Ni-Al exothermic resistance alloy wire

A technology of heating resistors and alloy wires, applied in the field of resistance materials, can solve the problems of not being able to meet the minimum service life, and can not meet the requirements, and achieve the effects of improving strength, improving high-temperature life, and improving high-temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

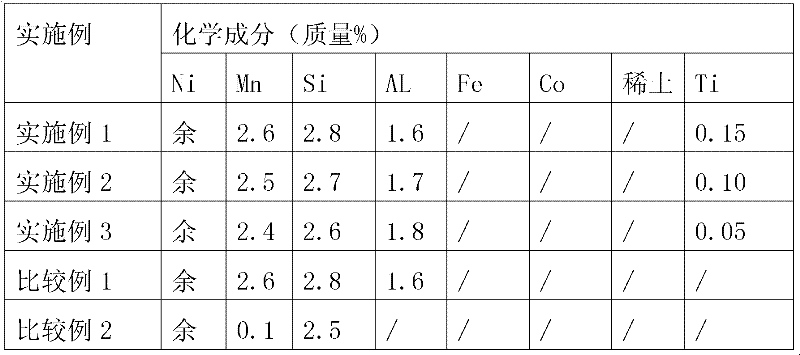

[0010] The proportioning ratio of the heating resistance alloy wire component mass percentage of the present invention is shown in Table 1, and the material according to the proportioning in Table 1 is smelted in a vacuum induction furnace, and argon is used for protection (also can use intermediate frequency, electroslag smelting), through hot forging---hot rolling---drawing---annealing, the nickel-aluminum heating resistance alloy wire of the present invention is obtained. The specific preparation method of the heating resistance material wire is as follows:

[0011] 1) Vacuum induction smelting or intermediate frequency + electroslag remelting is used to smelt the above-mentioned alloys. The addition of various elements can be added in pure metals or in the form of intermediate alloys.

[0012] 2) Drawing the above alloy through hot forging, hot rolling, and heat treatment, and then repeating heat treatment and drawing to the wire material of the required specification.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com