Egg yolk-egg shell structure type microsphere and preparation method thereof

A technology of microspheres and eggshells, applied in structural parts, electrical components, electrochemical generators, etc., can solve the problems of difficulty in controlling the volume of the empty layer, not meeting the needs of industrialization, and large environmental hazards, and achieving a regular structure and environmental hazards. Small, simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

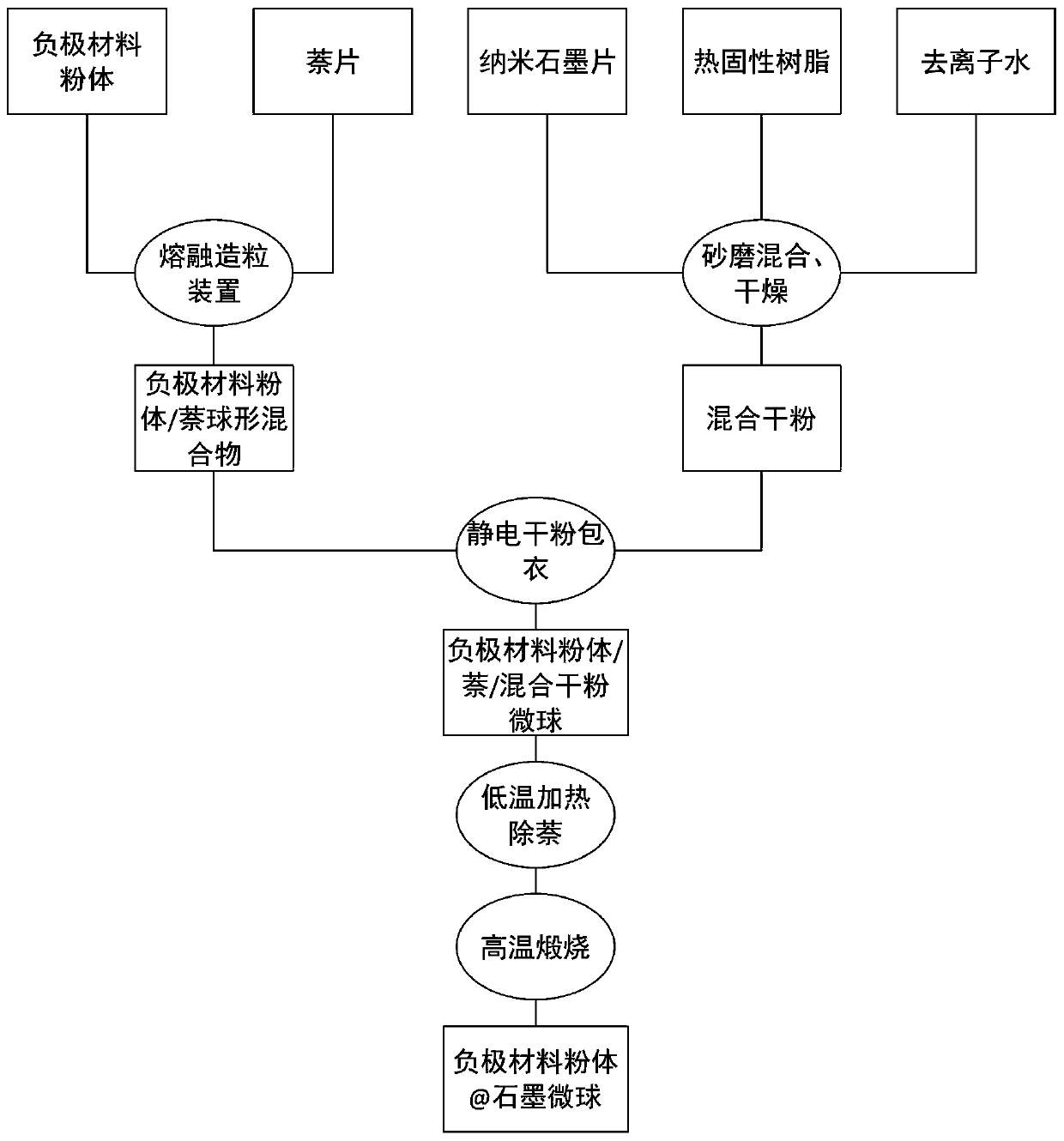

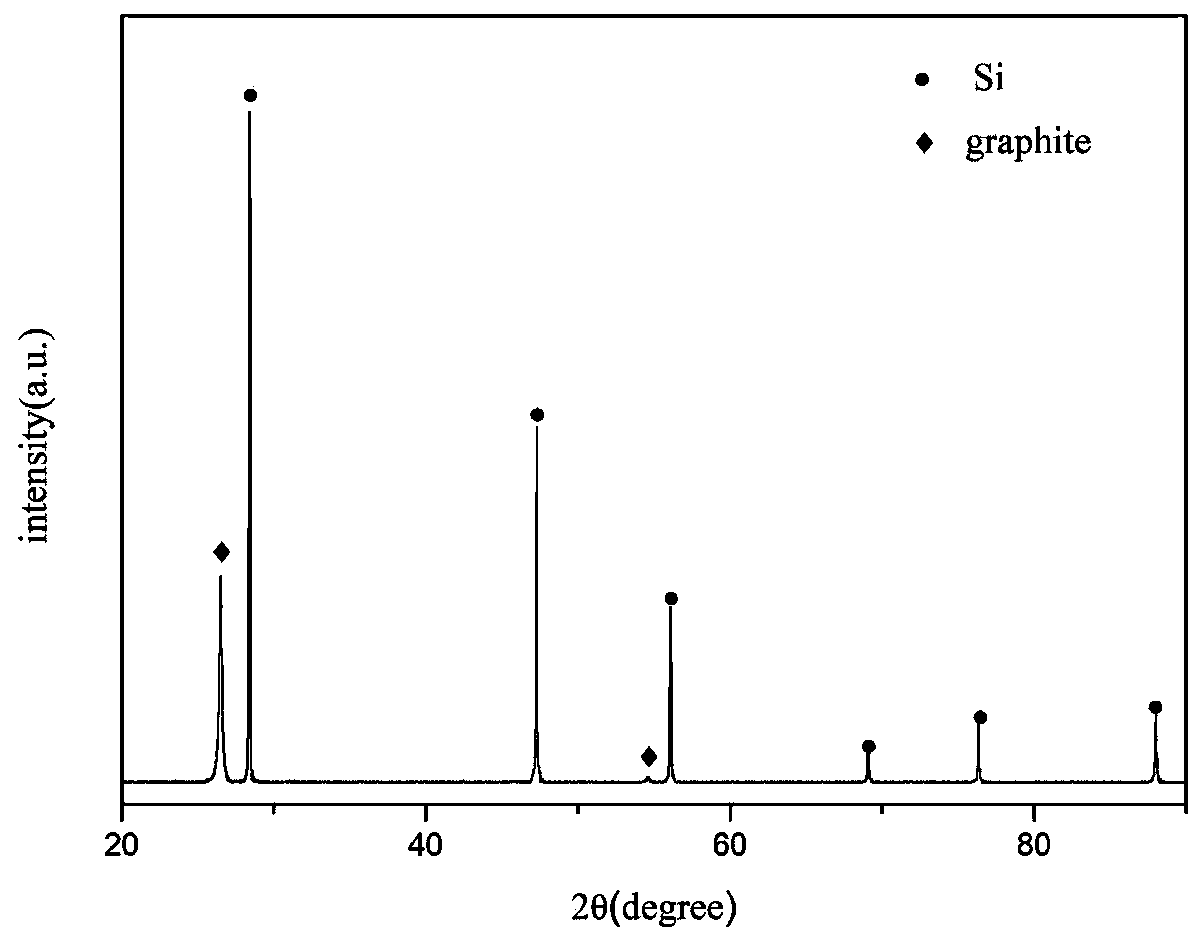

[0053] Example 1 (see figure 1 ):

[0054] (1) Preparation of silicon powder / naphthalene spherical mixture: silicon powder and naphthalene sheets are heated and stirred in a constant temperature water bath in a mass ratio of 1:2 until the naphthalene is completely melted to obtain a mixed dispersion, and the mixed dispersion is placed in a melting granulation device and heated to After cooling at 95°C, spraying is carried out to obtain a silicon powder / naphthalene spherical mixture.

[0055] (2) Prepare silicon powder / naphthalene / mixed dry powder: mix nano-graphite flakes, phenolic resin, and deionized water according to a mass ratio of 10:8:75 and sand mill them for 30 minutes, and dry to obtain nano-graphite flakes with a particle size of 200-300nm and Thermosetting phenolic resin mixed dry powder, according to the mass ratio of mixed dry powder and silicon powder / naphthalene spherical mixture of 1:20 by electrostatic dry powder coating method, the mixed dry powder is evenl...

Embodiment 2- Embodiment 7

[0059] The specific preparation process parameters and conditions of Example 2-Example 7 are shown in Table 1. Finally, a series of egg yolk-eggshell structure negative electrode material powder@graphite microspheres with firm, complete shells and regular structures without collapse can be obtained, which can be used as electrode negative electrodes Material.

[0060] Table 1

[0061]

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com