Reinforcing method for silicon-based ceramic core with excellent mechanical property

A ceramic core and silicon-based technology, applied in the field of silicon-based ceramic core preparation, can solve problems such as poor high temperature performance, fracture, deformation, etc., and achieve the effects of enhancing high temperature bending resistance, enhancing room temperature strength, and excellent physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

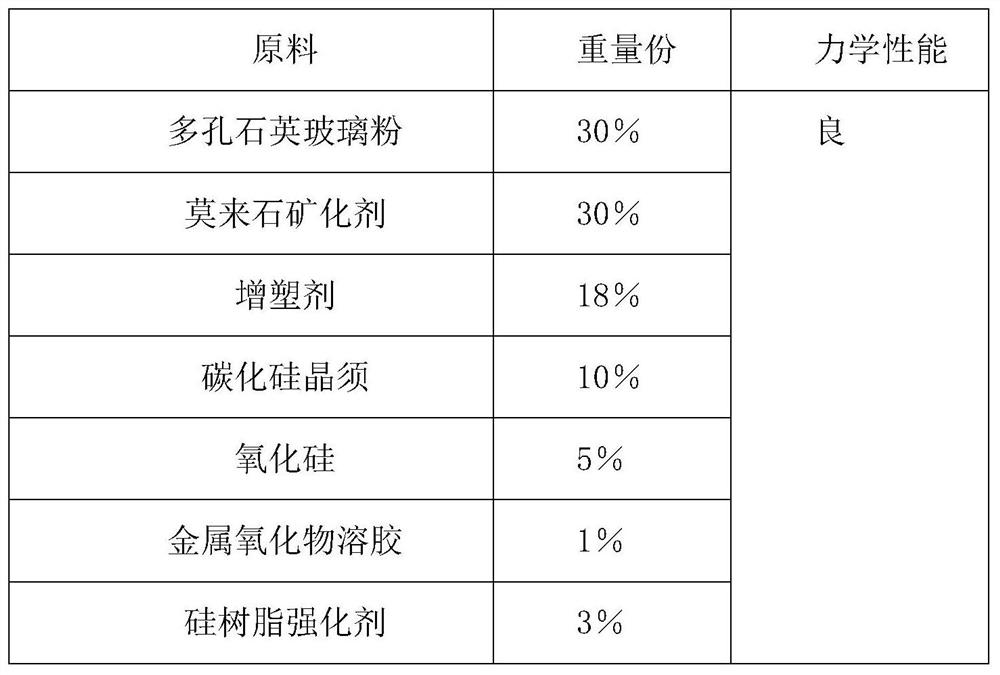

Embodiment 1

[0031] see Figure 1-3 , the present invention provides the following technical solutions: a silicon-based ceramic core with excellent mechanical properties, which is made up of the following raw materials in parts by weight: 30% of porous quartz glass powder, 30% of mullite mineralizer, plasticizer 30%, silicon carbide whisker 10%, silicon oxide 5%, metal oxide sol 1%, silicone resin strengthening agent 3%, and the balance is silicon carbide powder.

[0032] Specifically, the strengthening agent is methyl phenyl silicone resin, and its solid content is 45%.

[0033] Specifically, the plasticizer is a mixture of 11% beeswax, 3% polyethylene, and the balance paraffin.

[0034] Specifically, the particle size of the quartz glass powder is between 190 meshes.

[0035] Specifically, the particle size of the mullite mineralizer is 280 mesh.

[0036] A method for reinforcing a silicon-based ceramic core with excellent mechanical properties, comprising the following steps:

[003...

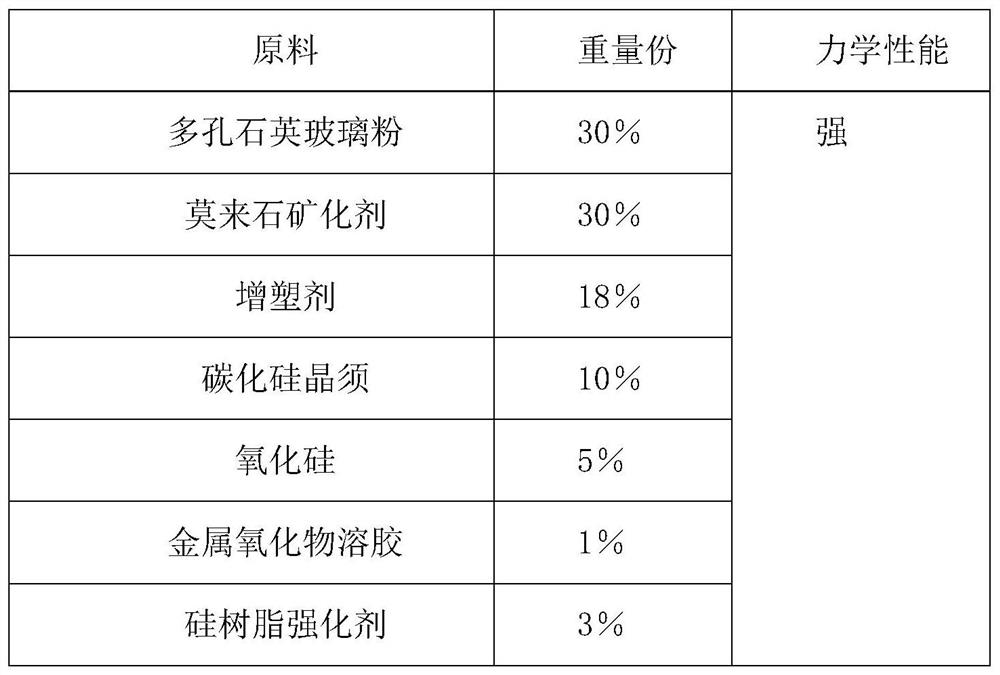

Embodiment 2

[0047] see Figure 1-3 , the present invention provides the following technical solutions: a silicon-based ceramic core with excellent mechanical properties, which is made up of the following raw materials in parts by weight: 40% of porous quartz glass powder, 12% of mullite mineralizer, plasticizer 20%, silicon carbide whisker 13%, silicon oxide 8%, metal oxide sol 3%, silicone resin strengthening agent 4%, and the balance is silicon carbide powder.

[0048] Specifically, the strengthening agent is methyl phenyl silicone resin, and its solid content is 45%.

[0049] Specifically, the plasticizer is a mixture of 13% beeswax, 4% polyethylene, and the rest is paraffin.

[0050] Specifically, the particle size of the quartz glass powder is between 210 meshes.

[0051] Specifically, the particle size of the mullite mineralizer is 300 mesh.

[0052] A method for reinforcing a silicon-based ceramic core with excellent mechanical properties, comprising the following steps:

[0053]...

Embodiment 3

[0063] see Figure 1-3 , the present invention provides the following technical scheme: a silicon-based ceramic core with excellent mechanical properties, which is made up of the following raw materials in parts by weight: 50% of porous quartz glass powder, 15% of mullite mineralizer, plasticizer 22%, silicon carbide whisker 15%, silicon oxide 10%, metal oxide sol 5%, silicone resin strengthening agent 5%, and the balance is silicon carbide powder.

[0064] Specifically, the strengthening agent is methyl phenyl silicone resin, and its solid content is 45%.

[0065] Specifically, the plasticizer is a mixture of 14% beeswax, 5% polyethylene, and the balance paraffin.

[0066] Specifically, the particle size of the quartz glass powder is between 230 meshes.

[0067] Specifically, the particle size of the mullite mineralizer is 310 meshes.

[0068] A method for reinforcing a silicon-based ceramic core with excellent mechanical properties, comprising the following steps:

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com