Organic electrolytic solution taking gamma-butyrolactone as basic solvent

An organic electrolyte and basic solvent technology, applied in the field of electrolytes, can solve the problems of reduced capacitor capacity, insufficient supply, and lack of discharge performance, and achieves small changes in electrical parameters, good low temperature performance, and improved low temperature conductivity and low temperature. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

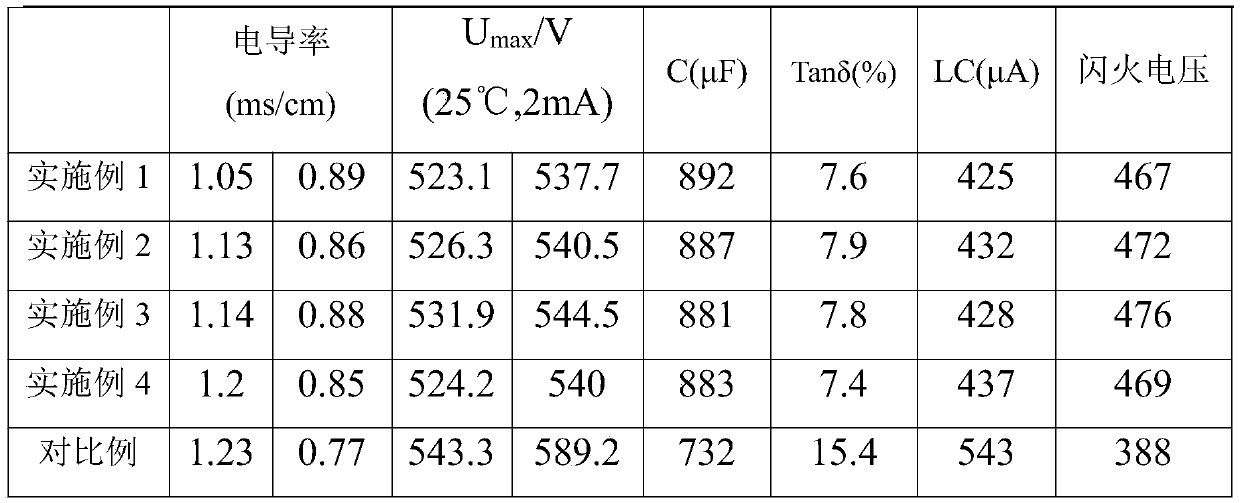

Examples

Embodiment 1

[0012] The organic electrolyte provided in this example is composed of tetraethylammonium tetrafluoroborate, a mixed solvent and a flame retardant additive. The concentration of tetraethylammonium tetrafluoroborate is 0.8M, and the mixed solvent consists of the following weight ratio: Composition of components: 40 parts of γ-butyrolactone, 21 parts of ethyl trifluoroacetate, 11 parts of 1,3-dioxolane-2-one, 14 parts of ethylene carbonate and 14 parts of ethyl methyl carbonate; The flame retardant additive occupies 2% of the total weight of the organic electrolyte, wherein the flame retardant additive is a mixture of trimethyl phosphate and tri-(2,2,2-trifluoroethyl) phosphate.

Embodiment 2

[0014] The organic electrolyte provided in this example is composed of tetraethylammonium tetrafluoroborate, a mixed solvent and a flame retardant additive. The concentration of tetraethylammonium tetrafluoroborate is 1M, and the mixed solvent consists of the following weight ratio: Composition: 33 parts of γ-butyrolactone, 22 parts of ethyl trifluoroacetate, 14 parts of 1,3-dioxolane-2-one, 16 parts of ethylene carbonate and 15 parts of ethyl methyl carbonate; The flame retardant additive accounts for 2.5% of the total weight of the organic electrolyte, and the flame retardant additive is triphenyl phosphate and hexamethylphosphazene.

Embodiment 3

[0016] The organic electrolyte solution provided in this example is composed of quaternary ammonium salt triethylmethylammonium tetrafluoroborate, a mixed solvent and a flame retardant additive. The concentration of the quaternary ammonium salt triethylmethylammonium tetrafluoroborate is 1.2M. The mixed solvent is composed of the following components by weight: 42 parts of γ-butyrolactone, 17 parts of ethyl trifluoroacetate, 13 parts of 1,3-dioxolane-2-one, 13 parts of ethylene carbonate and 15 parts of ethyl methyl carbonate; Described flame retardant additive occupies 1.5% of organic electrolyte gross weight, and flame retardant additive is hexamethylphosphazene and three one (2,2,2-trifluoroethyl) phosphoric acid ester mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com