Method for preventing looseness of rotating rod of feedback signal potentiometer of hydrogovernor

A technology of feedback signal and potentiometer, which is applied in the direction of machines/engines, hydroelectric power generation, mechanical equipment, etc., can solve the problems of loose unit at the connection, small contact area, small fastening force, etc., and achieve large contact area, large contact, The effect of high fastening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

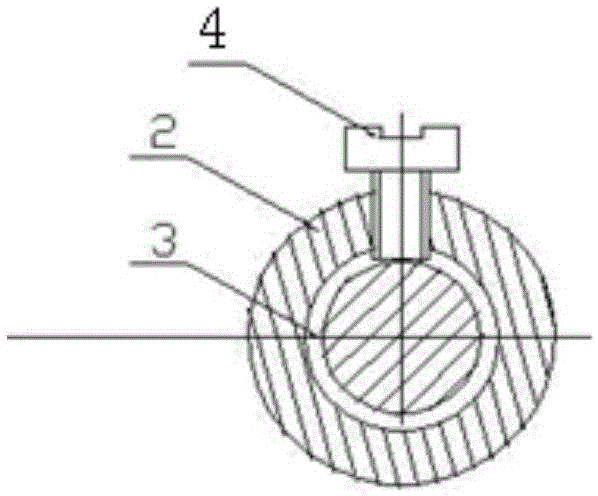

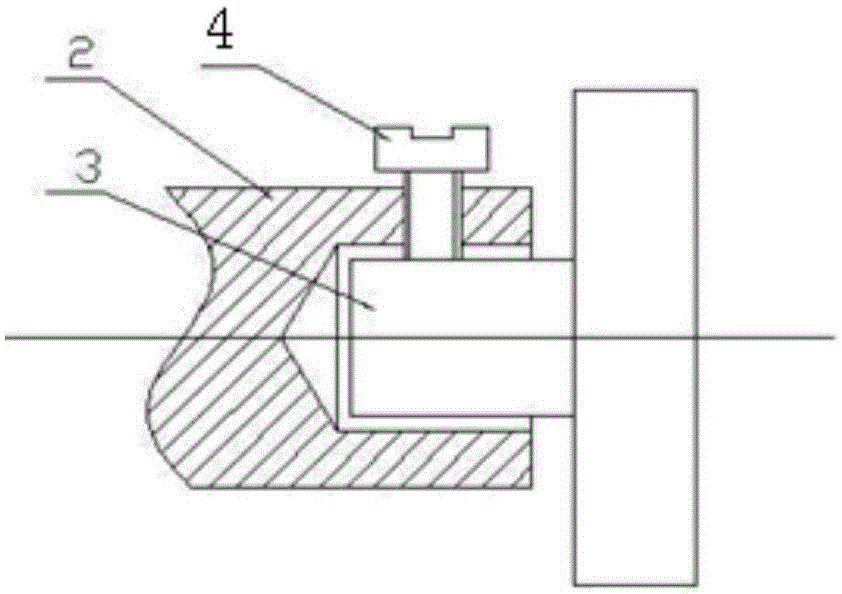

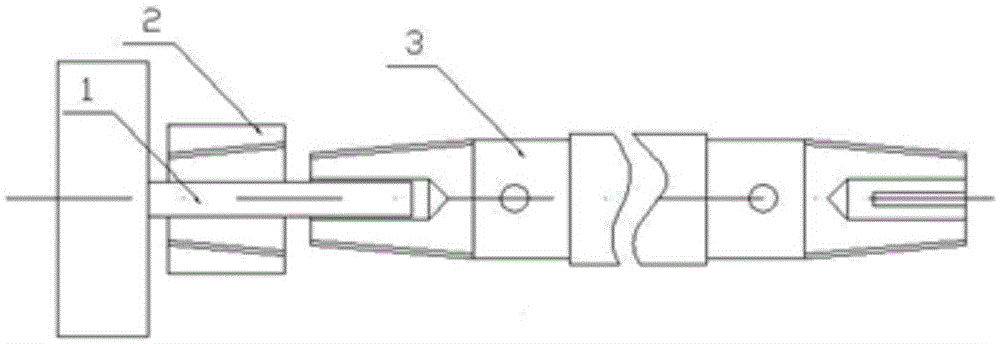

[0016] Specific implementation mode one: refer to image 3 and 4 Describe this embodiment in detail, a kind of method that prevents the rotating rod of feedback signal potentiometer of water turbine speed governor described in this embodiment from loosening, and described method is realized by following steps:

[0017] Step 1. Process the surfaces of both ends of the servomotor displacement transmission rod 3 into threads with gradually smaller diameters. The insides of both ends of the servomotor displacement transmission rod 3 are processed with central holes. The upper edge of the side wall of each end of the servomotor displacement transmission rod 3 Four circular grooves are evenly opened in the circumferential direction of the central hole;

[0018] Step 2. Connect two wedge nuts 2 with involute internal threads to one end of the two potentiometer rotating rods 1 respectively, and then screw one end of each potentiometer rotating rod 1 into the servomotor displacement t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com