Fabrication of lithium secondary battery

A technology for lithium secondary batteries and battery casings, applied in secondary batteries, secondary battery gas removal, lithium storage batteries, etc., can solve problems such as unfavorable expansion, achieve the effect of improving high-temperature life and eliminating expansion phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] As the positive electrode active material and the positive electrode conductive material, spinel-type LiMn 2 o 4 and acetylene carbon black, and graphite is used as the negative electrode active material. Use by adding 1M LiPF 6 An electrolytic solution obtained by dissolving the salt in an organic solvent mixture of EC (ethylene carbonate): EMC (ethylene carbonate) at a ratio of 3:7. PVDF (polyvinylidene fluoride) was used as the positive electrode binder, and an SBR / CMC (styrene-butadiene rubber / carboxymethyl cellulose) system was used as the negative electrode binder. The battery pouch was formed of aluminum, and its thickness was 120 μm. The separator is a polyethylene separator.

[0036] To prepare the positive plate, the positive active material, the conductive material and the binder were added to the binder solution (NMP (N-methylpyrrolidone) solvent containing 10% by weight binder) at a weight ratio of 94:3:3 , and then mixed together to prepare an electro...

Embodiment 2

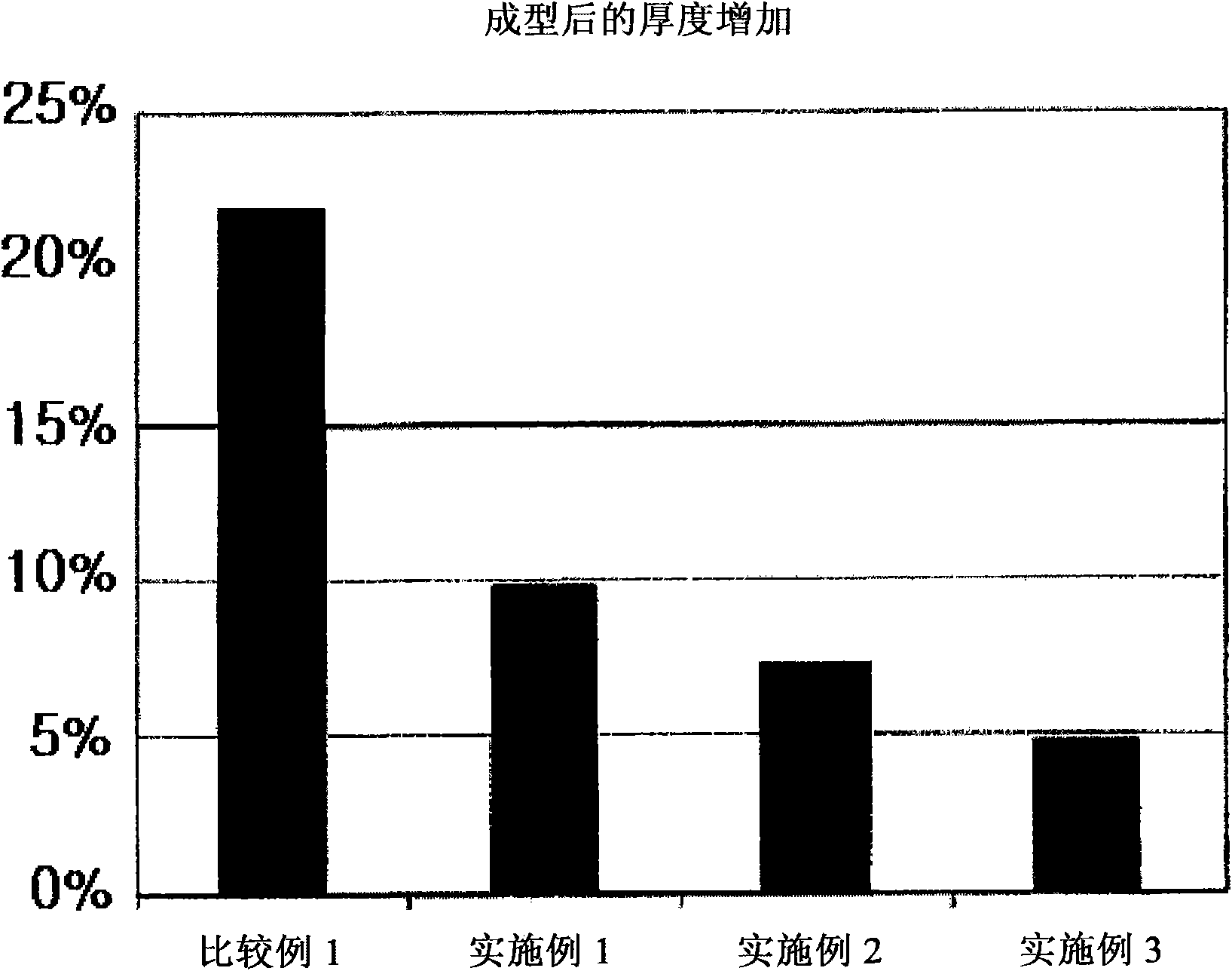

[0041] A lithium secondary battery was prepared in the same manner as in Example 1, except that it was precharged to 70% of the battery capacity. The thickness variation of the fabricated cells before and after the molding process was measured. Its thickness increases as figure 1 shown.

Embodiment 3

[0043] A lithium secondary battery was prepared in the same manner as in Example 1, except that it was precharged to 100% of the battery capacity, and the process of fully charging was omitted during the molding process. The thickness variation of the fabricated cells before and after the molding process was measured. The increase in its thickness is as figure 1 shown.

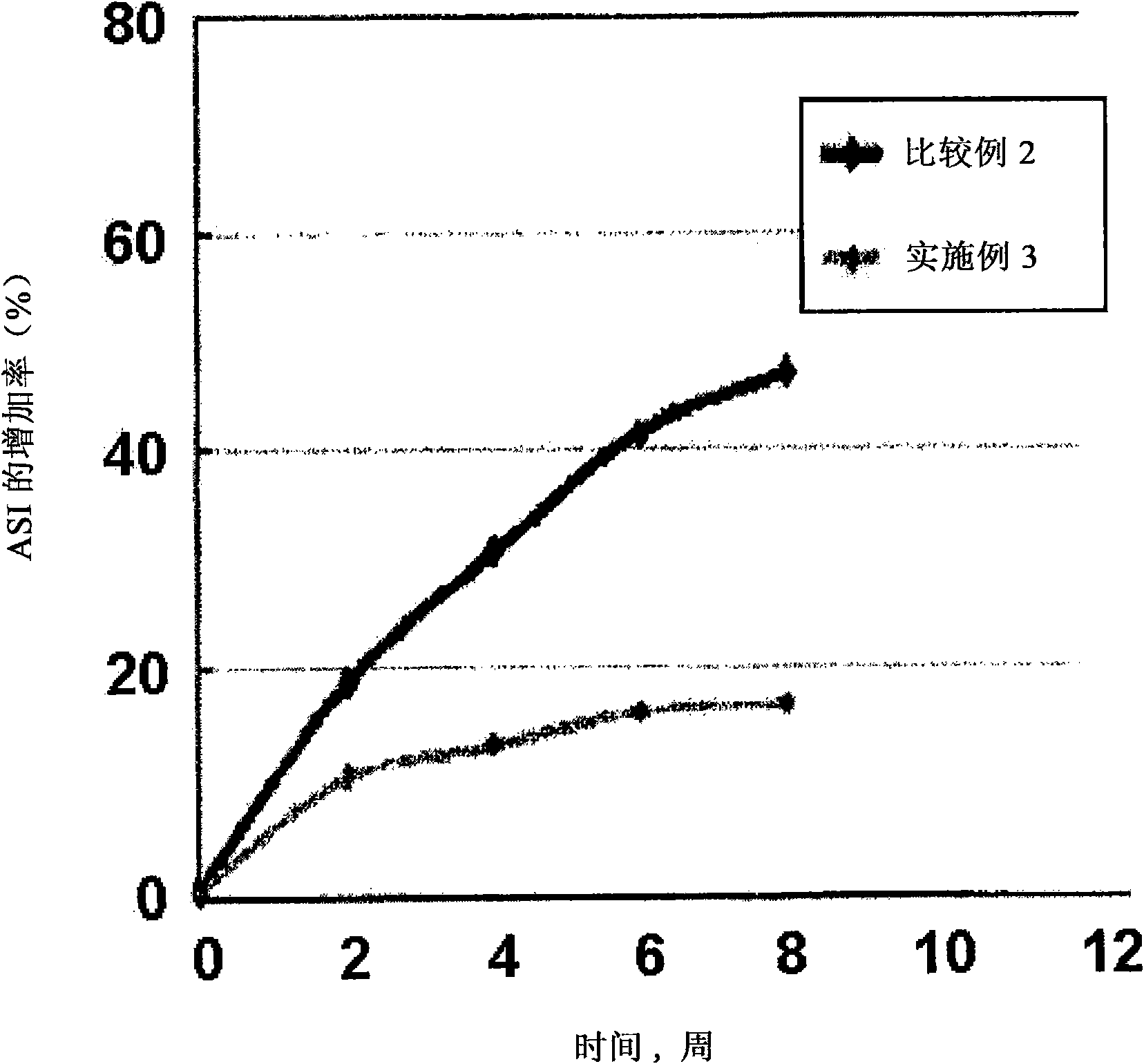

[0044] In addition, the battery was placed at a high temperature of 55° C., and the ASI was measured every 2 weeks to observe the change of ASI with time. The result is as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com