Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Increase pressure intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron-modified organic silicon resin high-temperature-resistant coating and preparation method thereof

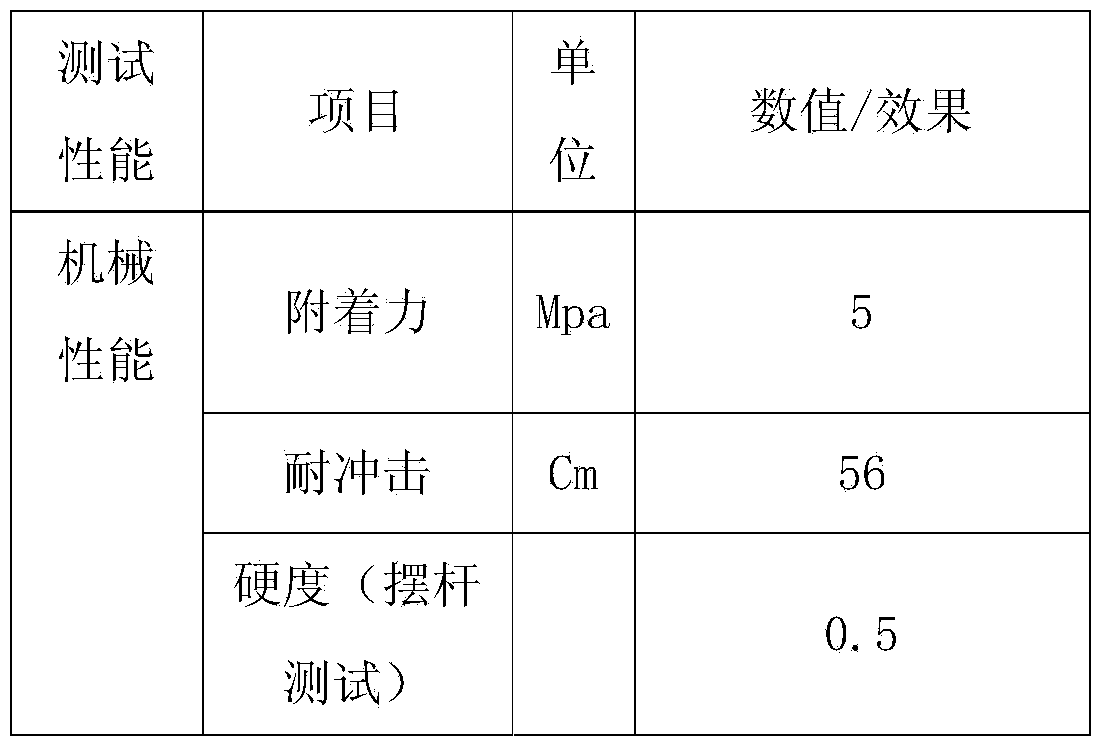

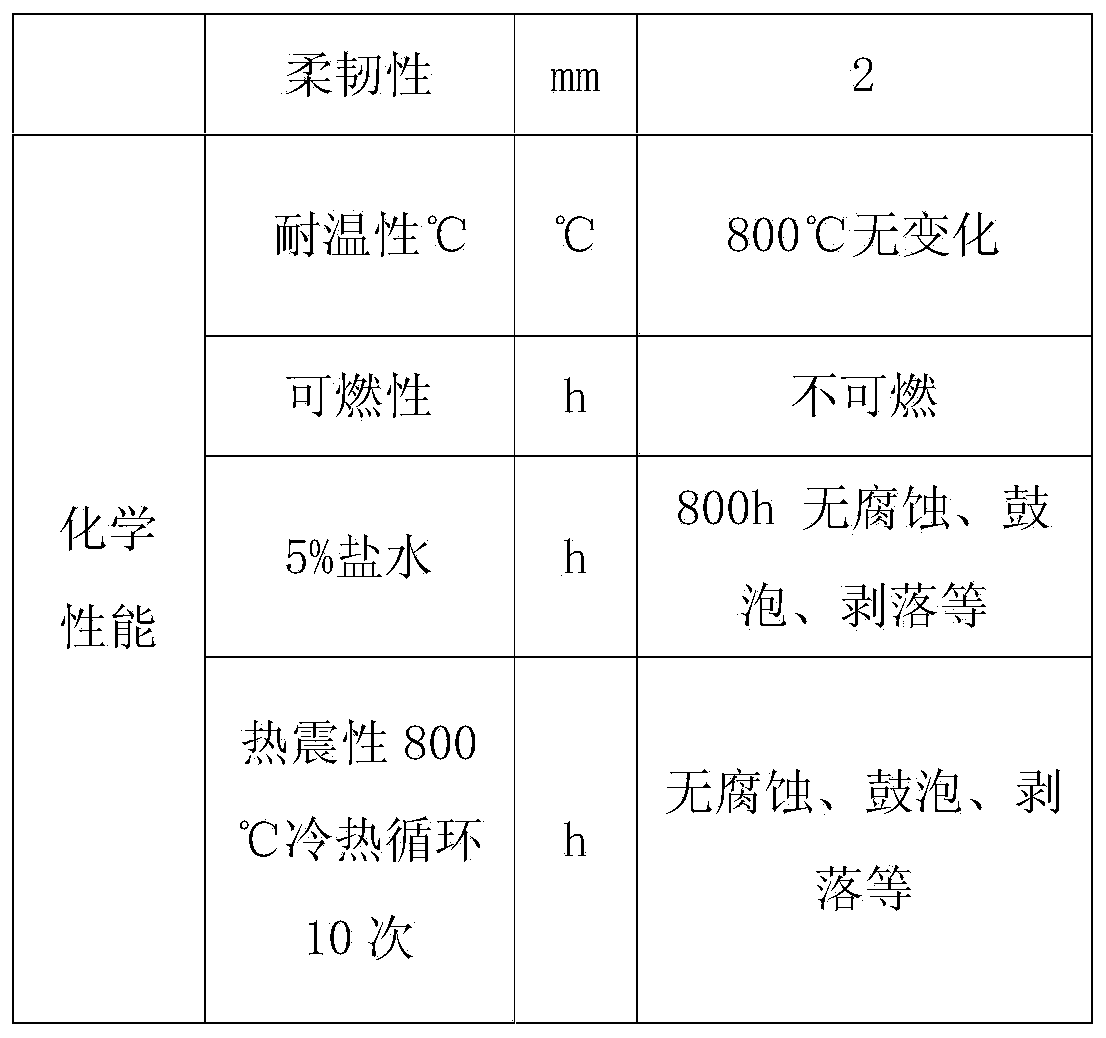

The invention discloses a boron-modified organic silicon resin high-temperature-resistant coating which comprises the following components in percentage by mass: 45%-58% of boron-modified organic silicon resin, 35%-45% of heat-resisting pigment fillers and 2%-4% of auxiliary agents, wherein the boron-modified organic silicon resin is boric-acid-modified organic silicon resin or epoxy-modified silicon-boron resin; and the mass ratio of nanometer silicon dioxide to barrier function fillers to aluminum powder which are contained in the heat-resisting pigment fillers is 1.5:1:1. The invention also discloses a preparation method of the boron-modified organic silicon resin high-temperature-resistant coating. The preparation method disclosed by the invention can be implemented on an existing coating preparation production line without increasing equipment investment; the prepared high temperature-resistant organic silicon coating can be coated by adopting a spray coating process and constructed by adopting a roll coating process, can be subjected to high temperature of 800 DEG C for a long time and has corrosion-resistant property.

Owner:JIANGSU MARINE VICTORY COATING

Vinyl for manufacturing toy and preparation method of vinyl

The invention relates to vinyl for manufacturing a toy. The vinyl for manufacturing a toy is prepared from the following raw materials in percentage by weight: phthalate, dioctyl phthalate, dibasic lead stearate, PVC (polyvinyl chloride) paste resin, PVC coarse powder, PVC medium powder, talcum powder, PVC hard oil, plasticizer TXIB, acetyl-tri-n-butyl citrate, vanillin, amyl acetate, geranyl butyrate and maltol. The vinyl has good hardness, smooth handfeel, strong plasticity, high re-shaping ability and high stability, and does not deform easily after multiple extrusions; and meanwhile, the vinyl is non-toxic and harmless and has fresh fruit aroma.

Owner:浙江银太郎动漫文化股份有限公司

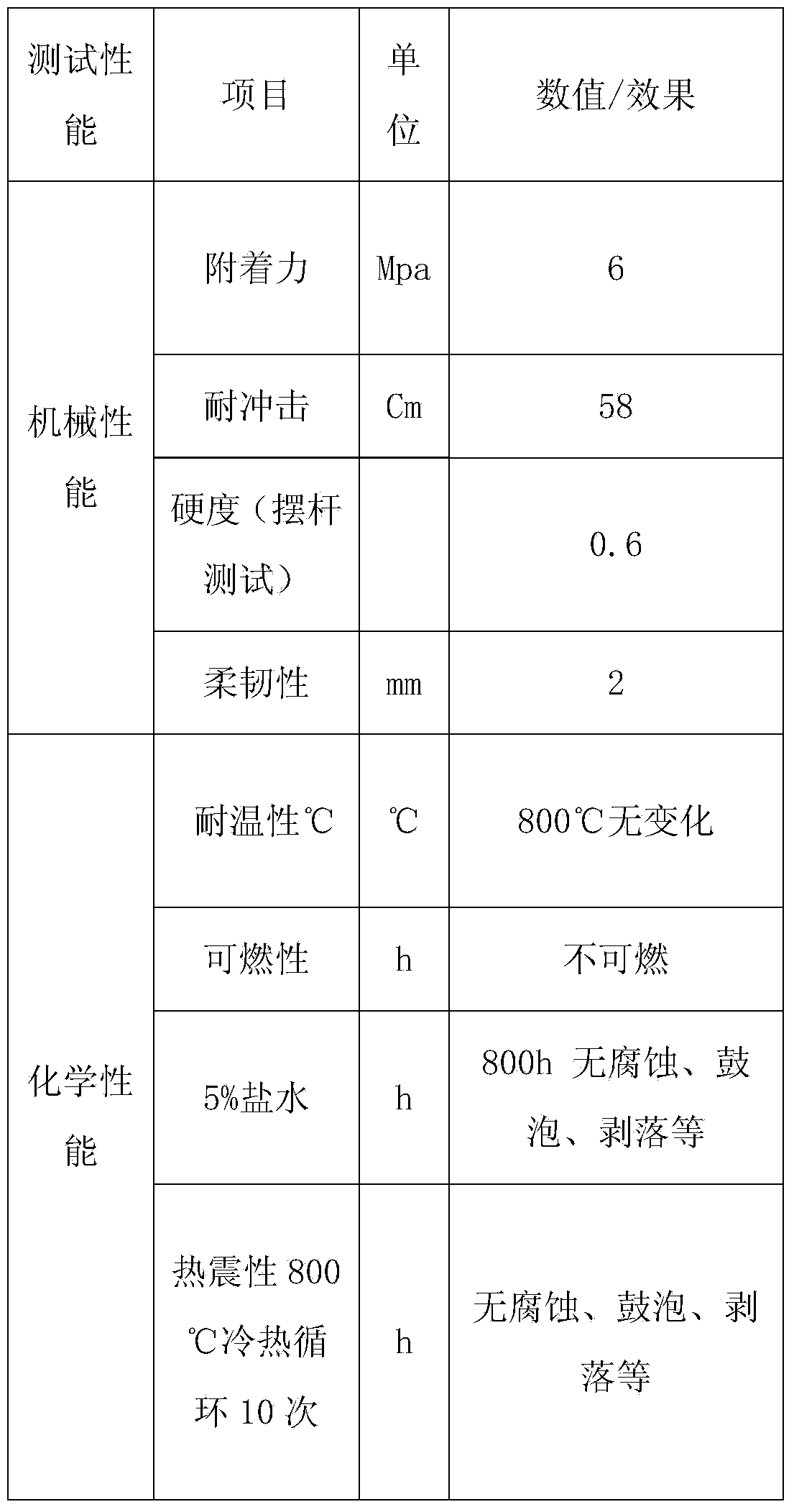

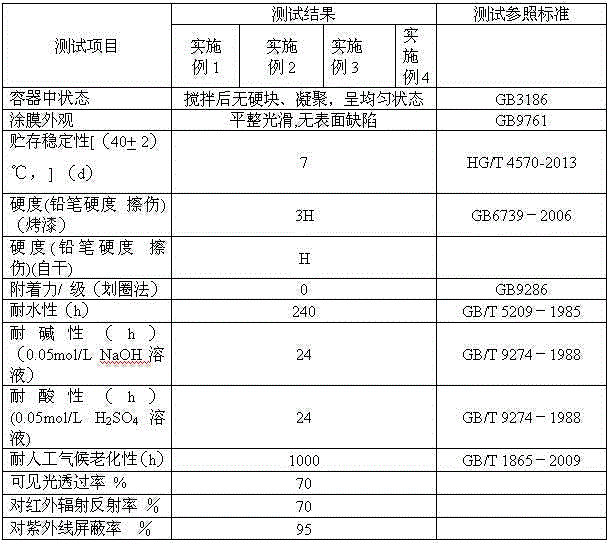

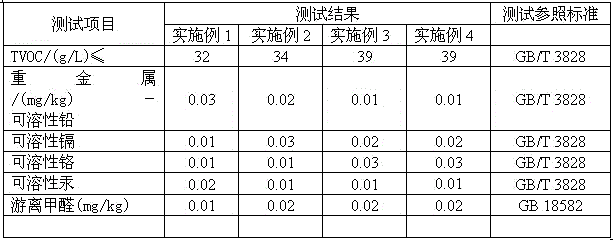

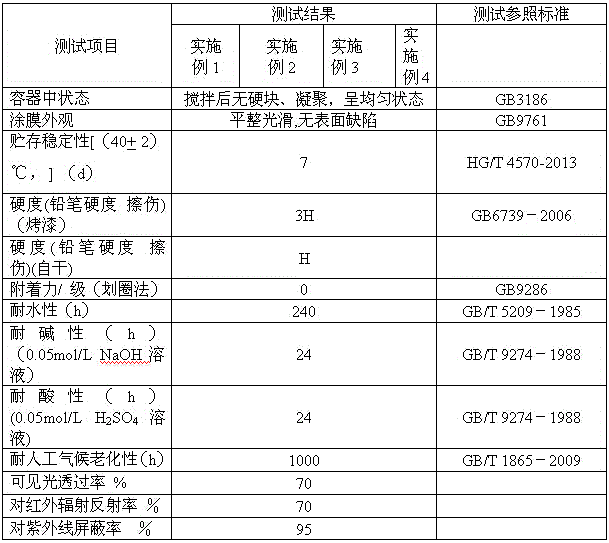

Aqueous colored transparent heat insulation coating, and preparation method and use method thereof

ActiveCN104151970AHigh hydroxyl contentImprove water resistanceReflecting/signal paintsMulticolor effect coatingsTin dioxidePolymer science

The invention discloses an aqueous colored transparent heat insulation coating, and a preparation method and a use method thereof. The aqueous colored transparent heat insulation coating is composed of a water-soluble hydroxy acrylic resin, an aqueous nanometer antimony-doped tin dioxide (ATO) slurry, an aqueous nanometer hydrotalcite slurry, an amino resin, an aqueous color paste, a film forming assistant, deionized water, a dispersant, a wetting agent, a pH adjusting agent, an antifoaming agent, an anti-settling slurry, a thickening agent, an adhesion accelerant and a leveling agent. The preparation method is characterized in that above substances are mixed under specific conditions to obtain the coating. The use method is characterized in that the addition amount of the amino resin is 4-8wt% when the coating is used as a single-component baking varnish; and the addition amount of the amino resin is 0 when the coating is used as a two-component air-dried paint. The coating has the advantages of very good adhesion, high hardness, excellent ageing resistance and good heat insulation effect on the surfaces of glass, plastic films and the like.

Owner:肇庆千江高新材料科技股份公司

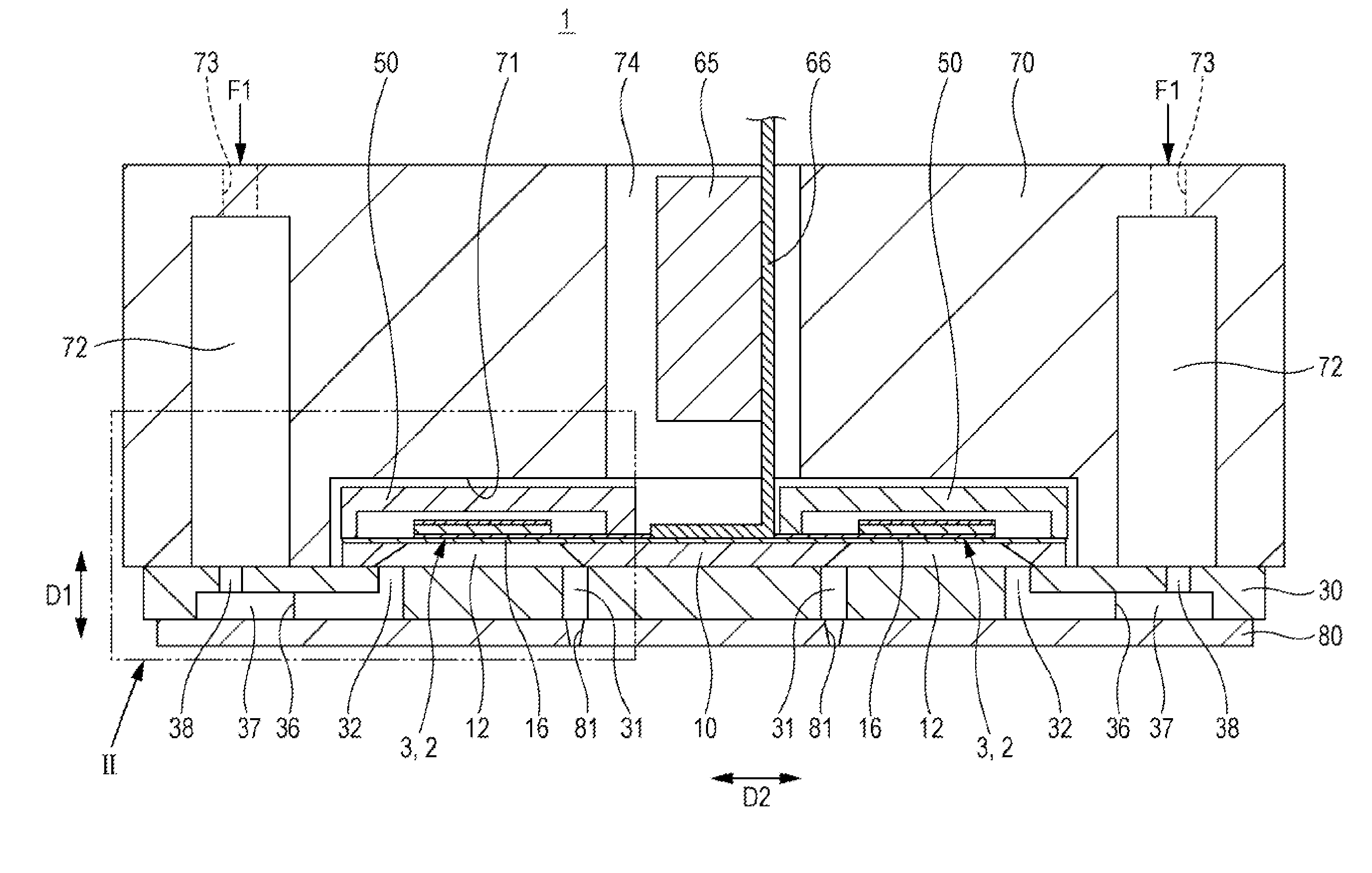

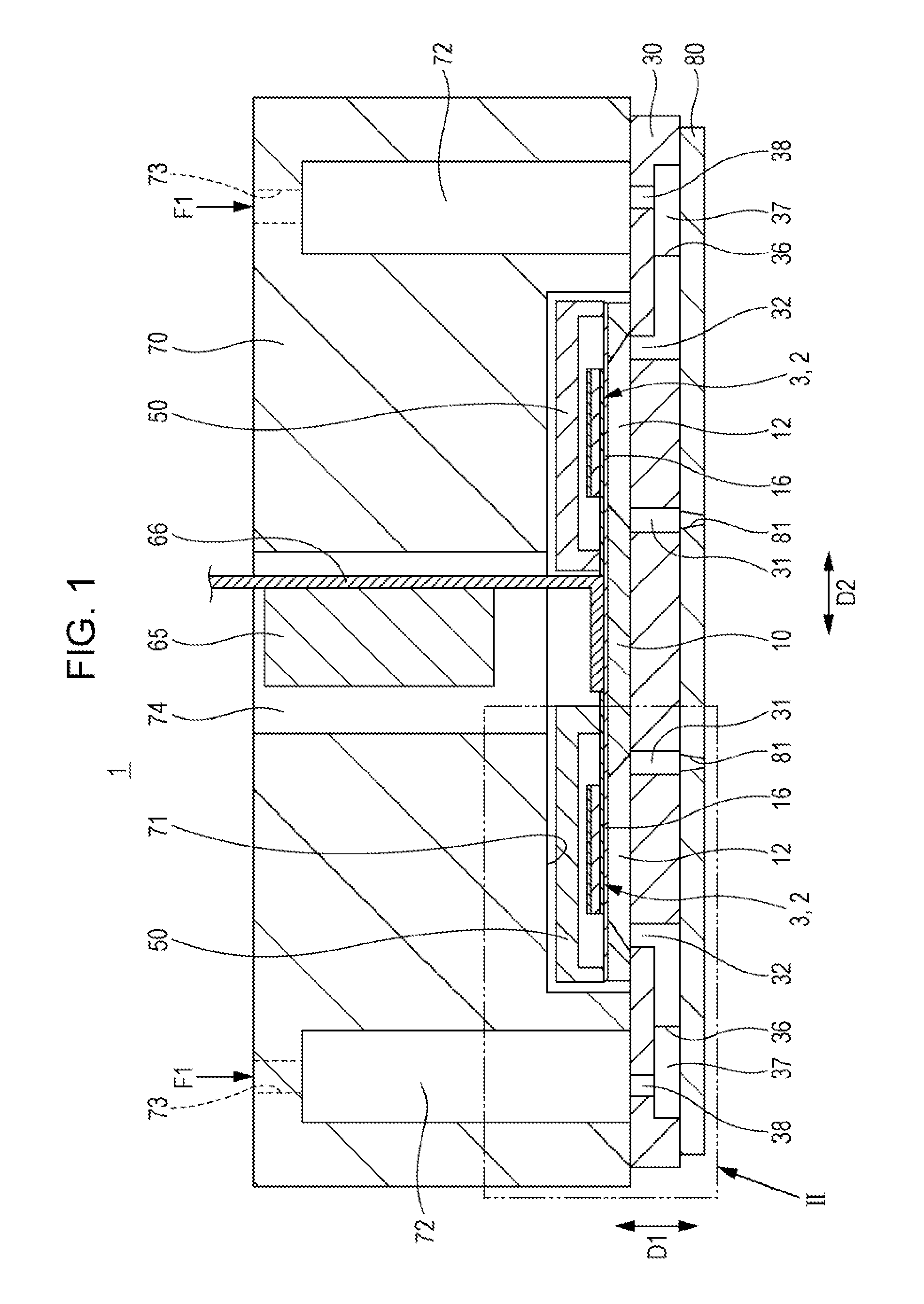

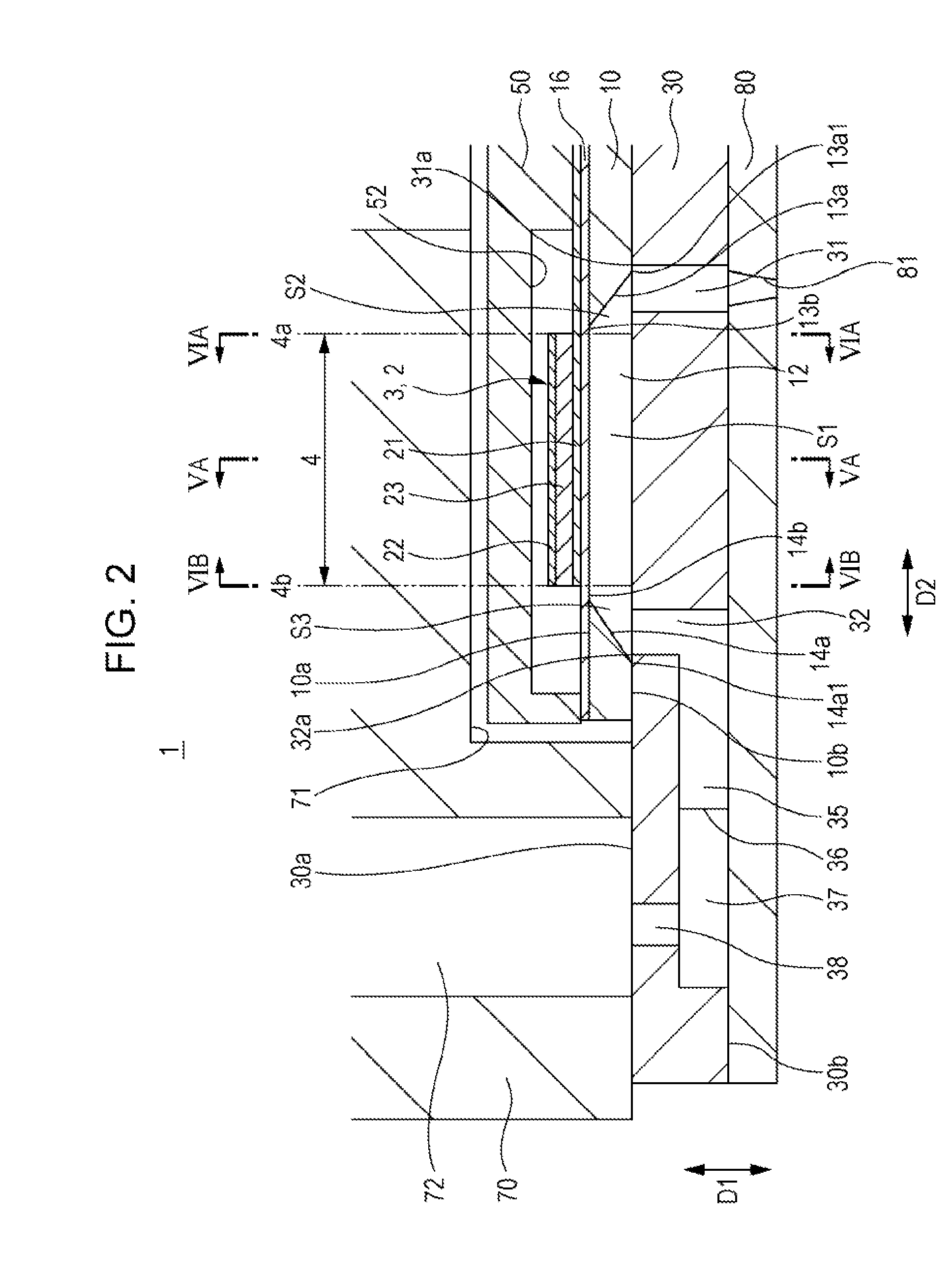

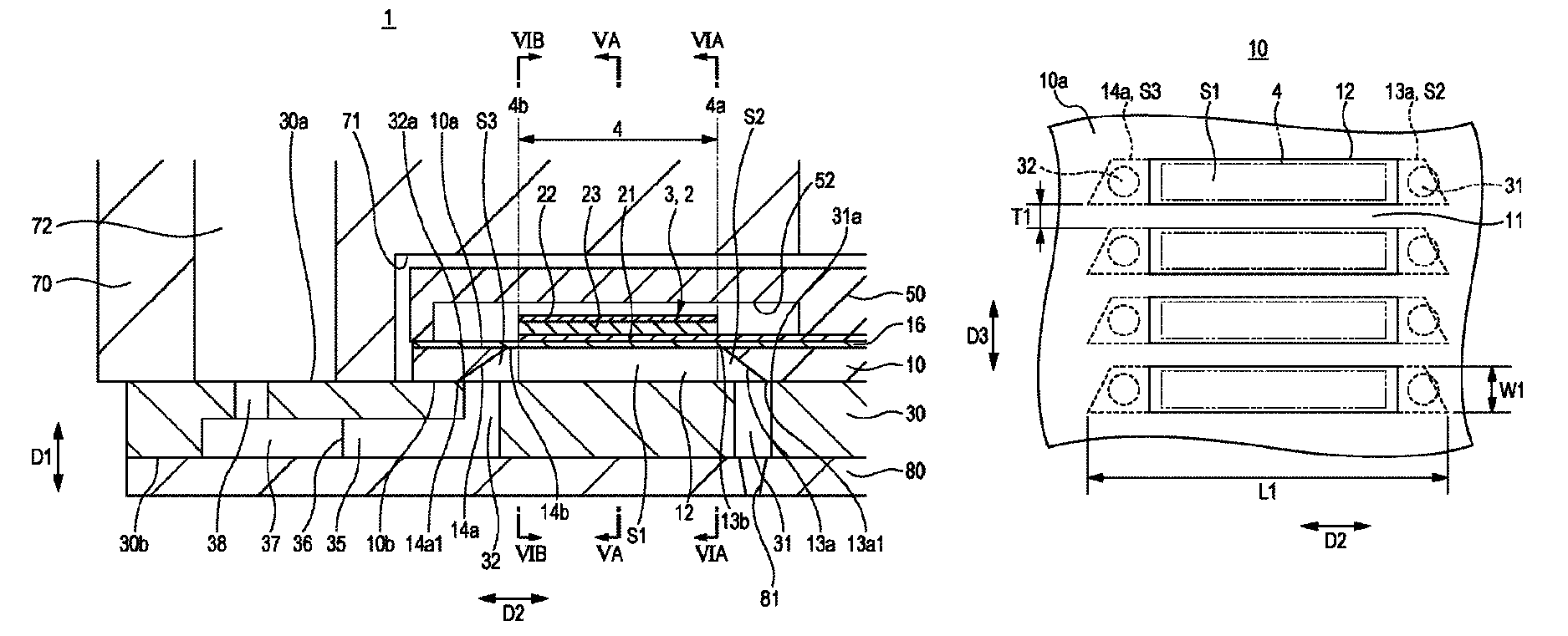

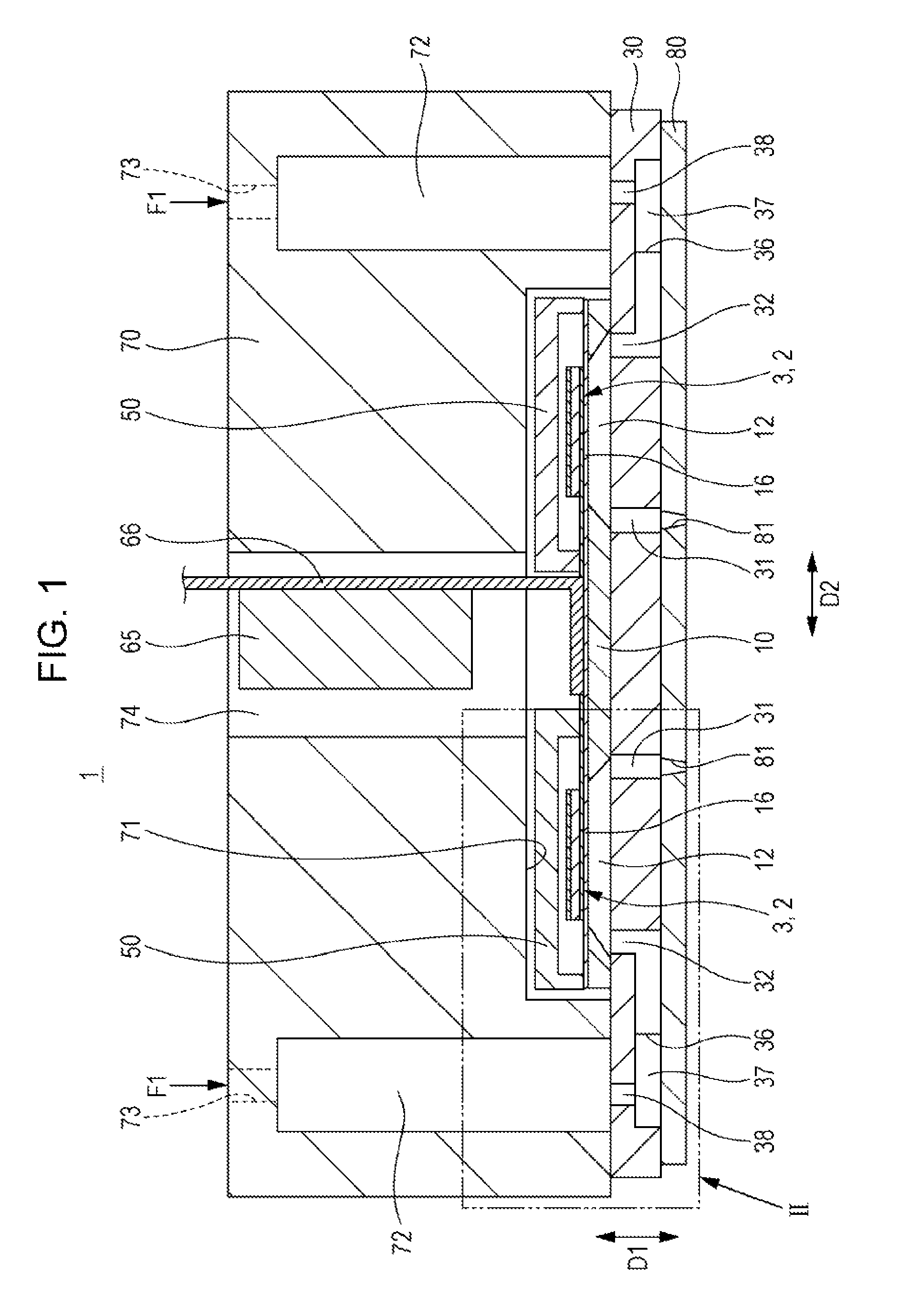

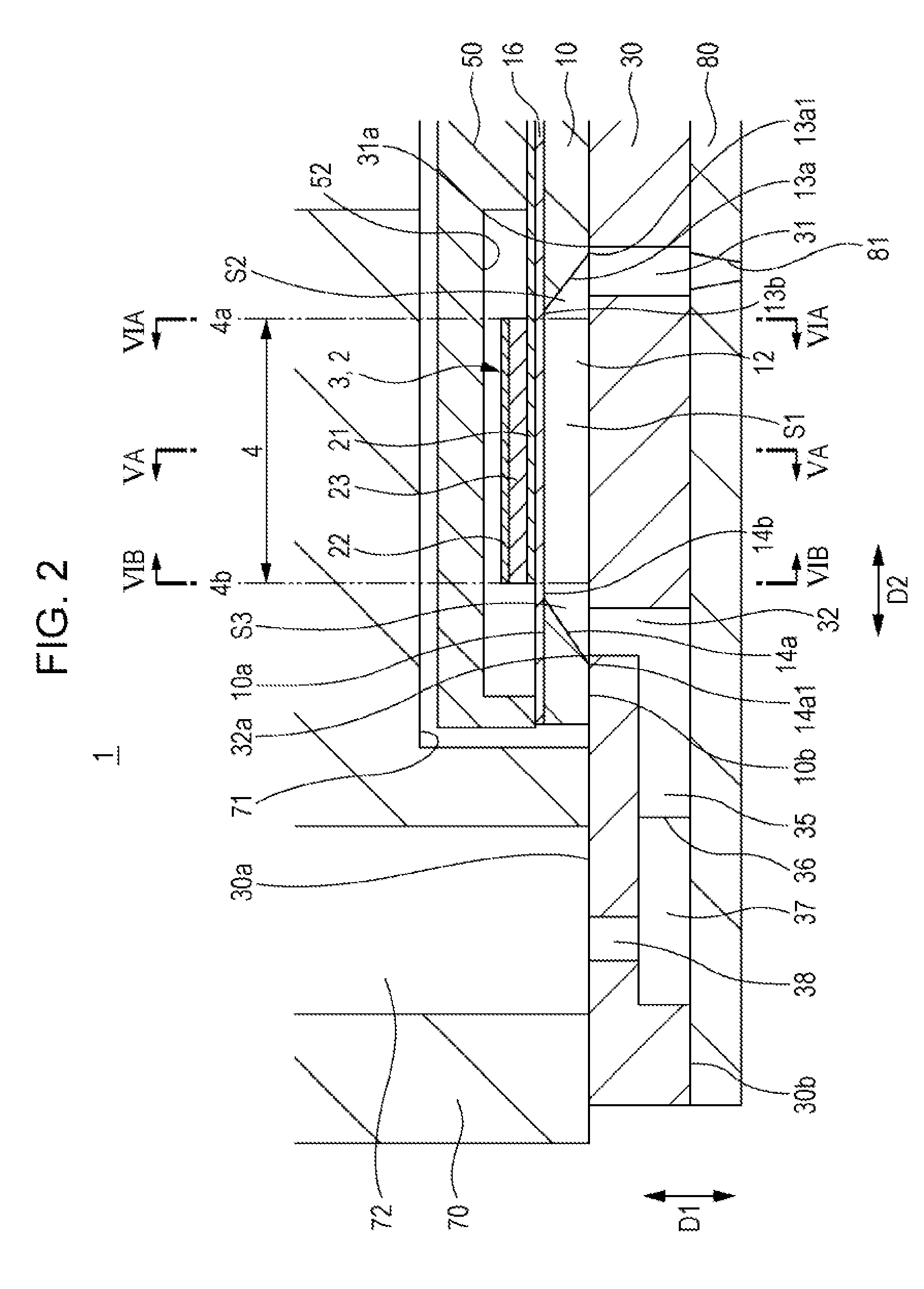

Liquid ejecting head and liquid ejecting apparatus

ActiveUS20150028125A1Improve rigidityImprove structural strengthInking apparatusMovable spraying apparatusActuatorElectrode

A liquid ejecting head in which a flow path substrate having a communication hole communicating with a nozzle and a pressure chamber substrate having a space that is a pressure chamber are at least laminated includes: an actuator having an active section that is interposed between electrodes and applies pressure to the pressure chamber. The pressure chamber substrate has a first space positioned in a region corresponding to the active section and a second space positioned nearer to the nozzle than the first space and communicating with the first space among the spaces. The communication hole does not overlap with the first space and overlaps with at least a part of the second space in a lamination direction.

Owner:SEIKO EPSON CORP

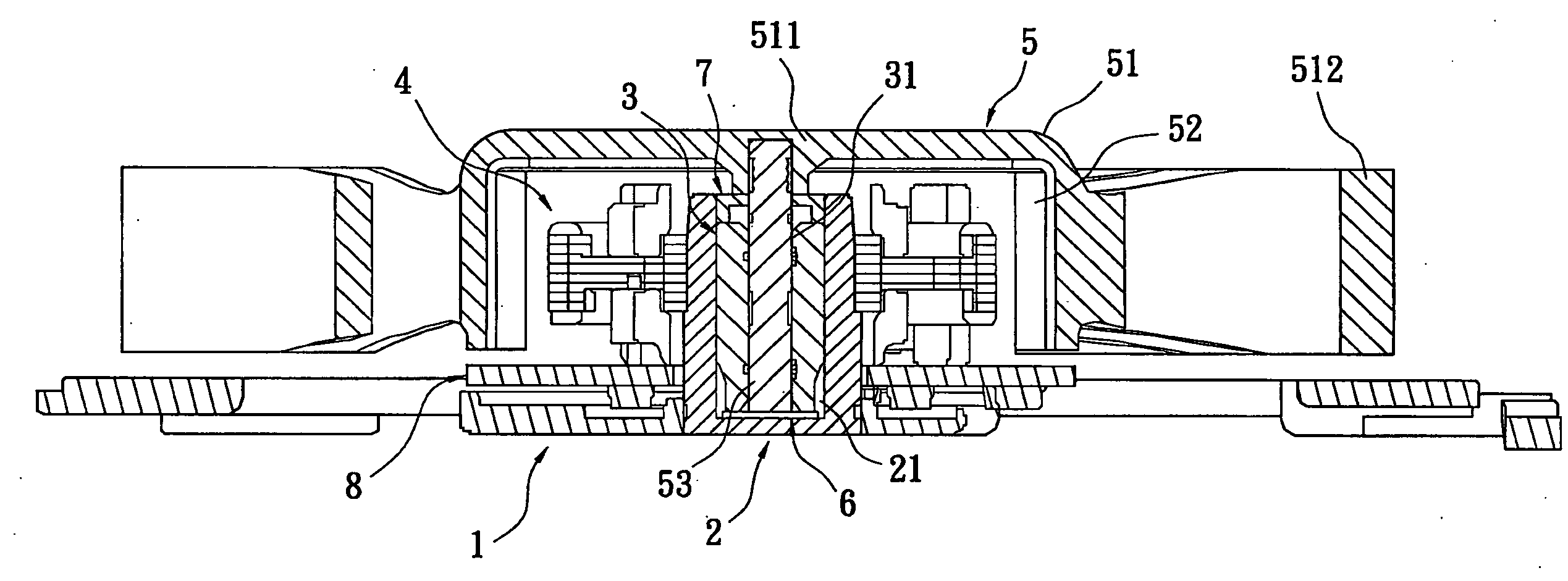

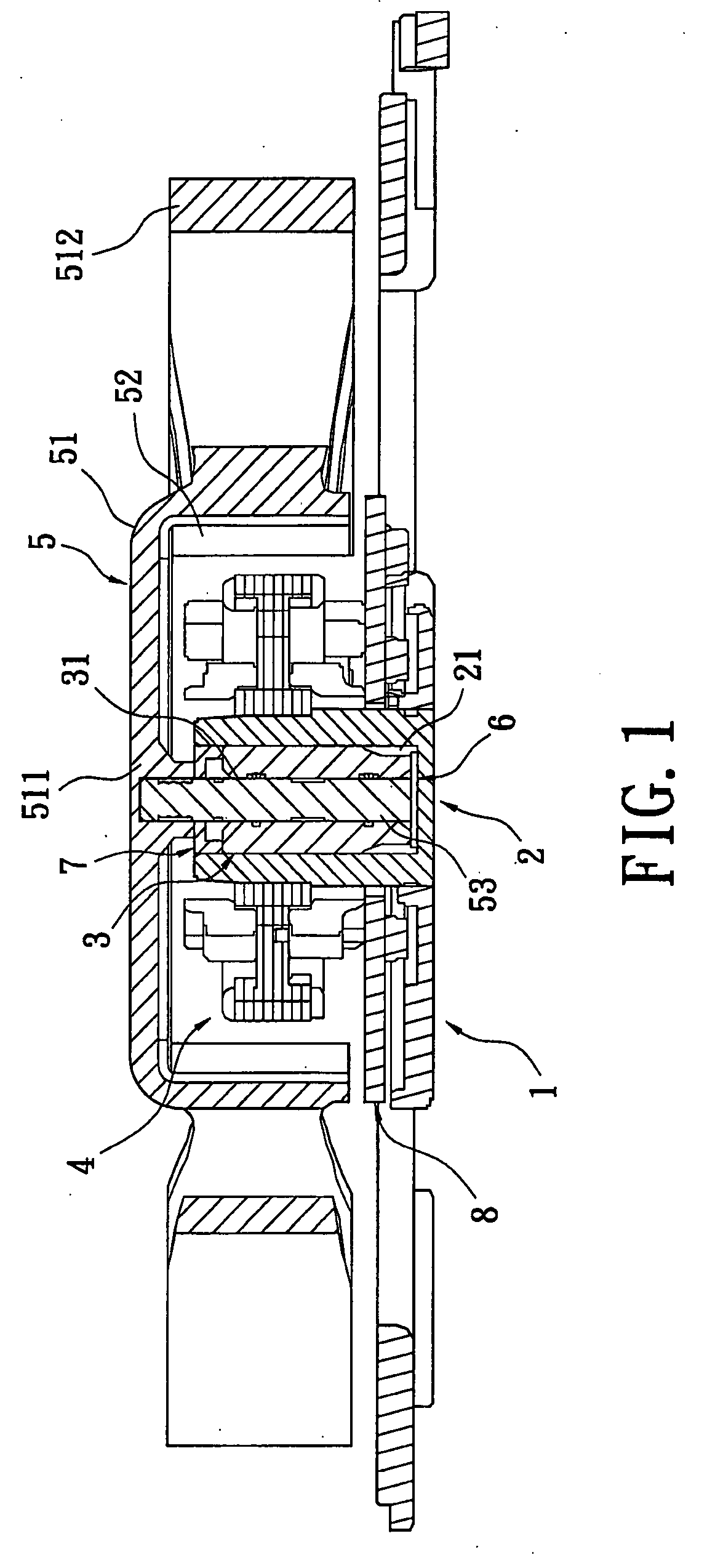

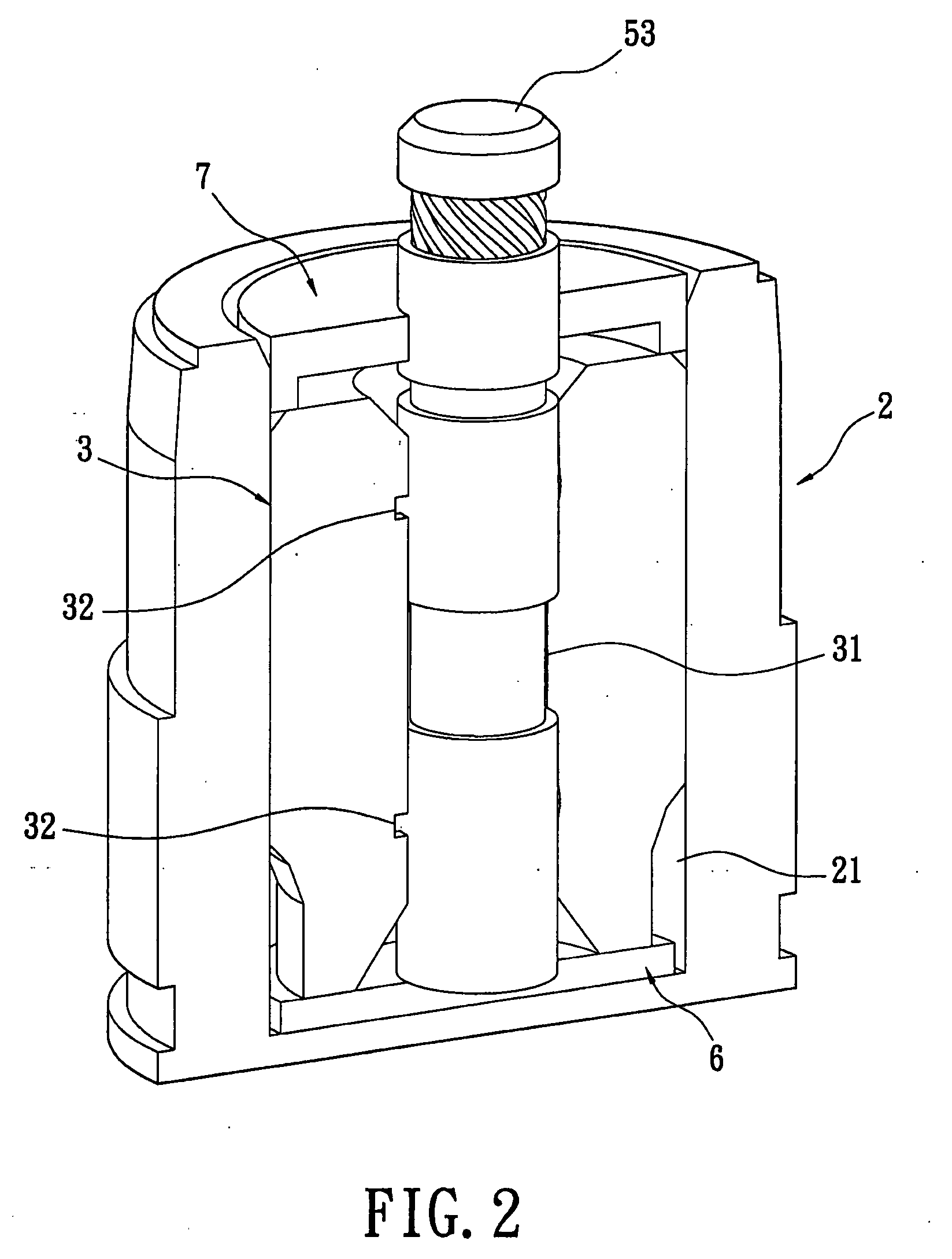

Cooling fan and dynamic pressure bearing structure

InactiveUS20080278911A1Reduce process load and production costReduce loadPump componentsBearing componentsImpellerSpecial design

A cooling fan and dynamic pressure bearing structure is disclosed. The cooling fan includes a base portion, a bearing portion, a dynamic pressure bearing, a coil assembly, and an impeller assembly. The dynamic pressure bearing is received in the bearing portion. A plurality of pressure collecting grooves is arranged in an inner surface of a shaft hole of the dynamic pressure bearing at intervals for receiving lubricating oil. Each pressure collecting groove has two slanted grooves extending slantways which connect with each other at one end to form a connecting point. A transverse groove extends from the connecting point backward the direction of the two slanted grooves. Based on the special design of the pressure collecting groove, the present invention increases the area that creates pressure to increase the intensity of the pressure and decrease the number of pressure collecting grooves to reduce processing loads and production costs.

Owner:DELPHI TAIWAN

Boron-modified organic silicon resin zinc-aluminum composite coating and preparation method thereof

InactiveCN104650731AAdsorptiveNo galling phenomenonAnti-corrosive paintsPolyether coatingsEpoxyAl powder

The invention discloses a boron-modified organic silicon resin zinc-aluminum composite coating. The boron-modified organic silicon resin zinc-aluminum composite coating comprises the following components in parts by mass: 45-48 parts of boron-modified organic silicon resin, 35-45 parts of heat-resistant pigments and fillers, 10-15 parts of polyarylether sulphone ketone modified resin, 15-25 parts of silicon carbide micro powder, 15-20 parts of graphite fluoride, 30-35 parts of a silane coupling agent and 2-4 parts of aids, wherein the boron-modified organic silicon resin is boric-acid-modified organic silicon resin or epoxy-modified silicon-boron resin; the polyarylether sulphone ketone modified resin comprises the following components in parts by mass: 40-70 parts of epoxy resin and 20-35 parts of polyarylether sulphone ketone; the particle size of the silicon carbide micro powder is 6 microns; the particle size of graphite fluoride is 5-10 microns; the heat-resistant pigments and fillers comprise nanosilicon dioxide, barrier function fillers and aluminite powder according to a mass ratio of 1.5 to 1 to 1. The invention also provides a preparation method of the boron-modified organic silicon resin zinc-aluminum composite coating.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Outer-wall insulated coating with nano silicate fillers and preparation method of outer-wall insulated coating

ActiveCN104212289AStrong thermal insulation functionImprove insulation effectReflecting/signal paintsNano siliconCarbide silicon

The invention discloses an outer-wall insulated coating with nano silicate filler. The outer-wall insulated coating comprises the following materials in percentage by mass: 18%-24% of silicone acrylic emulsion, 12%-14% of rutile type titanium dioxide, 2%-4% of additive, 55%-60% of functional filler and 3%-4% of propylene glycol, wherein the mass ratio of nano montmorillonite silicate in the functional filler to the barrier type functional filler is 1:1.5; and the barrier type functional filler comprises graphite, black silicon carbide and molybdenum disulfide. The invention also designs a preparation method for the outer-wall insulated coating with the nano silicon-salt filler. The outer-wall insulated coating and the preparation method thereof have the advantages that the heat-resistant and heat-insulated performances can be greatly improved, and the energy transfer is inhibited, so that the environmental-friendly and energy-saving effects are achieved.

Owner:JIANGSU MARINE VICTORY COATING

Corrosion resistant paint for hydraulic cylinder and preparation method of corrosion resistant paint

InactiveCN104804642AStrong adhesionNot easy to fall offAnti-corrosive paintsEpoxy resin coatingsCross linkerTrichloroethylene

The invention discloses corrosion resistant paint for a hydraulic cylinder and a preparation method of the corrosion resistant paint. The corrosion resistant paint for the hydraulic cylinder, provided by the invention includes the following components in parts by weight: 60-63 parts of epoxy-modified organic silicone resin, 40-45 parts of trichloro ethylene, 20-30 parts of bisphenol A epoxy resin, 12-14 parts of mica powder, 10-13 parts of an amino resin cross-linking agent, 7-9 parts of polydimethylsiloxane, 12-14 parts of silicone resin, 3-5 parts of rust-proof lubricating oil, 5-7 parts of copper powder, 2-4 parts of clay, 1-3 parts of ceramic powder, 2-5 parts of beryllium oxide, 1-3 parts of triethylene tetramine, 5-7 parts of zirconium oxide and 3-5 parts of auxiliaries.

Owner:SUZHOU JIN YUAN OIL MACHINERY

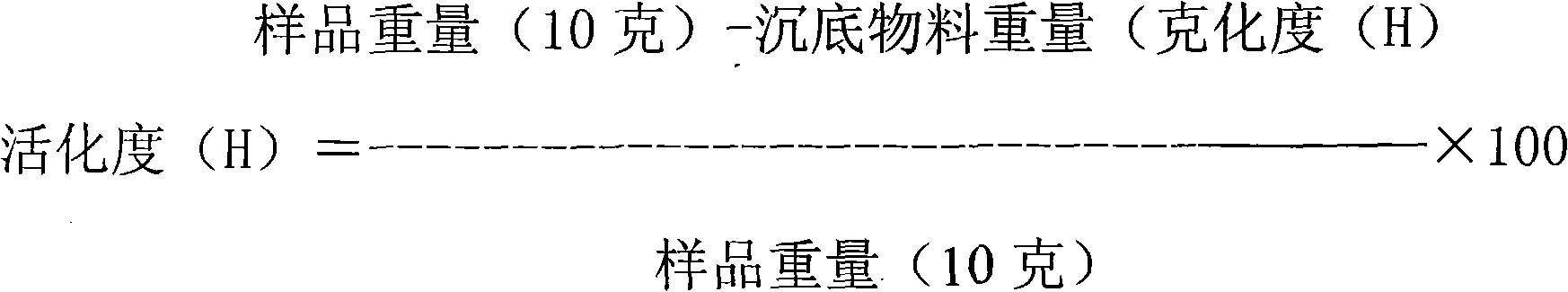

Inorganic flame retardant and preparation method thereof

InactiveCN103450502AHigh tinting strengthImprove processing fluidityPigment treatment with organosilicon compoundsDispersityFlexural strength

The invention discloses an inorganic flame retardant and a preparation method thereof. The inorganic flame retardant has the characteristic that the components of the inorganic flame retardant consist of ultrafine magnesium silicate, aluminum hydroxide and a modifying agent. The preparation method of the inorganic flame retardant comprises the following steps: material selection, material pretreatment, crushing treatment, modifying agent selection and treatment, and modifying treatment, wherein the modifying treatment is as follows: adding the product particles into a modifying machine; meanwhile, heating up the modifying machine, so that the materials in the modifying machine are heated up to 100 DEG C; dropwise adding a coupling agent after 10 minutes, wherein the adding amount of the coupling agent is 1.2%, and the temperature is kept at 100 DEG C for 30 minutes when the coupling agent is added. The inorganic flame retardant disclosed by the invention is not only used for improving tension strength, shearing strength, flexural strength and pressure strength of the product, but also is high in whiteness, uniform in grain size and strong in dispersity. Meanwhile, the inorganic flame retardant further can be used for improving CTI (Computer Telephony Integration) indexes, is not only good in thermal stability and invariant in color, but also is capable of improving the tinting strength of the material.

Owner:吴丛科

950-DEG G grade heat-insulating high-temperature-resisting and wear-resisting coating and preparation method thereof

InactiveCN104650698AReduce transfer speedChange delivery routeAnti-corrosive paintsEpoxy resin coatingsCelluloseCarbide silicon

The invention discloses a 950-DEG G grade heat-insulating high-temperature-resisting and wear-resisting coating which comprises components I and II, wherein the component I is a double component composition which is mixed by components A and B in a proportion of 1:1.5, and the component A in the component I comprises the following components: nano-montmorillonite silicate, a coupling agent and blocking function filler in a mass ratio of 1: 1: 1.5; the component B comprises the following components in parts by mass: 20-35 parts of black silicon carbide, 25-30 parts of fine crystal aluminum oxide, 5-10 parts of a dispersant, 1-5 parts of zinc oxide, 10-15 parts of modified epoxy resin and 2-6 parts of a delustering agent; the component II comprises the following components in parts by mass: 2-6 parts of a delustering agent, 2-6 parts of a wetting agent, 20-50 parts of a curing agent, 5-10 parts of a thickening agent, 5-10 parts of hydroxyethyl cellulose, 1-5 parts of a pH adjustor, 50-60 parts of organosilicone modified epoxy resin, 20-30 parts of filler, 5-10 parts of antimonous oxide and 5-10 parts of a coalescing agent. The invention further designs a preparation method of the 950-DEG G grade heat-insulating high-temperature-resisting and wear-resisting coating.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Fly ash high-foaming furniture plate

The invention discloses a fly ash high-foaming furniture plate which is prepared from 42-45kg of 280-300-mesh fine fly ash, 0.05-0.06kg of 1mm rock wool, 10-11kg of 80-100-mesh coarse fly ash, 2.5-2.7kg of 1000-1200-mesh talcum powder, 42-43kg of PVC (polyvinyl chloride), 6.8-7kg of PVC recycled waste, 1.9-2.1kg of lead salt composite stabilizer, 1.8-2kg of ABS (acrylonitrile-butadiene-styrene), 1.6-1.8kg of ACR (401), 0.5-0.75kg of NC white foaming agent, 0.2-0.3kg of paraffin, 0.25-0.3kg of LP-60 (neutral saturated fat alcohol dicarboxylate), 0.15-0.25kg of AC (azodicarbonamide) foaming agent, 7.5-8kg of ACR (530) foaming regulator, 0.8-1kg of ACR (175) lubricating processing assistant and 1-1.1kg of stearic acid. The manufacturing process comprises the following steps: weighing the materials; stirring the fly ash and talcum powder, adding the PVC, stirring, adding the other materials, and stirring; extruding a formed billet by an extruder; and preparing the formed billet into furniture. The fly ash high-foaming furniture plate has the advantages of light weight, elegant appearance, corrosion resistance and weathering resistance.

Owner:朔州市润臻新技术开发有限公司

Vinyl formula

The invention discloses a vinyl formula, comprising the following components by weight percent: PVC (polyvinyl chloride) crude powder, PVC baby powder 810, a plasticizer, hard oil TXIB, hard oil 57 degrees, heat-resistant oil ED-S, a stabilizing agent CE-116 and a release agent. The vinyl prepared by the formula disclosed by the invention is good in hardness, smooth in handfeel, strong in plasticity, good in stability, and closer to a real handle of human skin.

Owner:叶青华

Manufacturing process for metal expansion joint used for exhaust system of combustion gas turbine

The invention discloses a manufacturing process for a metal expansion joint used for an exhaust system of a combustion gas turbine. Chromated nickel molybdenum alloy structure steel is selected as a blank. A chromated nickel molybdenum alloy comprises, by weight, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015% of phosphorus, 0-0.015% of sulfur, 0-2.0% of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance Fe. A tetraethyl orthosilicate inorganic high-temperature-resistant coating is selected for carrying out coating. The manufacturing process for the metal expansion joint used for the exhaust system of the combustion gas turbine can greatly improve the abrasion resistance, the compressive resistance, the high-temperature resistance and the corrosion resistance of the metal expansion joint, and improve the production efficiency of the metal expansion joint, and is convenient to operate.

Owner:江苏华强新能源科技有限公司

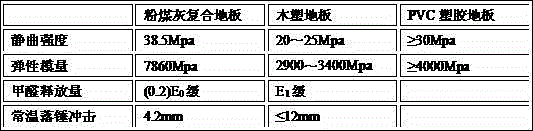

Coal ash composite floor

The invention discloses a coal ash composite floor. The coal ash composite floor is prepared from the following raw materials by weight: 130-132kg of 280-300-mesh coal ash, 8-10kg of 80-100-mesh coal ash, 0.05-0.06kg of 1mm rock wool, 45-48kg of PVC, 13-15kg of 1100-1200-mesh talcum powder, 1.4-1.5kg of lead salt composite stabilizer, 0.1-0.12kg of AC foaming agent, 1.8-2kg of CPE (chlorinated polyethylene), 0.7-0.8kg of ACR401 and 1.5-1.6kg of PE wax. A preparation method of the coal ash composite floor comprises the following steps: weighing the materials; pouring the weighed coal ash and talcum powder in a hot blending mixer, stirring, then adding the PVC, stirring, then adding the other materials, and stirring to obtain a mixture; putting the mixture in a storage hopper of an extruder, and controlling the feeding amount of the mixture by controlling the spiral revolution of the extruder; carrying out extrusion molding on the mixture to obtain a green body; cutting, polishing and slotting the green body to prepare a semi-finished product; and carrying out varnish stoving on the semi-finished product to prepare a finished product. By virtue of waste utilization, the semi-finished coal ash composite floor is capable of saving energy and protecting environment.

Owner:朔州市润臻新技术开发有限公司

Liquid ejecting head and liquid ejecting apparatus

A liquid ejecting head in which a flow path substrate having a communication hole communicating with a nozzle and a pressure chamber substrate having a space that is a pressure chamber are at least laminated includes: an actuator having an active section that is interposed between electrodes and applies pressure to the pressure chamber. The pressure chamber substrate has a first space positioned in a region corresponding to the active section and a second space positioned nearer to the nozzle than the first space and communicating with the first space among the spaces. The communication hole does not overlap with the first space and overlaps with at least a part of the second space in a lamination direction.

Owner:SEIKO EPSON CORP

Manufacturing technology of flue for gas turbine exhaust system

ActiveCN104405456AFast dryingHigh hardnessMachines/enginesEngine componentsManufacturing technologyManganese

The invention discloses a manufacturing technology of a flue for a gas turbine exhaust system. Chrome molybdenum low-alloy steel is selected to be used as a blank material, and the chrome molybdenum low-alloy steel comprises, by mass, 0.3 percent to 0.32 percent of carbon, 0.18 percent to 0.36 percent of silicon, 0.50 percent to 0.70 percent of manganese, 0.90 percent to 1.10 percent of chrome, 0.20 percent to 0.30 percent of molybdenum, 0 percent to 0.02 percent of phosphorus, 0 percent to 0.025 percent of sulphur, 0 ppm to 1.8 ppm of hydrogen, 0 percent to 0.40 percent of nickel, 0 percent to 0.03 percent of vanadium, 0 percent to 0.30 percent of copper, 0 percent to 0.9 percent of residual elements and the balance Fe. Boron-modified organic silicon resin high-temperature-resisting coatings are selected to coat the inner surface and the outer surface of the flue. By means of the manufacturing technology of the flue for the gas turbine exhaust system, the high wear-resisting, pressure-resisting, high-temperature-resisting and corrosion-resisting capability of a metal expansion joint can be greatly improved; operation is easy and convenient; and the production efficiency of the flue can be improved.

Owner:江苏华强新能源科技有限公司

High-ductility cable material for electric vehicle charging system and preparation method thereof

InactiveCN109233277AExtended service lifeImprove ductilityPlastic/resin/waxes insulatorsEpoxyFlexural strength

The invention relates to the technical field of cable materials, and discloses a high-ductility cable material for an electric vehicle charging system. The high-ductility cable material is prepared from the following raw materials in parts by weight: 50 to 100 parts of polyphenylene sulfide resin, 20 to 40 parts of polyethylene resin, 10 to 20 parts of brominated epoxy resin, 6 to 12 parts of talcpowder, 10 to 20 parts of glass fiber, 10 to 20 parts of carbon black, 20 to 30 parts of titanium dioxide, 5 to 15 parts of a flame retardant, 2 to 6 parts of a coupling agent, 1 to 2 parts of a copper inhibitor, 2 to 3 parts of an antioxidant and unavoidable impurities. According to the high-ductility cable material for the electric vehicle charging system the stability, the stability, tensile strength, shear strength, flexural strength and pressure strength of the cable material can be effectively enhanced by adding the talc powder and the glass fiber; the flame-retarding property of the cable material can be effectively improved by adding the carbon-containing flame retardant and a flame retardant made of a carbon compound, so that the service life of a cable is further prolonged.

Owner:ANHUI CABLE

Rub resistant paint for hydraulic cylinder and preparation method of rub resistant paint

The invention discloses rub resistant paint for a hydraulic cylinder and a preparation method of the rub resistant paint. The rub resistant paint for the hydraulic cylinder consists of a component A and a component B, wherein the component A consists of the following materials in parts by weight: 63-65 parts of epoxy-modified organic silicone resin, 12-14 parts of silicon carbide, 32-34 parts of bisphenol A epoxy resin, 5-7 parts of styrene, 10-13 parts of butyl rubber, 5-7 parts of a GPES type defoaming agent, 15-18 parts of deionized water, 3-5 parts of talcum powder and 1-3 parts of silica; the component B consists of the following materials in parts by weight: 20-23 parts of benzyl silicon resin, 6-8 parts of dioctyl phthalate, 3-5 parts of mica powder, 45-50 parts of bisphenol F epoxy resin, 1-3 parts of perchloroethylene, 30-35 parts of deionized water, 1-3 parts of triethylene tetramine, 5-7 parts of methacrylic acid and 2-4 parts of an antioxygen 264.

Owner:SUZHOU JIN YUAN OIL MACHINERY

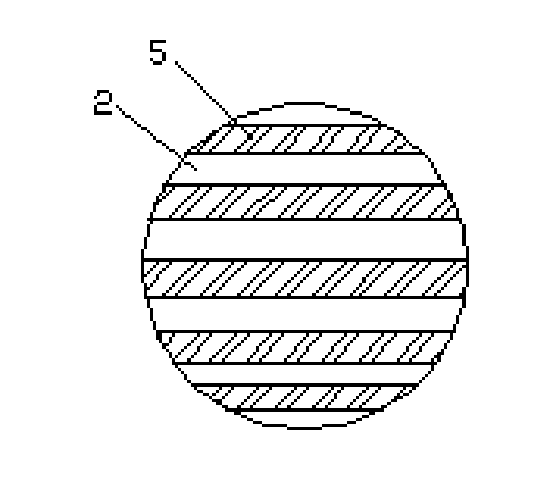

Switch Contact Element and Its Preparation Method

ActiveUS20160126024A1Improve conductivityIncrease pressure intensityContact materialsContact surface shape/structureInter layerContact element

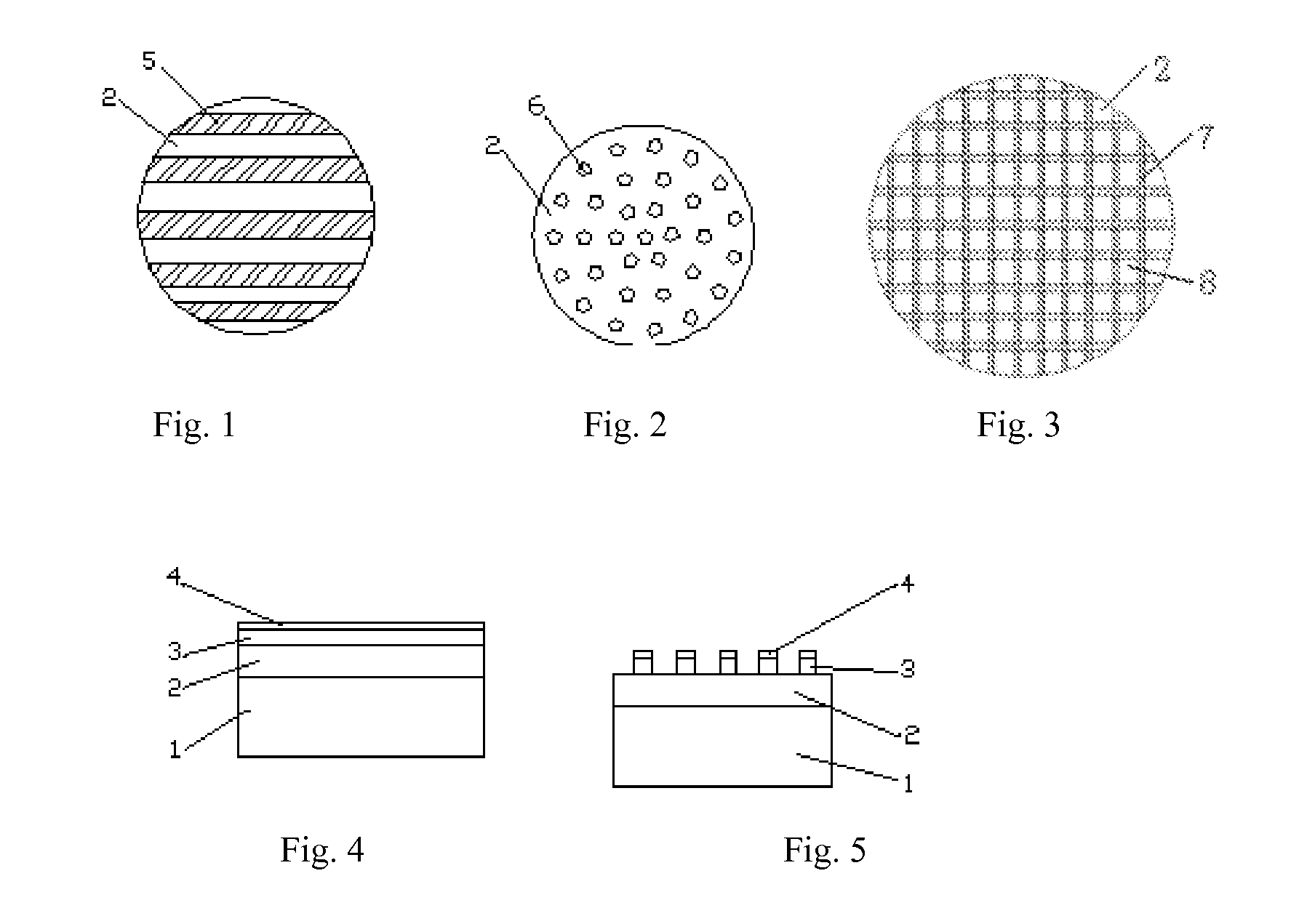

A switch contact element, having a layered structure comprising three layers: the bottom layer is silicone rubber, the middle layer is a continuous base metal sheet layer, and the upper layer is a discontinuous (stripe-shaped, raised-point-shaped or lattice-shaped) precious metal plated layer or a double-metal composite layer of a discontinuous base metal plated layer and a precious metal plated layer. The thickness of the bottom layer is greater than that of the middle layer, the thickness of the middle layer is greater than that of the upper layer, and the thickness of the upper layer meets the conditions that the conductive current is greater than safe current of conductive contacts on a circuit board, and the service life of a switch for the design is ensured.

Owner:NANTONG MEMTECH TECH

High-efficiency flame-retardant ceramic particle water-based thermal insulation coating and preparation method thereof

InactiveCN110964394AImprove flame retardant performanceFlame retardancy does not affectFireproof paintsAnti-corrosive paintsSolid componentMeth-

The invention provides a high-efficiency flame-retardant ceramic particle water-based thermal insulation coating, comprising a liquid component I, a liquid component II and a solid component which aremixed according to a mass ratio of 7: (0.2-0.4): (3-4). The liquid component I comprises the following components in percentage by mass: 35.0%-55.0% of an acrylate emulsion, 1.5%-3.0% of texanol, 0.5%-1.5% of 2-amino-2-methyl-1-propanol, 0.5%-1.0% of an antifoaming agent, 1.0%-2.0% of a wetting agent, 0.5%-1.5% of a leveling agent, 3.0%-6.0% of a dispersing agent, 10.0%-20.0% of a liquid flame retardant and the balance of water. The liquid component II comprises the following components in percentage by mass: 50% of a thickening agent and 50% of water. The solid component comprises the following components in percentage by mass: 10.0%-20.0% of talcum powder, 5.0%-15.0% of mica powder, 5.0%-15.0% of titanium dioxide, 15.0%-30.0% of heat insulation powder and 30.0%-60.0% of hollow ceramic particles. The flame retardant property of the thermal insulation coating can be remarkably improved, and meanwhile, the thermal insulation property of the coating is not influenced.

Owner:YUEYANG CHANGLING EQUIP RES INST

Archaized brick

InactiveCN106007667AImprove plasticityImprove fire resistanceCeramic materials productionClaywaresBrickCrushed stone

The invention discloses an archaized brick and relates to the technical field of ceramic tiles. The archaized brick is prepared from raw materials in parts by weight as follows: 25-32 parts of kaolin, 16-22 parts of quartz sand, 12-18 parts of fly ash, 8-14 parts of clay, 4-6 parts of cement, 4-6 parts of talc powder, 6-12 parts of crushed stone, 10-20 parts of water and 12-20 parts of a glaze. Compared with the prior art, the strength of the archaized brick can be improved.

Owner:岑溪市新建球陶瓷有限公司

Composite reinforced anticorrosive coating composition containing graphene and nano titanium

InactiveCN112592616AStrong adhesionImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentGraphite

The invention provides a composite reinforced anticorrosive coating composition containing graphene and nano titanium, and particularly relates to the technical field of coatings. The coating comprises the following components in percentage by weight: 13-15% of epoxy resin, 13-18% of graphene, 1-6% of nano titanium powder, 15-20% of zinc powder, 5-10% of a filler, 1-5% of pigment, 0.1-2% of an additive, 0.1-3% of a dispersing agent, 1-3% of a coupling agent, 5-8% of a curing agent and 24-35% of a mixed solvent. The composite reinforced anticorrosive coating composition containing graphene andnano titanium provided by the invention can improve the corrosion resistance and aging resistance of anticorrosive paint.

Owner:江苏超途新材料科技有限公司

Archaized brick and preparation method thereof

The invention provides an archaized brick and a preparation method thereof. The archaized brick is at least prepared from raw materials in parts by weight as follows: 100-200 parts of cement, 100-260 parts of diamond, 80-160 parts of potash feldspar and soda feldspar, 80-120 parts of bentonite, 3-10 parts of titanium dioxide, 1-6 parts of copper sulfate, 6-12 parts of silicon dioxide and 10-40 parts of vinyl ester resin. All the components are well compatible, and the prepared brick has high structural density and has the advantages of improved tensile strength, shear strength and pressure intensity as well as reduced deformation, elongation and thermal expansion coefficient.

Owner:贞丰县恒山建材有限公司

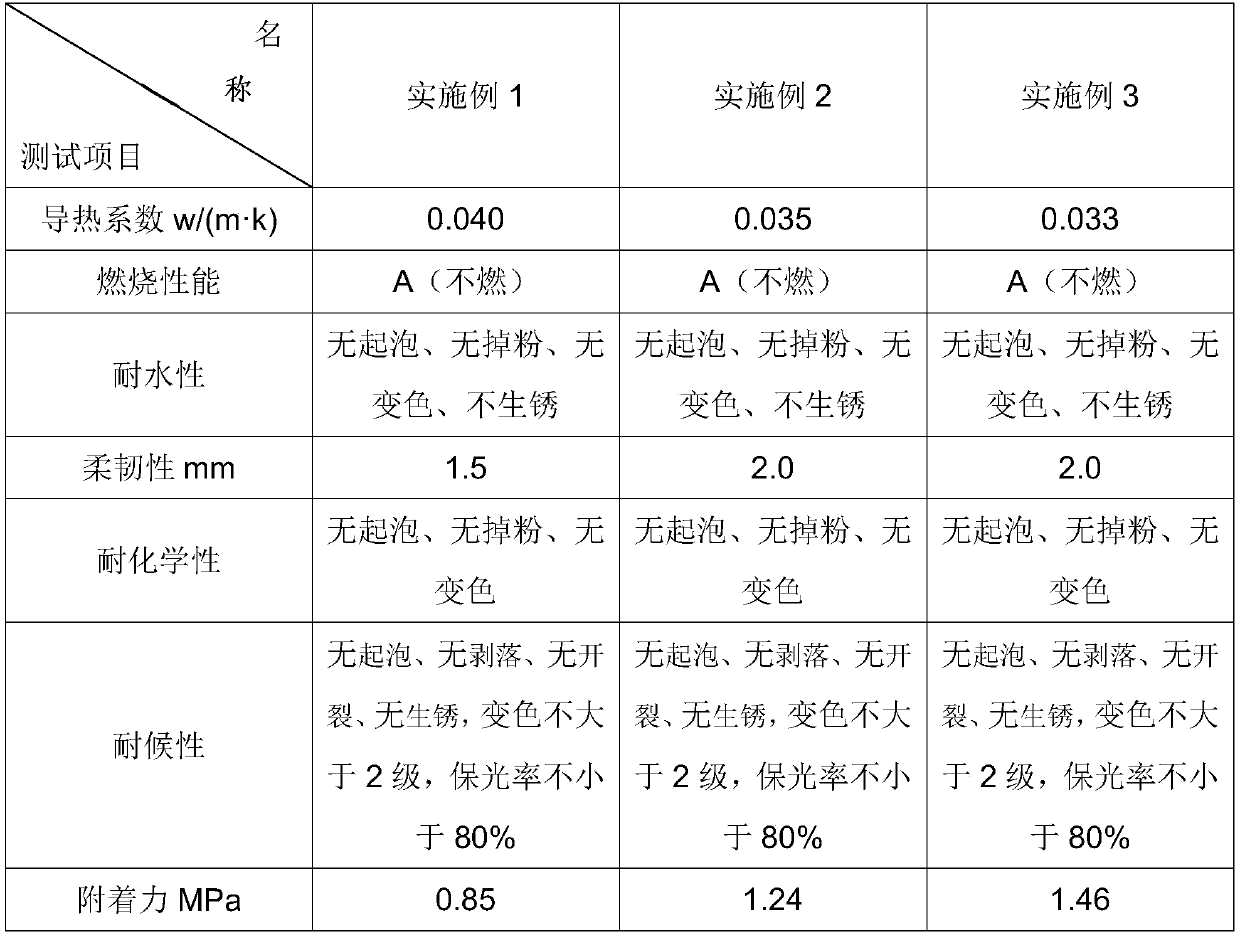

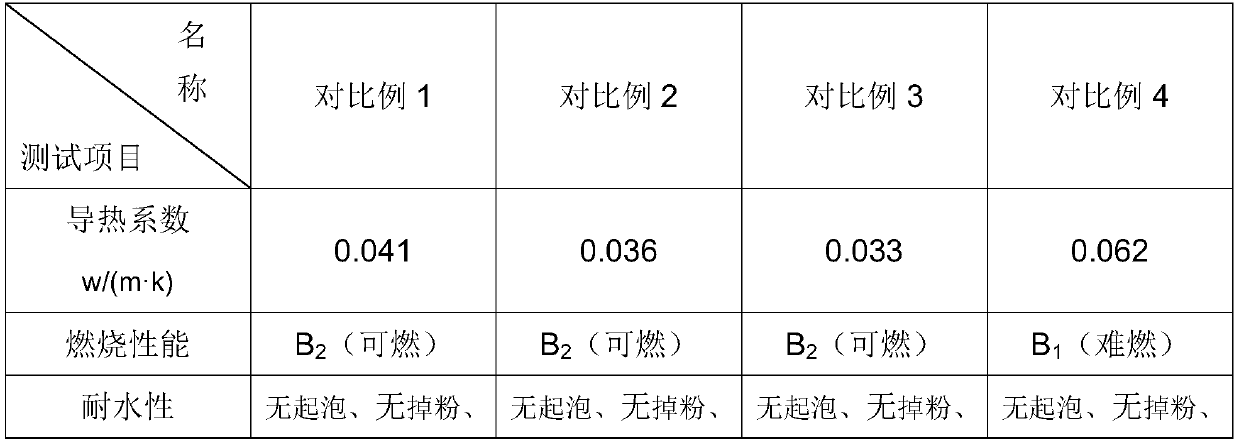

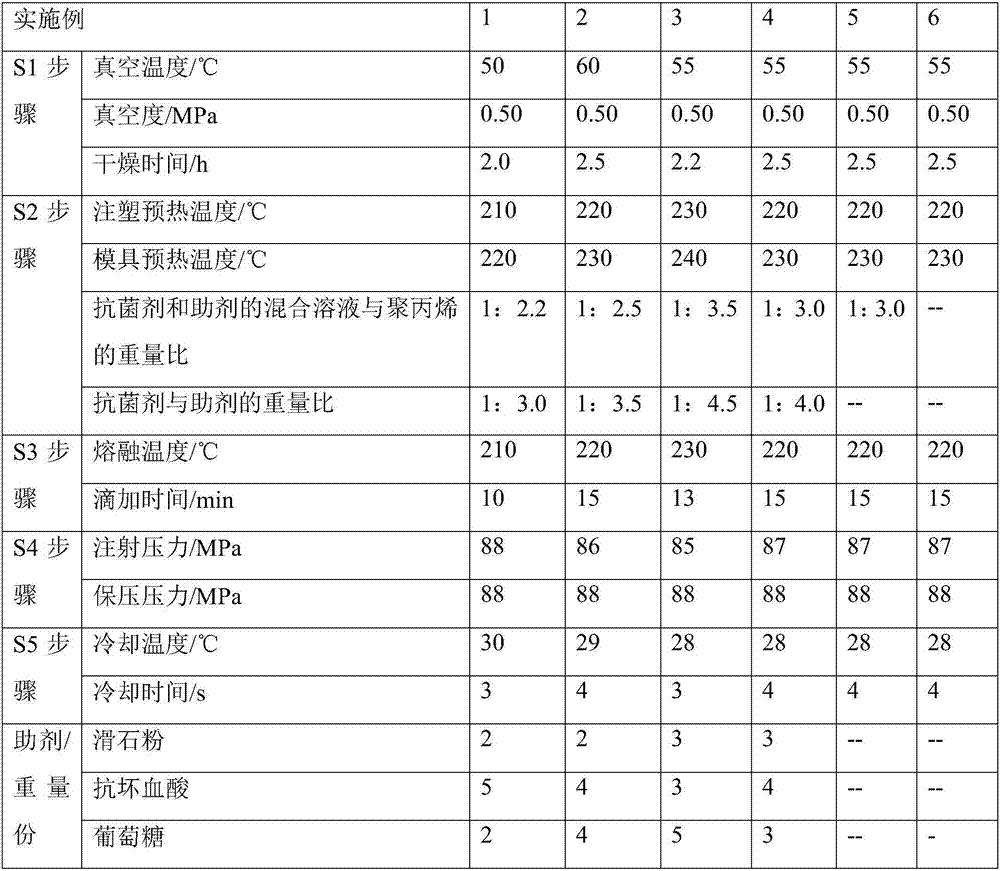

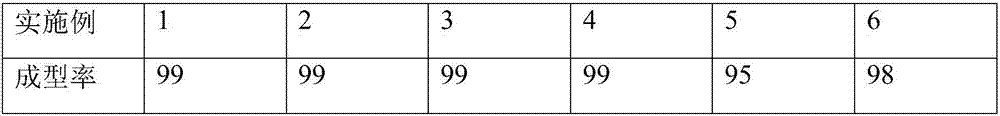

Preparation process of antibacterial polypropylene plastic

InactiveCN107984717AReductiveGood antibacterial effectFlat articlesHot meltInjection molding machine

The invention relates to a preparation process of antibacterial polypropylene plastic. The preparation process comprises the following steps that S1, raw materials are pretreated; S2, preheating treatment is conducted, specifically, an injection molding cylinder is preheated, injection moulds are mounted, and the upper mould and the lower mould are both preheated; S3, the hot melting stage is conducted, specifically, S31, pretreated objects are added into the injection molding cylinder to be heated to be melted, S32, after the objects in the step S31 are melted, a mixture solution of an antibacterial agent and an auxiliary is dropwise added, and S33, after dropwise adding in the step S32 is completed, melting is conducted again for 15-30 min to obtain hot-melted plastic; S4, the injectionmolding stage is conducted, specifically, the hot-melted plastic in the step S33 is injected to the preheated upper mould and lower mould in the step S3, and the pressure is maintained for 5-8 s; andS5, cooling forming is conducted, specifically, a plastic plate after pressure maintaining in the step S4 is placed into a cooling water tank to be cooled, and the plastic plate is obtained after themoulds are opened. The preparation process has the advantages that the antibacterial effect is good, dispersibility is good, the forming rate is high, and the process is simple.

Owner:四川威亿塑胶制品有限公司

Silicon-containing polyimide anti-static antifouling coating as well as preparation method and application thereof

PendingCN112940608ALow relative permittivityReduce erosionAnti-corrosive paintsElectrically-conductive paintsPtru catalystPower grid

The invention discloses a silicon-containing polyimide antistatic antifouling coating and a preparation method and application thereof, and belongs to the technical field of coatings. The silicon-containing polyimide antistatic antifouling coating comprises the following components by weight: 45-60 parts of silicon-containing polyimide resin, 10-15 parts of a filler, 3-8 parts of a flame retardant, 2-6 parts of a pigment, 2-4 parts of a coupling agent, 1-5 parts of a catalyst, 5-10 parts of a diluent, 5-13 parts of a cross-linking agent and 1-5 parts of a thickener. The coating integrates the antifouling and antistatic characteristics, can be used on the surface of electric porcelain of electric insulation equipment such as an insulator, forms a compact coating layer after being cured, has excellent antifouling and antistatic effects, radically solves the pollution flashover phenomenon, effectively ensures smooth operation of a power grid, reduces the maintenance cost, and ensures normal power supply.

Owner:成都普利美特科技有限公司

Wear-resistant anti-corrosion parallel bars for sports and forming technology of such parallel bars

InactiveCN109128014AApplicable castingReduce heat transferAnodisationFoundry mouldsMetallurgyEngineering

The invention discloses wear-resistant anti-corrosion parallel bars for sports. The wear-resistant anti-corrosion parallel bars for sports comprise transverse bars, vertical posts and bases, wherein the vertical posts are arranged on the lower sides of the transverse bars and used for supporting the transverse bars, the bases are arranged at the bottom ends of the vertical posts and used for fixing the vertical posts, and the transverse bars, the vertical posts and the bases are made of a same material. The material comprises, by mass, Mg, Mn, Zn, C, Cu, Si, Cr, Ti, S, P, Fe, inert filler, thebalance Al and inevitable impurities. The invention further provides a forming technology of the wear-resistant anti-corrosion parallel bars for sports. The forming technology is simple and easy to implement. The prepared parallel bars are highly resistant to heat, good in size stability, long in service life and low in cost.

Owner:江苏天泽教育咨询有限公司

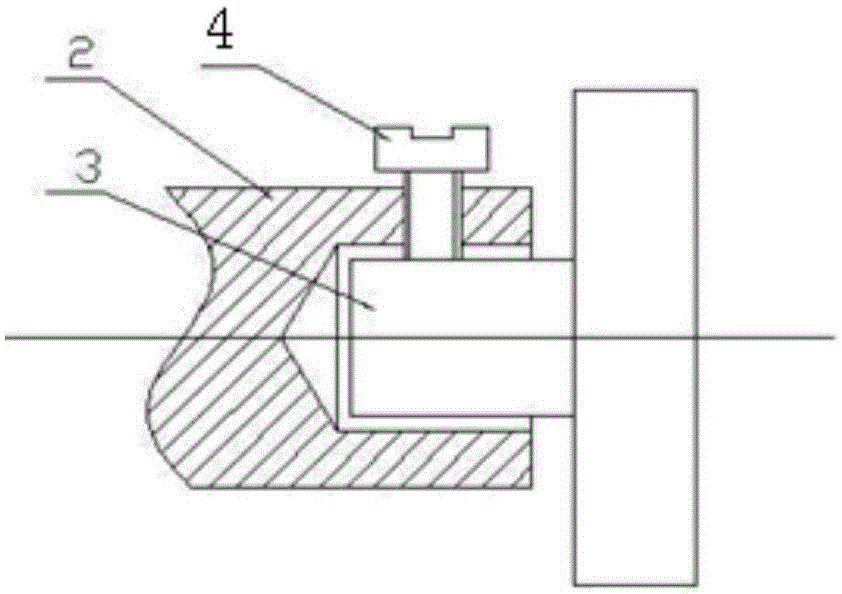

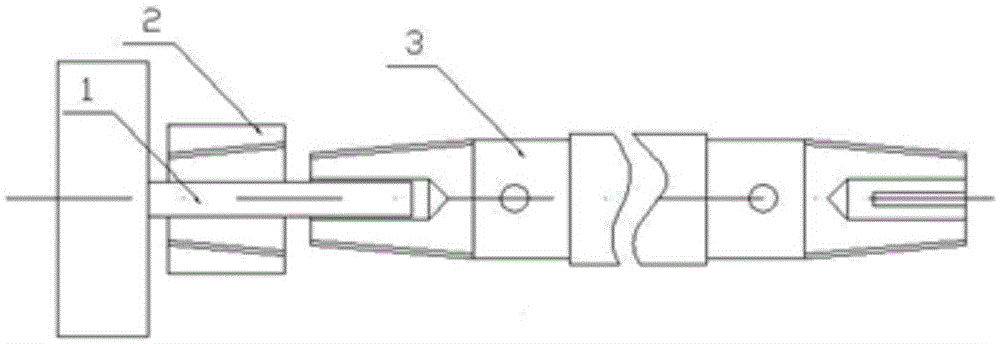

Method for preventing looseness of rotating rod of feedback signal potentiometer of hydrogovernor

InactiveCN105003385AImprove fastening forceIncrease contactHydro energy generationMachines/enginesPotentiometerInstability

The invention discloses a method for preventing looseness of a rotating rod of a feedback signal potentiometer of a hydrogovernor, relates to the field of actions of servomotors of hydrogovernors, and aims to solve the problems of set instability caused by looseness in the connecting place due to small contact area and small fastening force in a traditional connecting mode between a servomotor displacement transmission rod and a potentiometer rotating rod and limitation on a connecting environment. The surfaces of two ends of the servomotor displacement transmission rod are machined to threads with gradually decreased diameters, and are both provided with center holes inside; four annular grooves are uniformly formed on the side wall of each end in the peripheral direction of the center hole; two wedged nuts with growing internal threads are respectively inserted at one ends of two potentiometer rotating rods; one end of each potentiometer rotating rod is correspondingly screwed into the center hole of one end of the servomotor displacement transmission rod; and the two wedged nuts are tightened with the threads on the surface of one end of the servomotor displacement transmission rod after passing through one end of one potentiometer rotating rod. The method can be used for fixing the servomotor displacement transmission rod and the potentiometer rotating rod.

Owner:STATE GRID HEILONGJIANG ELECTRIC POWER COMPANY +1

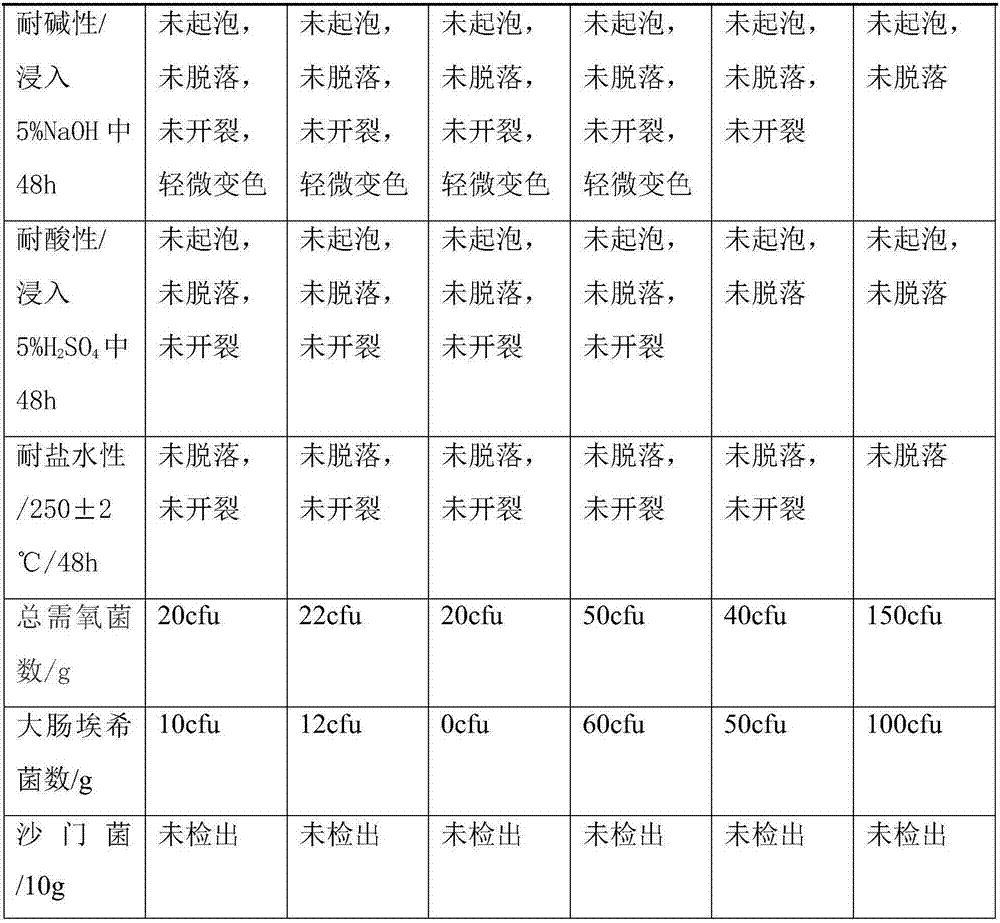

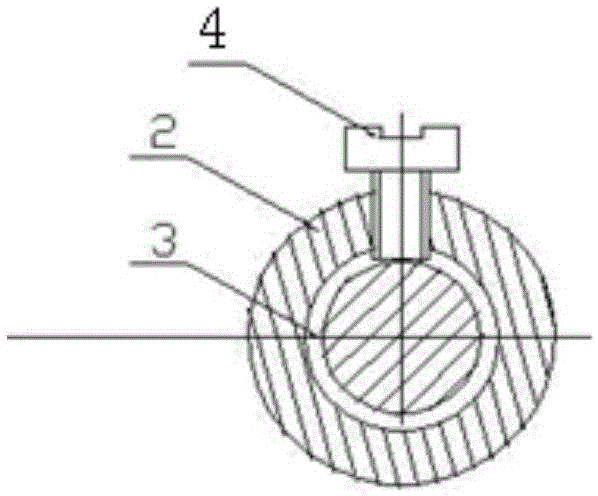

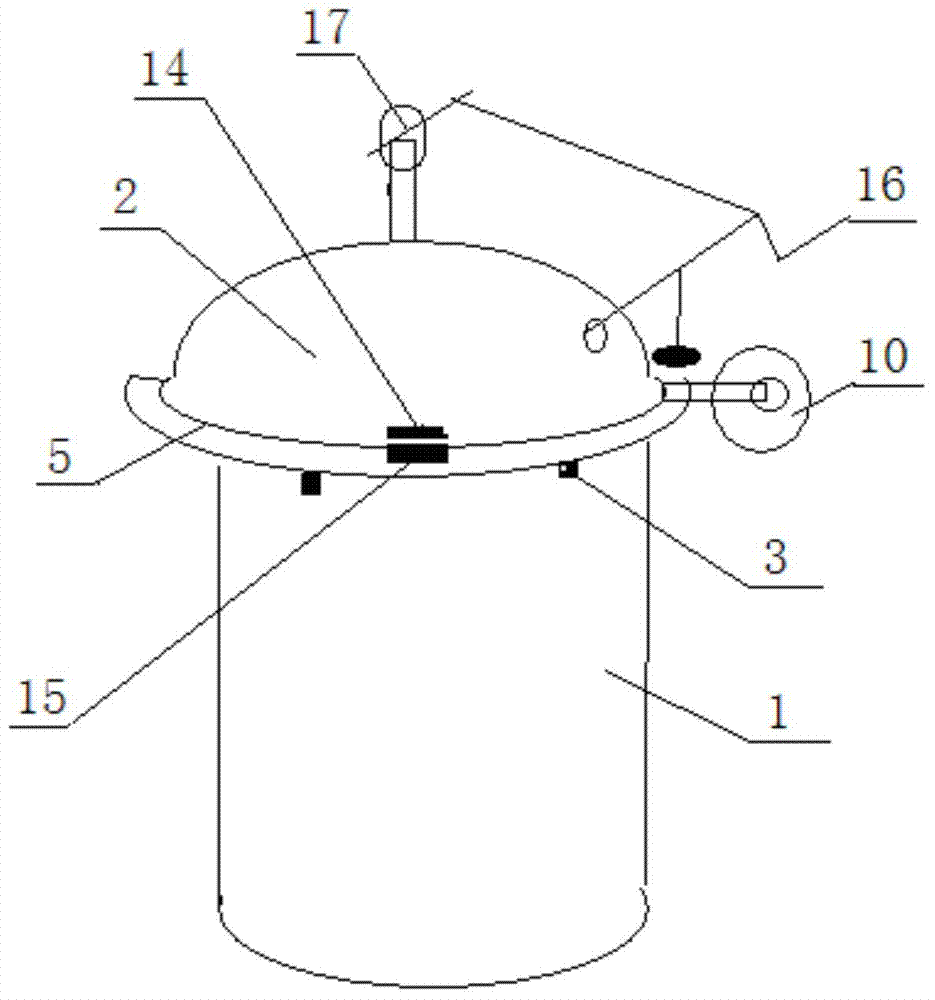

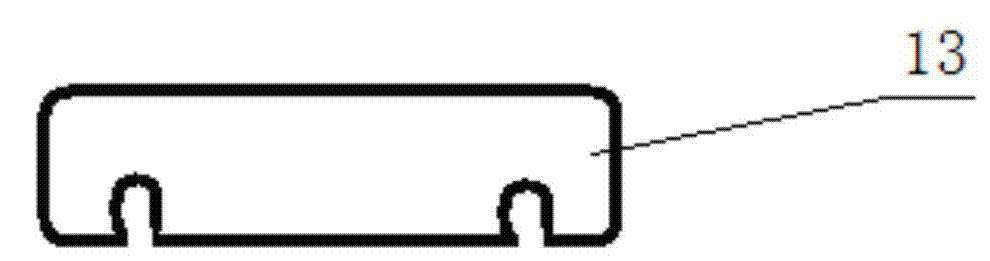

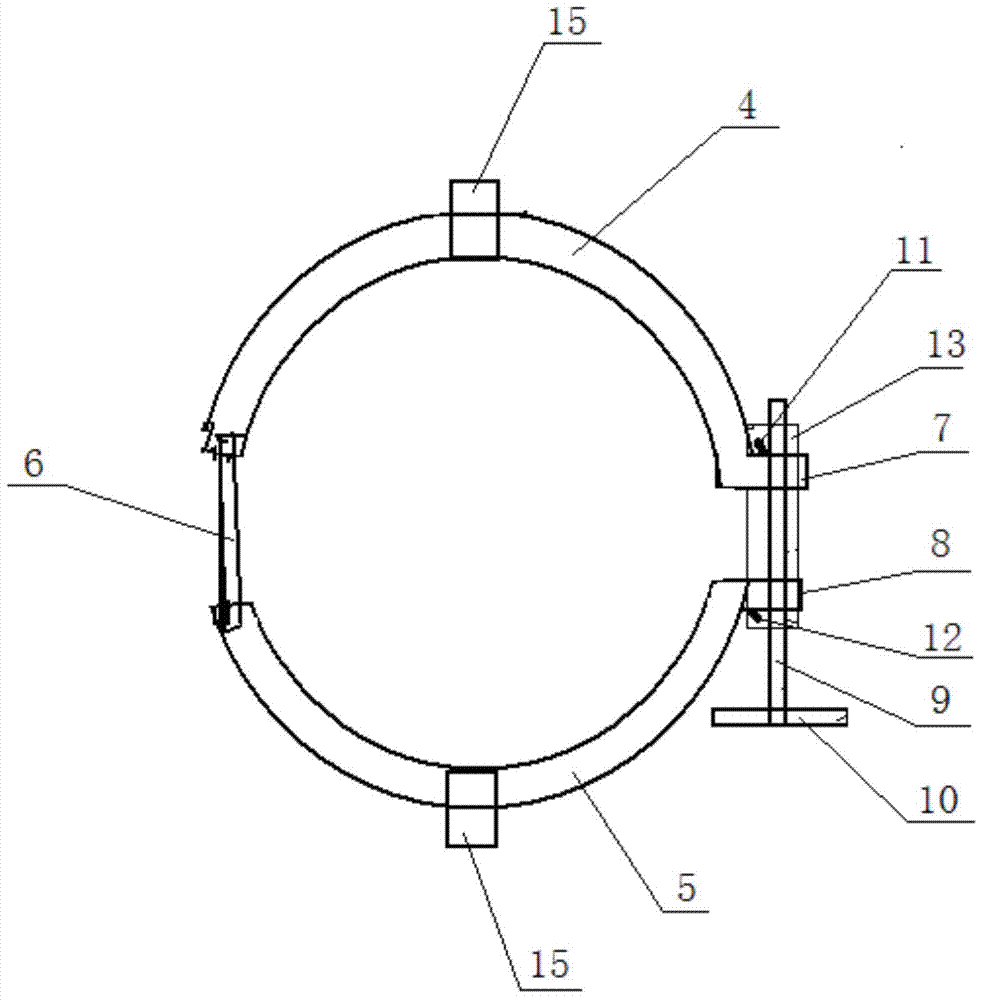

Hoop split locking structure of bag type filter

ActiveCN103933804AReduce turn-on timeEasy to operateDispersed particle filtrationFiltration separationScrew threadLeft handed

The invention relates to a hoop split locking structure of a bag type filter. The structure comprises a tank body, a tank cover, a hoop support plate, a left hoop, a right hoop, a connecting rod, a left-handed nut, a right-handed nut, a locking screw rod, a hand wheel, a left locking plunger column, a right locking plunger column and a locking plate, wherein the left hoop and the right hoop are arranged on the left hoop support plate; one end of the left hoop is hinged to one end of the connecting rod; one end of the right hoop is hinged to the other end of the connecting rod; the left-handed nut is fixed at the other end of the left hoop; the right-handed nut is fixed at the other end of the right hoop; a left-handed outer thread and a right-handed outer thread are arranged on the locking screw rod; the hand wheel is fixed at one end of the locking screw rod; the left locking plunger column is fixed on the left hoop; the right locking plunger column is fixed on the right hoop; the locking plate is hinged on the tank cover; a left locking notch and a right locking notch are formed in the locking plate. The tank cover opening operation can be accomplished within seconds, the tank cover opening time is greatly shortened, the operation is simple, the working intensity is alleviated, and the pressure intensity that the structure bears is greatly improved compared with that of an ordinary bolt.

Owner:无锡强工机械工业有限公司

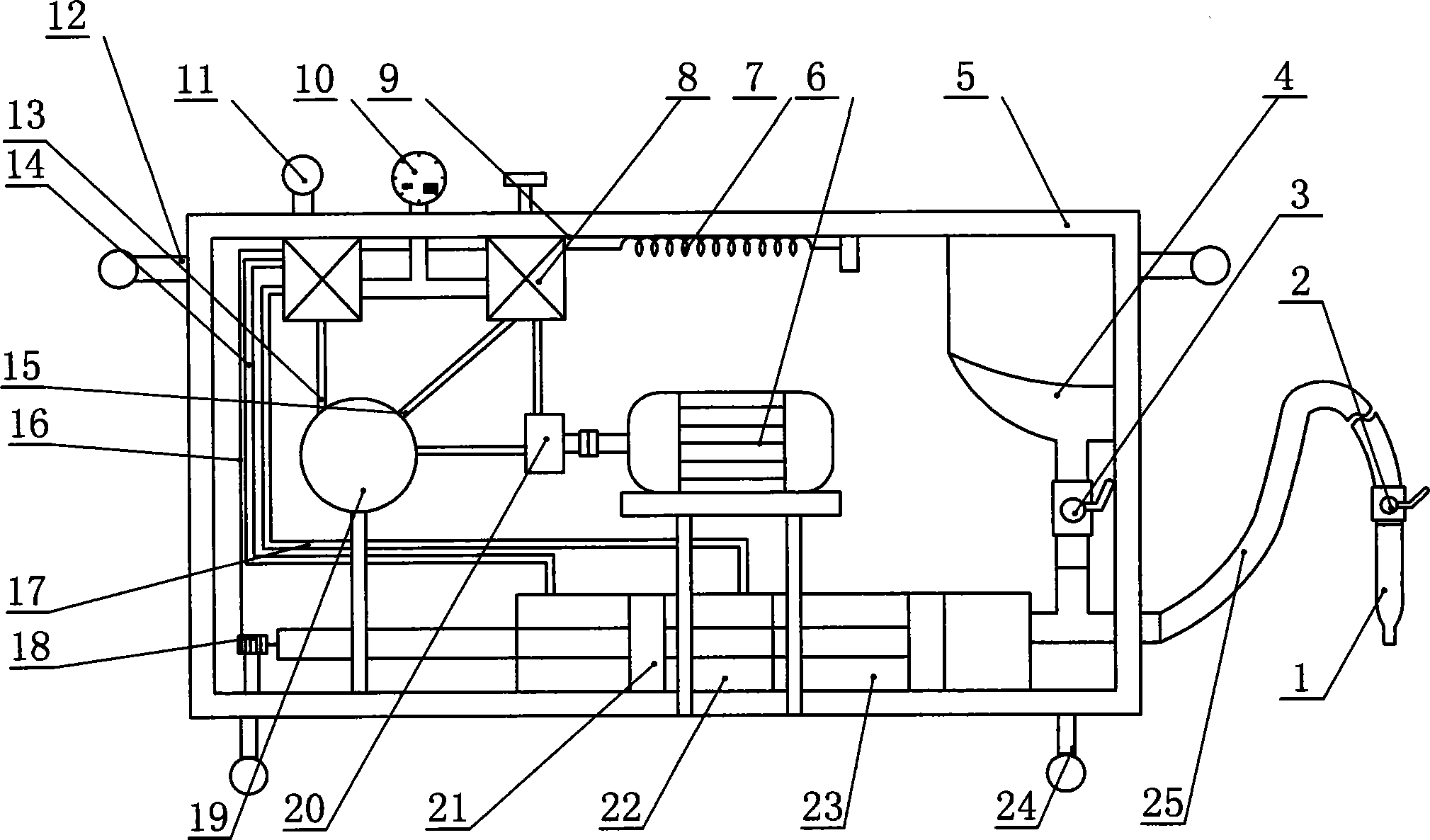

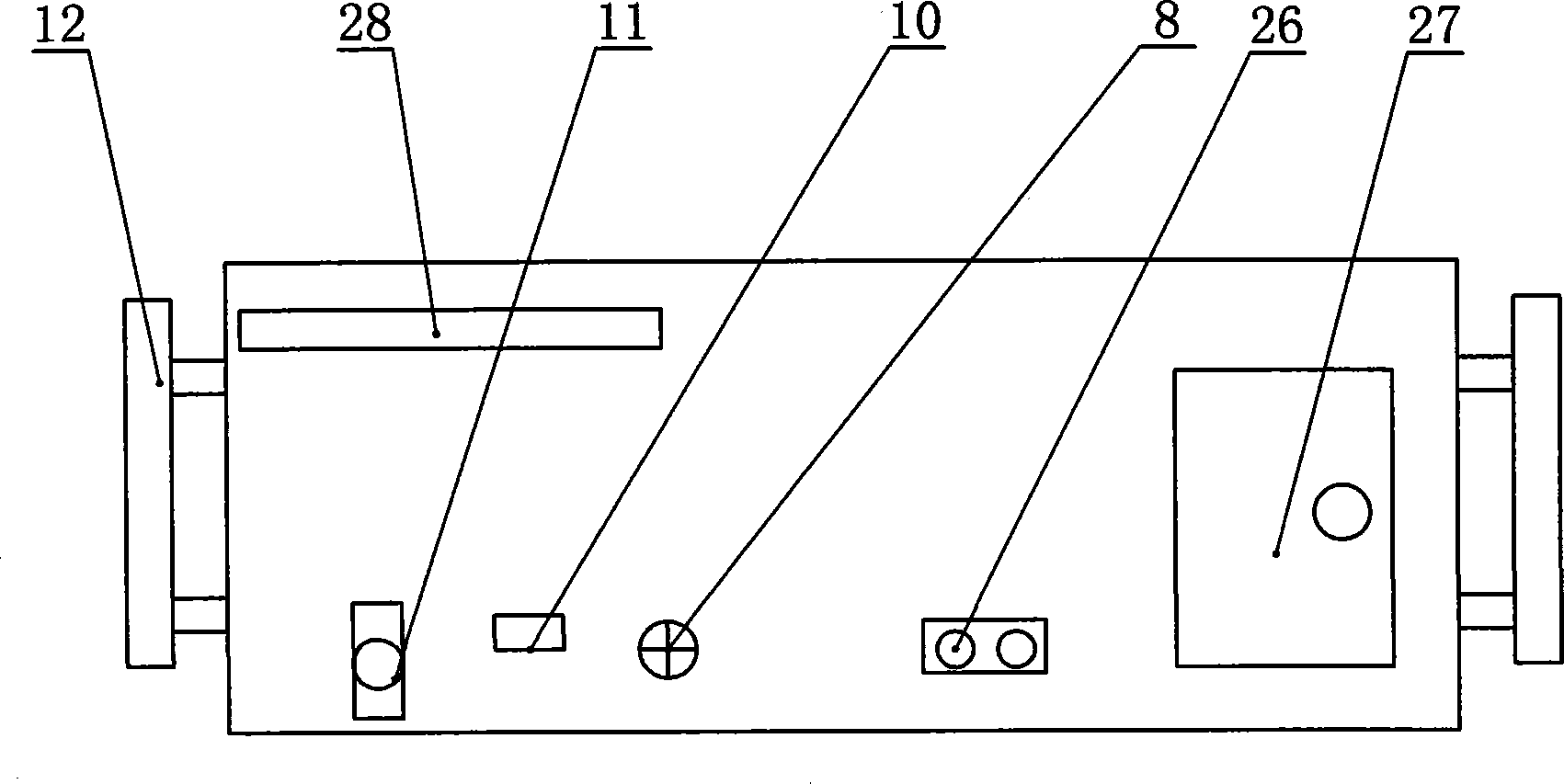

Hydraulic butter oiling machine

InactiveCN102278586BIncrease pressure intensityReduce labor intensityEngine lubricationGear pumpSurface mounting

The invention provides a hydraulic butter oiling machine with a good use effect, and the machine is used for oiling butter or engine oil. The oiling machine comprises a machine shell, wherein the front surface of the machine shell is equipped with a door, the machine shell is fixedly connected with a push handle, the lower surface of the machine shell is fixedly connected with a roll wheel, the upper surface of the machine shell is designed with a shell cover, the lower part of the machine shell is equipped with a hydraulic oil cylinder and a butter cylinder, double-headed pistons are installed in the hydraulic oil cylinder and the butter cylinder, the lower end of a buffer tank is fixedly connected with a control ball valve, the joint of an oil outlet nozzle and a connecting pipe is fixedly connected with an oil nozzle ball valve, a motor and a gear pump are also installed in the machine shell, the gear pump is connected with a relief valve through a pump pipe, the gear pump is connected with a hydraulic oil tank, the relief valve is connected with a pressure gauge valve, the pressure gauge valve is connected with a reversing valve, the reversing valve is connected with the left part of the hydraulic oil cylinder, the reversing valve is connected with the right part of the hydraulic oil cylinder, the reversing valve is connected with the hydraulic oil tank, the hydraulic oil tank is connected with the relief valve, the upper surface of the machine shell is equipped with a switch button and the switch button is electrically connected with the motor.

Owner:王思河

Water-based color transparent heat-insulating coating, preparation method and application method thereof

ActiveCN104151970BHigh hydroxyl contentImprove water resistanceReflecting/signal paintsMulticolor effect coatingsWater basedAcrylic resin

The invention discloses a water-based color transparent heat-insulating coating, a preparation method and a use method thereof. The water-based color transparent heat-insulating coating is composed of water-soluble hydroxy acrylic resin, water-based nano-antimony-doped tin dioxide (ATO) slurry, water-based nano-hydrotalcite slurry, Amino resin, water-based colorant, film-forming aid, deionized water, dispersant, wetting agent, PH regulator, defoamer, anti-settling agent, thickener, adhesion promoter, leveling agent. The preparation method is as follows: the above-mentioned substances are mixed successively under specific conditions to obtain it. The method of use is: when used as a one-component baking varnish, the amount of amino resin added is 4-8% (by weight). When used as a two-component self-drying paint, the amount of amino resin added is 0. The paint has good adhesion on surfaces such as glass and plastic films, and has high hardness, excellent aging resistance and good heat insulation effect.

Owner:肇庆千江高新材料科技股份公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com