Fe monatomic catalyst Fe-PANI and preparation method thereof

A catalyst and atom technology, which is applied in the field of Fe single-atom catalyst Fe-PANI and its preparation, can solve the problems of the narrow pH range of homogeneous Fenton and the inability to recycle Fe of the catalyst, and achieve high heterogeneous Fenton catalytic activity. and stability, less environmental hazard, and the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 0.2g of acid-doped polyaniline and 20mL of 0.2mol·L -1 NaOH solution, ultrasonically oscillating for 0.5h to de-dope the polyaniline, separate the polyaniline and wash it with deionized water until the washing solution is neutral, then transfer the polyaniline carrier to 20mL 0.12mol·L -1 The ferrous sulfate solution was stirred magnetically at room temperature for 2 hours, and then the polyaniline carrier was separated and washed fully with deionized water, drained and dried in an oven at 60°C to obtain the Fe-PANI catalyst.

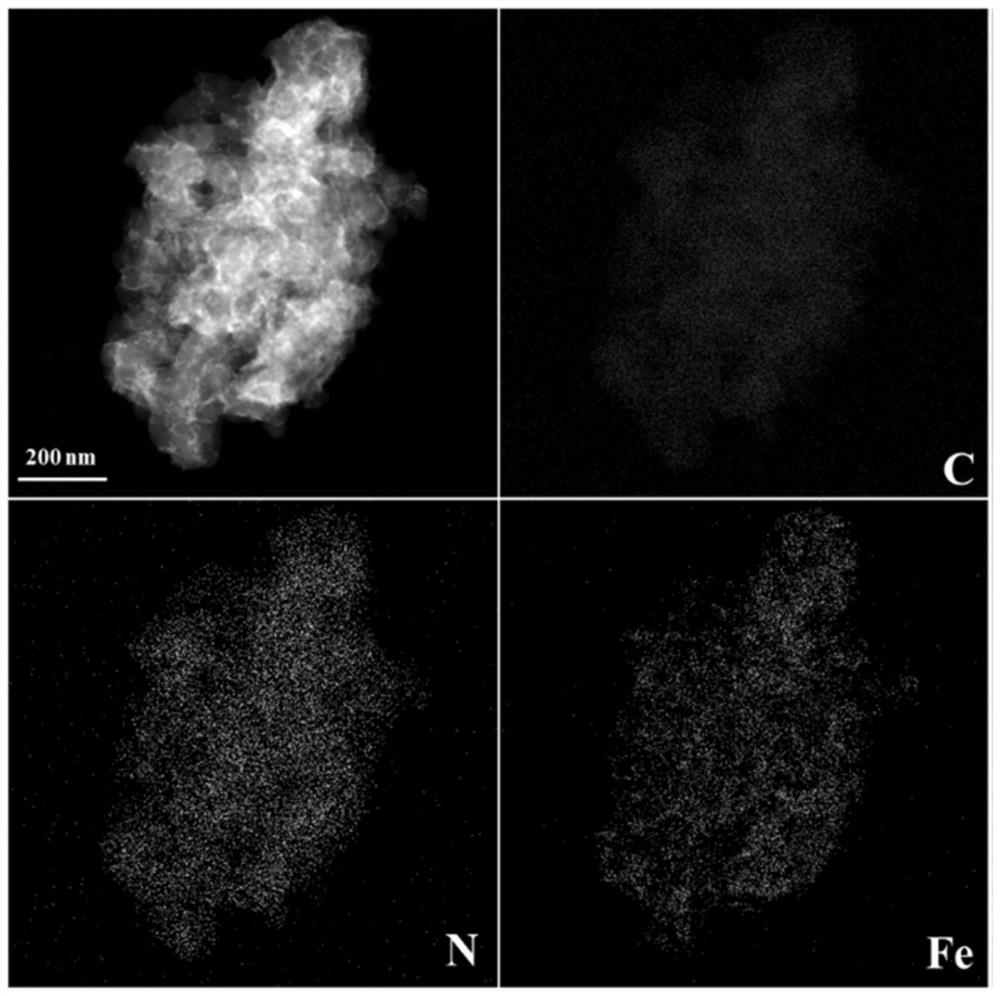

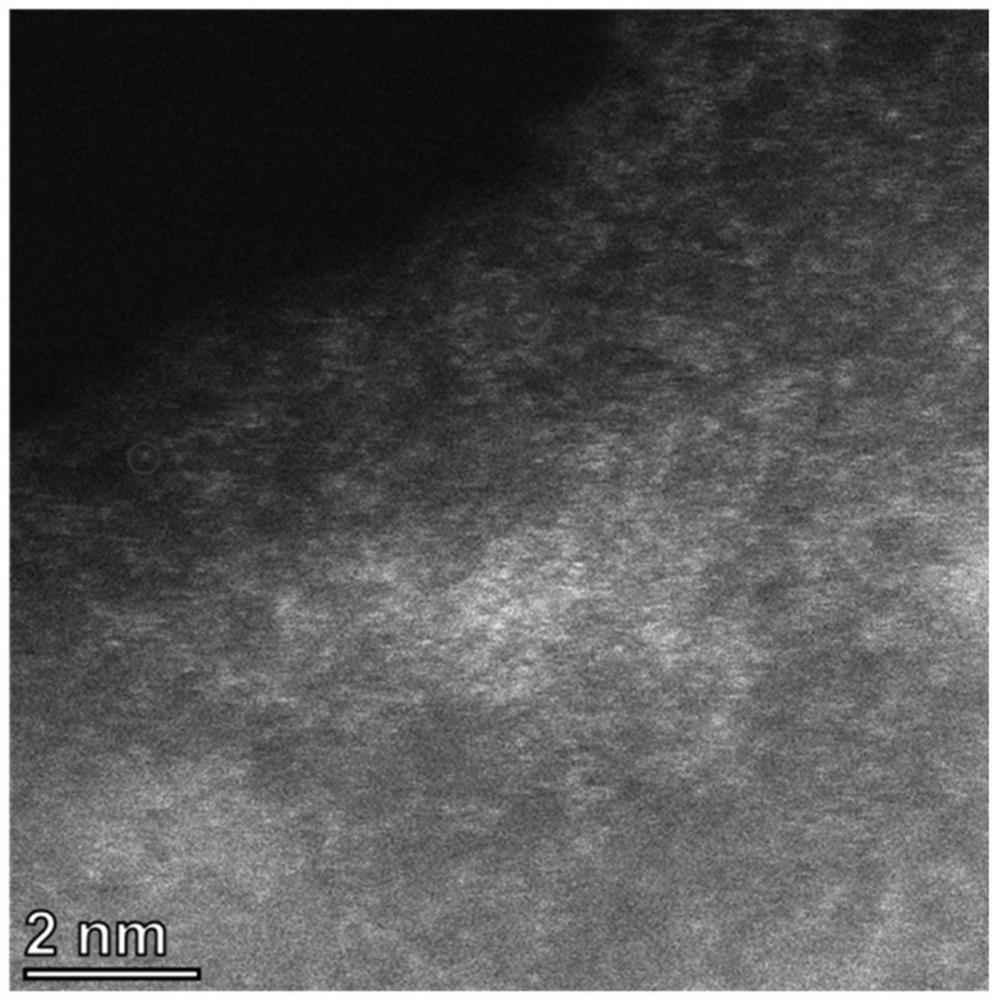

[0027] figure 1 and figure 2 These are the high-resolution transmission electron microscope image and the spherical aberration-corrected transmission electron microscope image of the Fe single-atom catalyst Fe-PANI prepared in this example, respectively. Depend on figure 1 It can be seen that the Fe atoms are evenly distributed on the surface of the polyaniline carrier, and there is no agglomeration phenomenon. and figure 2 The spheric...

Embodiment 2

[0030] Add 0.2g of acid-doped polyaniline and 20mL of 0.02mol·L -1 NaOH solution, after ultrasonic oscillation for 0.5h, the polyaniline was separated and washed with deionized water until the washing liquid was neutral, and then the polyaniline carrier was transferred to 20mL0.12mol·L -1 The ferrous sulfate solution was stirred magnetically at room temperature for 2 hours, and then the polyaniline carrier was separated and washed fully with deionized water, drained and dried in an oven at 60°C to obtain the Fe-PANI catalyst.

Embodiment 3

[0032] Add 0.2g of acid-doped polyaniline and 20mL of 0.2mol·L -1 NaOH solution, after ultrasonic oscillation for 0.5h, the polyaniline was separated and washed with deionized water until the washing liquid was neutral, and then the polyaniline carrier was transferred to 20mL 1.0mol·L -1 The ferrous sulfate solution was stirred magnetically at room temperature for 2 hours, and then the polyaniline carrier was separated and washed fully with deionized water, drained and dried in an oven at 60°C to obtain the Fe-PANI catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com