Method of utilizing zinc hydro-metallurgy oxygen pressure acid leaching slag to prepare demercuration adsorbent

A technology of oxygen pressure acid leaching and wet zinc smelting, which is applied in the field of adsorption materials, can solve the problems of difficult application, high difficulty, and high quotation cost, and achieve the effects of low cost, reduced environmental hazards, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a mercury-removing sorbent by using zinc oxygen pressure acid leaching slag from wet smelting, comprising the following steps:

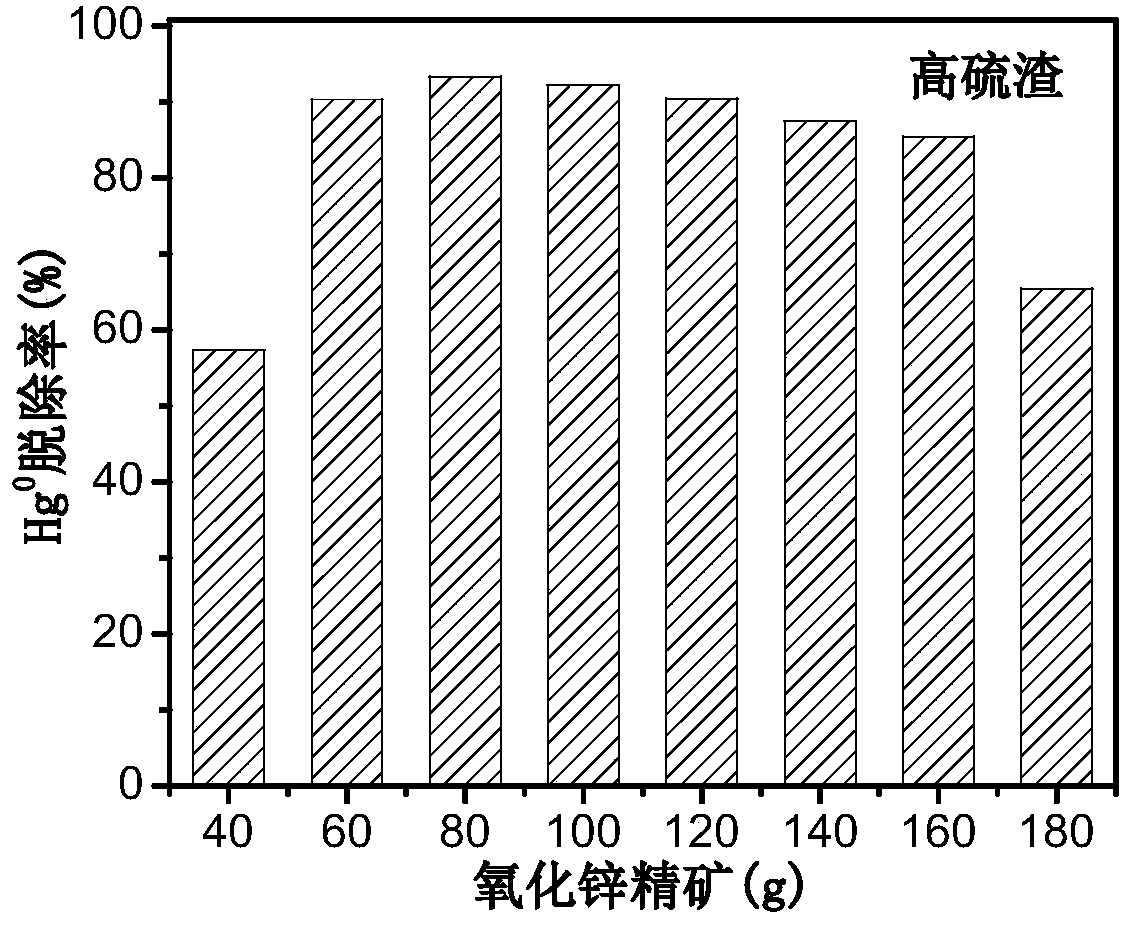

[0038] (1) Pass the finely ground zinc oxide ore (zinc oxide concentrate) through a 100-mesh sieve to obtain zinc oxide ore particles with a particle size less than 150 μm, and then take 40g, 60g, 80g, 100g, 120g, 140g, 160g and 180g are uniformly mixed with 20g pressurized oxidation acid leaching residue (ie high sulfur residue) to obtain different premixes;

[0039] (2) Prepare a mixed solution of ethanol and water at a ratio of 1:1, and add sodium sulfide to the mixed solution of ethanol and water so that S 2- The concentration of ions is 0.02mol / L to obtain a sulfide salt solution;

[0040](3) Mix the different premixes obtained in step (1) with the sulfide salt solution obtained in step (2) respectively, the mass solid-to-liquid ratio is controlled to be 0.3:1, and ultrasonically stirred for 10 minutes to make the ...

Embodiment 2

[0046] A method for preparing a mercury-removing sorbent by using zinc oxygen pressure acid leaching slag from wet smelting, comprising the following steps:

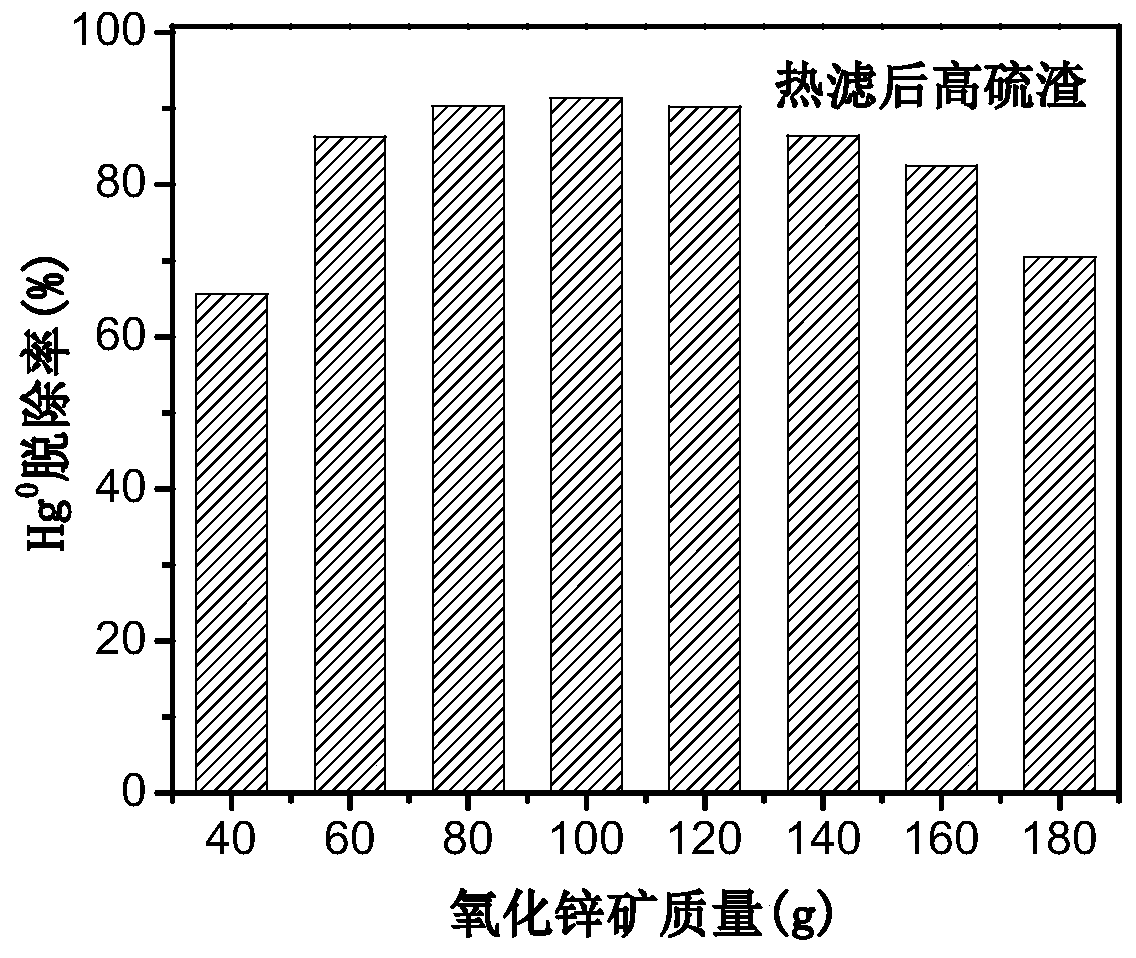

[0047] (1) Pass the finely ground zinc oxide ore (zinc oxide concentrate) through a 100-mesh sieve to obtain zinc oxide ore particles with a particle size less than 150 μm, and then take 40g, 60g, 80g, 100g, 120g, 140g, 160g and 180g and 20g of pressurized oxidation acid leaching slag are mixed evenly to obtain different premixes with the tailings obtained after hot filtration (i.e. the high-sulfur slag after hot filtration);

[0048] (2)-(4) are the same as steps (2)-(4) of Example 1.

[0049] In the high-sulfur slag after hot filtration, the mass fraction of zinc is 10.24%, and the mass fraction of elemental sulfur is 38.63%.

[0050] Take the prepared mercury removal adsorbent, place it in a fixed bed, and evaluate the flue gas mercury removal performance of the mercury removal adsorbent. The specific process is: fi...

Embodiment 3

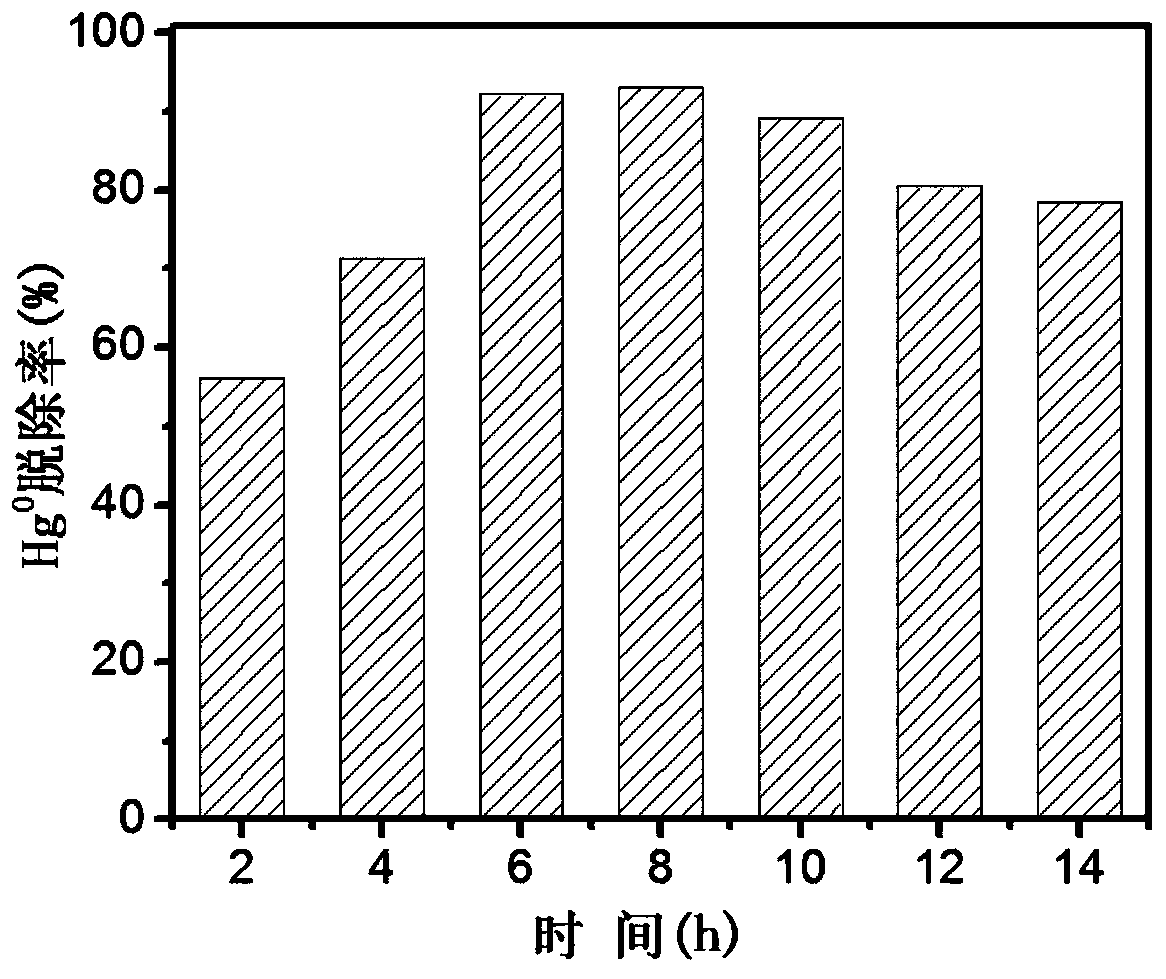

[0053] A method for preparing a mercury-removing sorbent by using zinc oxygen pressure acid leaching slag from wet smelting, comprising the following steps:

[0054] (1) Pass the finely ground zinc oxide ore (zinc oxide concentrate) through a 100-mesh sieve to obtain zinc oxide ore particles with a particle size of less than 150 μm, and then take 100 g of zinc oxide ore and 20 g of pressurized oxidation acid leaching residue to mix evenly to obtain premix;

[0055] (2) Prepare a mixed solution of ethanol and water at a ratio of 1:1, and add sodium sulfide to the mixed solution of ethanol and water so that S 2- The concentration of ions is 0.02mol / L to obtain a sulfide salt solution;

[0056] (3) Mix the premix obtained in step (1) with the sulfide salt solution obtained in step (2), control the mass solid-to-liquid ratio to 0.3:1, stir ultrasonically for 10 minutes to make the solution into a suspension, and then Put the turbid liquid into a closed hydrothermal reaction kett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com