Hoop split locking structure of bag type filter

A bag filter, split locking technology, applied in the direction of filtration and separation, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of unable to maintain and repair, and the internal parts of the filter cannot be replaced, so as to shorten the opening time, The effect of increased pressure strength and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

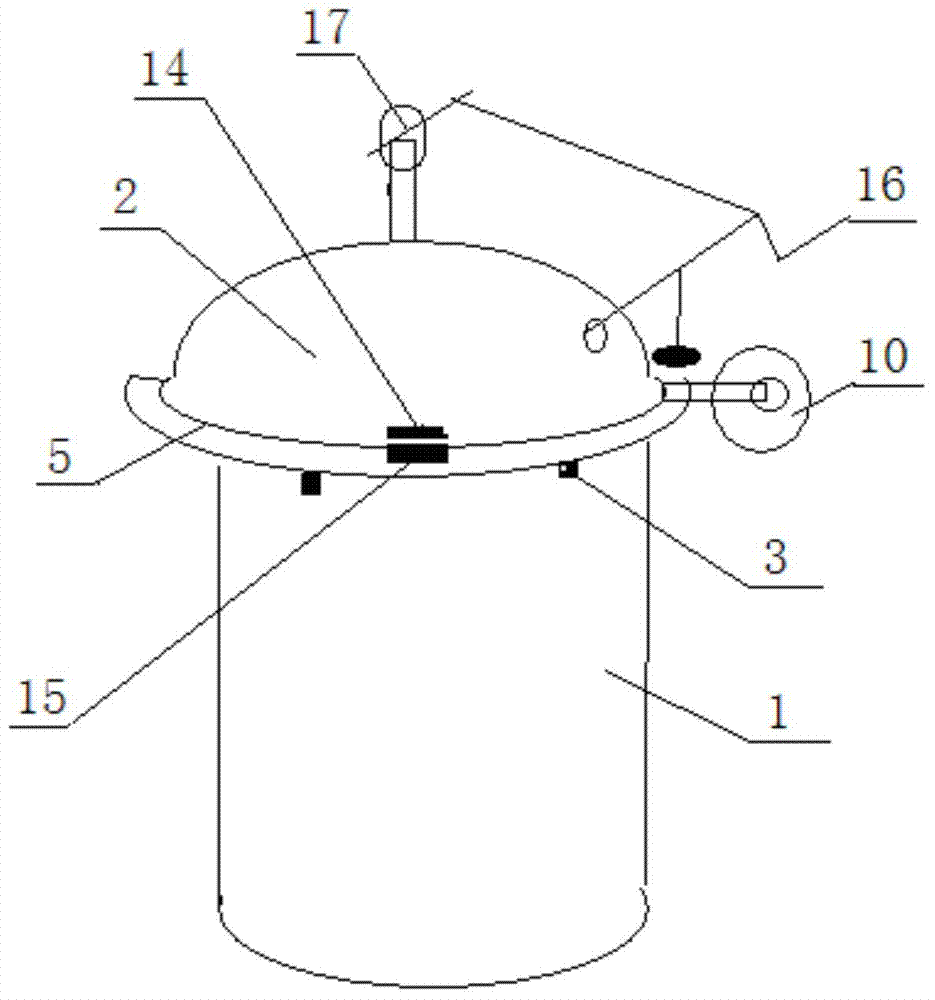

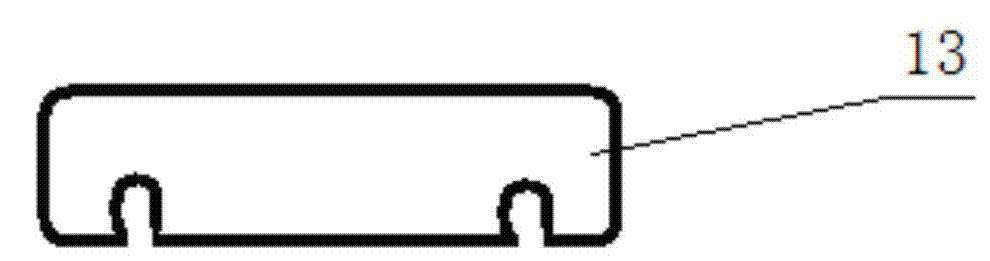

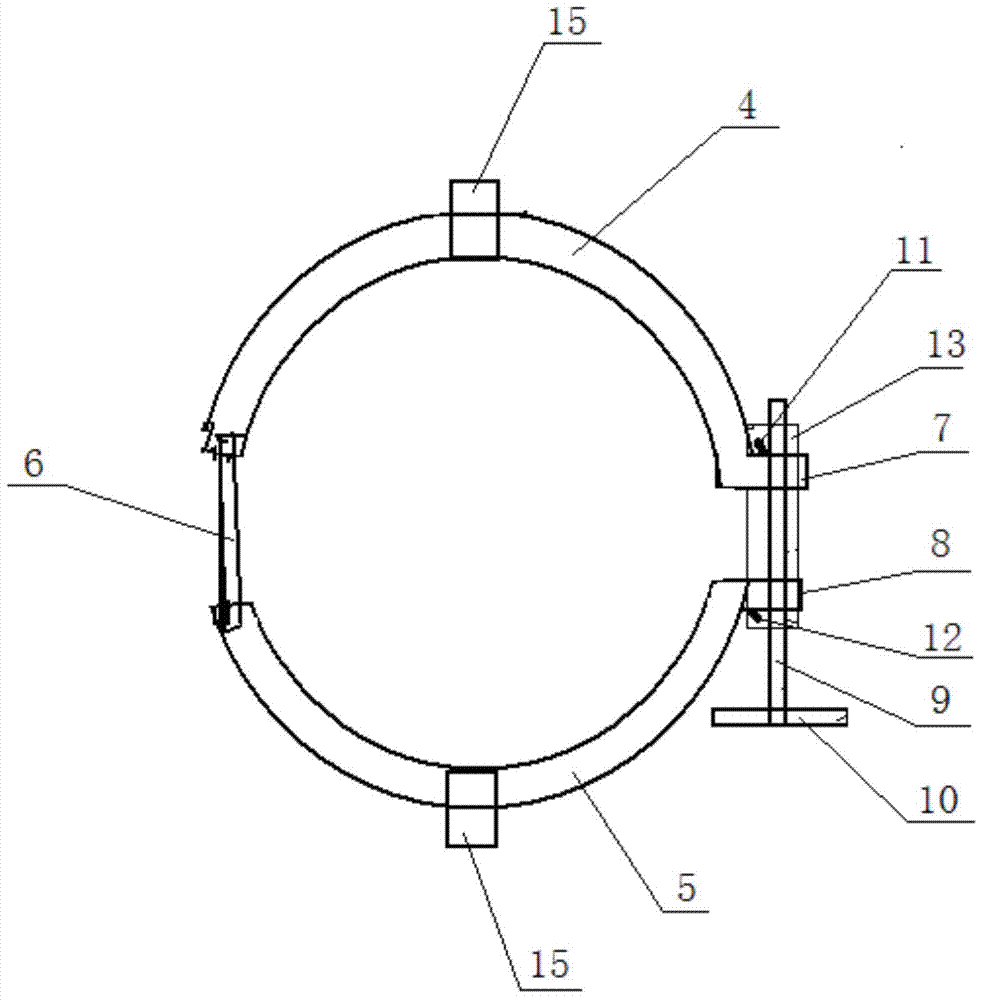

[0015] The hoop split locking structure of the bag filter includes a tank body 1, a tank cover 2 and a hoop support plate 3, a tank body flange is provided at the upper end of the tank body 1, and a tank body flange is provided at the lower end of the tank cover 2. A tank cover flange is provided, and a hoop support plate 3 is fixed on the outer wall of the tank body 1 below the tank body flange, and also includes a left hoop 4, a right hoop 5, a connecting rod 6, a left-handed nut 7, Right-handed nut 8, locking screw 9, hand wheel 10, left locking bolt column 11, right locking bolt column 12 and locking plate 13, place left hoop 4 and right hoop 5 on hoop support plate 3 , one end of the left hoop 4 is hinged with one end of the connecting rod 6, one end of the right hoop 5 is hinged with the other end of the connecting rod 6, a left-handed nut 7 is fixed at the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com