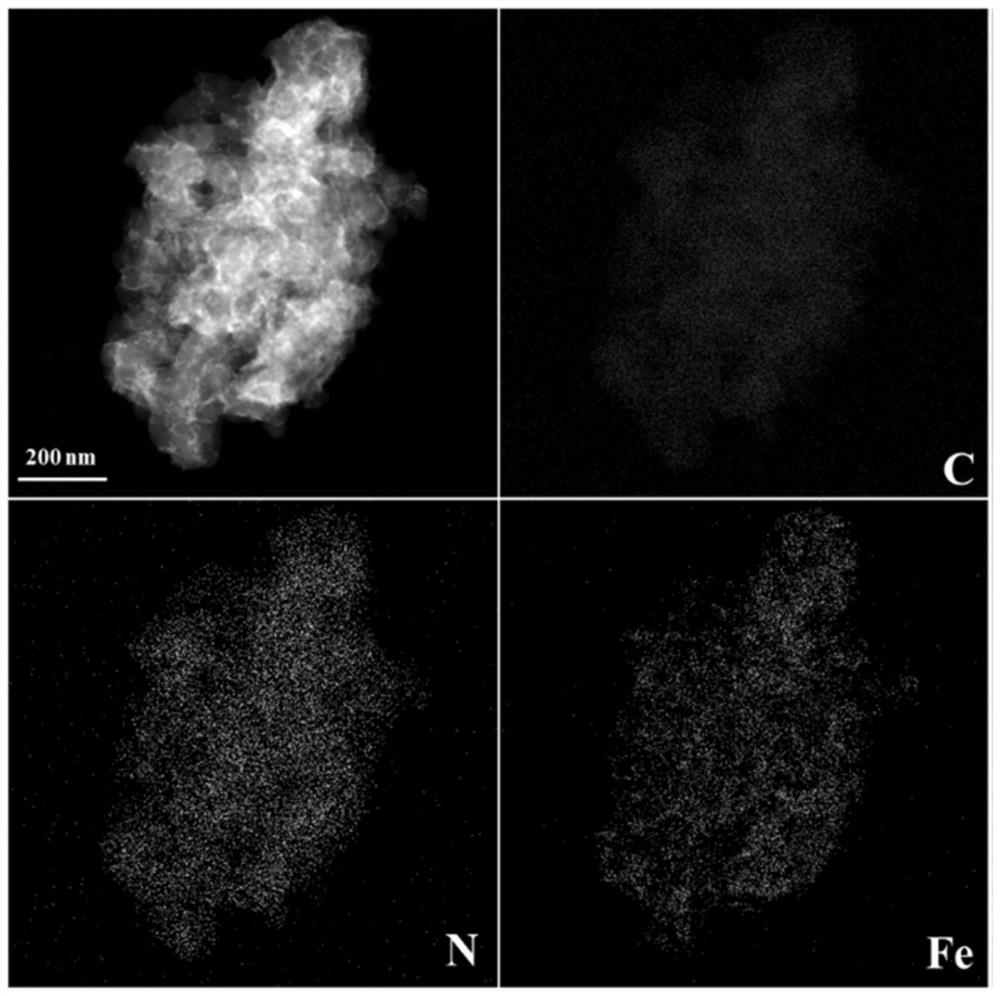

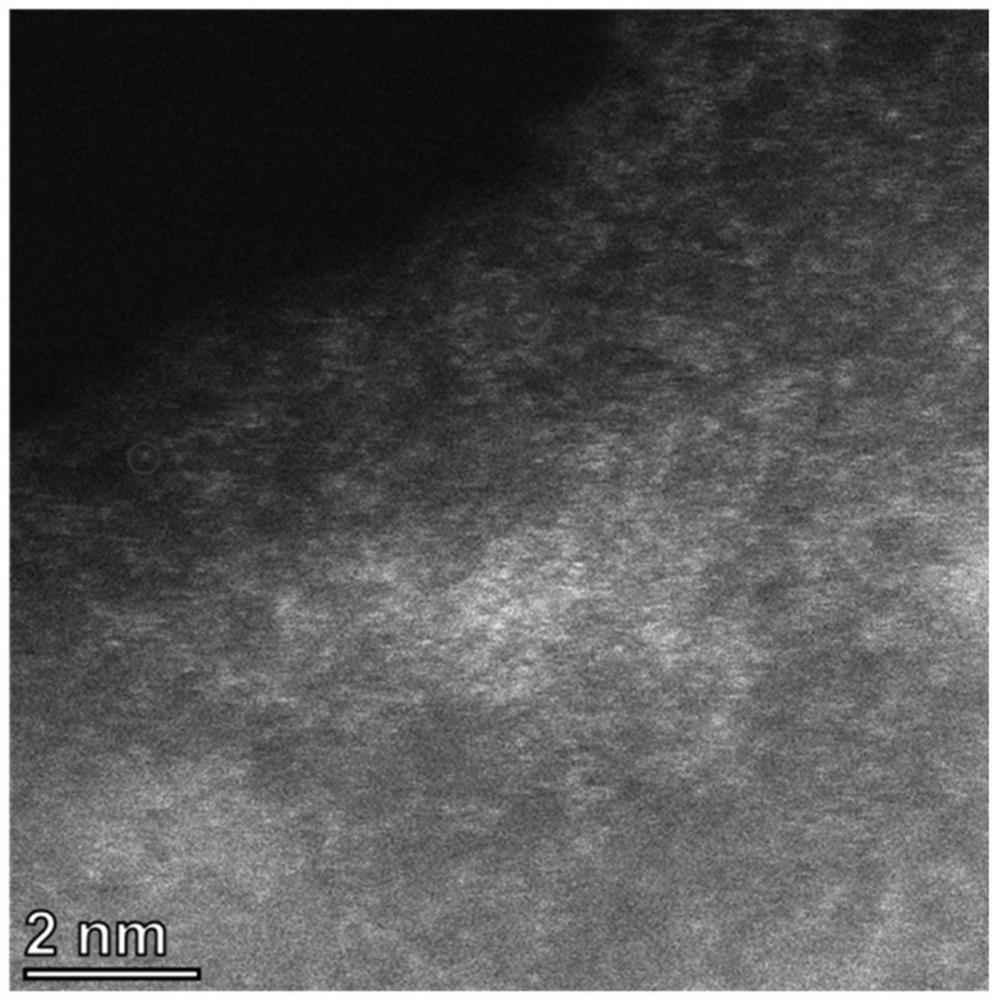

Fe monatomic catalyst Fe-PANI and preparation method thereof

PendingCN114558617ALittle environmental hazardEasy to handleWater treatment parameter controlWater treatment compoundsChemistryImine

The invention discloses a preparation method of a Fe monatomic catalyst Fe-PANI. The preparation method comprises the following steps: 1) pretreating a polyaniline carrier; polyaniline in a complete oxidation state or an intermediate oxidation state is directly used as a carrier; the polyaniline in the acid-doped state is used as a carrier after being subjected to alkali washing; (2) dipping the polyaniline carrier in a ferric salt solution or a ferrous salt solution or a mixed solution of ferric salt and ferrous salt, so that Fe atoms are coordinated with imine nitrogen atoms in polyaniline to be loaded on the surface of polyaniline; and 3) separating out the polyaniline carrier loaded with Fe atoms, washing the polyaniline carrier with deionized water, and drying to obtain the Fe monatomic catalyst Fe-PANI. The invention further relates to the Fe monatomic catalyst Fe-PANI prepared through the method, polyaniline serves as a carrier of the Fe monatomic catalyst Fe-PANI, and Fe monatomic atoms are stably loaded on the surface of the polyaniline carrier in a highly dispersed mode through coordination.

Owner:XI AN JIAOTONG UNIV

Environment-friendly type dyeing assistant for natural blended fabric and preparation method thereof

The invention discloses an environment-friendly type dyeing assistant for natural blended fabric. The environment-friendly type dyeing assistant is mainly prepared from the following main raw materials: a rare earth compound, organic acid, borax, chitosan, a leveling agent, a dispersant, zinc oxide and sodium hexametaphosphate. In the environment-friendly type dyeing assistant, the main raw materials are the borax and the sodium hexametaphosphate, and a trace of the rare earth compound and a small amount of the zinc oxide are supplemented, so that the content of inorganic salt is reduced to be less than 1 percent, and environmental hazard is remarkably reduced; meanwhile, during a preparation process, compounds, such as halogens and heavy metal, which are harmful to a human body and the environment are not added. The environment-friendly type dyeing assistant disclosed by the invention is matched with active dye for use, and dyed natural blended fabric is uniform in color, has no chromatic aberration, is bright in color and good in color fixing effect.

Owner:何帅松

Polymer gel crosslinking agent capable of realizing controllable gelling time

ActiveCN108517043ALittle environmental hazardGuaranteed long-term thermal stabilityIonSodium sulfite

The invention relates to the field of oil field chemistry, and belongs to a polymer gel crosslinking agent capable of realizing the controllable gelling time. The polymer gel crosslinking agent mainlysolves the problems of gelling time uncontrollability and environment pollution of the frequently-used polymer gel crosslinking agents in an oil field. The polymer gel crosslinking agent is preparedfrom the following ingredients in percentage by weight: 0.2 to 0.3 percent of trivalent metal chromium ion salt, 0.01 to 0.03 percent of low-carbon mixed organic acid, 0.02 to 0.05 percent of organicacid, 0.03 to 0.06 percent of melamine, 0.01 to 0.04 percent of sodium sulfite and the balance of water. The polymer gel crosslinking agent has the advantages that the gelling time is controllable; the harm to the environment is small; good long-period thermal stability is realized, and the like.

Owner:PETROCHINA CO LTD +1

Method for modifying carbon fibers for paper-based friction material

The invention relates to a method for modifying carbon fibers for a paper-based friction material, and belongs to the technical field of preparation of paper-based friction materials. The method comprises the following operation steps of 1, adopting a carbon fiber pretreatment system; 2, implementing a carbon fiber pretreatment process; and 3, adopting a layer assembly deposition modification system of the carbon fibers, wherein the suspension liquid of the carbon fibers is used as a matrix for layer deposition modification, a multi-layer alternate deposition mode is adopted for layer deposition adsorption modification, and a modifier is divided into polymers with different anion and cation strengths; and 4, carrying out a layer assembly deposition modification process on the carbon fibers, and repeating the steps, modifying for 3-4 times, filtering and drying to obtain the modified carbon fiber. The obtained carbon fiber can be added as a component for the paper-based friction material. The method has the advantages of simple process and low energy consumption. The technical problems of dispersion, combination and the like of reinforced fibers in the preparation process of the paper-based friction material are solved. The method is suitable for modifying the carbon fibers in the large-scale production process of the paper-based friction material.

Owner:杭州萧山红旗摩擦材料有限公司

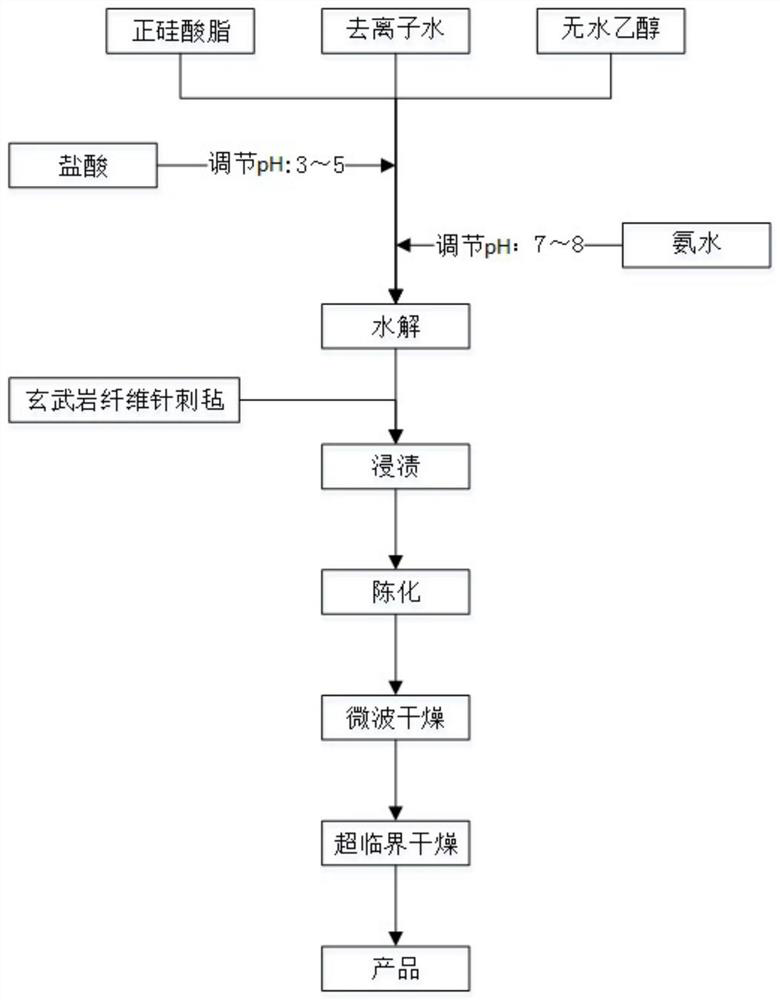

A composite thermal insulation pad and its manufacturing process

The invention belongs to the technical field of heat-resistant materials, and discloses a composite thermal insulation pad and a manufacturing process thereof. Using the ultra-fine basalt fiber needle-punched felt as the raw material, an ultra-thin (1mm thick) ultra-fine basalt fiber aerogel composite thermal insulation pad can be prepared, which can be used in the field of high-temperature thermal insulation materials for power batteries. A product with higher temperature resistance and lower thermal conductivity is prepared and obtained, which not only has better thermal insulation performance, but also has higher insulation performance, longer service life and less environmental hazard. The ultra-fine basalt fiber aerogel composite thermal insulation pad can be used as a thermal insulation material with better performance and can be widely used in metallurgy, machinery, electric power, chemical thermal equipment, aerospace, and military fields. The supercritical method is used to directly dry the aged ultrafine basalt fiber needled felt to obtain a gel-like ultrafine basalt fiber needled felt, which saves the step of replacing the solvent, improves the production efficiency, and shortens the drying time. Reduced production costs.

Owner:重庆智笃新材料科技有限公司

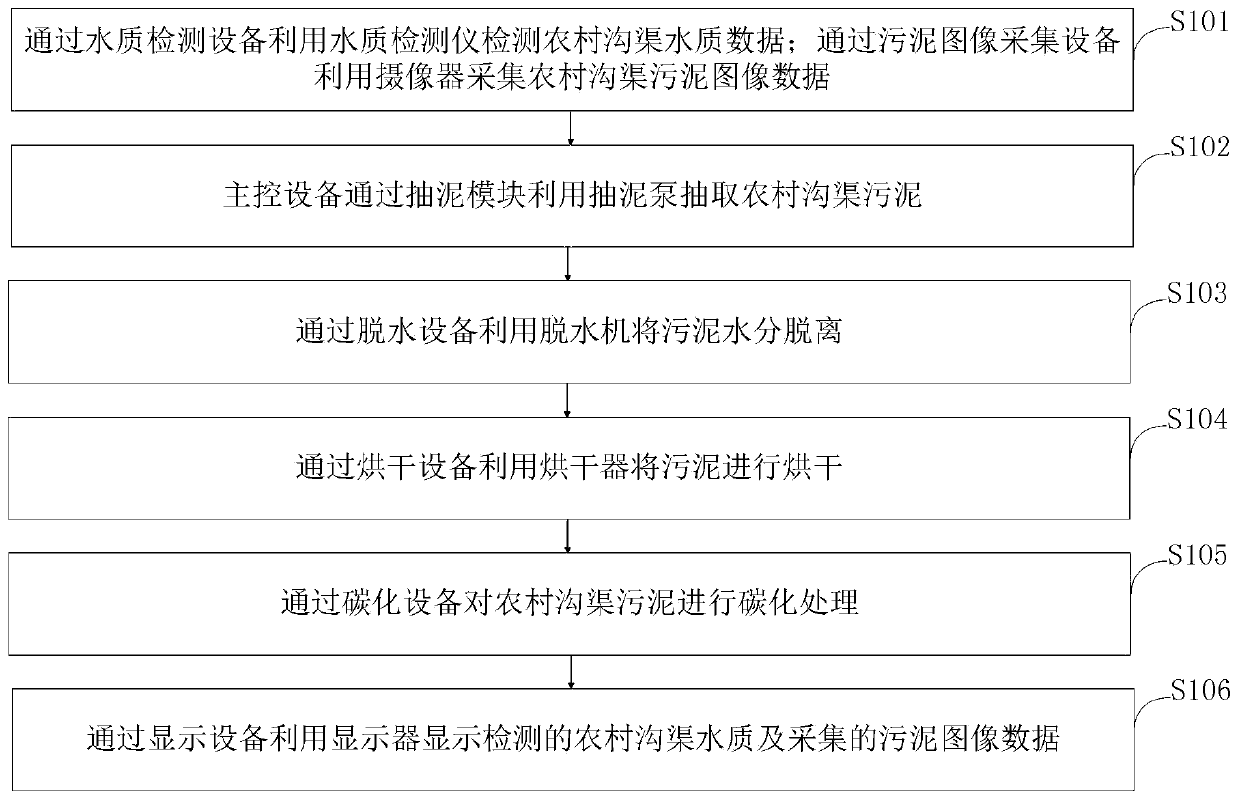

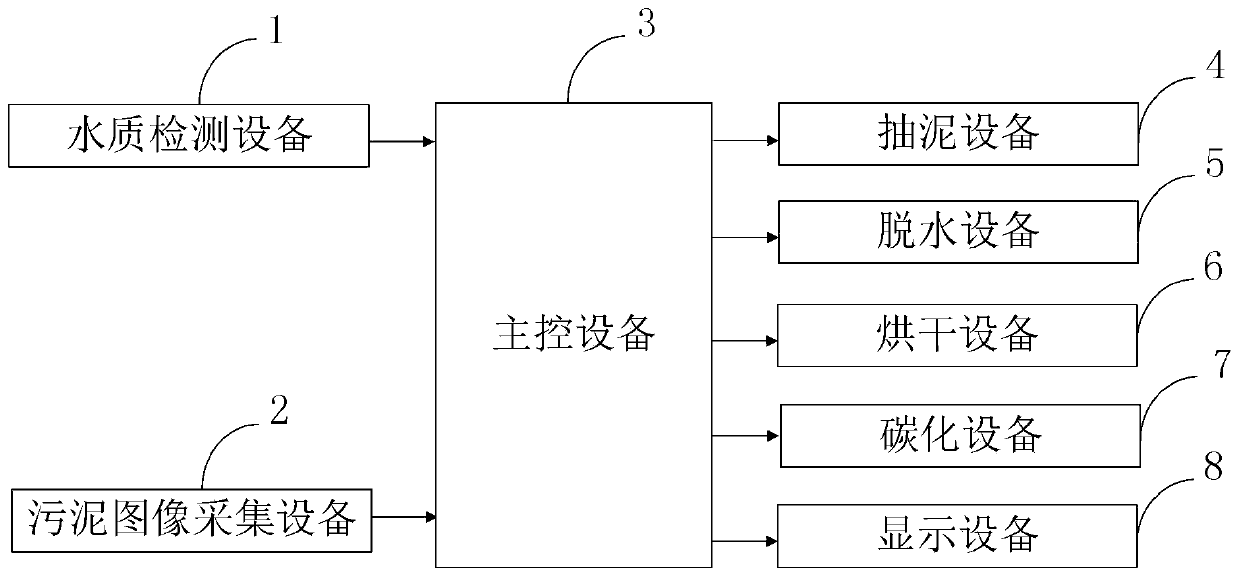

Treatment method and treatment system for rural ditch sludge

InactiveCN110357390AGood sludge dehydration effectLittle environmental hazardSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludge dewateringWater quality

The invention belongs to the technical field of treatment of rural ditch sludge, and discloses a treatment method and a treatment system for rural ditch sludge. The treatment system for the rural ditch sludge comprises a water quality detection device, a sludge image collection device, a main control device, a sludge extracting device, a dewatering device, a drying device, a carbonization device and a display device. Lysozyme is used to hydrolyze the cell walls of microorganisms in the sludge through the dewatering device, so the system can achieve a good sludge dewatering effect and has few harms to the environment. The carbonization device utilizes the deodorizing function of the microorganisms and the filtering function of carbonized sludge to effectively remove the odor of the sludge after long-time sludge before drying the sludge, so the health of the worker is prevented from being damaged.

Owner:SINOMINE ROCK & MINERAL ANALYSIS TIANJIN CO LTD

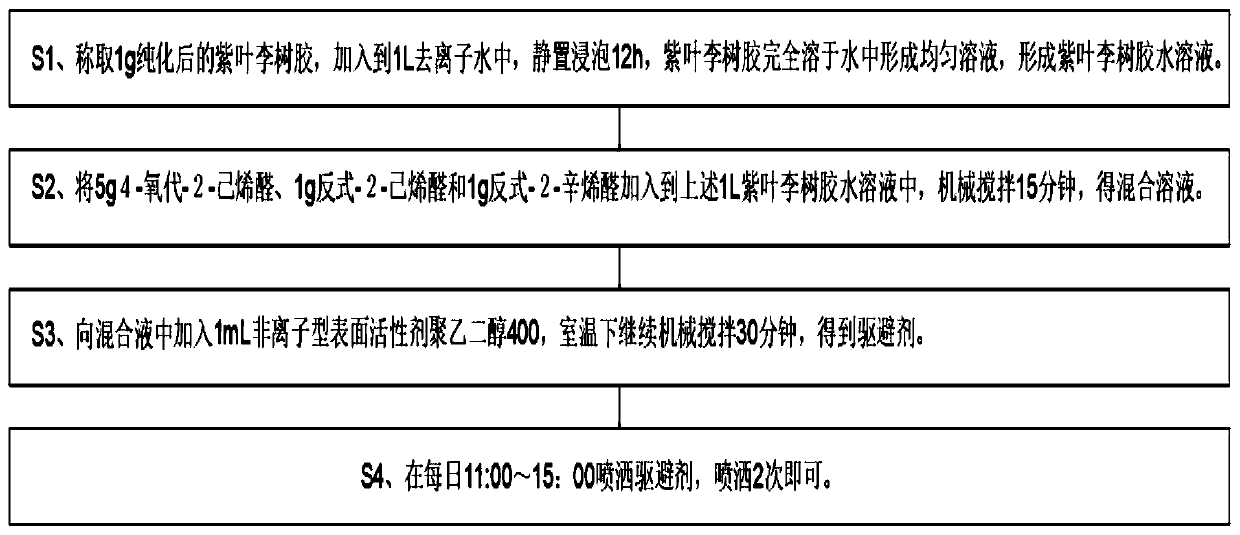

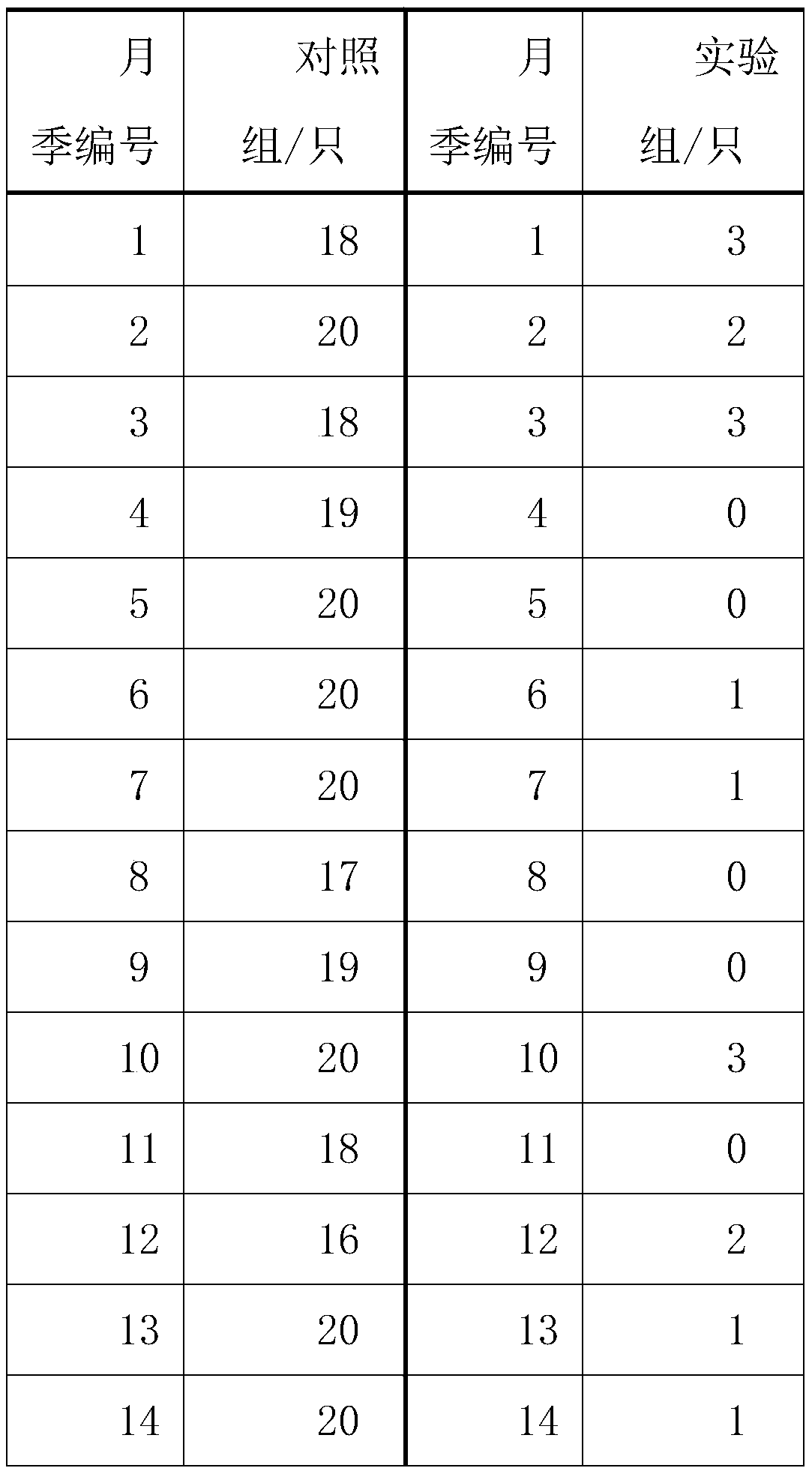

Aphid repellent based on multi-component linear chain unsaturated aldehydes

InactiveCN109892329ALittle environmental hazardImprove compatibilityBiocidePest repellentsPesticideToxicity

The invention discloses the technical field of agricultural chemical engineering, and particular to an aphid repellent based on multi-component linear chain unsaturated aldehydes. A preparation methodof 1L of repellent includes the steps: S1 weighing 1g of purified purple-leaf plum, adding the purple-leaf plum into 1L of deionized water, standing and soaking mixture for 12hours, and completely dissolving the purple-leaf plum in water to form homogeneous solution to obtain purple-leaf plum water solution; S2 adding 5g of 4-oxo-2-hexenoic aldehyde, 1g of trans-2-hexenoic aldehyde and 1g of trans-2-octenal into 1L of purple-leaf plum water solution, and mechanically stirring mixture for 15 minutes to obtain mixed solution; S3 adding 1mL of nonionic surface active agent polyethylene glycol 400 into the mixed solution, and continuing to mechanically stir mixture for 30 at the indoor temperature to obtain the repellent. The prepared aphid repellent cannot kill aphids and effectively repelsthe aphids. Compared with a pesticide for killing the aphids, the prepared aphid repellent is free from toxicity and harm, less in environmental harm and more suitable for outdoor viewing and gardening flowers.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Surface coating process of neodymium-iron-boron magnet

PendingCN114381773AThe process is easy to operateLittle environmental hazardLiquid/solution decomposition chemical coatingSuperimposed coating processPhysicsCorrosion resistant

The invention relates to the technical field of neodymium-iron-boron magnets, in particular to a neodymium-iron-boron magnet surface coating process which comprises the following steps: S1, polishing; s2, removing oil and cleaning; s3, acid pickling; s4, performing surface conditioning processing; s5, activating treatment; s6, nickel electroplating treatment, wherein an electroplating solution comprises the following components: 100-110 g / L of nickel sulfate, 60-80 g / L of nickel chloride, 20-50 g / L of sodium sulfate, 40-60 g / L of boric acid and 0.05-0.1 g / L of lauryl sodium sulfate; the pH value of the electroplating solution is 4.0-5.0, the electroplating treatment time is 30-60 minutes, the temperature is 60-65 DEG C, the current density is 0.5-0.6 A / dm < 2 >, and the thickness of a plating layer is 2-6 microns; s7, chemical nickel-tungsten-phosphorus alloy plating treatment; according to the coating technology, operation is easy and convenient, in the coating process, used reagents have little harm to the environment, the composite coating almost has no influence on the thermal demagnetization rate of the magnet, the binding force between the composite coating and a base body is very good, the composite coating is not prone to falling off, and the corrosion resistance of the neodymium-iron-boron magnet is greatly improved.

Owner:NINGBO ZHAOBAO MAGNET

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com