Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Improve high temperature life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fabrication of lithium secondary battery

ActiveUS20100024204A1Extend battery lifeSimple methodFinal product manufacturePrimary cellsSilanesPre-charge

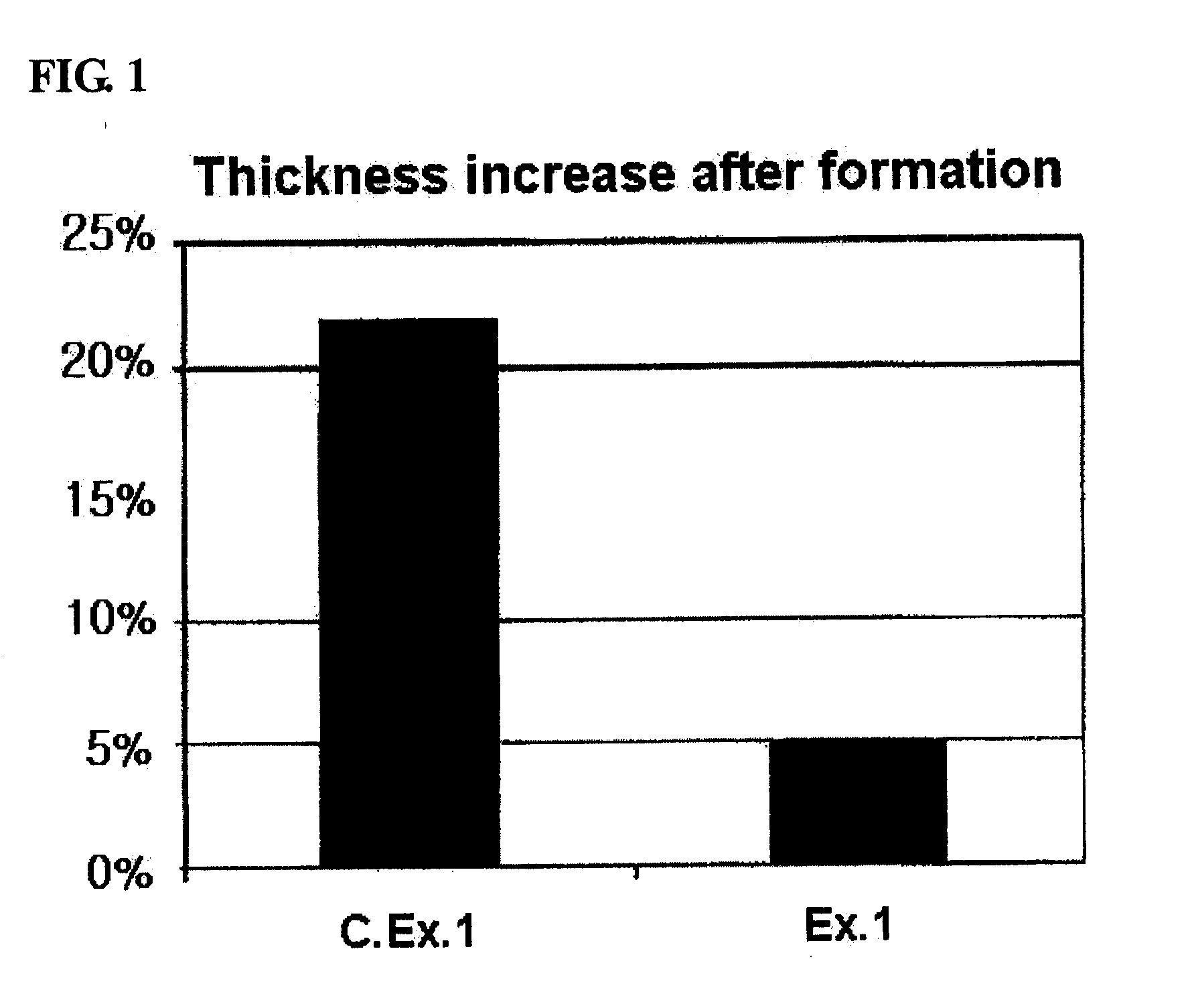

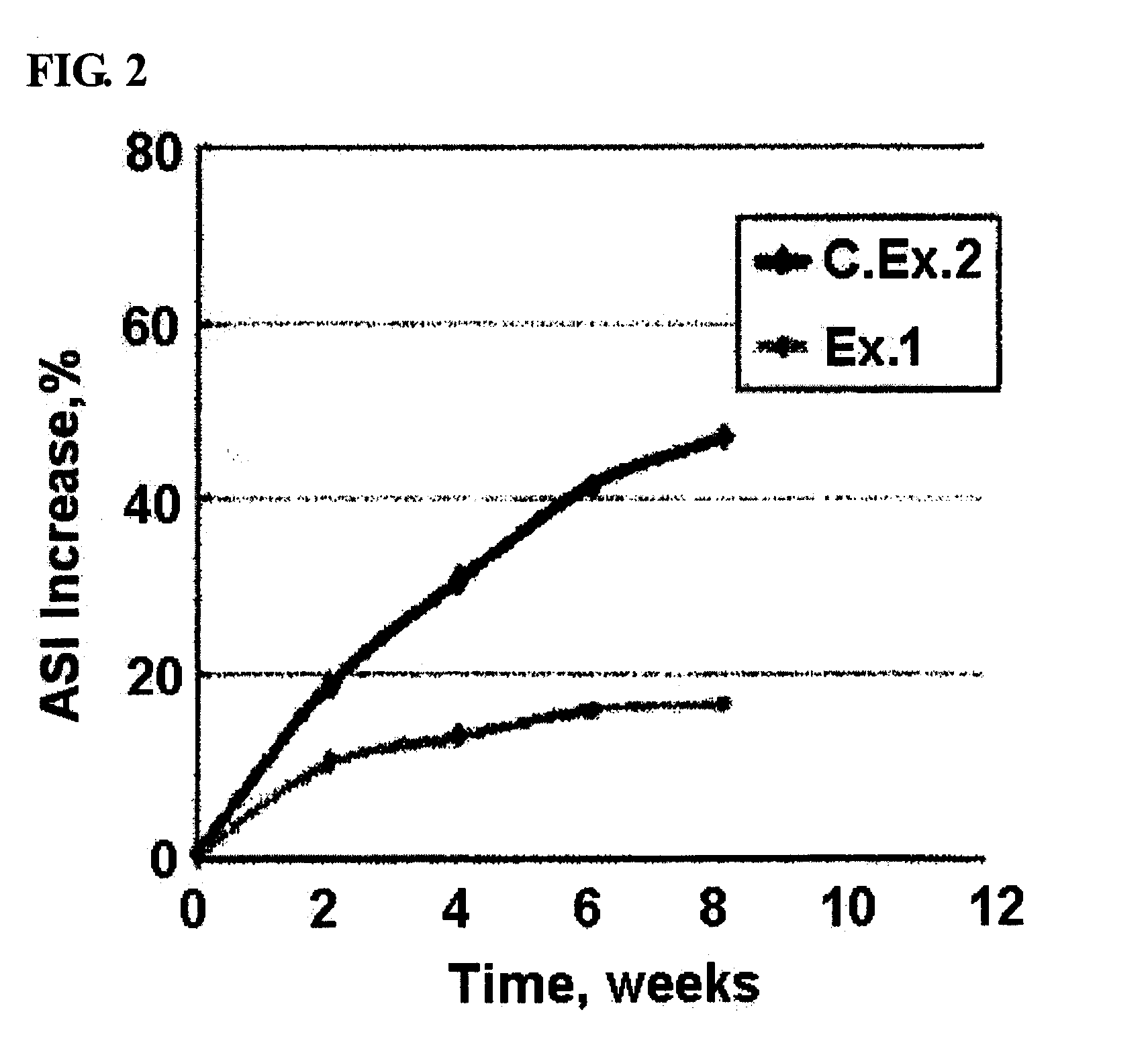

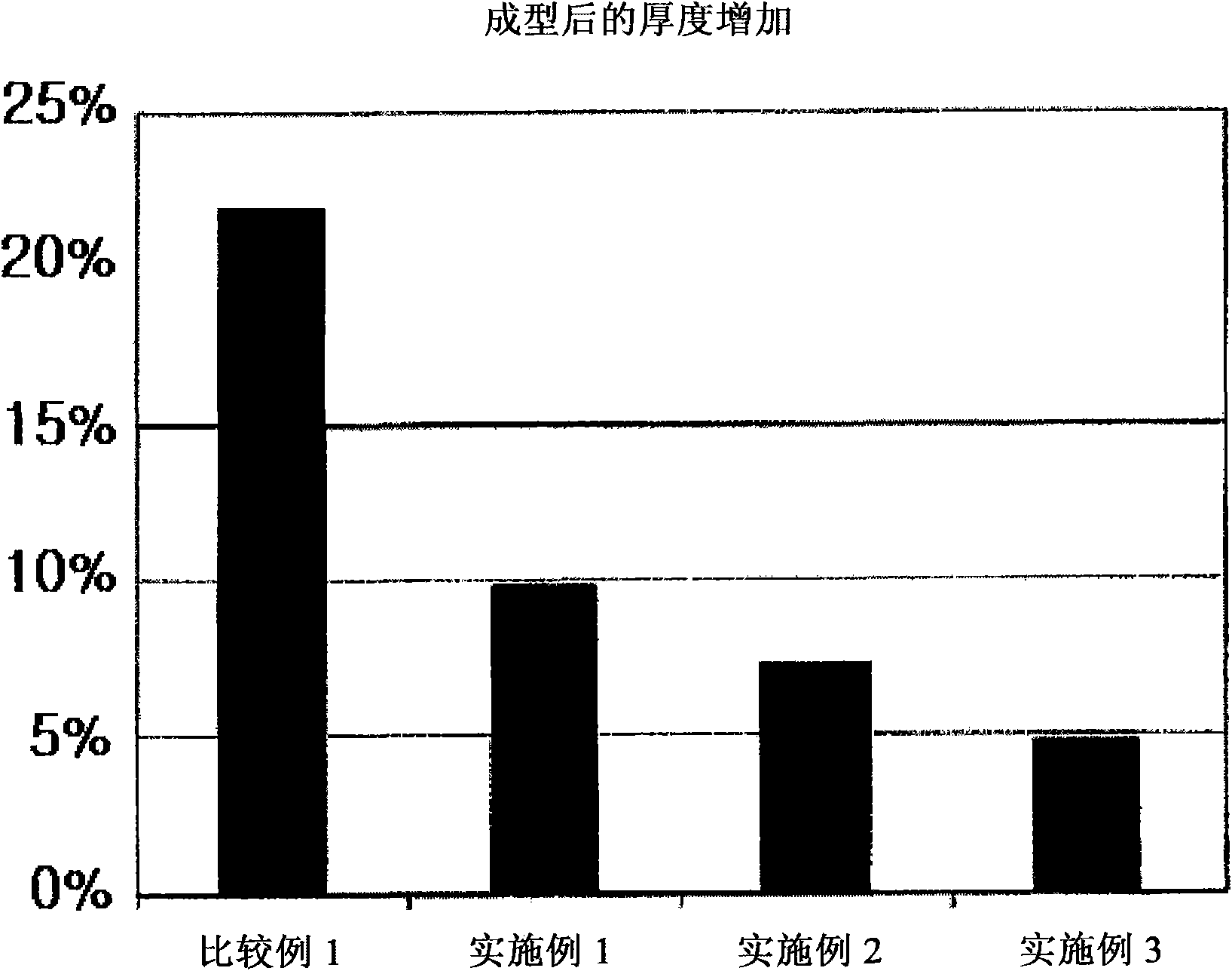

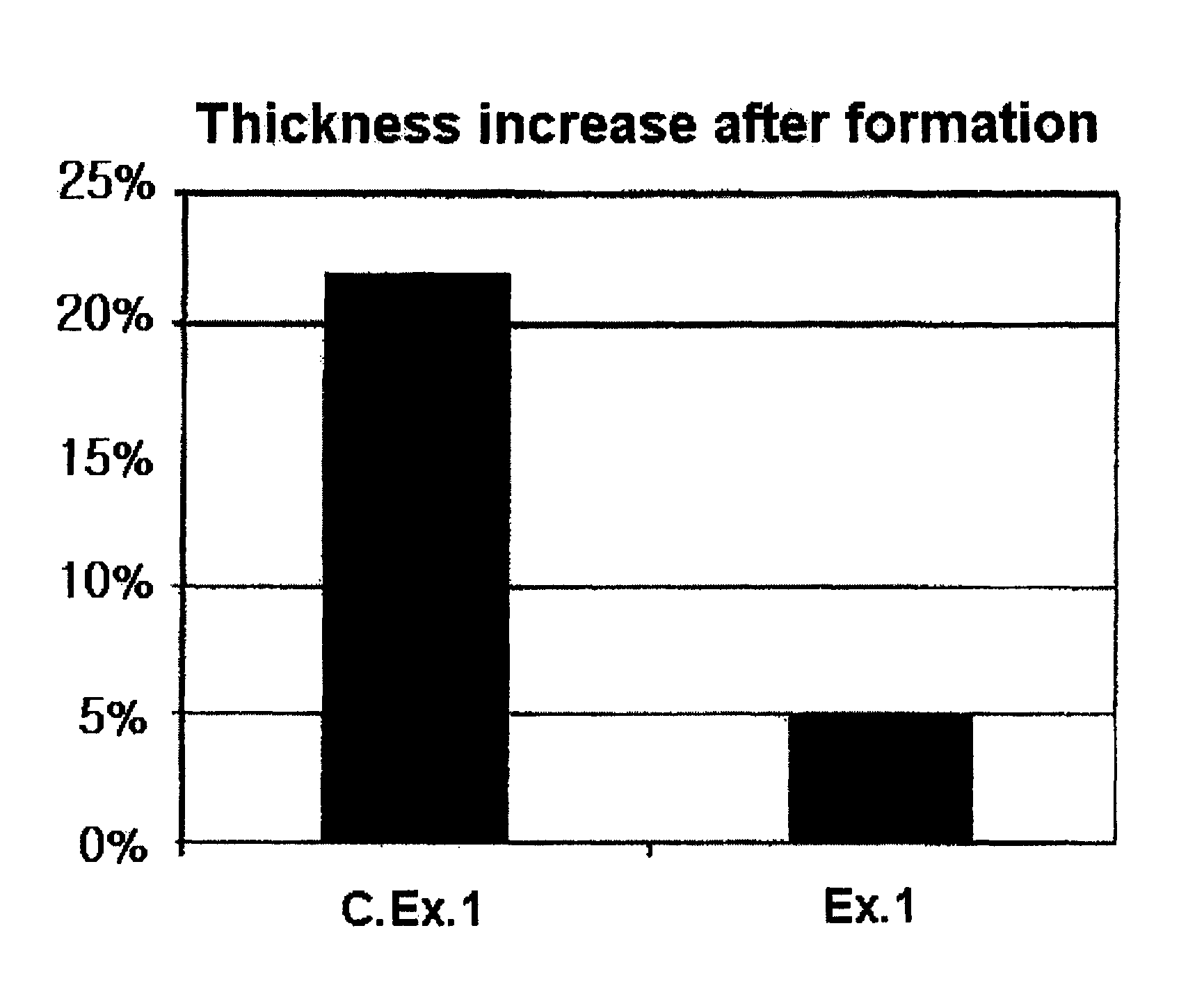

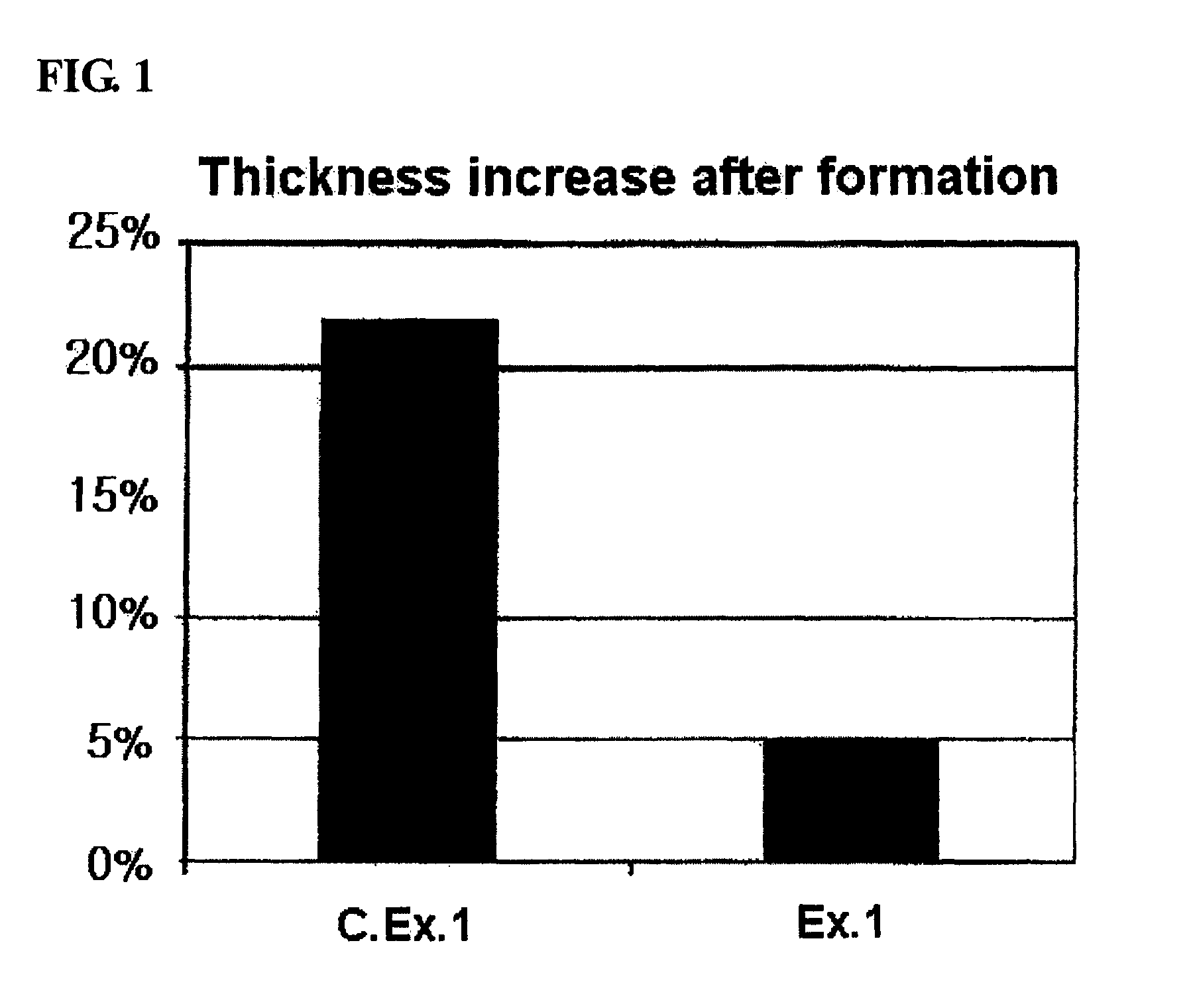

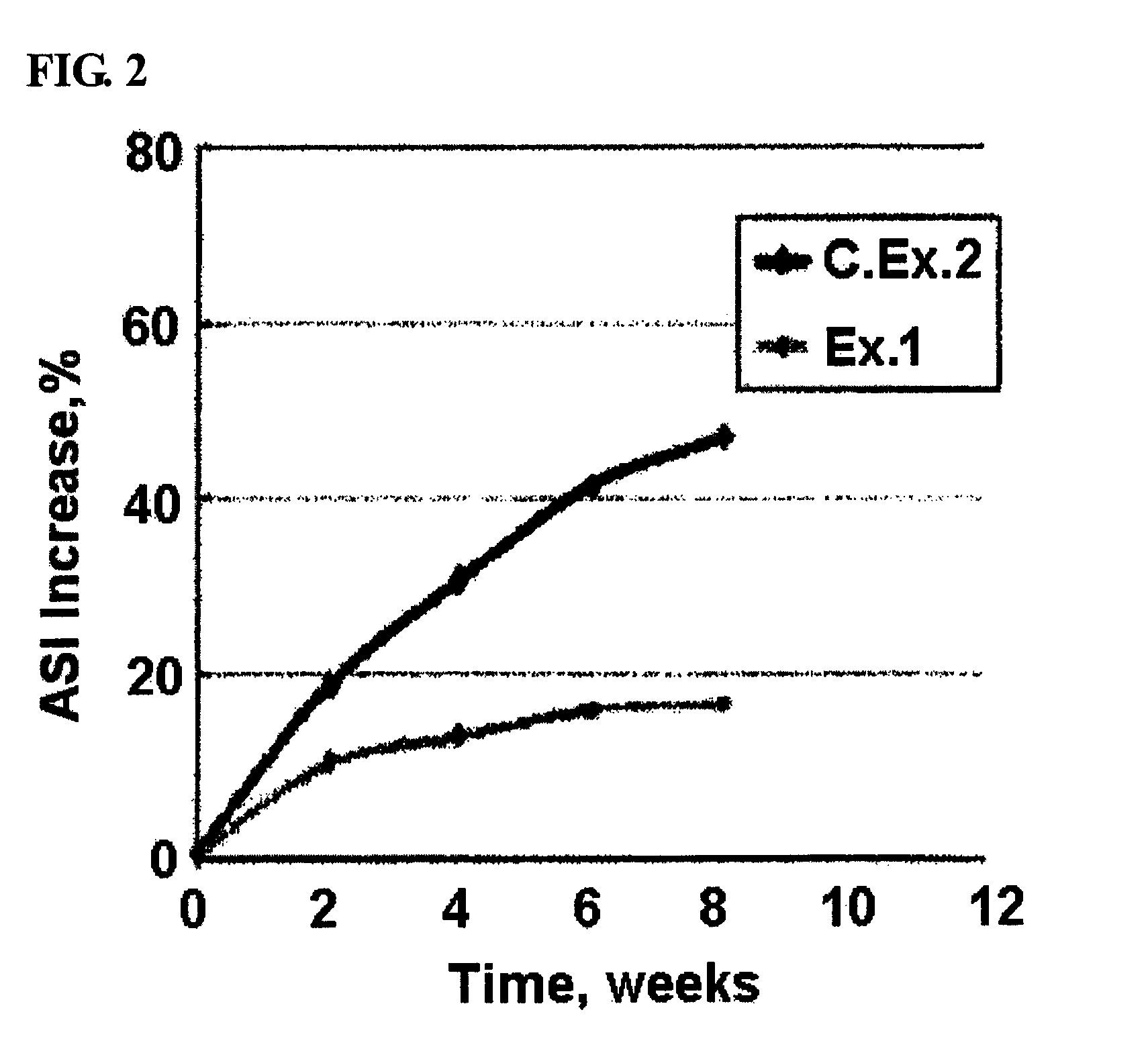

A method of fabricating a lithium secondary battery, which improves charge-discharge characteristics, lifespan, and temperature characteristics of the battery and which includes interposing a separator between a positive electrode plate and a negative electrode plate, thus manufacturing an electrode assembly; housing the electrode assembly in a battery case, introducing an additive-containing electrolytic solution, and then sealing the battery case; subjecting the sealed battery case to pre-charging, and then removing gas generated by the pre-charging; subjecting the battery case to formation; and removing gas generated by the formation, wherein the additive is one or more selected from among LiF2BC2O4, 3,9-divinyl-2,4,8,10-tetraoxaspiro[5,5]undecane, LiBC(C2O4)2, poly(ethyleneglycol)borate and derivatives thereof, halogen-substituted carbonate, and vinyl silane, and the pre-charging is conducted in a range of 10% or less of a battery capacity.

Owner:SK ON CO LTD

Anti-agglomeration high-temperature resistant coating of furnace bottom roller

ActiveCN102650028AImprove high temperature lifeGood high temperature performanceMolten spray coatingTemperature resistanceCermet

The invention provides an anti-agglomeration high-temperature resistant coating of a furnace bottom roller. The coating comprises a substrate, wherein the substrate includes the following components by weight: 35-63 percent of Co, 20-30 percent of Cr, 10-20 percent of Ta, 5-10 percent of Al and 2-5 percent of y. According to the invention, a metal-ceramic material is coated on a furnace bottom roller body in a spraying manner by adopting an explosion method, thus the characteristics of the surface of the furnace bottom roller body is changed, a better prevention of the agglomeration of the furnace bottom roller body is achieved, and further the high-temperature resistance of the furnace bottom roller is enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Fabrication of lithium secondary battery

InactiveCN101606264AImprove high temperature lifeEliminate swellingFinal product manufactureVent arrangementsSilanesPre-charge

This invention relates to a method of fabricating a lithium secondary battery, which improves charge-discharge characteristics, lifespan, and temperature characteristics of the battery and which includes interposing a separator between a positive electrode plate and a negative electrode plate, thus manufacturing an electrode assembly; housing the electrode assembly in a battery case, introducing an additive-containing electrolytic solution, and then sealing the battery case; subjecting the sealed battery case to pre-charging, and then removing gas generated by the pre-charging; and subjecting the battery case to formation, wherein the additive is one or more selected from among LiF2BC2O4, 3,9-divinyl-2,4,8,10-tetraoxaspiro [5,5]undecane, LiBC(C2O4)2, poly(ethyleneglycol)borate and derivatives thereof, halogen- substituted carbonate, and vinyl silane, and the pre-charging is conducted in a range of 50-100% of a battery capacity.

Owner:SK ENERGY CO LTD (KR)

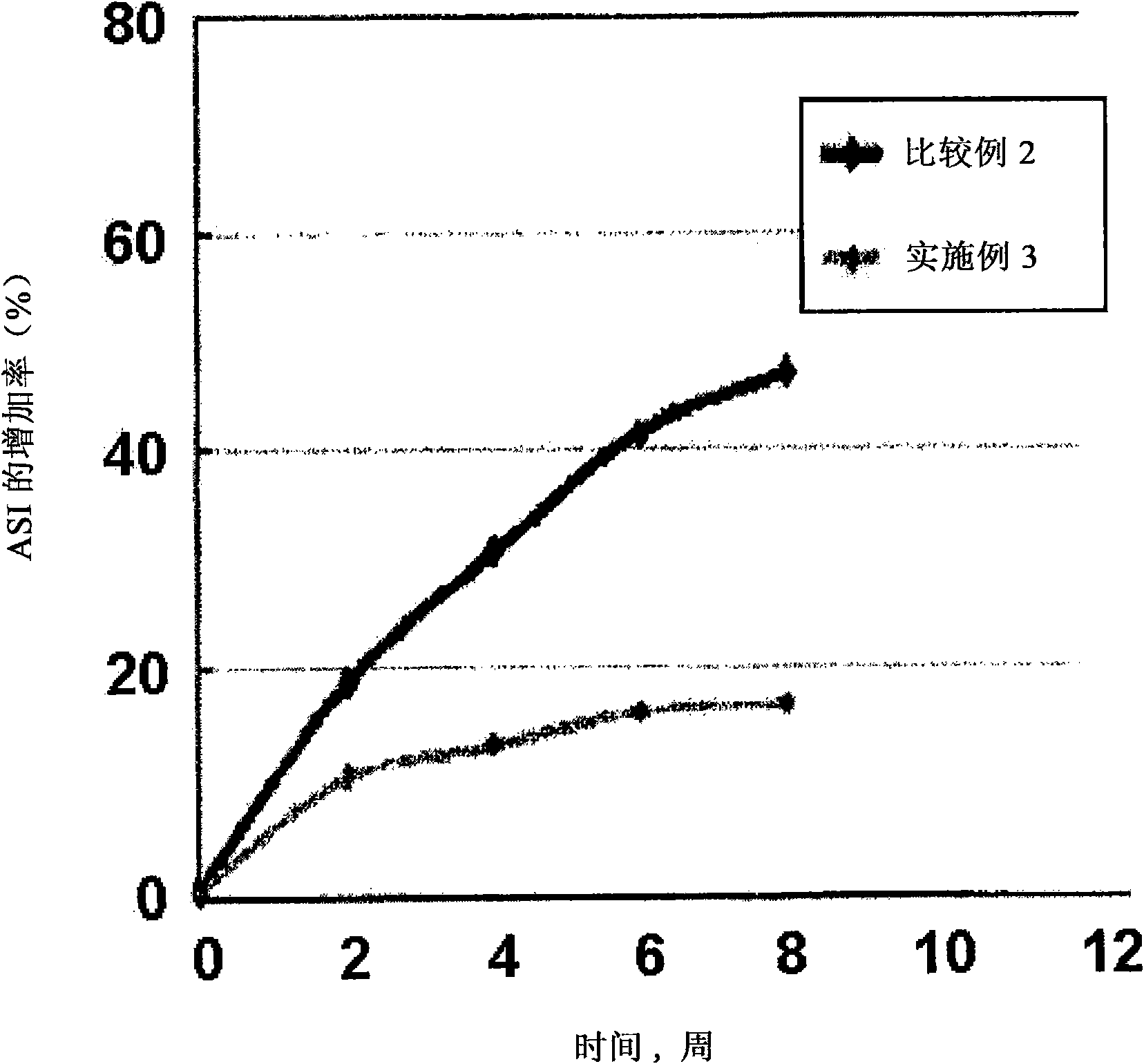

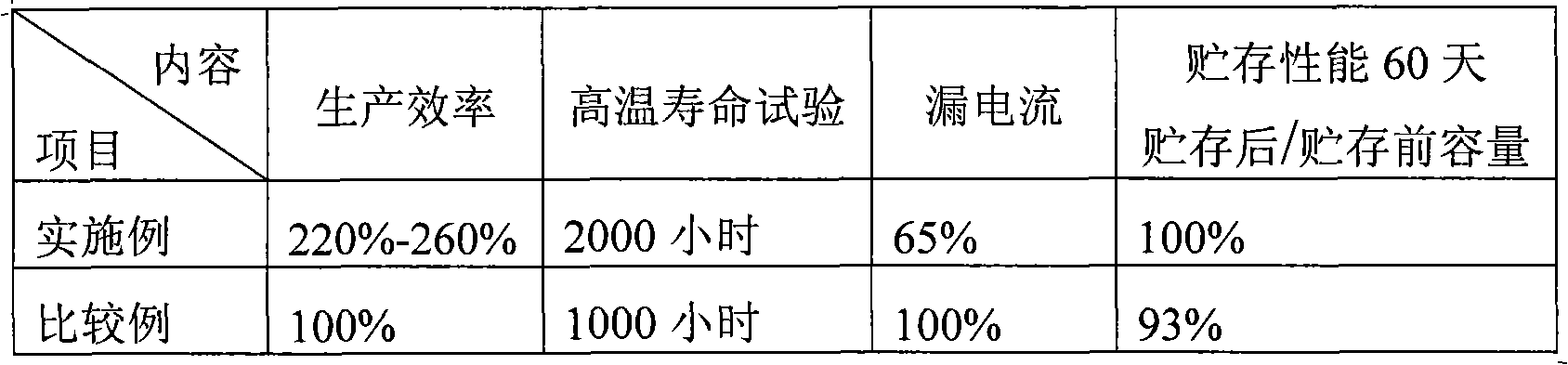

Five-stage manufacturing method of low voltage electrode foil for aluminum electrolytic capacitor

InactiveCN101593628AImprove the efficiency of formationImprove high temperature lifeElectrolytic capacitorsAluminiumAluminum electrolytic capacitor

Aiming to solve the problems of poor storage performance of the electrode foil and life time prolong of the capacitor, the invention provides a novel five-stage manufacturing method of low voltage electrode foil for an aluminum electrolytic capacitor, which comprises the processes of first forming, second forming, third forming, fourth forming, fifth forming, high-temperature processing, after-forming 1, after-processing, and after-forming 2. The produced low voltage electrode foil for the aluminum electrolytic capacitor has high forming effect of up to 220 percent to 260 percent, long high-temperature life, good storage performance and less electricity leakage.

Owner:NANTONG HAIYI ELECTRONICS

Preparation method of silver solder paste and silver solder paste product

ActiveCN101837526AWell mixedIncrease the baking temperatureWelding/cutting media/materialsSoldering mediaRetention timePotassium fluoride

The invention provides a preparation method of silver solder paste, which comprises the following steps: 1, preparing raw materials and pretreating the raw material; 2, stirring the raw materials; 3, roasting the raw materials; and 4 grinding the raw materials. The invention also provides silver solder paste prepared by the method. The silver solder paste is prepared from the following raw materials in percentage by weight: boric acid 33-38, potassium fluoborate 28-32, potassium fluoride 20-25, monomer boron 2.0-2.5 and distilled water 10-20. Compared with the prior art, the method has the advantages of stable product quality and high material utilization rate. The product has the characteristics of long soldering high-temperature life, long activity retention time, high solder wettability and high soldered joint quality.

Owner:HUIZHOU WUFU IND TECH

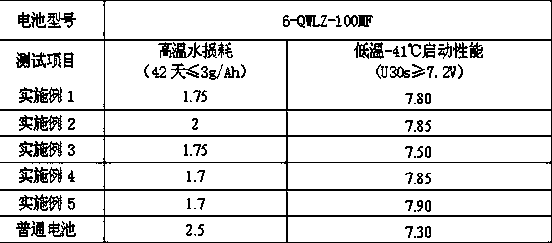

Negative electrode lead paste suitable for high and low temperature environments, and preparation method thereof, and lead-acid storage battery

PendingCN111600018AImprove stabilityReduce solubilityFinal product manufactureNegative electrodesCarbon nanotubeEngineering

The invention discloses negative electrode lead paste suitable for high and low temperature environments, and a preparation method thereof, and a lead-acid storage battery. The formula of the negativeelectrode plate lead paste comprises the following components in parts by weight: 100 parts of lead powder, 8-11 parts of sulfuric acid, 7-10 parts of deionized water, 0.04-0.06 part of high-strengthshort fiber, 0.1-0.2 part of lignin, 0.1-0.25 part of granular carbon black, 0.65-0.95 part of nano barium sulfate, 0.4-0.6 part of humic acid, 0.25-0.45 part of a surfactant, 2-4 parts of a carbon nanotube solution and 0.10-0.25 part of a hydrogen evolution inhibitor. According to the lead-acid storage battery produced by adopting the negative electrode plate lead paste formula, the high-temperature and low-temperature performances of the lead-acid storage battery are comprehensively improved, and the lead-acid storage battery has the advantages of long high-temperature service life and goodlow-temperature large-current discharge performance.

Owner:骆驼集团蓄电池研究院有限公司

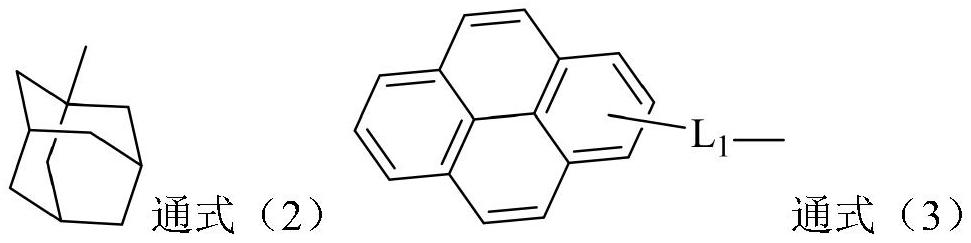

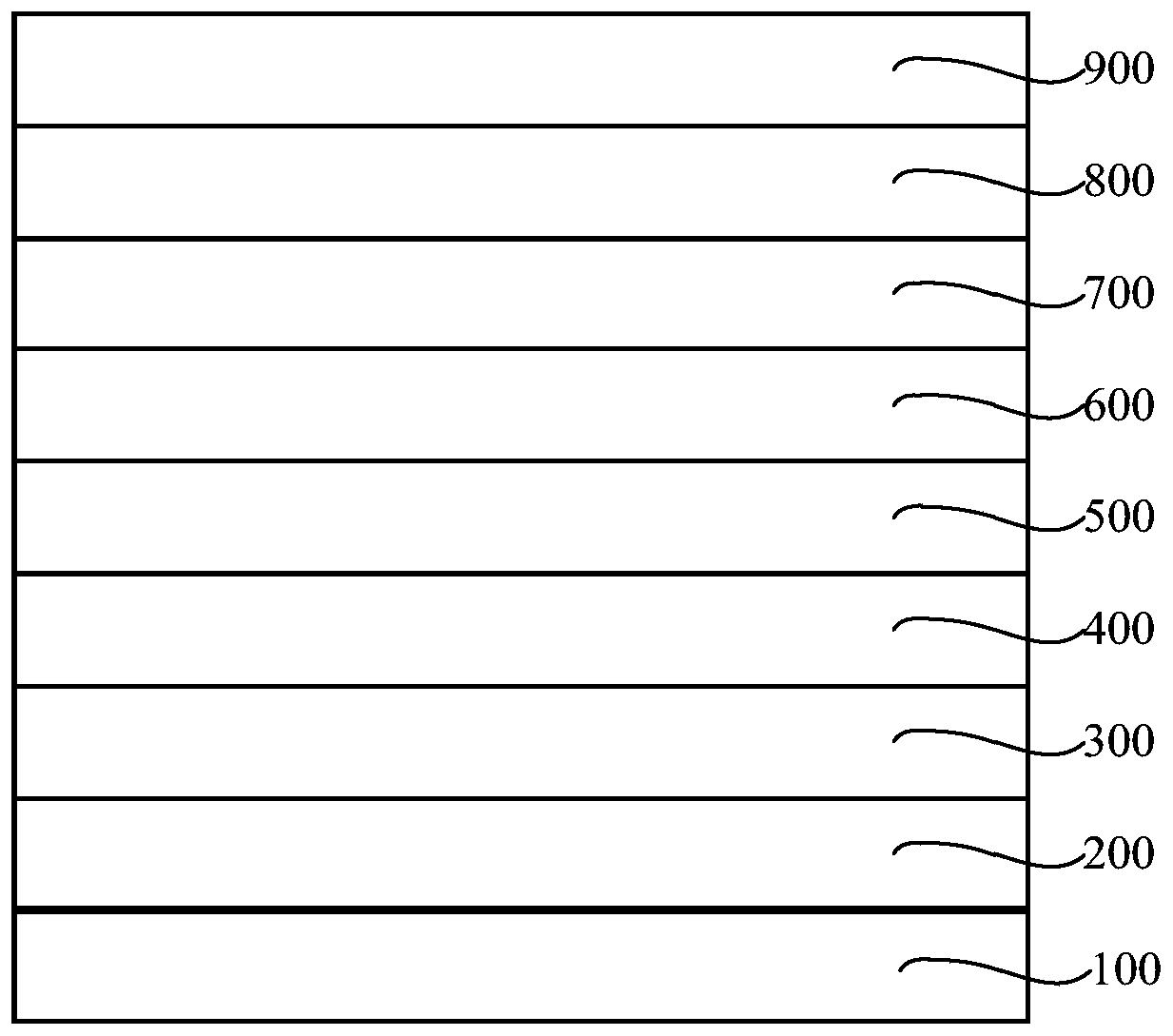

Organic light emitting diode (OLED) device

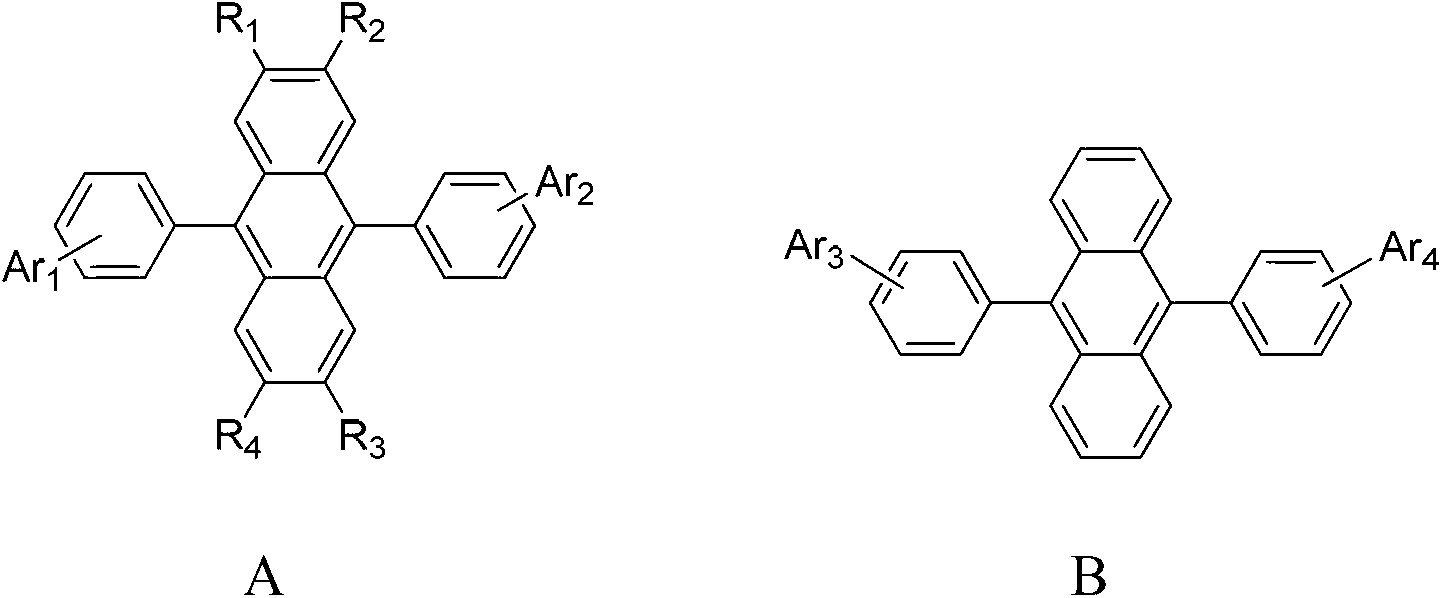

ActiveCN103066215AExtend your lifeGuaranteed photoelectric performanceSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionHost material

The invention belongs to the field of organic electroluminescence devices, and particularly relates to an organic light emitting diode (OLED) device utilizing organic electroluminescence material as a lighting layer. According to the OLED, the lighting material forming the lighting layer comprises subject material and object material, wherein the subject material comprises compound shown in a structural formula A, and compound shown by a structural formula B in a mixed mode, and the weight proportion of the compound shown in the structural formula A, and the compound shown by the structural formula B is 1-20:10. According to the OLED device, the compound shown by the structural formula A, high in steric hindrance, and the compound shown by the structural formula B, high in electronic mobility, are utilized for the organic electroluminescence material utilizes the compound, the proportion relation of the two compounds is adjusted and optimized to adjust electronic transmission performance of a new subject, and therefore a device having good luminance and long service life is obtained.

Owner:KUNSHAN VISIONOX DISPLAY TECH +2

Fabrication of lithium secondary battery

ActiveUS8523958B2Improve high temperature lifeDecreasing a swelling phenomenonFinal product manufacturePrimary cellsSilanesPre-charge

A method of fabricating a lithium secondary battery, which improves charge-discharge characteristics, lifespan, and temperature characteristics of the battery and which includes interposing a separator between a positive electrode plate and a negative electrode plate, thus manufacturing an electrode assembly; housing the electrode assembly in a battery case, introducing an additive-containing electrolytic solution, and then sealing the battery case; subjecting the sealed battery case to pre-charging, and then removing gas generated by the pre-charging; subjecting the battery case to formation; and removing gas generated by the formation, wherein the additive is one or more selected from among LiF2BC2O4, 3,9-divinyl-2,4,8,10-tetraoxaspiro[5,5]undecane, LiB(C2O4)2, poly(ethyleneglycol)borate and derivatives thereof, halogen-substituted carbonate, and vinyl silane, and the pre-charging is conducted in a range of 10% or less of a battery capacity.

Owner:SK ON CO LTD

High temperature resistant surface-insulated FeCrAl electrothermal alloy and preparation method thereof

InactiveCN101562913AWith surface insulationHigh temperature resistantSolid/suspension decomposition chemical coatingHeating element materialsSol-gelAlloy surface

The invention relates to a high temperature resistant surface-insulated FeCrAl electrothermal alloy, which is characterized in that a FeCrAl electrothermal alloy matrix is provided with a high temperature resistant insulated composite alumina protective layer containing rare earth; the preparation method for the high temperature resistant surface-insulated FeCrAl electrothermal alloy comprises the following steps: firstly, cleaning the surface of a FeCrAl electrothermal alloy; secondly, putting the FeCrAl electrothermal alloy into sol-gel for soaking; and finally taking the FeCrAl electrothermal alloy out, drying and performing proper heat treatment on the FeCrAl electrothermal alloy, and obtaining a high temperature resistant surface-insulated protective layer on the surface of the FeCrAl electrothermal alloy. For the FeCrAl electrothermal alloy prepared by the method, a compact composite film is formed through high-temperature solution treatment, is well combined with the matrix, takes composite alumina as a main raw material, and is formed on the surface of the FeCrAl electrothermal alloy by rare earth micro-alloying action. The thickness of the composite film is between 5 and 10 mu m, and the composite film has surface insulation, high temperature resistance and the like.

Owner:杭州强泰科技有限公司

Low-noise lubricating grease and preparation method thereof

InactiveCN104312679AEasy to prepareImprove antioxidant capacityLubricant compositionLow noiseTert butyl phenol

The invention discloses low-noise lubricating grease and a preparation method thereof. The lubricating grease consists of base oil, a thickener and an additive, wherein the thickener accounts for 12-14% by weight of the base oil and the additive accounts for 1.6-2.5% by weight of the base oil. The base oil is a mixture of silicon oil, pentaerythritol, alkylbenzene and poly-alpha-olefin oil, the thickener is a mixture of paraffin, asbestos and ozocerite, and the additive is a mixture of dialkyl dithiophosphate, dodecenylsuccinic acid, zinc naphthenate, di-tert-butyl phenol and polyisobutene. The lubricating grease disclosed by the invention is simple in preparation method. By using the mixture of silicon oil, pentaerythritol, alkylbenzene and poly-alpha-olefin oil as the base oil, the lubricating grease is good in lubricating effect. By using paraffin, asbestos and ozocerite as the thickener, the noise of the lubricating grease is reduced. By adding dialkyl dithiophosphate, dodecenylsuccinic acid, zinc naphthenate, di-tert-butyl phenol and polyisobutene, the resistance to oxidation and wear resistance of the lubricating grease are improved.

Owner:WUXI FEITIAN GREASE

Fabrication of lithium secondary battery

ActiveCN101606265AImprove high temperature lifeEliminate swellingFinal product manufactureVent arrangementsSilanesPre-charge

This invention relates to a method of fabricating a lithium secondary battery, which improves charge-discharge characteristics, lifespan, and temperature characteristics of the battery and which includes interposing a separator between a positive electrode plate and a negative electrode plate, thus manufacturing an electrode assembly; housing the electrode assembly in a battery case, introducing an additive-containing electrolytic solution, and then sealing the battery case; subjecting the sealed battery case to pre-charging, and then removing gas generated by the pre-charging; subjecting the battery case to formation; and removing gas generated by the formation, wherein the additive is one or more selected from among LiF2BC2O4, 3,9-divinyl-2,4,8,10-tetraoxaspiro [5,5]undecane, LiBC(C2O4)2, poly(ethyleneglycol)borate and derivatives thereof, halogen-substituted carbonate, and vinyl silane, and the pre-charging is conducted in a range of 10% or less of a battery capacity.

Owner:SK ON CO LTD

Thermosetting Resin Composite Material and Method for Producing the Same

InactiveUS20070261598A1High mechanical strengthImprove high temperature lifePigmenting treatmentMaterial nanotechnologyAspect ratioResin composite

The present invention provides a thermosetting resin composite material excellent in mechanical strength and wear resistance at high temperature, which is achieved by converting graphite into thin-layered one and dispersing it in a thermosetting resin homogeneously. A thermosetting resin composite material, wherein an organically modified graphite having an organic compound molecule inserted between graphite layers is mixed with a thermosetting resin, the organically modified graphite being prepared by subjecting graphite to a chemical treatment to form a graphite interlayer compound having a low-molecular substance inserted between graphite layers and subsequently immersing the resultant product in a solution of an organically modifying agent, as well as a process for producing the same. Preferably, the organically modified graphite is mixed with a thermosetting resin to be converted into thin-layered one having a layer thickness of 0.1 to 100 nm, a layer length of 100 nm to 100 μm, and an aspect ratio of 100 to 1,000,000.

Owner:AKEBONO BRAKE IND CO LTD

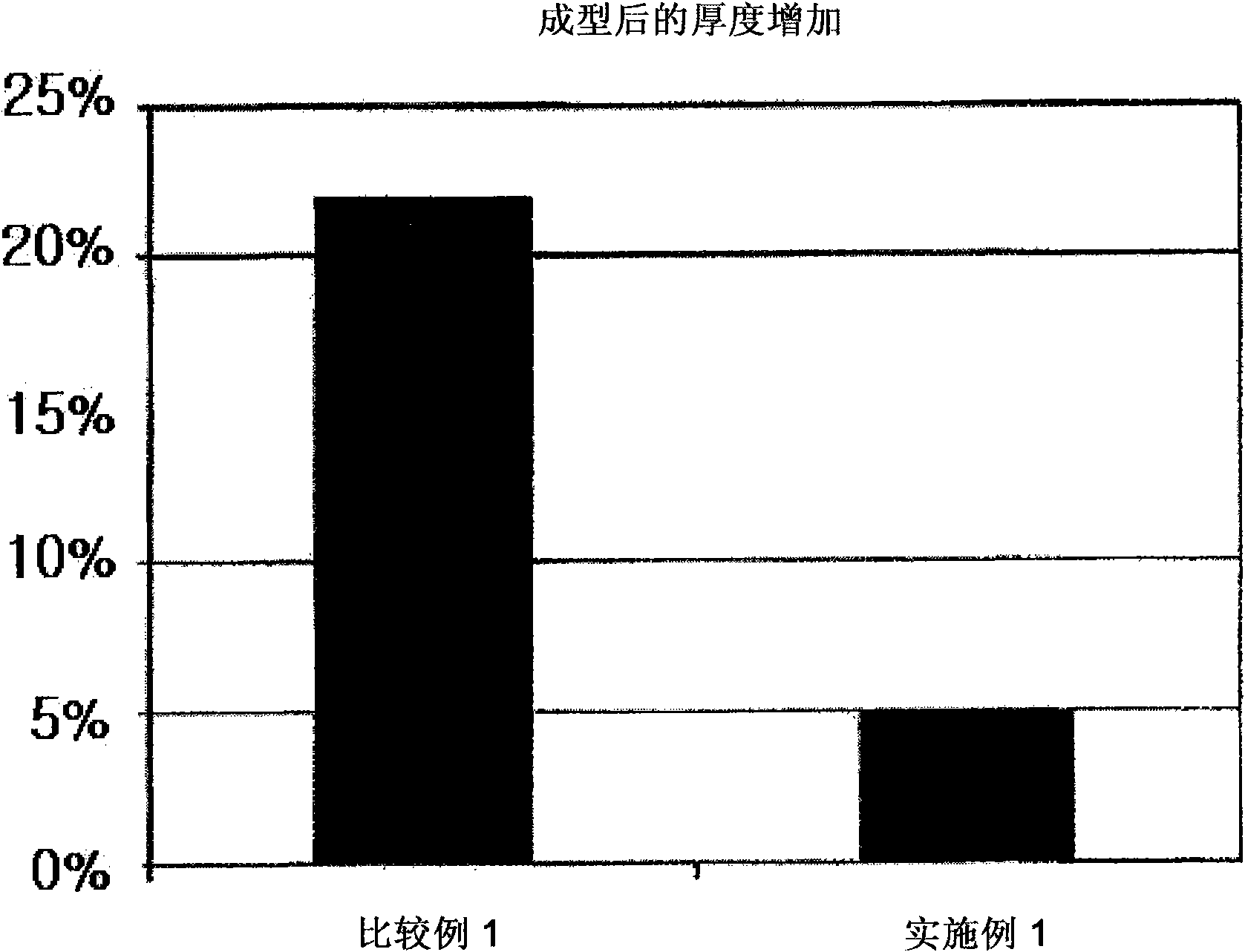

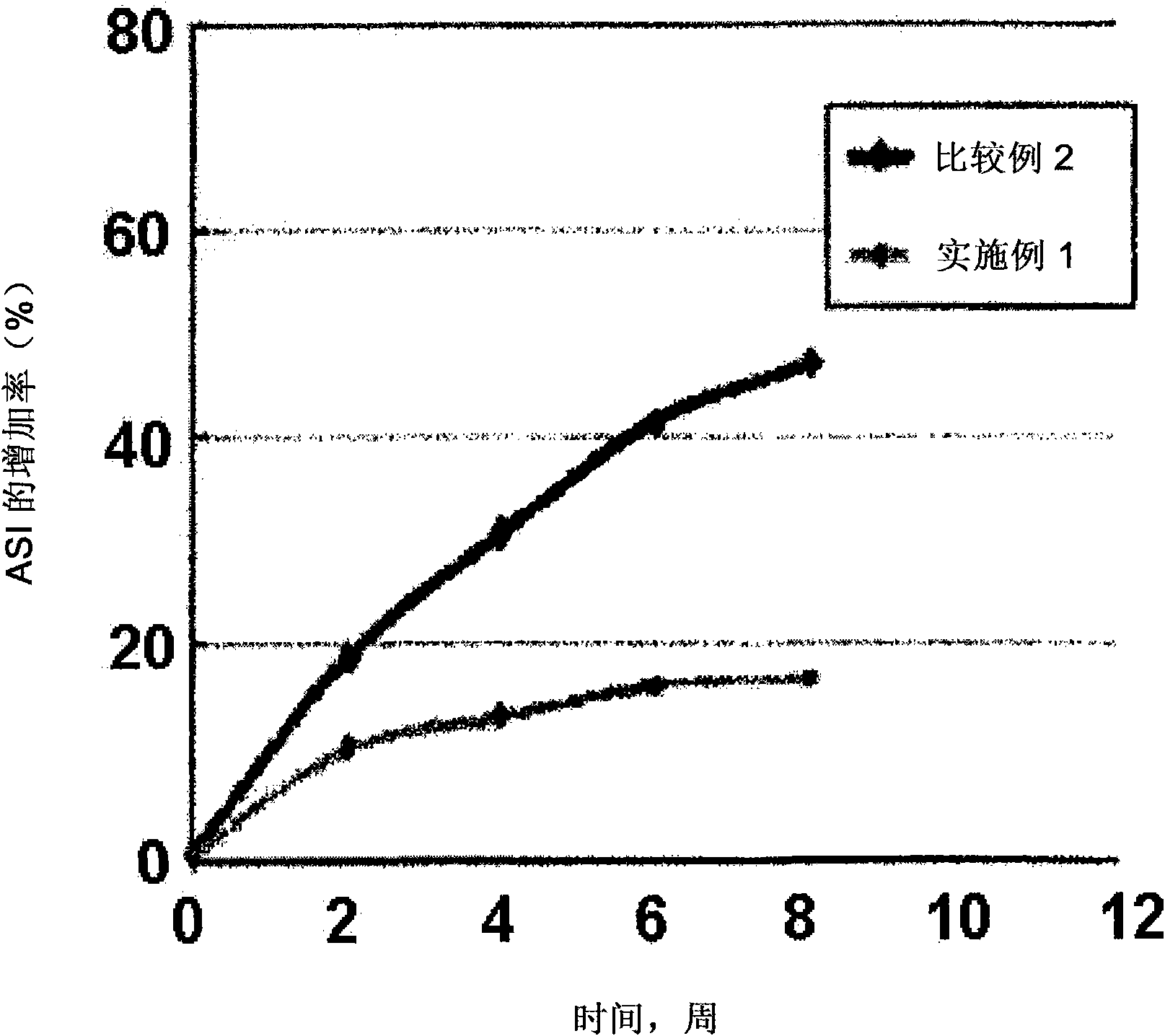

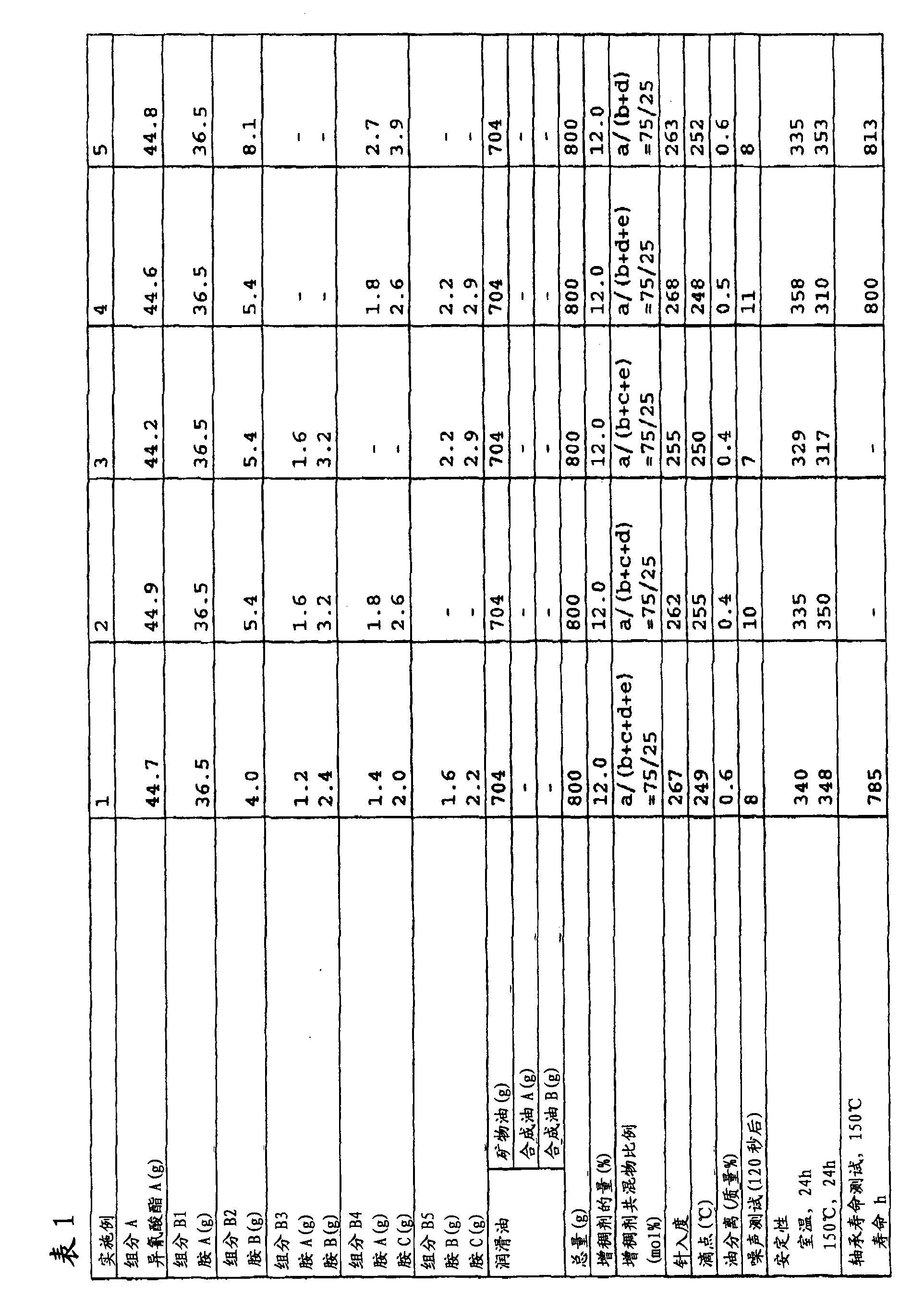

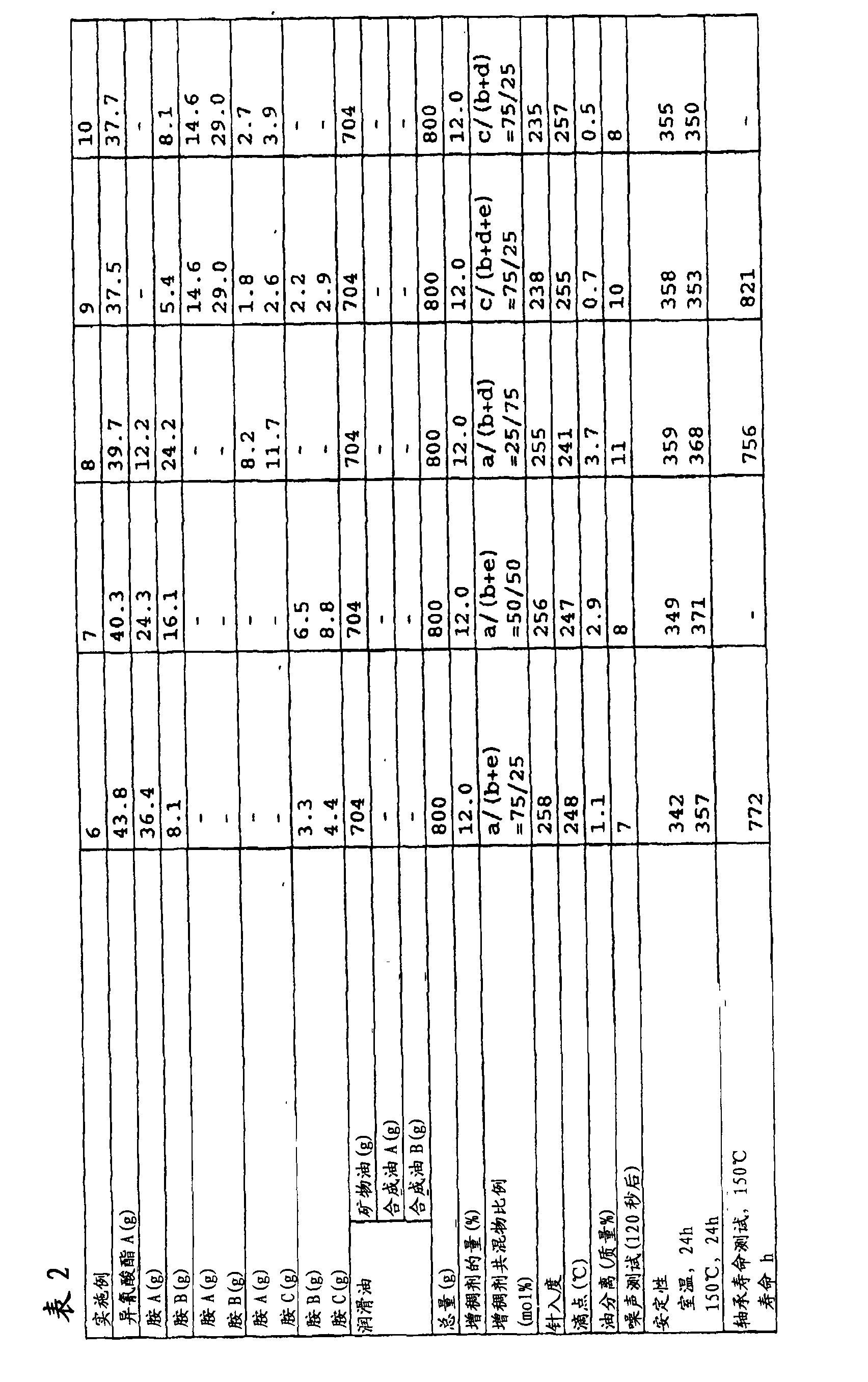

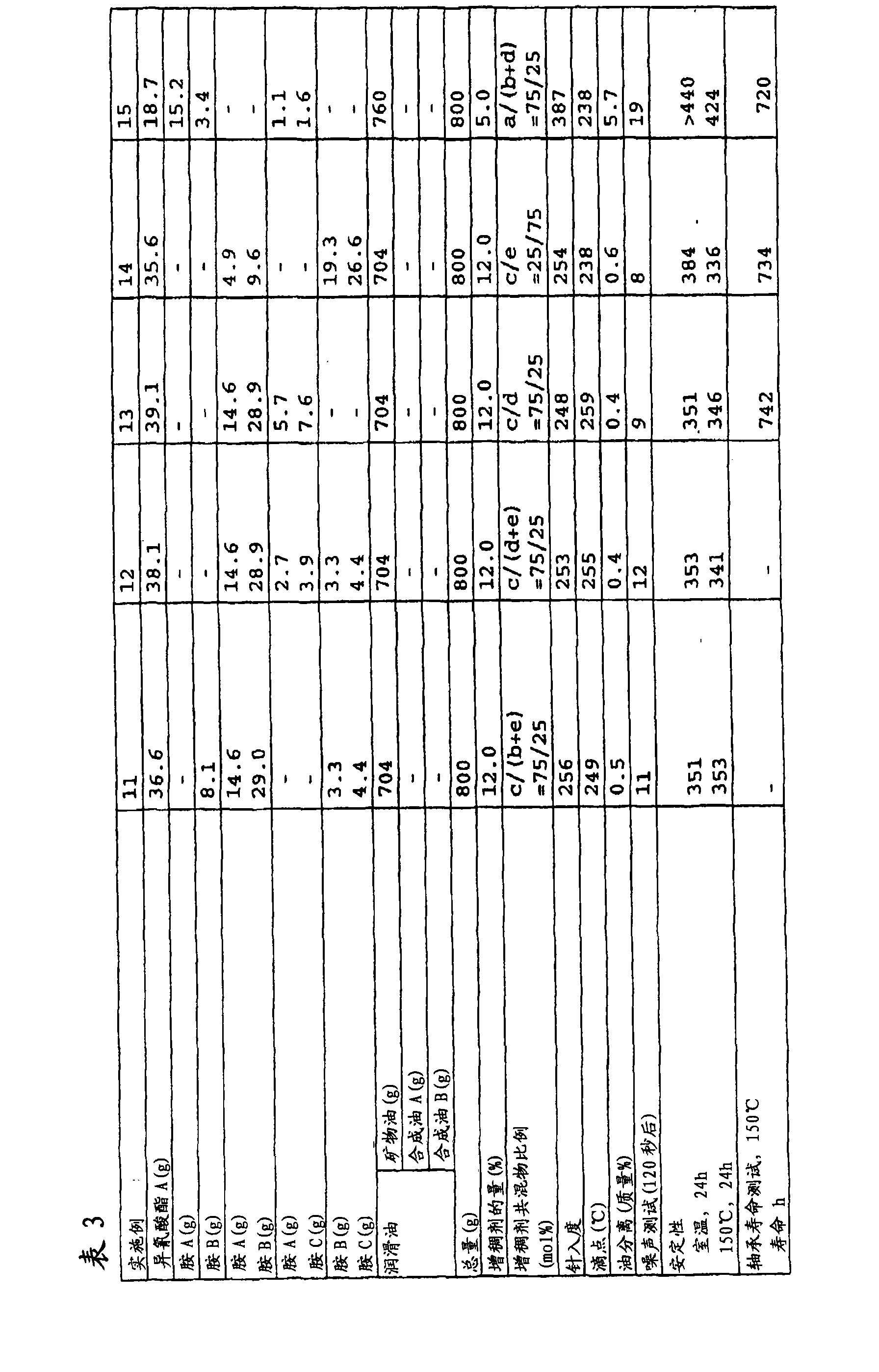

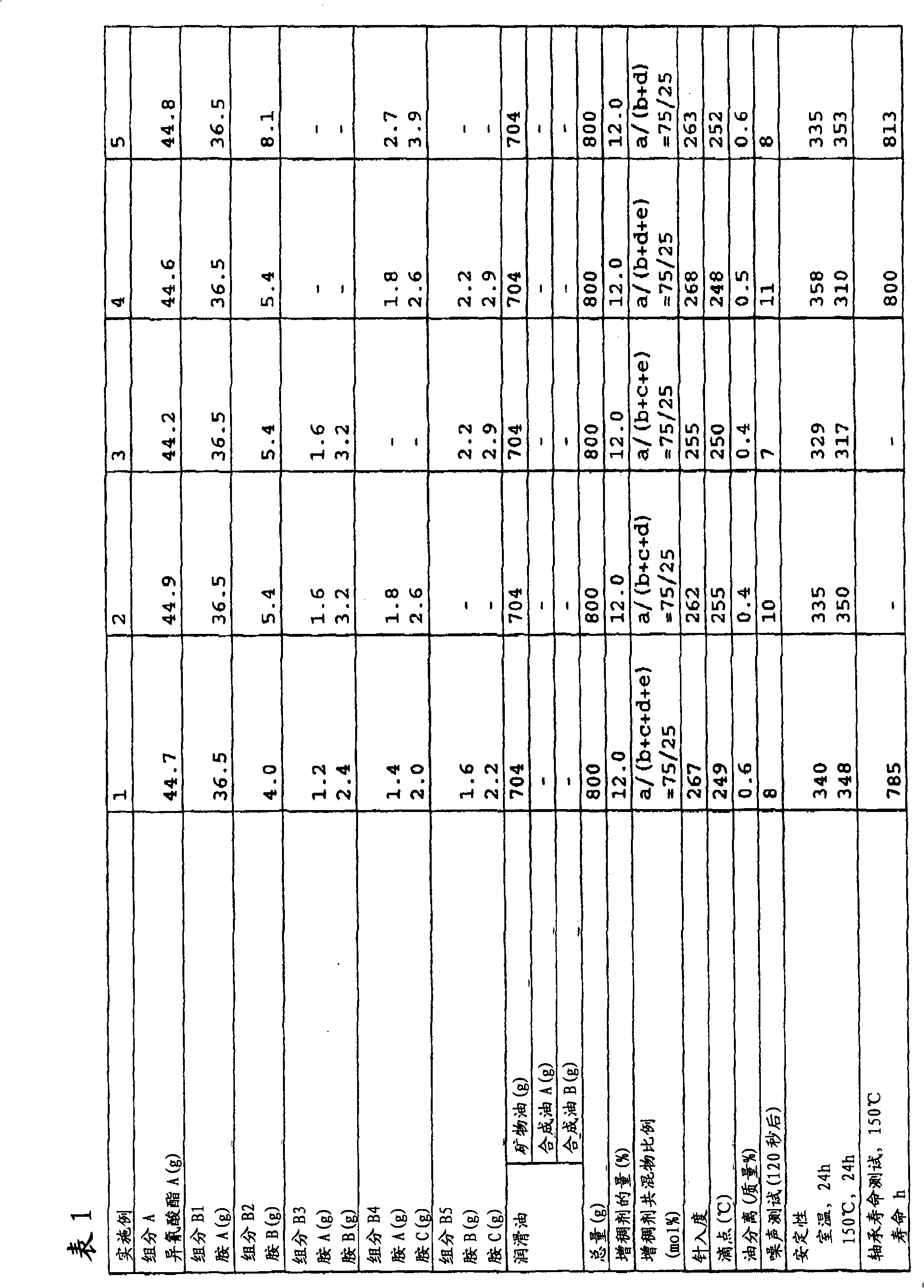

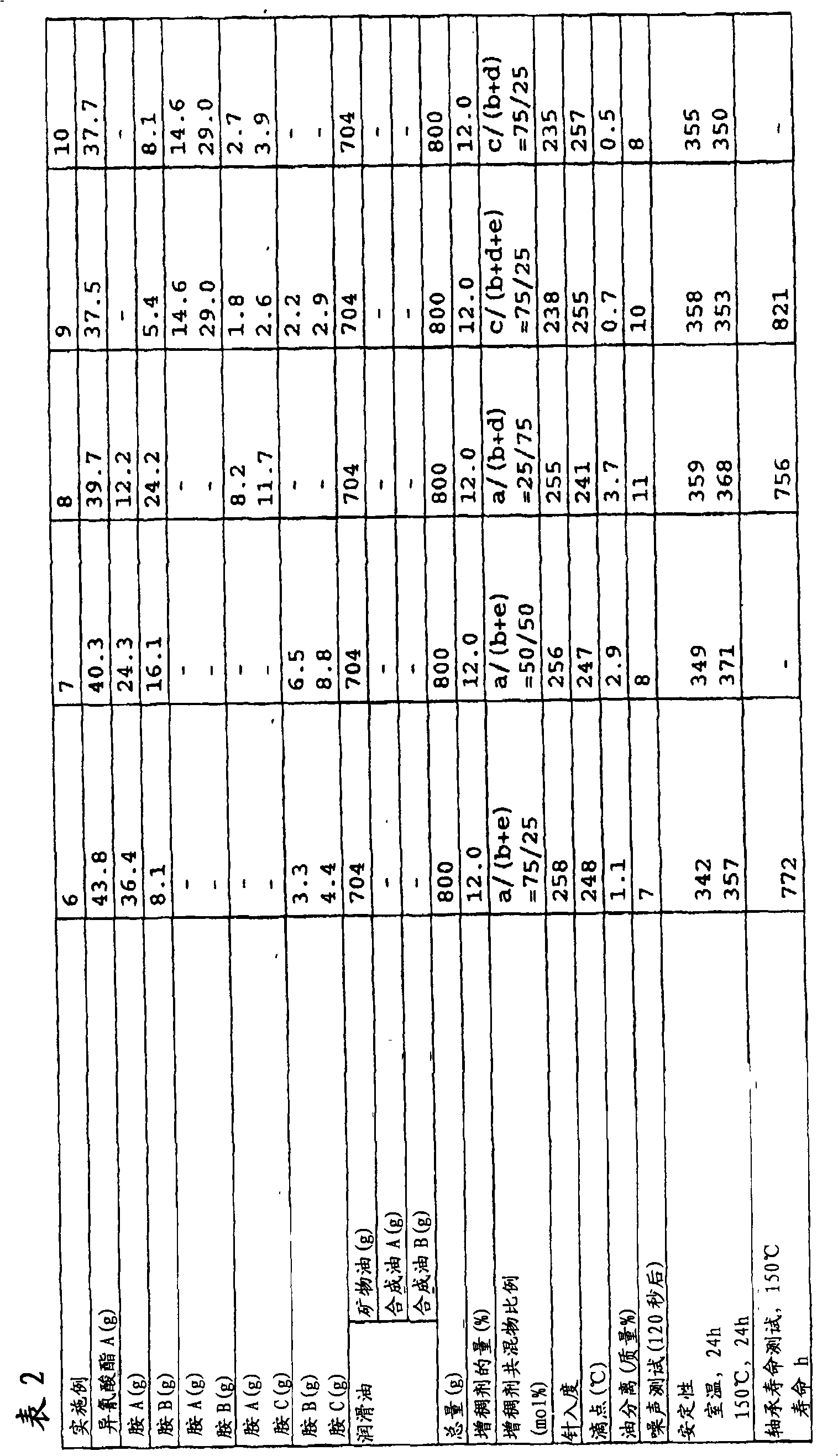

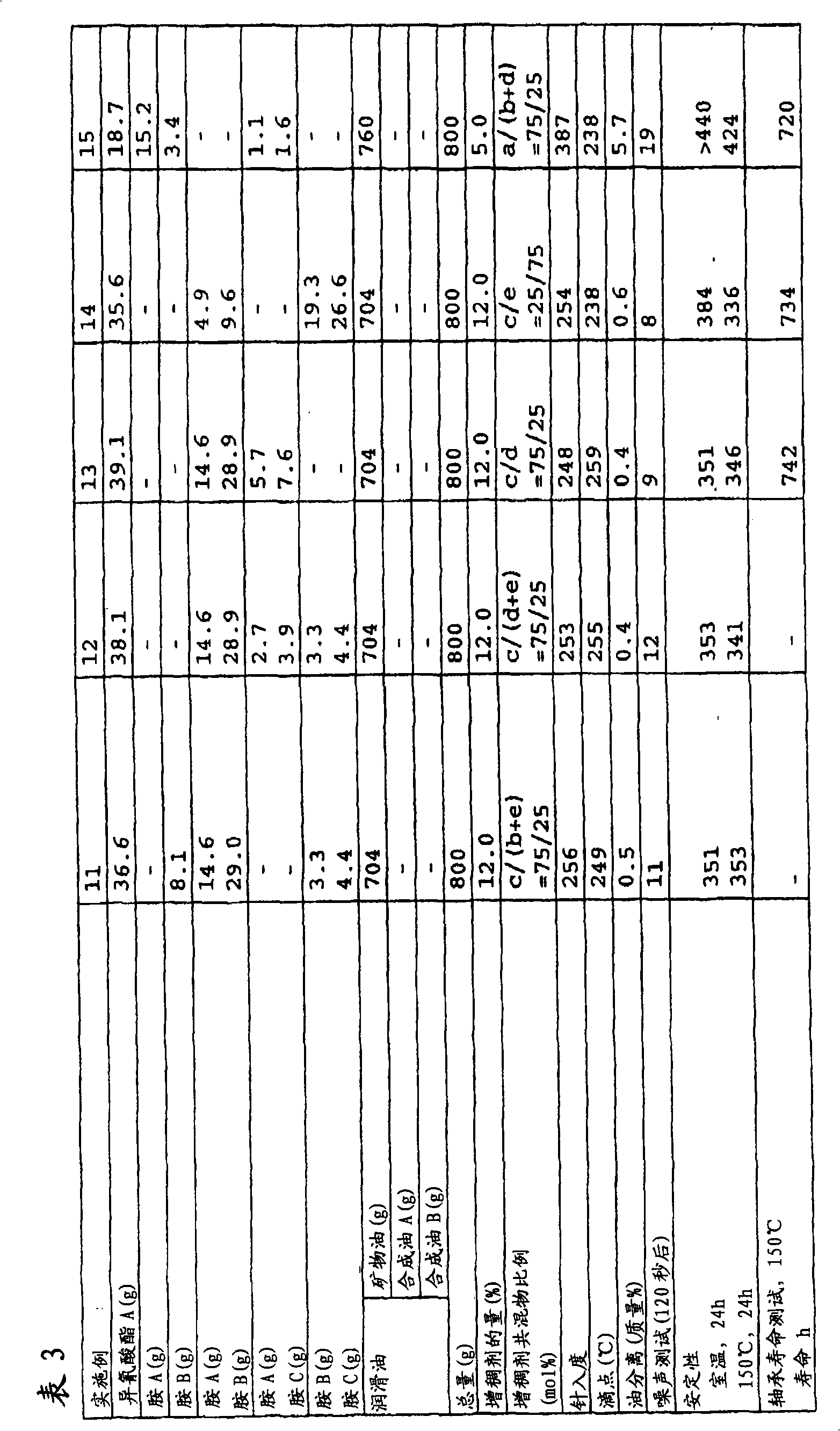

Urea grease composition

ActiveCN101541933AImprove Noise PerformanceImprove high temperature lifeThickenersDiphenylmethaneHeat resistance

The present invention aims to offer a urea grease composition which excels in noise performance, has long life at high temperatures and, further, also provides the basic performance of greases such as shear stability and heat resistance, as well as appropriate oil separation properties. The present invention provides a urea grease composition comprising: a diurea compound as shown by the General Formula (A) below: R<11>NHCONHR<12>NHCONHR<13>.... (A), (where R<11> and R<13> are groups selected from the group consisting of hydrocarbon groups having from 6 to 20 carbons, at least one of R<11> and R<13> is a dodecyl group and R<12> is a diphenylme thane group); and a diurea compound as shown by the General Formula (B) below: R<21>NHCONHR<22>NHCONHR<23>.... (B), (where R<21 > and R<23> are groups selected from the group consisting of hydrocarbon groups having from 6 to 20 carbons, at least one of R<21> and R<23> is an oleyl group, and R<22> is a diphenylmethane group).

Owner:SHELL INT RES MAATSCHAPPIJ BV

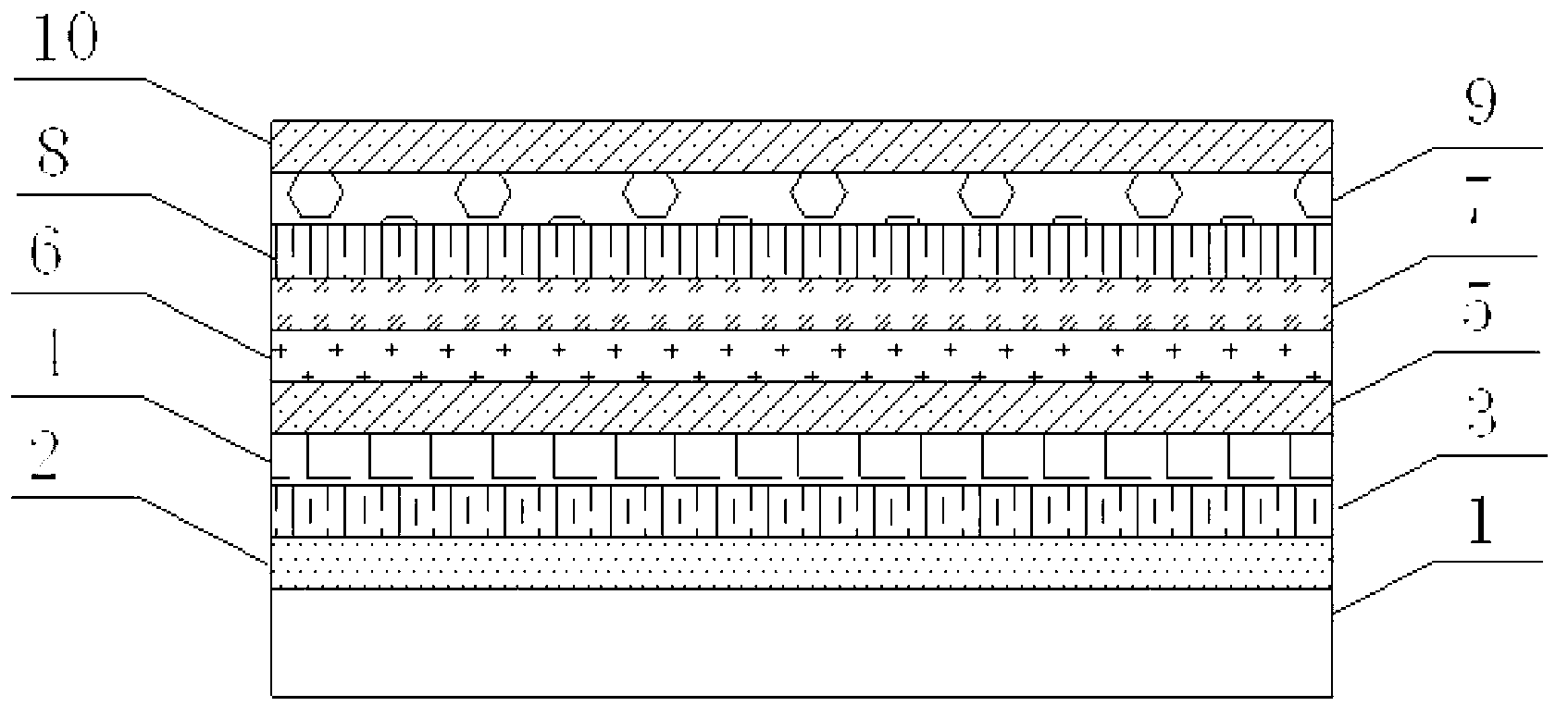

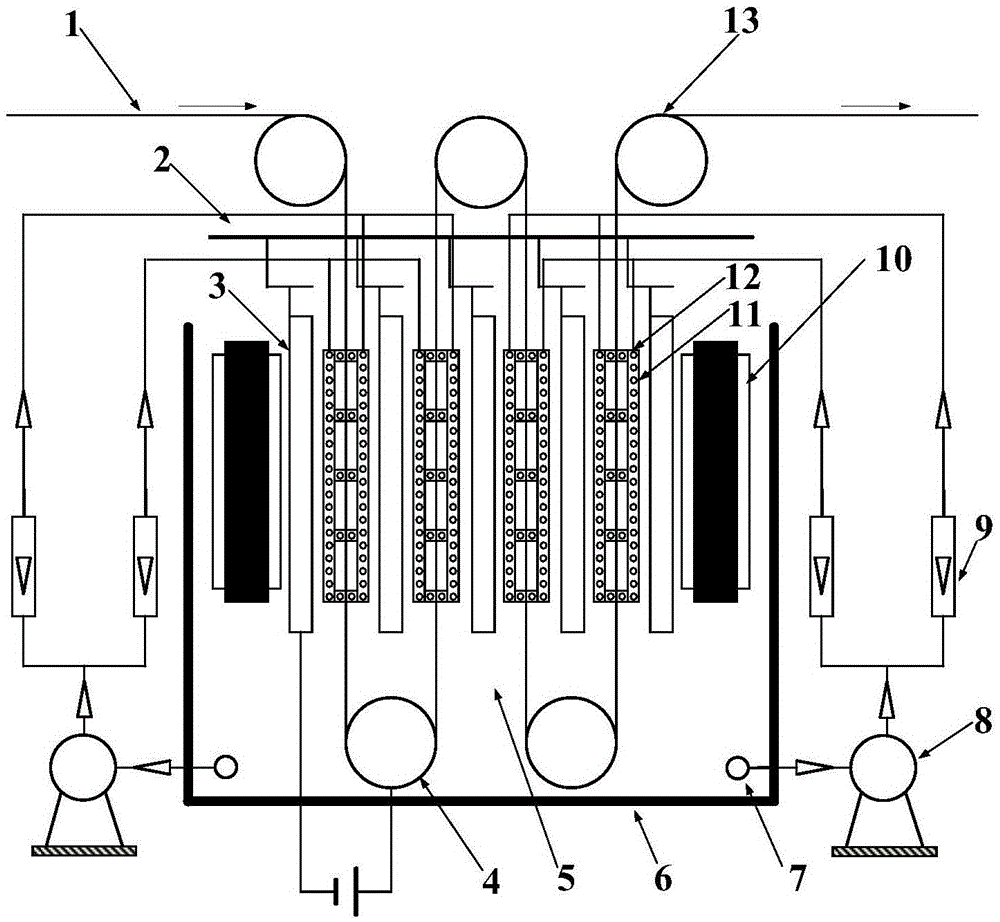

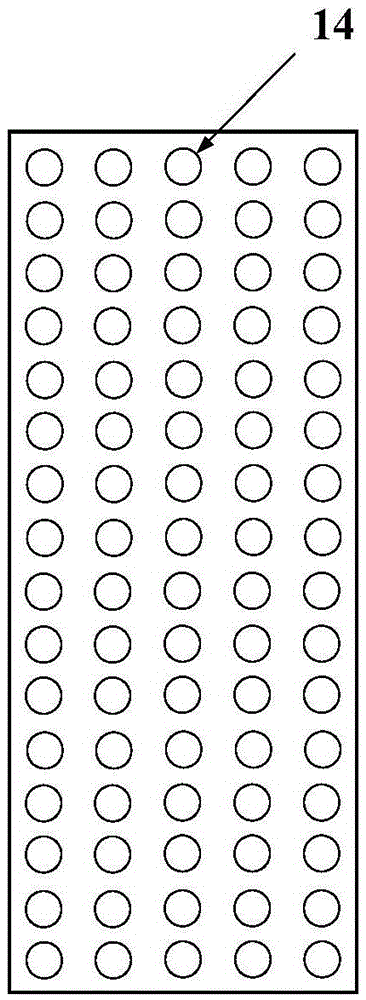

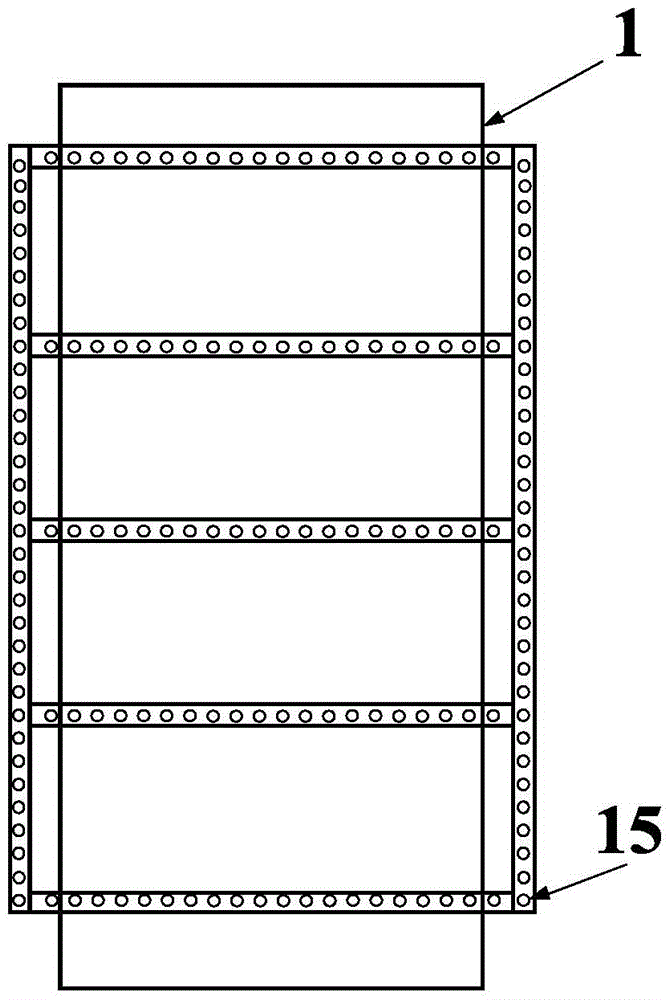

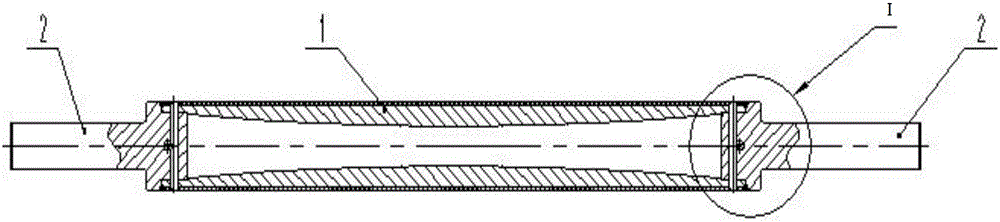

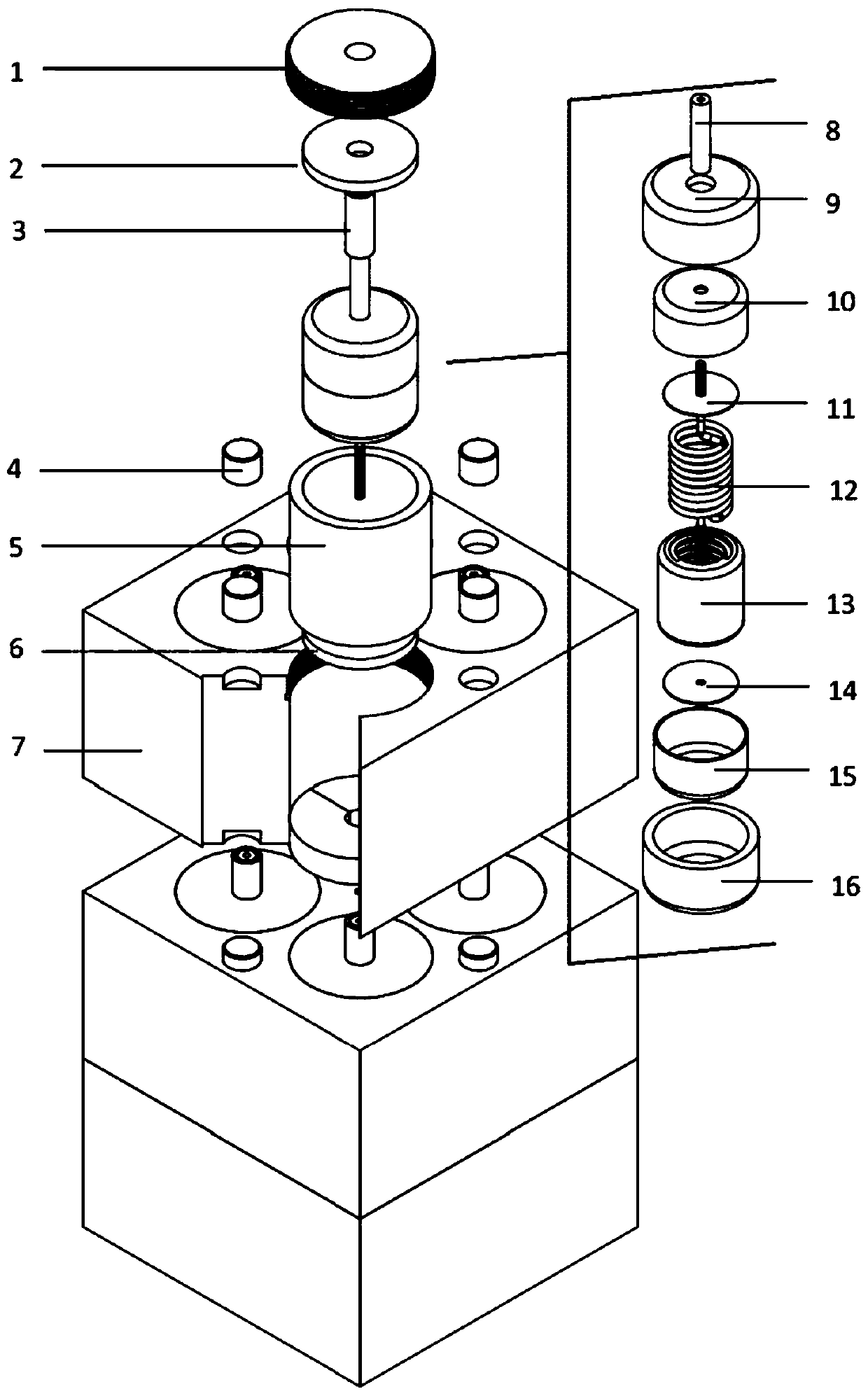

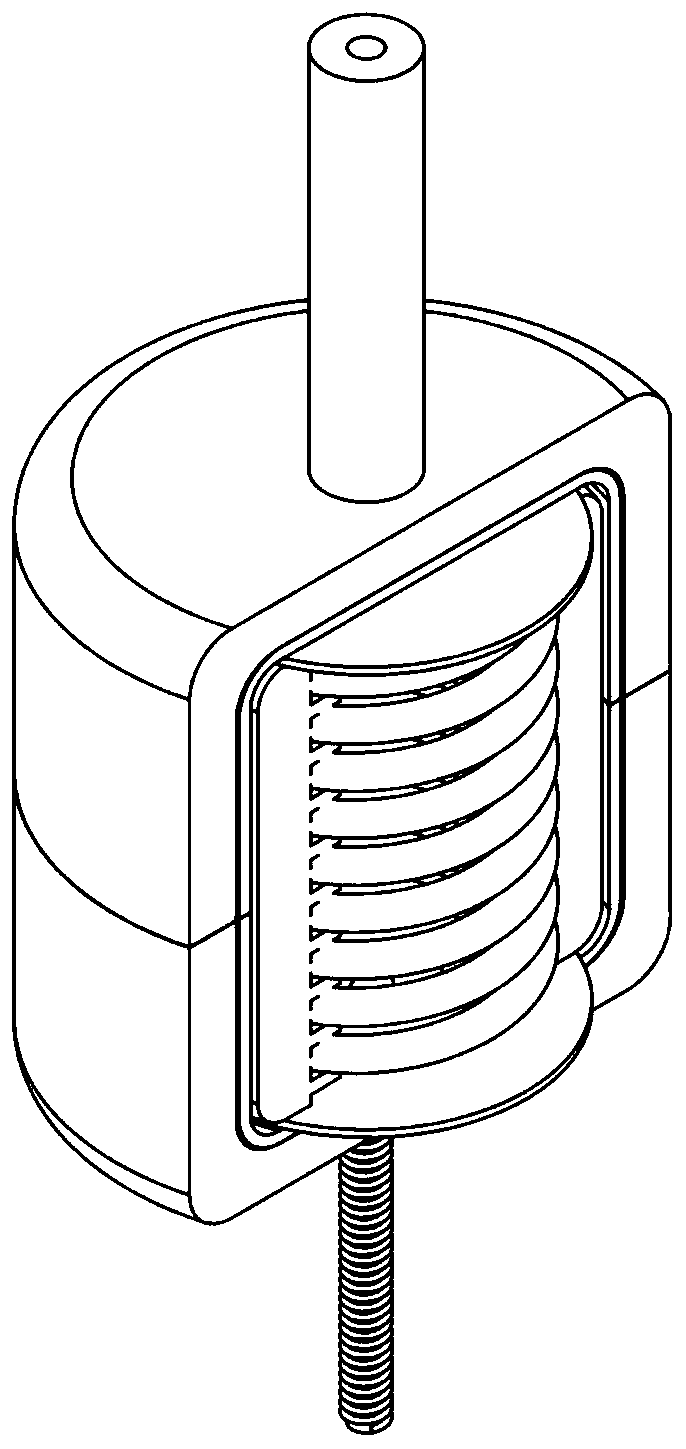

Anode aluminum foil forming device

InactiveCN105648515ATemperature controlControl concentrationCapacitor electrodesOxygen vacancySpecific volume

The invention discloses an anode aluminum foil forming device. The anode aluminum foil forming device comprises multiple electrode plates (3), inner circulation pipe networks (11) and a circulation pump (8) connected with the inner circulation pipe networks, wherein the electrode plates (3) and the inner circulation pipe networks (11) are arranged in a forming tank (6). The anode aluminum foil forming device further comprises direct-current electromagnets (10) arranged in the forming tank (6). The direct-current electromagnets (10) are soaked in forming liquid (5) in the forming tank. Multiple heat uniformization holes are evenly distributed in each electrode plate (3). The anode aluminum foil forming device has the beneficial effects that forming liquid circulating performance is good, electrical conductivity is high, interface tension is large, and the concentration and temperature of the forming liquid are uniform in distribution, so that the number of oxygen vacancies of forming films is small, the thickness of oxide films is uniform, the specific volume is large, bending performance is good, and the high-temperature service life is long.

Owner:YANGZHOU UNIV

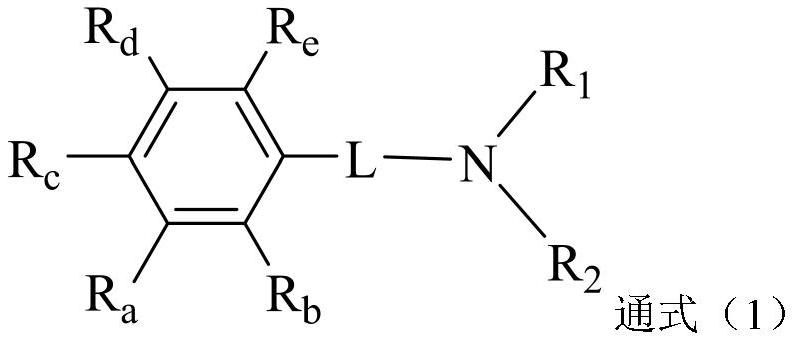

Arylamine compound and application thereof in organic electroluminescent device

PendingCN114478265AExcellent hole migration abilityExtend your lifeOrganic chemistrySolid-state devicesEngineeringOrganic electroluminescence

The invention discloses an arylamine compound and application thereof in an organic electroluminescent device, and belongs to the technical field of semiconductors. The structure of the arylamine compound is shown as a general formula (1), arylamine serves as a basic framework of the compound, pyrene and adamantane are connected to the same phenyl in the arylamine, and due to the connection mode, the compound has the excellent hole migration capacity, membrane phase state stability and weather resistance; when the arylamine compound is used as a hole transport material of an organic electroluminescent device, the effects of improving the efficiency of the device and prolonging the service life of the device can be shown.

Owner:JIANGSU SUNERA TECH CO LTD

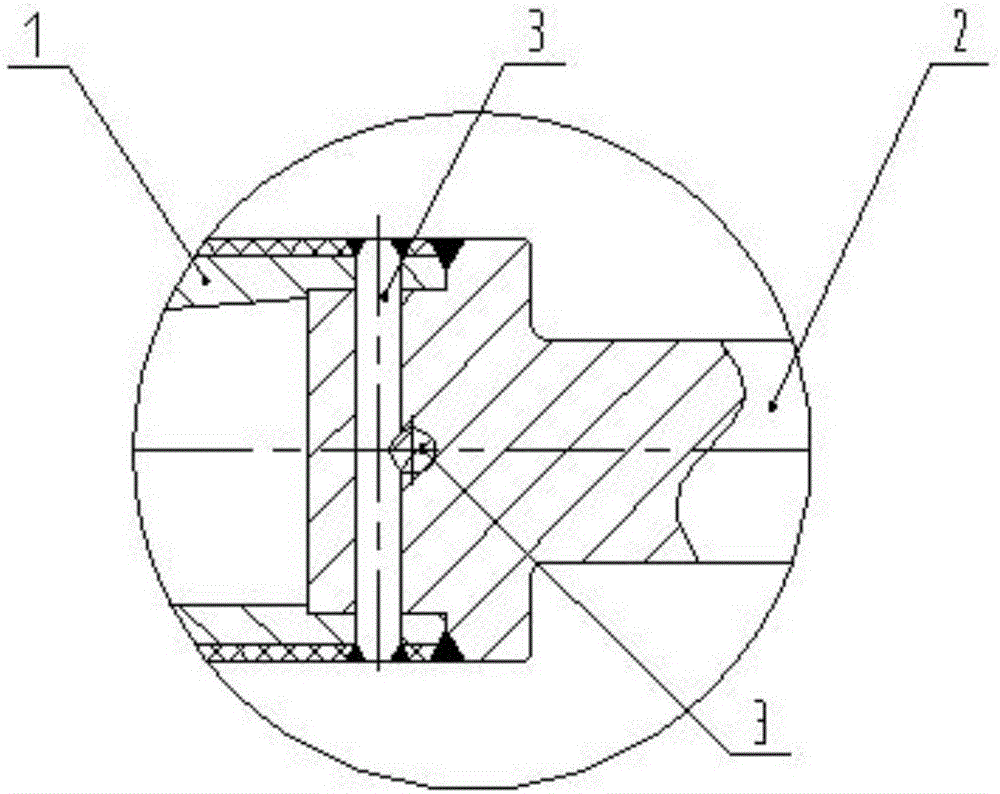

Corrosion-resistant and enhanced furnace bottom roller

InactiveCN106636575AImprove structural rigidityHigh strengthMolten spray coatingFurnace typesThermal expansionPulp and paper industry

The invention discloses a corrosion-resistant and enhanced furnace bottom roller. The roller comprises a roller body and roller shafts connected at two ends of the roller body; the roller shafts are inserted into the ends of the roller body to be matched and fixedly connected; the closer the wall of the roller body between the roller shafts at the two ends is to the axial central line of the roller body, the thicker the wall thickness is; the roller is further improved in that the axial section of the inner wall of the roller body is an arc-shaped curved surface; a metal ceramic coating is arranged on the outer wall of the roller body and comprises a bottom coating sprayed onto the outer wall of the roller body, a working layer sprayed onto the bottom coating and a sealing layer sprayed onto the working layer; two positioning hinge pins which radially penetrate through matched parts of the roller body and the roller shafts are arranged at the matched parts of the roller body and the roller shafts; and one positioning hinge pin partially penetrates through the other positioning hinge pin. The roller is high in structural strength, high-temperature-resistant, corrosion-resistant, low in thermal expansion, good in chemical stability, stable in high-temperature performance, free of deformation, good in wear resistance and high in conveying quality.

Owner:王秋林

Composition, OLED device, OLED display panel and display device

InactiveCN110911574AImprove balanceImprove high temperature lifeSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsElectron transmission

The invention provides a composition, an OLED device, an OLED display panel and a display device. The composition comprises 1%-99% of a partial electron transport type low-mobility metal complex material and 1%-99% of an organic electron transport material, and the electron mobility of the partial electron transport type low-mobility metal complex material is smaller than 1 * E-7cm < 2 > / Vs. According to the invention, the influence of an electric field and temperature on the electron mobility in the electron transport layer can be reduced, the balance of a carrier system in a high-temperatureenvironment is good, and the service life at a high temperature is long.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

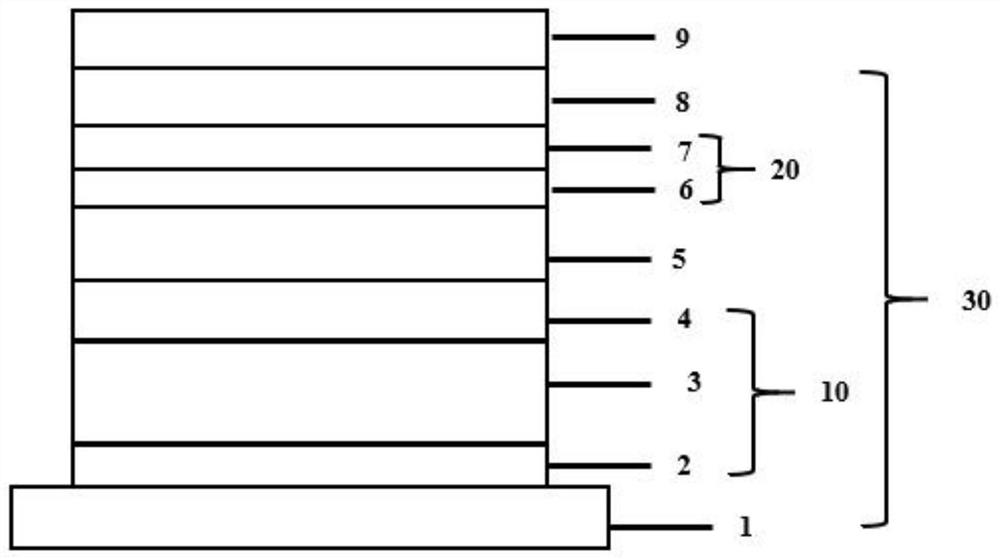

Modular electric heating simulation heat source for ETG

ActiveCN110927775AHeat flow path is the sameUniform surface temperature distributionThermometers using electric/magnetic elementsUsing electrical meansInsulation layerThreaded pipe

The invention relates to a modular electric heating simulation heat source for ETG. The modular electric heating simulation heat source comprises at least two stacked modules. The module comprises a module box and an electric heating unit arranged in the module box. The electric heating unit is wrapped with a heat insulation layer. The electric heating unit comprises a cladding, a coil holding threaded pipe and a resistance wire spiral coil. The coil holding threaded pipe is mounted in the cladding. The resistance wire spiral coil is installed in the coil maintaining threaded pipe, and the coil maintaining threaded pipe is provided with internal threads matched with the resistance wire spiral coil. The beneficial effects of the heat souorce are as follows: the spiral coil simulates the radioactive source for heating, it is guaranteed that the heat flow path of the electric heating unit and the heat flow path of the radioactive source fuel pellet single body are basically the same, surface temperature distribution is basically consistent, overall temperature distribution is also basically consistent, a radioactive source is replaced to test and verify the performance of the generator, early-stage research cost is greatly reduced, and the research progress is accelerated.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

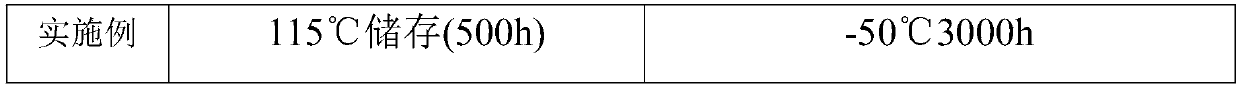

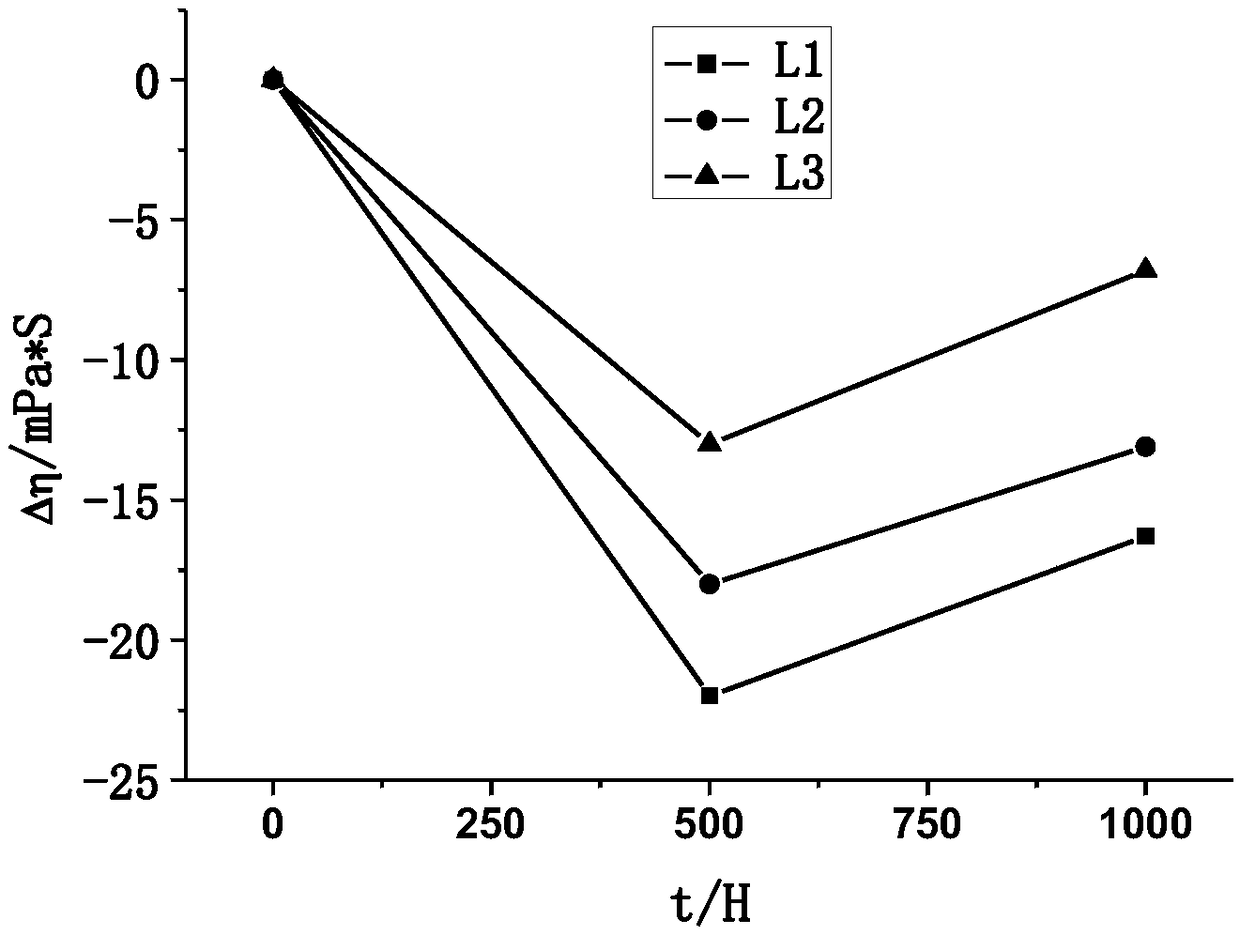

Organic electrolytic solution taking gamma-butyrolactone as basic solvent

InactiveCN109616325AImprove low temperature performanceImprove high temperature lifeElectrolytic capacitorsTetrafluoroborateKetone

The invention discloses an organic electrolytic solution taking gamma-butyrolactone as a basic solvent. The organic electrolytic solution comprises a catenulate quaternaries main electrolyte, a mixedsolvent and a flame retardant additive, wherein the mixed solvent comprises the following components by weight proportion: 30-45 parts of gamma-butyrolactone, 15-25 parts of ethyl trifluoroacetate, 10-15 parts of 1,3-dioxolane-2-ketone, 10-20 parts of ethylene carbonate and 10-20 parts of methyl ethyl carbonate. The organic electrolytic solution replaces the traditional polycarbonate ammonium saltwith tetraethyl ammonium tetrafluoroborate, so that a battery has good low-temperature performance; the change of various electric parameters of the electrolytic solution is obviously small after 500h storage at 115 DEG C high temperature, so that the high-temperature service life of the electrolytic solution is long; and the methyl ethyl carbonate is added, so that the low-temperature conductivity and the low-temperature performance of the electrolytic solution can be improved.

Owner:JIANGSU FALA ELECTRONICS

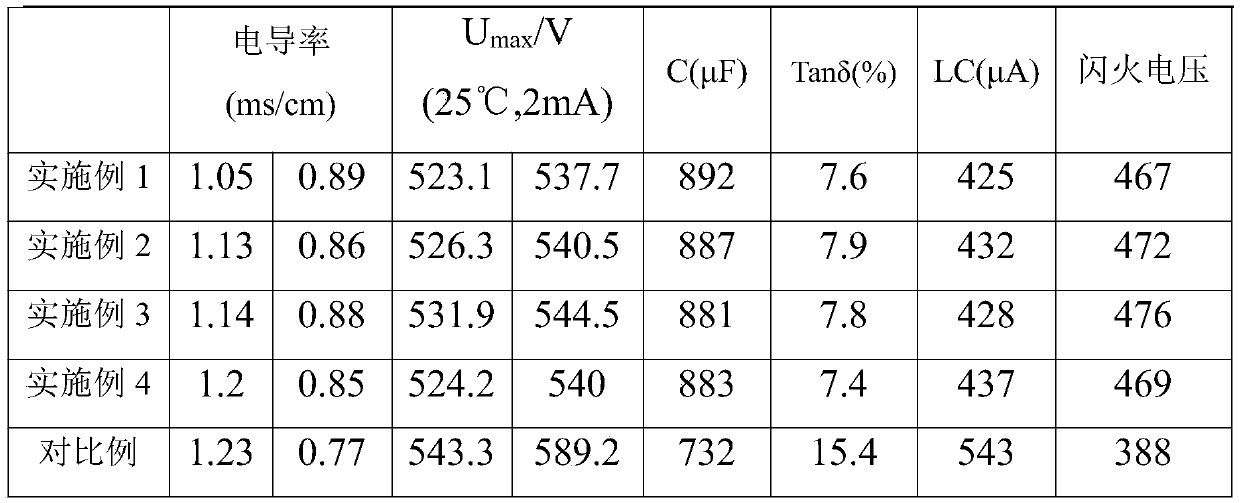

Ni-Al exothermic resistance alloy wire

ActiveCN102337426ASignificant intragranular strengtheningHigh strengthElectrical resistance and conductanceAlloy

Owner:CHONGQING CHUANYI AUTOMATION

Preparation method of silver solder paste and silver solder paste product

ActiveCN101837526BImprove utilization efficiencyWell mixedWelding/cutting media/materialsSoldering mediaPotassium fluorideRetention time

The invention provides a preparation method of silver solder paste, which comprises the following steps: 1, preparing raw materials and pretreating the raw material; 2, stirring the raw materials; 3, roasting the raw materials; and 4 grinding the raw materials. The invention also provides silver solder paste prepared by the method. The silver solder paste is prepared from the following raw materials in percentage by weight: boric acid 33-38, potassium fluoborate 28-32, potassium fluoride 20-25, monomer boron 2.0-2.5 and distilled water 10-20. Compared with the prior art, the method has the advantages of stable product quality and high material utilization rate. The product has the characteristics of long soldering high-temperature life, long activity retention time, high solder wettability and high soldered joint quality.

Owner:HUIZHOU WUFU IND TECH

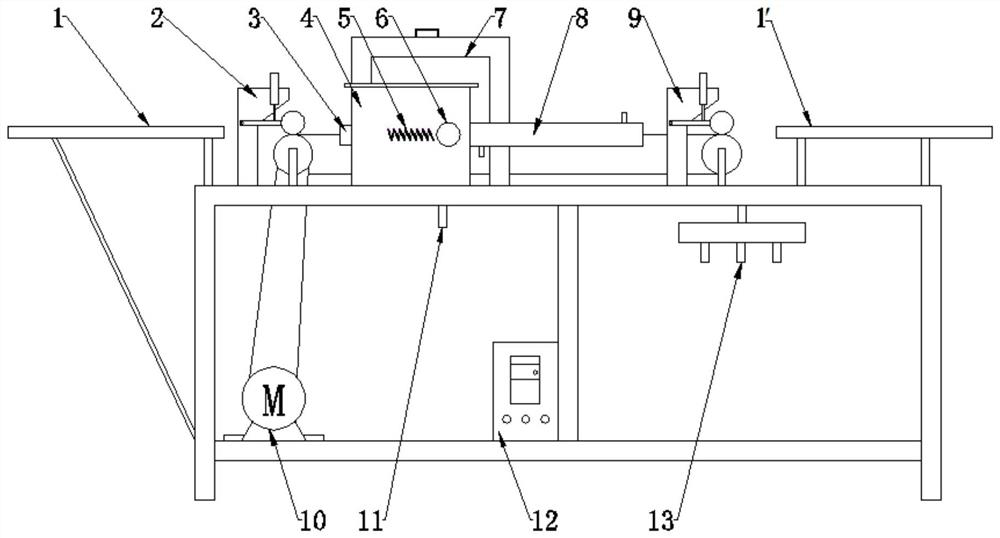

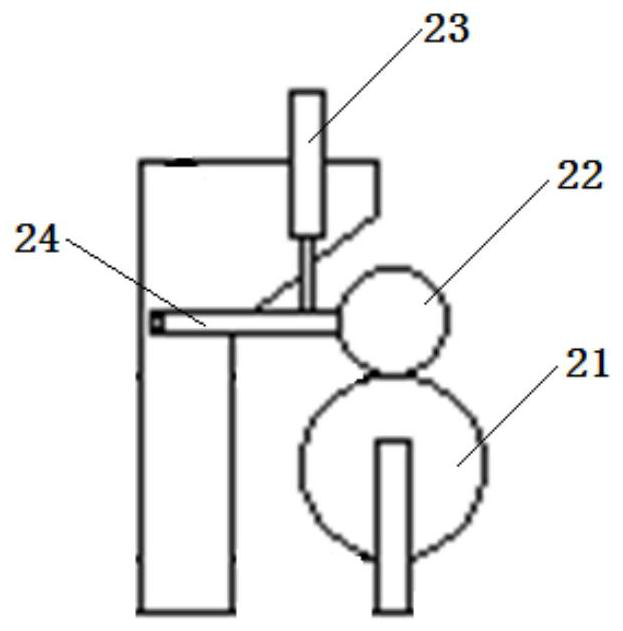

Large-diameter tungsten bar annealing device and annealing process

InactiveCN111793737AInternal stress reliefEasy to processFurnace typesHeat treatment furnacesInternal stressManufacturing engineering

The invention relates to the technical field of metal heat treatment, and discloses a large-diameter tungsten bar annealing device and annealing process. The annealing device comprises a first trough,a feeding device, a hydrogen protection box, an induction coil, an IGBT high-frequency induction power supply, a discharging device, a second trough, a motor, an electric control cabinet and a cooling system. The large-diameter tungsten bar annealing device and annealing process provided by the invention can achieve the effects that the internal stress of the large-diameter tungsten bar can be effectively eliminated; the phenomena of splitting, edge breakage, surface micro-cracks and the like which possibly occur in subsequent processing are avoided, the processability of the tungsten bar isimproved, the service life of consumables such as machining tools is prolonged, the service performance of the tungsten bar is improved, and the high-temperature service life of the tungsten bar is prolonged, have the advantages of being high in speed, high in quality, low in cost and convenient to maintain, can guarantee smooth implementation of industrial production, and achieve the reduction ofproduction cost and improvement of the production quality.

Owner:威海多晶钨钼科技有限公司

Lubricating grease and preparation method thereof

InactiveCN103937582AReduce frictionImprove high temperature performanceLubricant compositionManufacturing technologyLithium hydroxide

The invention relates to lubricating grease and a preparation method thereof and discloses a manufacturing technology of the lubricating grease. The lubricating grease is prepared from the following raw materials: lithium-series base oil A1, HVI650 dewaxed low condensate, calcium hydroxide, lithium hydroxide, stearic acid, tricresyl phosphate (TCP), dodecahydroxyl stearic acid, Span-80, anti-oxidation preservative T202, an anti-rust agent T706 and an extreme pressure anti-wear agent (T321). The lubricating grease provided by the invention has a wide range of applications, including roller bearings for hot rolling in metallurgical industry, ladle turrets of continuous casting equipment, crystallizers, conveyor roller lubrication and the like.

Owner:青州市东能润滑油脂有限公司

Anti-agglomeration high-temperature resistant coating of furnace bottom roller

ActiveCN102650028BImprove high temperature lifeImprove high temperature performanceMolten spray coatingTemperature resistanceHot Temperature

Owner:BAOSHAN IRON & STEEL CO LTD +1

Urea grease composition

ActiveCN101541933BImprove Noise PerformanceImprove high temperature lifeThickenersDiphenylmethaneHeat resistance

The present invention aims to offer a urea grease composition which excels in noise performance, has long life at high temperatures and, further, also provides the basic performance of greases such as shear stability and heat resistance, as well as appropriate oil separation properties. The present invention provides a urea grease composition comprising: a diurea compound as shown by the General Formula (A) below: R11 NHCONHR12NHCONHR13 . . . (A), (where R11 and R13 are groups selected from the group consisting of hydrocarbon groups having from 6 to 20 carbons, at least one of R11 and R13 is a dodecyl group and R12 is a diphenylme thane group); and a diurea compound as shown by the General Formula (B) below: R21 NHCONHR22NHCONHR23 . . . (B), (where R21 and R23 are groups selected from the group consisting of hydrocarbon groups having from 6 to 20 carbons, at least one of R21 and R23 is an oleyl group, and R22 is a diphenylmethane group).

Owner:SHELL INT RES MAATSCHAPPIJ BV

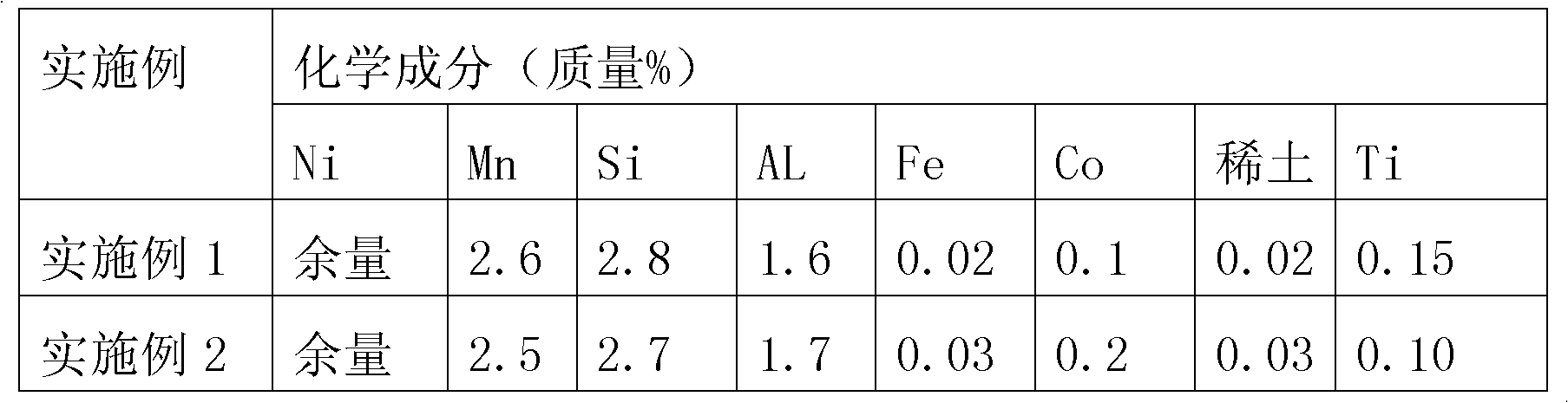

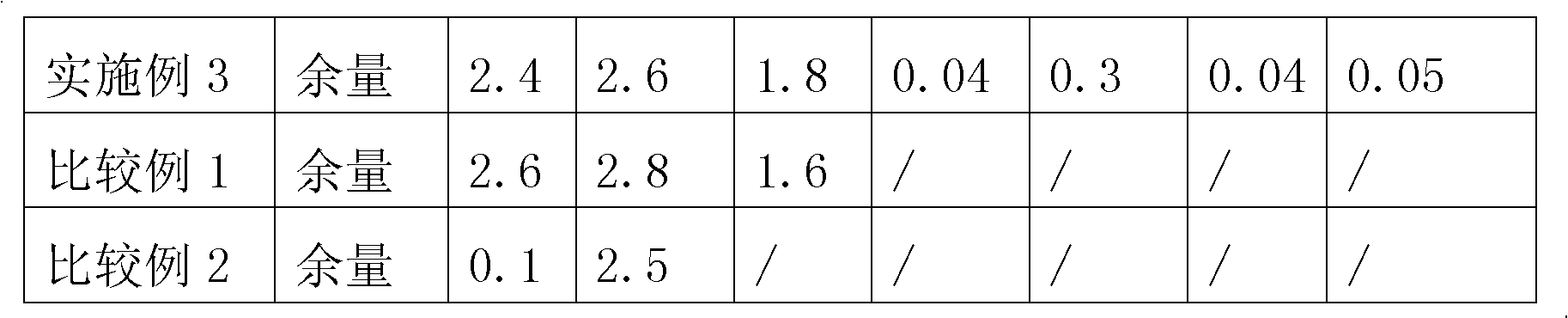

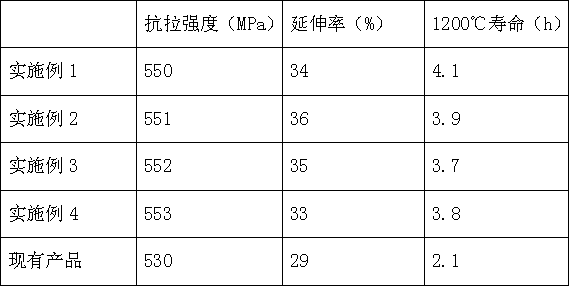

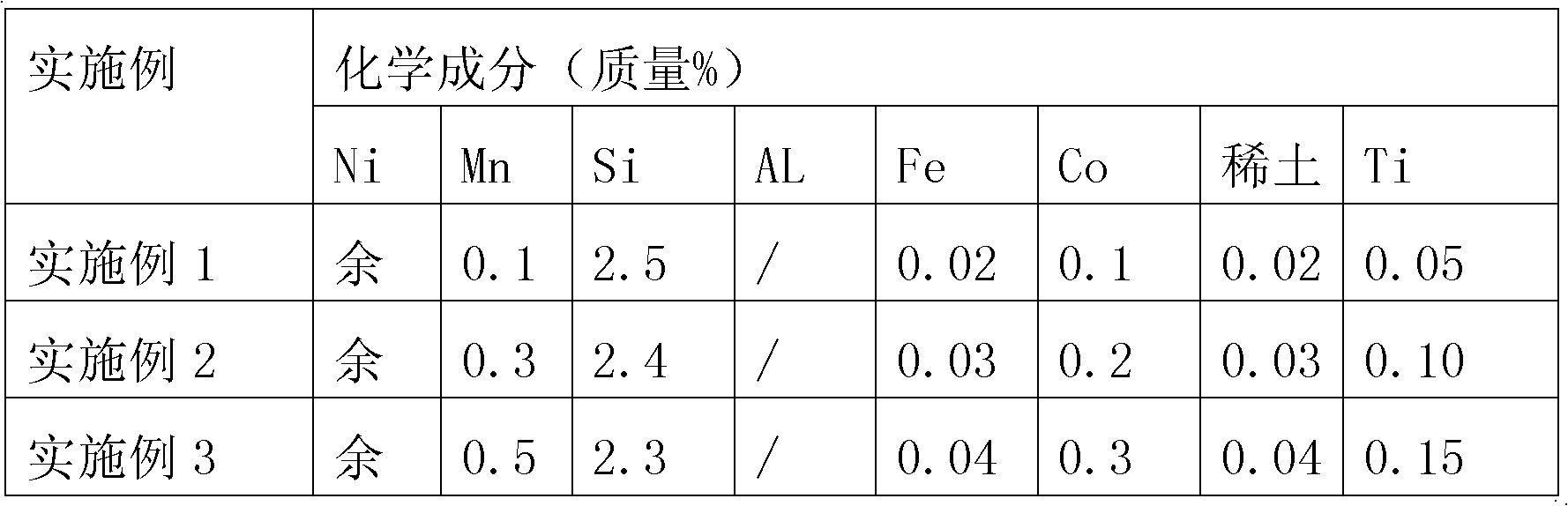

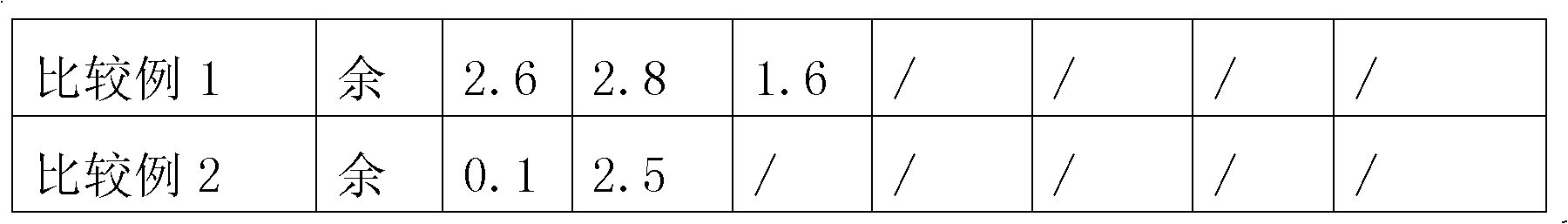

Ni-Al exothermic resistance alloy material

The invention discloses a Ni-Al exothermic resistance alloy material. The main components of the Ni-Al exothermic resistance alloy material are composed of Ni, Si, Mn, Al and Ti and separately added with one or more of microelements Fe, Co and rare earth. The high-temperature life of the resistance alloy manufactured from the Ni-Al exothermic resistance alloy material is obviously improved when the resistivity is guaranteed.

Owner:CHONGQING CHUANYI AUTOMATION

Resistance alloy wire

InactiveCN108504902AGuaranteed resistivityImprove high temperature lifeMetal/alloy conductorsElectrical resistance and conductanceMisch metal

The invention discloses a resistance alloy wire. The resistance alloy wire consists of nickel, silicon, manganese, yttrium, copper, misch metal and iron. Through the mode, as for the provided resistance alloy wire, the high temperature life is prolonged obviously under the situation that the electrical resistivity is ensured.

Owner:苏州天鸿电子有限公司

Resistance material capable of preventing overheat generation caused by excessive current

ActiveCN102352453BSignificant intragranular strengtheningHigh strengthElectrical resistance and conductanceRare earth

The invention discloses a resistance material capable of preventing overheat generation caused by excessive current. The main composition of the resistance material is as follows: one or more of microelements, such as Al, Fe, Co and rare earth are added on the basis of NiSiMnTi. The high-temperature life of the prepared resistance alloy can be increased obviously on the condition of ensuring the resistivity.

Owner:CHONGQING CHUANYI AUTOMATION

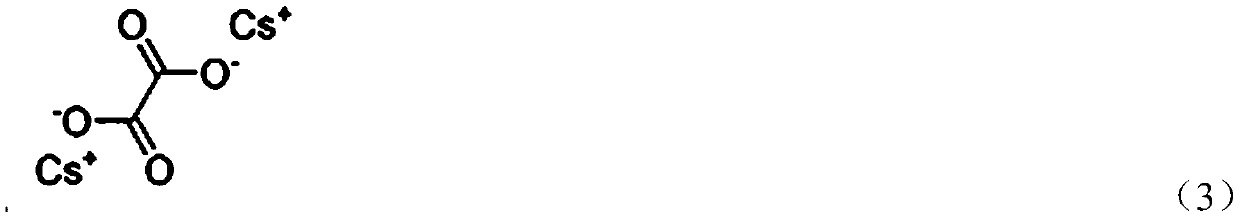

A kind of electrolytic solution for aluminum electrolytic capacitor

ActiveCN107256799BImprove low temperature performanceLittle change in parametersLiquid electrolytic capacitorsSolventAluminum electrolytic capacitor

The invention discloses an electrolyte used for an aluminium electrolytic capacitor. The electrolyte comprises solvent, main solute, auxiliary solute, and optimization additive. The main solute is a compound expressed by a formula (1), and the electrolyte mainly composed by the main solute expressed by the formula (1) is advantageous in that the high temperature performance of the working electrolyte is improved, and a produced capacitor product has longer high temperature-resistant service lifetime. (img file=DDA0001341960870000011. TIF wi=1110 he=247).

Owner:DONGGUAN HEC CONDENSER CO LTD +1

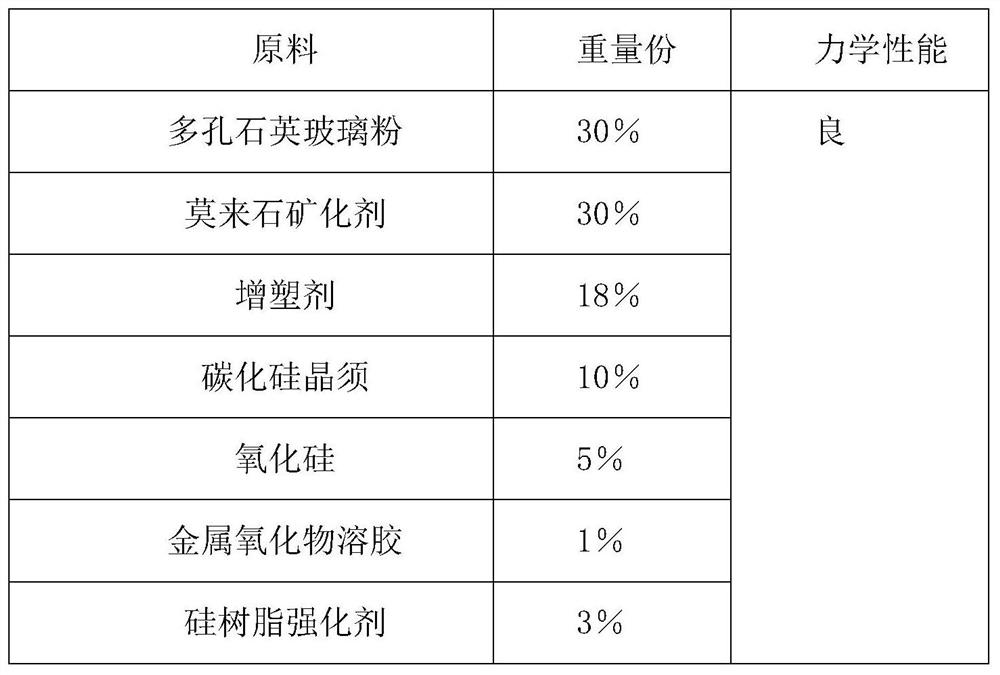

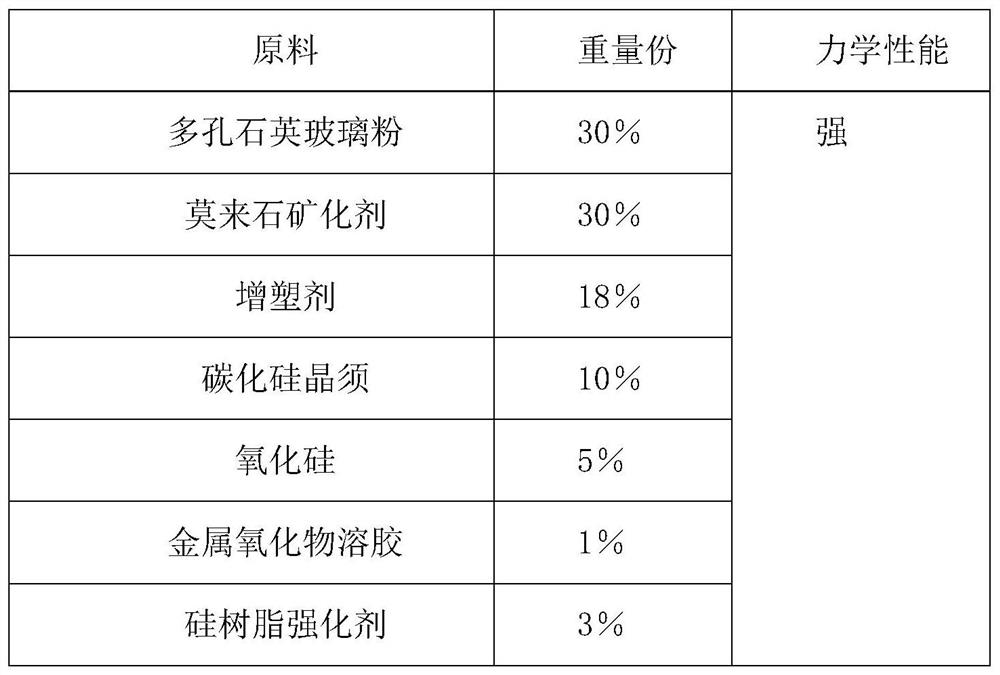

Reinforcing method for silicon-based ceramic core with excellent mechanical property

PendingCN114656247AImprove room temperature strengthEnhance high temperature bending resistanceCarbide siliconSilicone resin

The invention belongs to the technical field of silicon-based ceramic core preparation, and particularly relates to a silicon-based ceramic core with excellent mechanical properties. The silicon carbide ceramic is prepared from the following raw materials in parts by weight: 30-50% of porous quartz glass powder, 10-15% of a mullite mineralizer, 18-22% of a plasticizer, 10-15% of silicon carbide whiskers, 5-10% of silicon oxide, 1-5% of metal oxide sol, 3-5% of a silicon resin enhancer and the balance of silicon carbide powder. According to the invention, a layer of metal oxide sol is pre-sprayed on the surface of the silicon-based ceramic core, the silicon resin reinforcer is permeated into the silicon-based ceramic core under a vacuum condition, and the reinforced ceramic core has excellent physical properties through silicon carbide oxidation compounding and connection support of the porous quartz glass powder as a core skeleton; the high temperature resistance, the impact resistance, the high temperature resistance, the service life and the like of the product can be improved, and the excellent ceramic core with a compact internal structure and a high-strength and high-stability carbide and nitride outer layer for toughening and reinforcing can be obtained.

Owner:兴化市兴东铸钢有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com