Preparation process of antibacterial polypropylene plastic

A kind of antibacterial polypropylene and preparation technology, which is applied in the direction of flat products, applications, household appliances, etc., can solve the problems of poor antibacterial effect and uneven distribution, achieve good antibacterial effect, good dispersion performance, and reduce deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

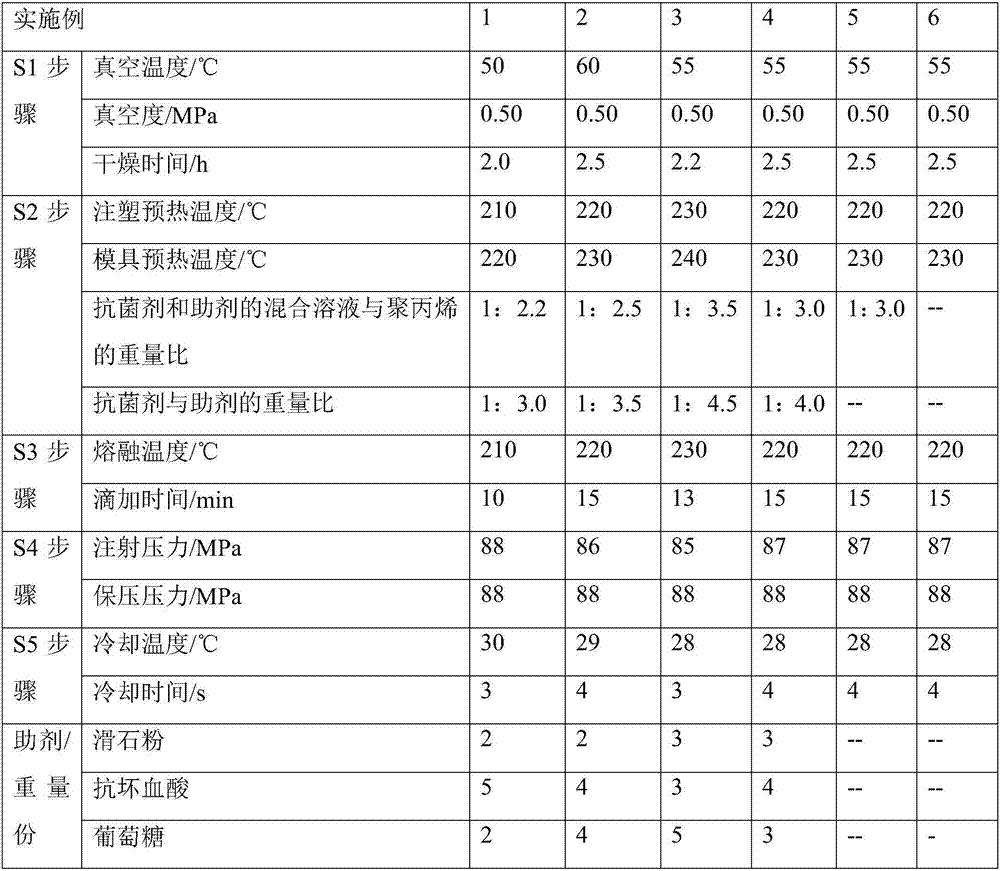

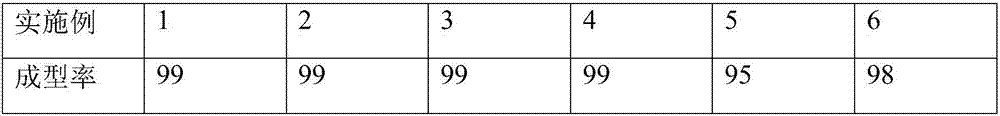

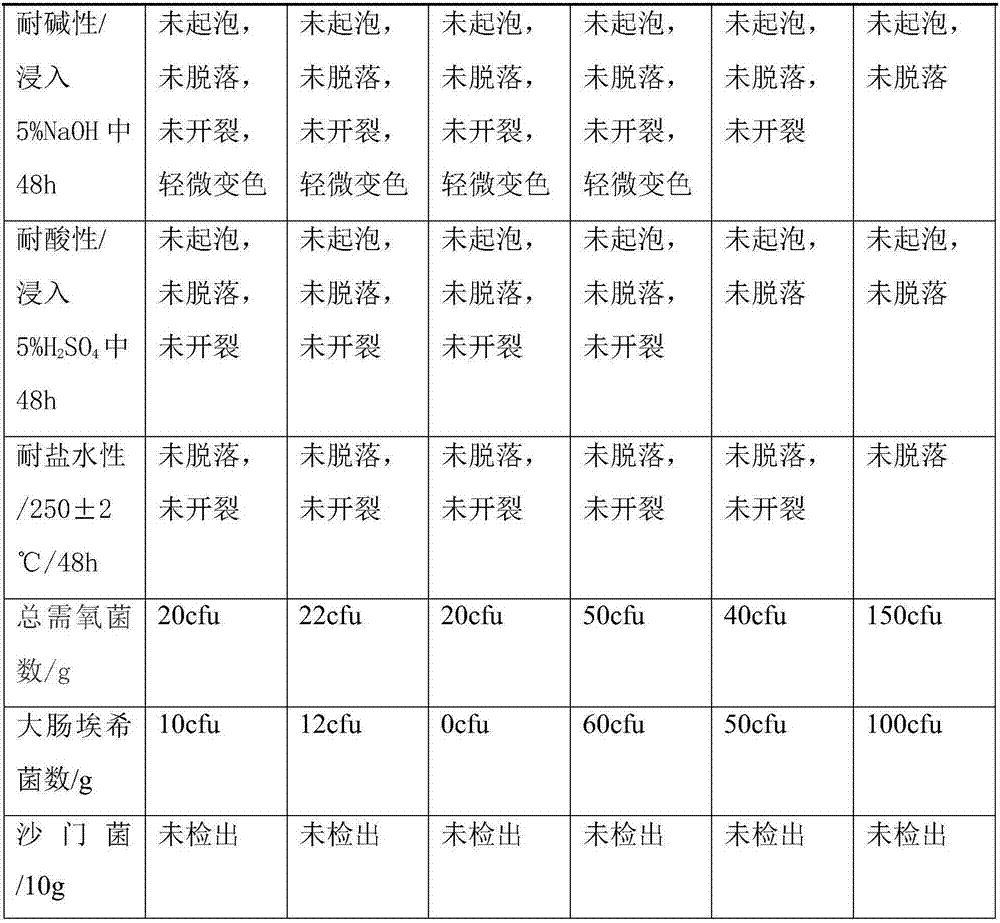

[0041] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

[0042] A preparation process for antibacterial polypropylene plastics, comprising the steps of:

[0043] S1 raw material pretreatment: put polypropylene into a vacuum oven, and vacuum dry to obtain pretreated materials for use;

[0044] S2 preheating treatment: Preheat the injection cylinder; install the injection mold, and preheat both the upper mold and the lower mold;

[0045] S3 hot melt stage:

[0046] S31: adding the pretreated substance into the injection molding cylinder and heating until melting;

[0047] S32: dropwise adding the mixed solution of antibacterial agent and auxiliary agent after melting in step S31;

[0048]S33: Melt again for 15-30 minutes after the step S32 is added dropwise to obtain a hot-melt plastic;

[0049] S4 inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com