Corrosion-resistant and enhanced furnace bottom roller

An enhanced type, hearth roller technology, applied in furnaces, furnace types, heat treatment furnaces, etc., can solve problems such as structural strength, poor rigidity, deformation, and affecting conveying quality, so as to achieve good corrosion resistance, improve conveying quality, and reliable connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

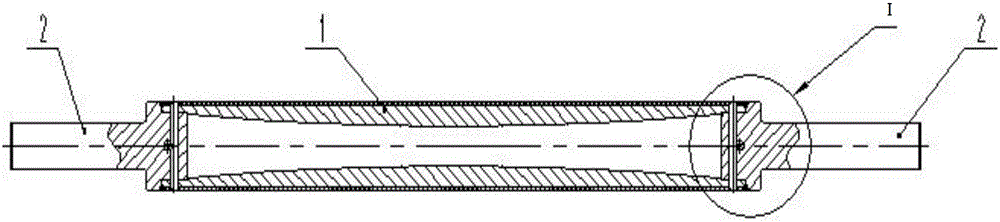

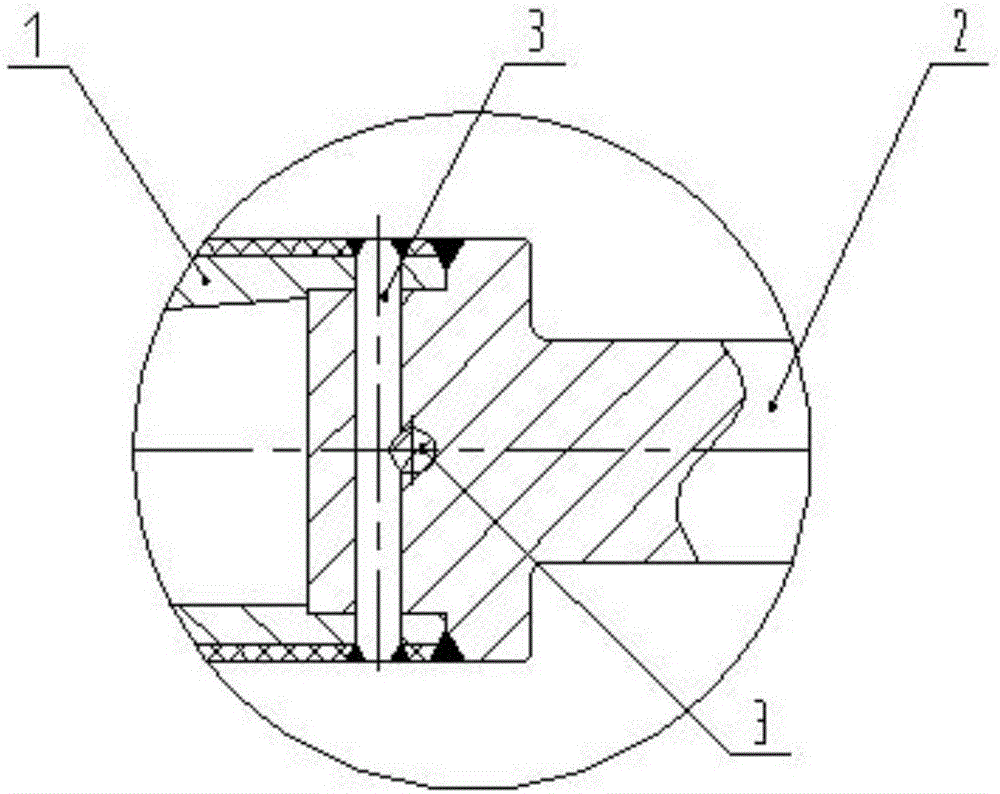

[0022] The corrosion-resistant enhanced hearth roll shown in the accompanying drawings includes a roll 1 and a roll shaft 2 connected to both ends of the roll 1; the roll shaft 2 is inserted into the end of the roll 1 to form a fit and fixed connection; the roll 1, the roll The matching part of shaft 2 is provided with two positioning pins 3 radially penetrating through the matching parts of roller 1 and roller shaft 2, one of which partly runs through the other positioning pin 3, and the two ends of positioning pin 3 The welding is fixedly connected in the positioning hole of the roller 1.

[0023] The wall thickness of the roller 1 between the roller shafts 2 at both ends is thicker as it gets closer to the axial centerline of the roller 1. In this embodiment, the axial section of the inner wall of the roller 1 is an arc-shaped curved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com