A new environment-friendly gold ore beneficiation process under simulated natural conditions

A technology based on natural conditions and gold ore, which is applied in the fields of new environmental protection gold ore beneficiation process, environmental protection measures and tailings resource utilization technology, which can solve the problems that restrict the practical application of pollution control technology, tailings dust pollution, large equipment investment, etc. problems, to achieve the effect of reducing treatment costs, reducing environmental hazards, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

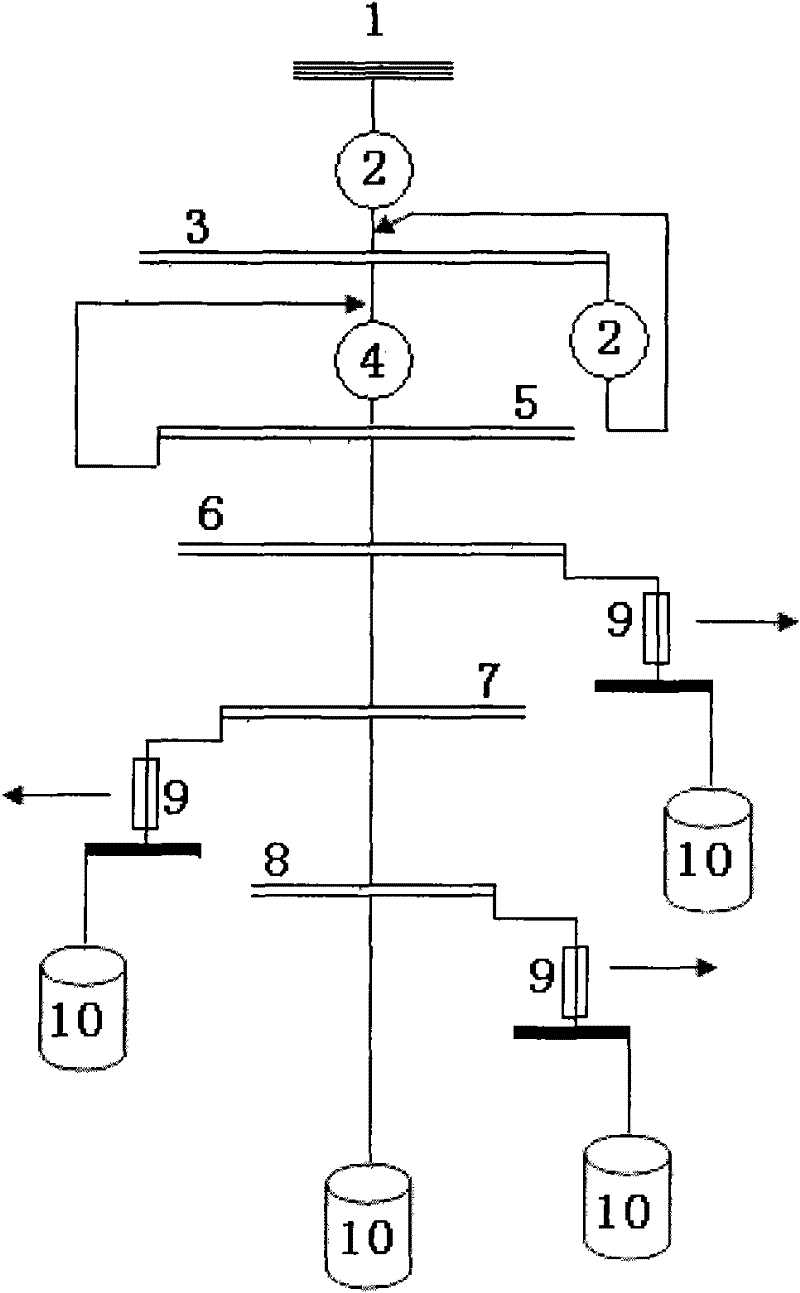

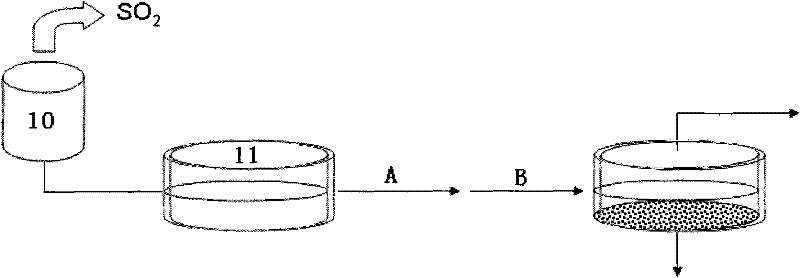

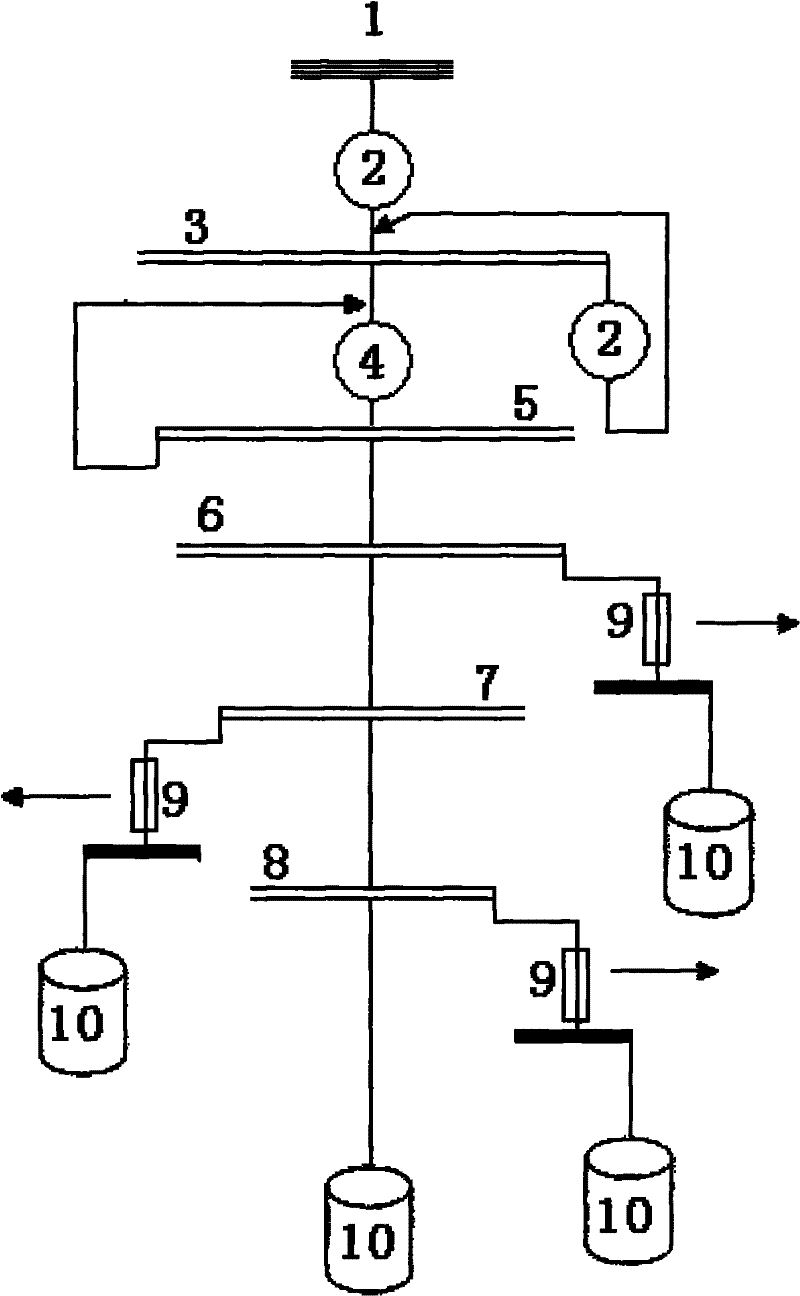

Method used

Image

Examples

Embodiment 1

[0026] Gold sample 1, produced in Gansu, is a primary quartz mine with a gold content of 5.5 g / t. The main components are 94% quartz, 5% pyrite, and 1% silicate. The average particle size of gold particles is 11.2 microns, and 66% is Quartz-coated, 34% pyrite-coated. The traditional process adopts amalgamation gravity gravity pretreatment, sodium cyanide solution leaching, the gold recovery rate is 94%, the grade of fine gold is 100-110 g / ton, and the grade of tailings is 0.3 g / ton. After adopting the process disclosed in this patent, the recovery rate of gold is 99%, the grade of fine gold ore is 500-1000 g / ton, the grade of tailings is lower than 0.1 g / ton, and the amount of sodium cyanide, the main pollutant per gram of gold produced, is reduced 82%, the cost is reduced by 41%, and the power consumption is reduced by 53%.

Embodiment 2

[0028] Gold ore sample 2, produced in Shandong, belongs to pyrite gold-bearing quartz vein ore, with a gold content of 8 g / t, a sulfide (pyrite-based) content of 13%, a quartz content of 83%, and an average particle size of gold particles of 10.1 Micron, more than 90% of which are closely symbiotic with pyrite, traditionally grind to more than 60% and pass through a 200-mesh sieve (aperture 74 microns), and then use air flotation, the gold recovery rate is 96%, and the gold concentrate grade is 90 g / ton. Cyanide leaching adopts roasting acid production process in advance, and 4kg of industrial sulfuric acid can be produced for every 1g of gold produced. Using the process disclosed in this patent, without using any flotation agent, the gold recovery rate is 97%, the gold concentrate grade reaches 600-700 g / t, and 7 kg of industrial sulfuric acid can be produced for every 1 gram of gold produced, and every gram of gold produced Costs are reduced by 27% and power consumption is r...

Embodiment 3

[0030] Gold ore sample 3, produced in Henan, is a refractory ore with high arsenic content, the gold content is 4g / ton, the recovery rate of traditional cyanidation extraction is 50-60%, the tailings grade is 1.7g / ton, and the gold concentrate grade is 50-60 g / t, the arsenic content of gold concentrate exceeds the national precious metal smelting standard. After using the process disclosed in this patent, the gold recovery rate is 92%, the tailings grade is 0.3 g / ton, the gold concentrate grade is 350-400 g / ton, and the arsenic in the flue gas is recovered in the form of white arsenic, which is comprehensively recovered The efficiency reaches 99.9%, and the consumption of cyanide per ton of raw ore is reduced by 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com