Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Improve final product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low pollution vanadium settling iron-removing wet zinc smelting method

ActiveCN1900330AHigh recovery rateReduce consumptionProcess efficiency improvementAcid concentrationZinc smelting

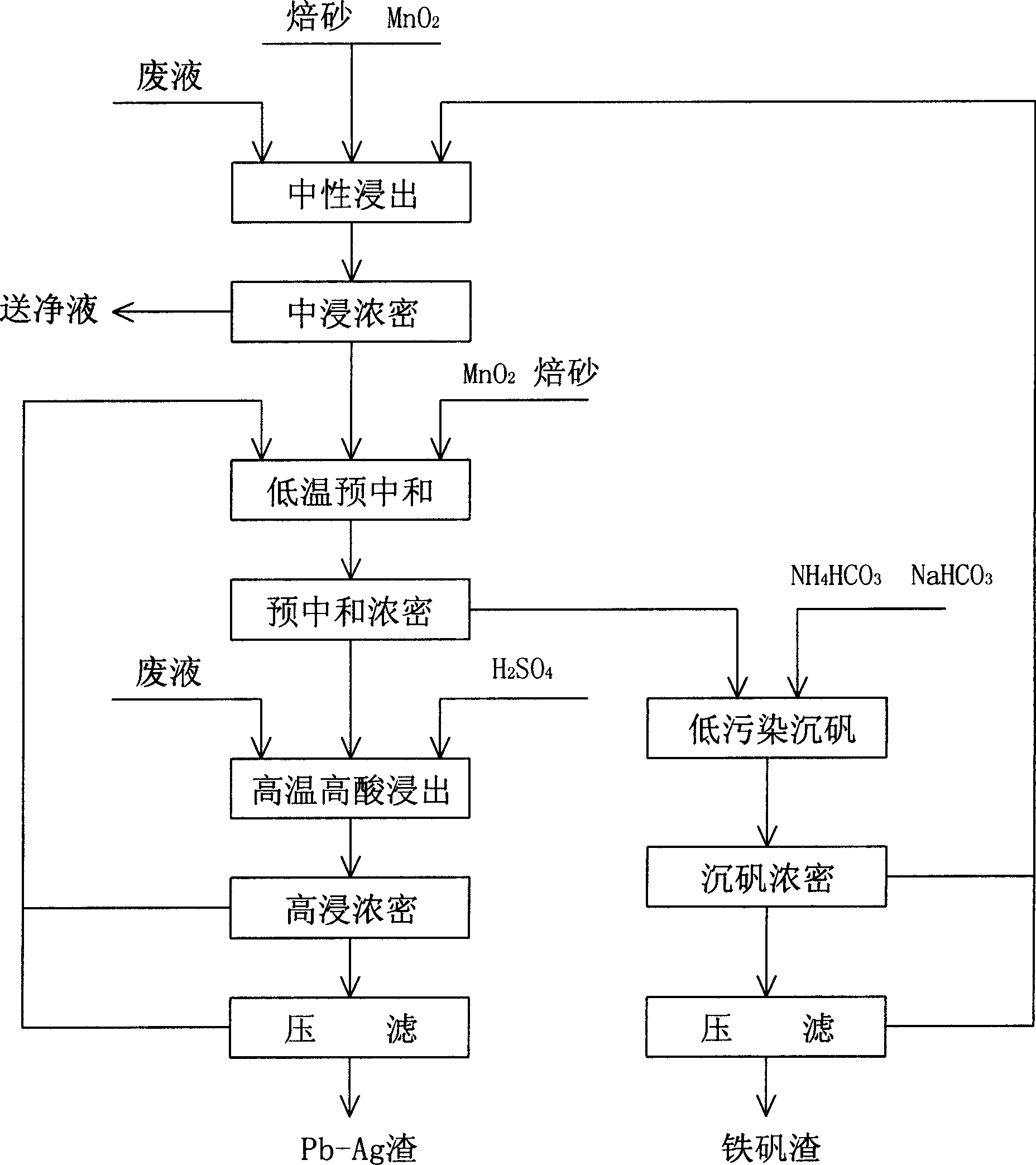

The present invention discloses a kind of wet zinc smelting process, which includes four main technological steps of neutral leaching, low temperature pre-neutralizing, high temperature high acid concentration leaching, and low pollution vanadium settling and iron removing. Before low pollution vanadium settling and iron removing, the high temperature high acid concentration leaching step has iron leached at most, and the solution composition is regulated in the low temperature pre-neutralizing step for satisfactory iron removing effect during vanadium settling without need of adding neutralizing agent. The technological process is suitable for treating complicated zinc concentrate, and has raised metal recovering rate, strengthened impurity removing capacity, raised ultimate product quality, lowered material and power consumption and reduced pollution.

Owner:CHIFENG ZHONGSE ZINC IND CO LTD +1

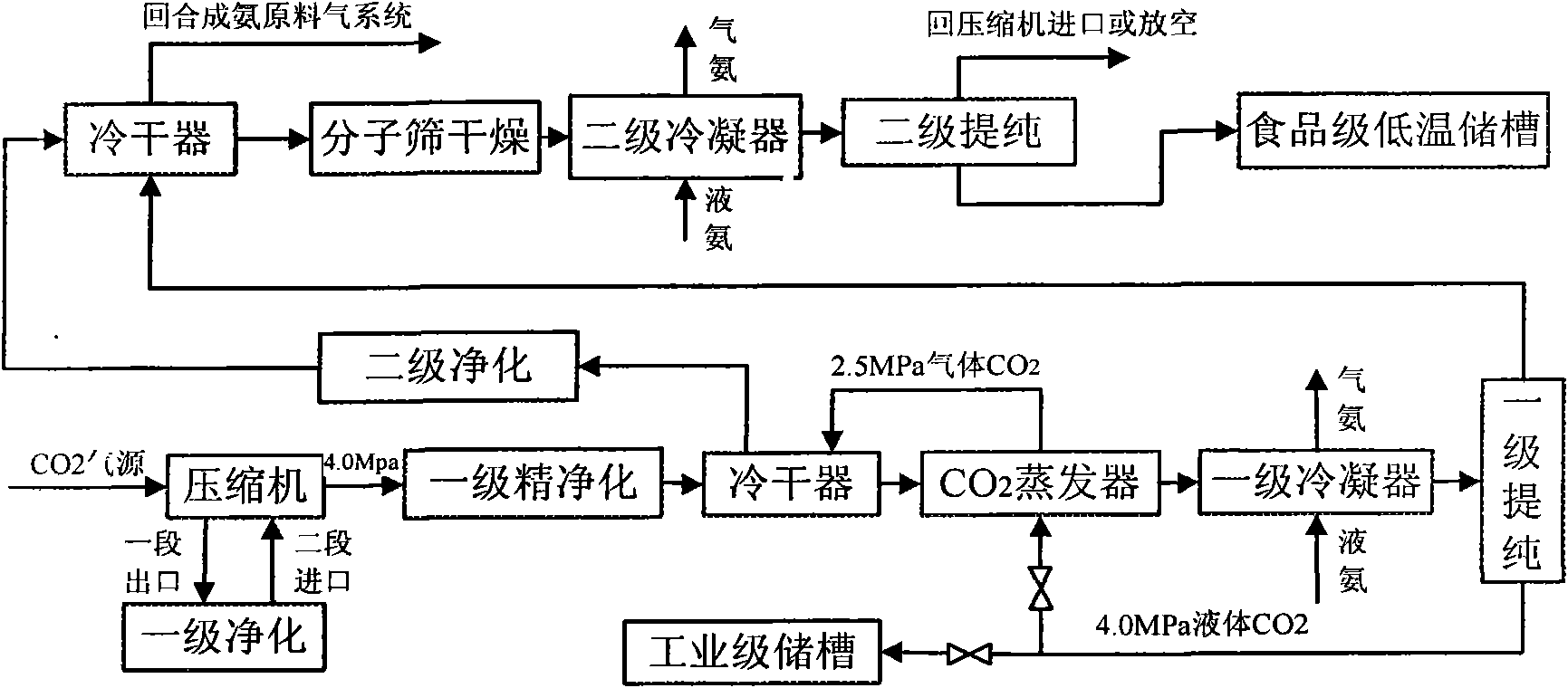

Method for coproducing or singly producing food grade carbon dioxide and industrial grade carbon dioxide by utilizing industrial waste gas

ActiveCN101538040AHigh recovery rateReduce ventingCarbon compoundsChemical industryEnergy consumptionToxic industrial waste

Owner:重庆川茂化工科技有限公司

Method for preparing pentaerythritol triacrylate

InactiveCN101462953AReduce pollutionReduce by-productsOrganic compound preparationCarboxylic acid esters preparationPentaerythritolColor intensity

The invention belongs to a method for preparing pentaerythritol trimethylacrylate, comprising the steps as follows: (1) pentaerythritol, acrylic acid, catalyst, solvent and polymerization inhibitor are put into a reaction kettle to be fully mixed and stirred so as to form a miscible liquid; (2) a steam valve of the reaction kettle is opened to slowly heat the miscible liquid, and the temperature is controlled and maintained at 70-90 DEG C for a 20-40min reaction; (3) the mixture is continued to be heated, when the temperature is increased to 80-115 DEG C, reflow is carried out for 3-5h and then the reaction is finished; (4) soda water solution and sodium chloride water solution are added into the mixture and after washing the upper organic phase is extracted; (5) the upper organic phase is separated from the solvent; (6) and filter pressing is carried out to obtain the end product. The method has simple process, good quality, activity and flexibility, low shrinking percentage and color intensity and high yield coefficient, and produces few by-products or little waste water.

Owner:TIANJIN CHEM REAGENT RES INST

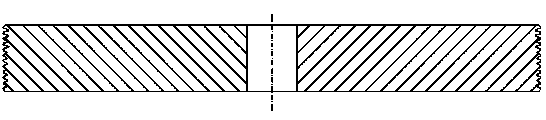

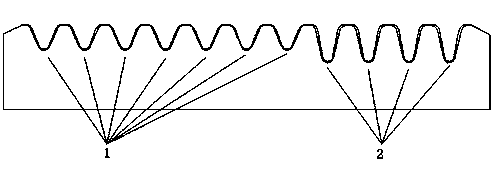

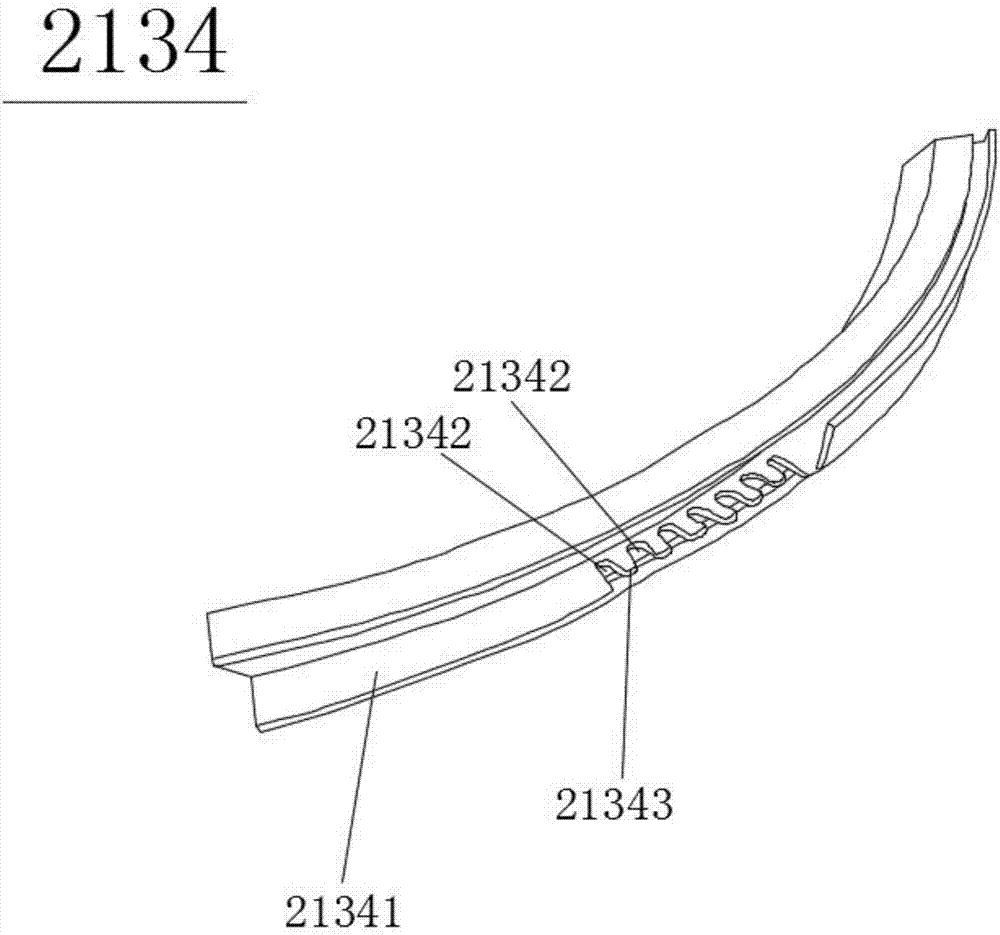

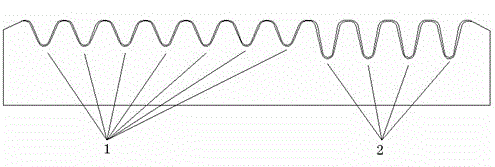

Chamfering grinding wheel for machining silicon single crystal wafer for thick-layer epitaxy, and chamfering method

ActiveCN103394982AHigh edge contour accuracyConsistent edge qualityEdge grinding machinesMicrometerSlip line

The invention relates to a chamfering grinding wheel for machining a silicon single crystal wafer for thick-layer epitaxy, and a chamfering method. The diameters of coarse chamfering grooves of the grinding wheel are 120-150 micrometers less than the thickness of the wafer; half angles are 18-22 degrees; the depths are 900-1100 micrometers; the diamond sizes are 600-1000#; the diameters of fine chamfering grooves are 160-180 micrometers less than the thickness of the wafer; half angles are 11 degrees; the depths are 1400-1600 micrometers; the diamond sizes are 1000-2000#; the rotating speed of the coarse chamfering grinding wheel is 2500-5000rpm; machining is conducted for 1-2 rings; the rotating speed of the wafer is 16-20mm / s; the rotating speed of the fine chamfering grinding wheel is 3000-5000rmp; machining is conducted for 2-4 rings; and the rotating speed of the wafer is 10-15mm / s. The edge chamfering is conducted on the wafer by adopting the chamfering grinding wheel, so that the accuracy of an edge contour is high, the consistency of the edge quality is good, and the problem of a slip line due to the defect of the edge of the silicon wafer in a growth process of the thick-layer epitaxy is solved effectively.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Functional polyester filament and its production process

InactiveCN101046006AImprove qualityLong-lasting and efficient negative oxygen ion far-infrared functionMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

The composite functional polyester filament is one composite structure comprising one core layer of common polyester and one coating layer of functional modified polyester with functions of releasing negative oxygen ion and emitting far infrared ray, with the linear density ratio between the coating layer and the core layer being 2:8 to 4:6. The functional modified polyester for the coating layer can release negative oxygen ion in over 4000 / cu cm for long term and has far infrared emissivity over 0.88. The composite functional polyester filament is produced in a double screw composite spinning machine, and has one coating layer to release negative oxygen ion and emit far infrared ray for long term and one core layer with high mechanical strength.

Owner:ZHEJIANG SCI-TECH UNIV

Stirring device capable of realizing cascading fermentation of solid waste and reactor

ActiveCN105436193AReduce mixImprove degradation efficiencySolid waste disposalAxial thrustEngineering

The invention discloses a stirring device capable of realizing cascading fermentation of solid waste and a reactor. The stirring device comprises a center shaft, a conveying screw and a plurality of stirring blades, wherein the conveying screw is used for axially pushing materials, is concentrically fixed on one side of the center shaft and extends from the shaft end to the middle of the shaft in tapered manner; the stirring blades and the conveying screw are coaxially fixed on the other side of the center shaft. The stirring device can be arranged in a barrel to form the reactor used for the solid waste. The layout standard of the stirring blades is that the axial thrust along the center shaft is not generated in the rotation process. Thus, a layered fermentation system can be formed in the reactor. The system can greatly reduce the mixing ratio of new and old materials, effectively control the standing time of solid materials in the reactor, improve the degradation efficiency of output materials, and increase the final product quality.

Owner:ZHEJIANG UNIV

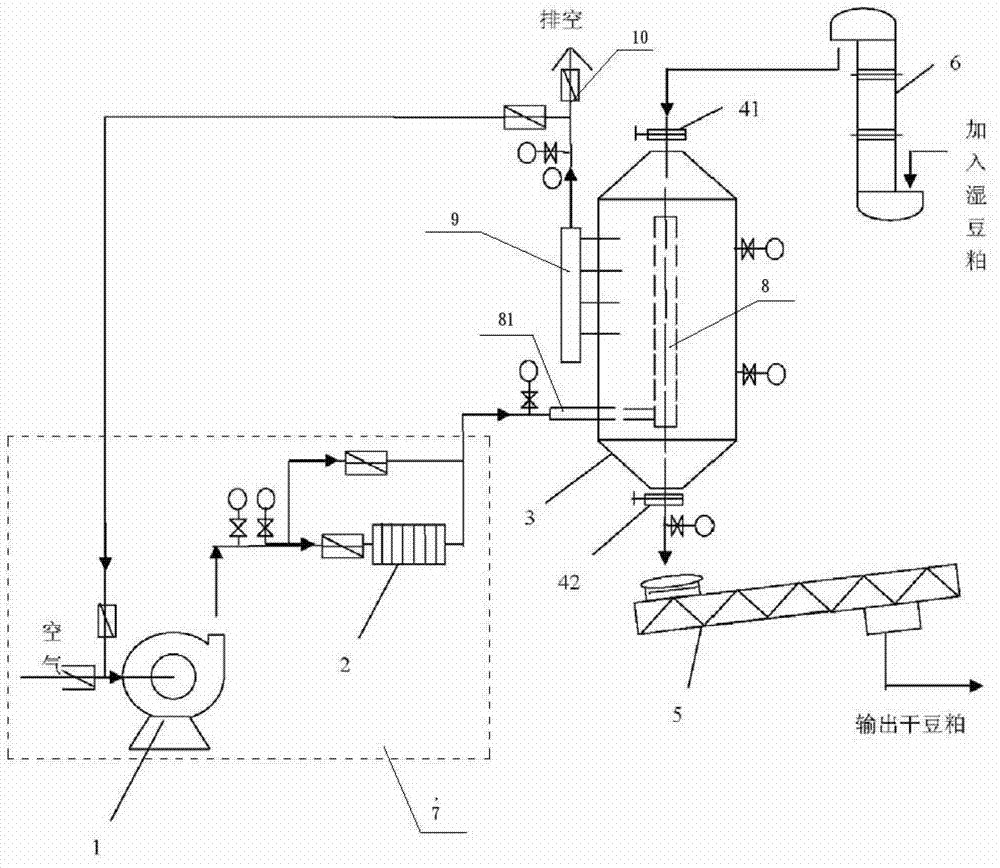

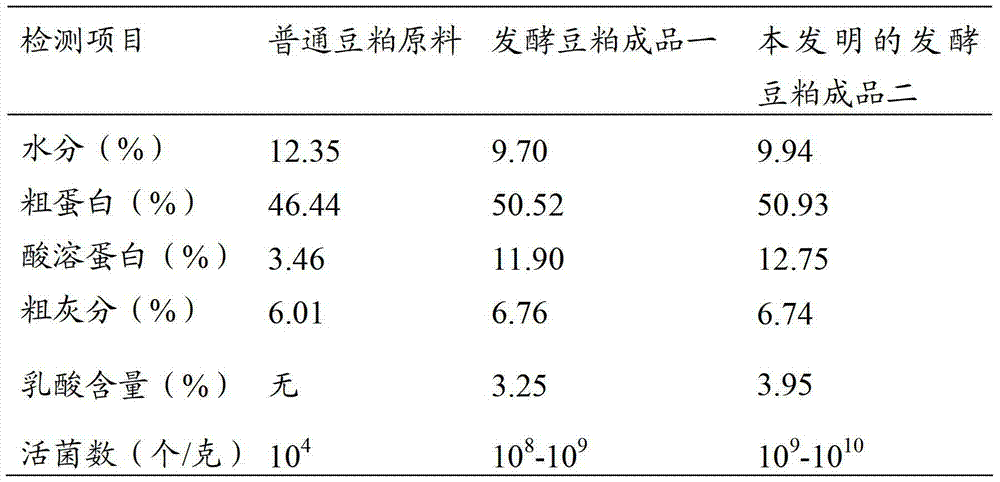

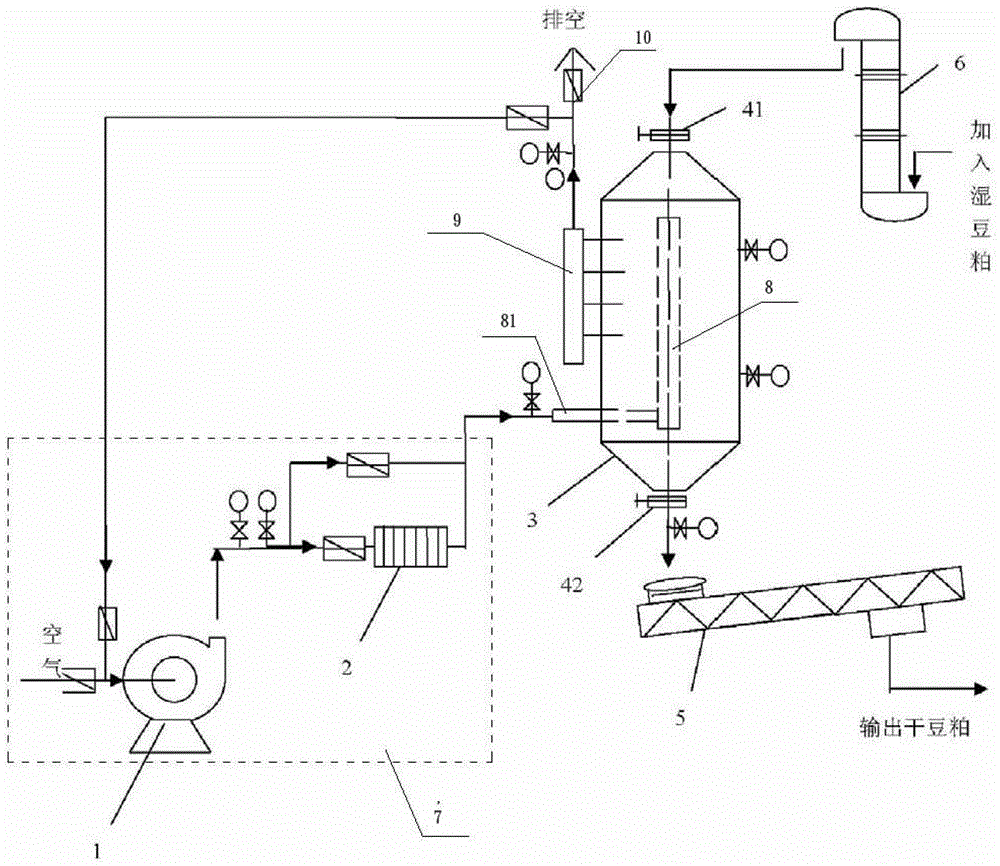

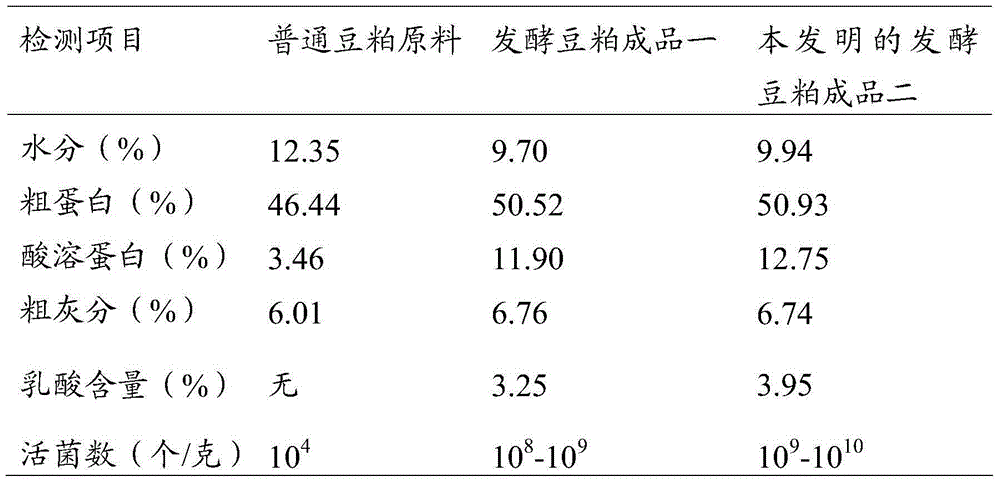

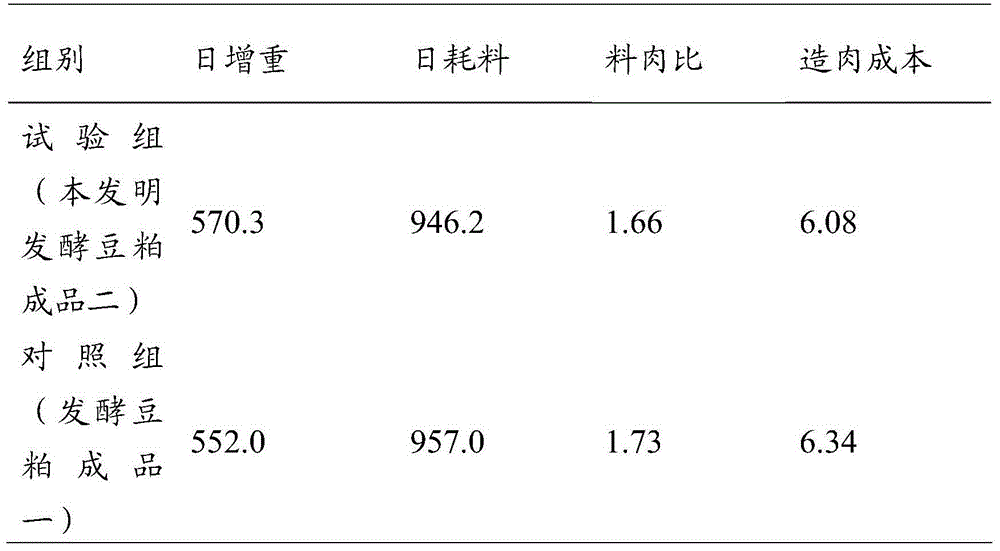

Novel low-temperature-dried fermented soybean meal preparation method

ActiveCN103315143AReduce labor costsImprove labor efficiencyAnimal feeding stuffHeat sensitiveFermentation

The invention provides a novel low-temperature-dried fermented soybean meal preparation method comprising the steps that: prepared bacillus broth, lactobacillus broth, and yeast broth are added into soybean meal and honey according to a certain ratio; water is added, and the mixture is well mixed, such that a wet soybean mixture is prepared; the prepared wet soybean mixture is delivered into a fermentation tank, wherein a temperature in the fermentation tank is controlled at 20-24 DEG C; fermentation is stopped after 3-5 days of fermentation, such that a fermented soybean wet material is prepared; the prepared fermented soybean wet material is subjected to in-situ bake-drying under a temperature of 50-70 DEG C in the same fermentation tank; the dried material is delivered from the bottom of the fermentation tank, and is crushed, such that the novel low-temperature-dried fermented soybean meal provided by the invention is obtained. With the method provided by the invention, labor efficiency is improved, and heat-sensitive substances and active probiotics with good biological characteristics in the fermented soybean meal are preserved to a maximal extent. Therefore, the quality of a finished product is greatly improved, and feeding performance and nutritional value of fermented soybean meal are greatly improved.

Owner:ANHUI TECH BANK BIO TECH

Online chemical tempering method of aluminosilicate glass

InactiveCN102531364AImprove wear resistanceImprove impact resistanceGlass tempering apparatusGlass productionManufacturing cost reductionProduction line

The invention discloses an online chemical tempering method of aluminosilicate glass. An online chemical tempering region which is hermetically connected with a pre-annealing region and an annealing region is additionally arranged between the pre-annealing region and the annealing region, and the online chemical tempering temperature is not more than the outlet temperature of the pre-annealing region. The online chemical tempering method comprises the following steps: enabling a glass substrate which is formed by melting to enter into the online chemical tempering region for performing surface spray-coating of a tempering solution after passing through the pre-annealing region, so as to form a pressure stress layer on the glass substrate, and then enabling the glass substrate to enter into the annealing region for completing online chemical tempering during the annealing process of the glass substrate. According to the online chemical tempering method disclosed by the invention, the online chemical tempering can be directly completed during the annealing process of a glass production line, the production efficiency of products can be greatly improved, the manufacturing cost can be reduced and large-scale benefits can be further realized; and furthermore, the online chemical tempering method disclosed by the invention can be directly applied to the existing glass production line without performing large-scale technical transformation, so that the technical application threshold and technical development risk can be further reduced.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

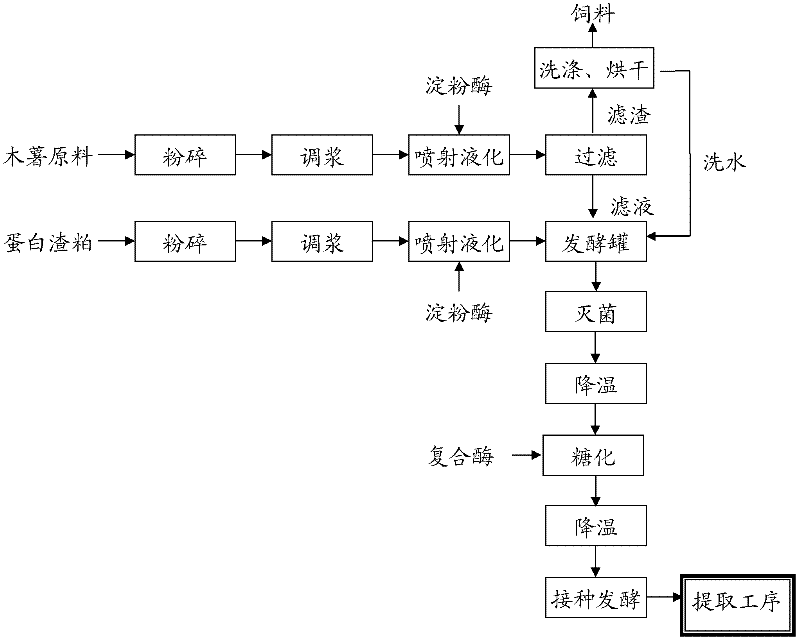

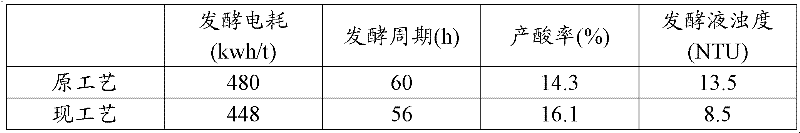

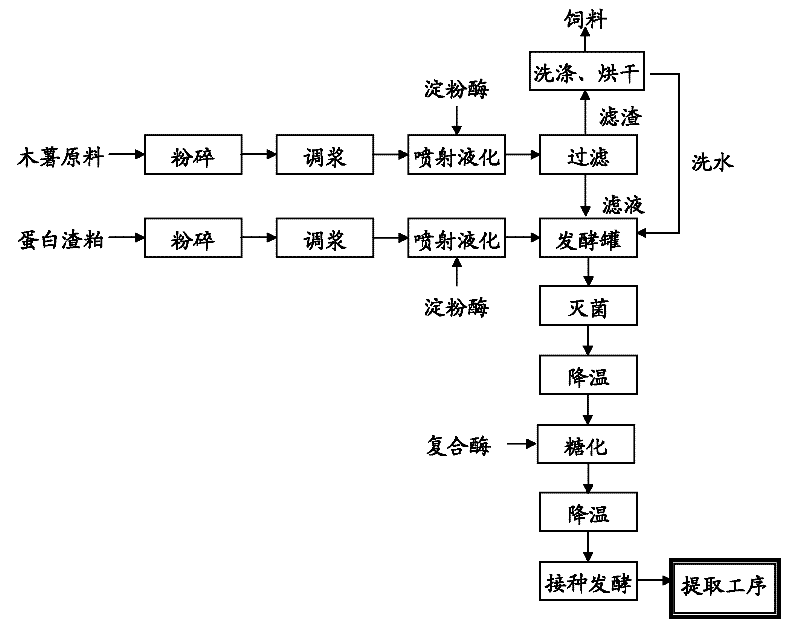

Method for producing citric acid through complete cassava fermentation

InactiveCN102399830AImprove fermentation conversion rateIncrease acid production rateMicroorganism based processesFermentationSlagFiltration

The invention relates to a method for producing citric acid through fermentation, in particular to a method for producing citric acid through complete cassava fermentation, which comprises work procedures of pulverization, size mixing, liquefaction, filtration and fermentation. Before the fermentation, acid compound enzyme is adopted for saccharifying raw materials; and during the fermentation, protein slag or protein meal is adopted as a nitrogen source. The protein slag or protein meal is added for supplementing the fermentation nitrogen source, the goal of complete non-grain fermentation is reached, the defect of poor oxygen dissolution effect in the fermentation process caused by too high cassava high-sugar fermentation material concentration can also be overcome through the addition of a filtration process, simultaneously, the residue carbon sources in the protein slag or the protein meal are utilized, the integral utilization of raw materials is realized, and the fermentation grain consumption is reduced.

Owner:RIZHAO LUXIN JINHE BIOCHEM

Production equipment and method for plastic products for medical equipment

InactiveCN107498876AGuaranteed performanceImprove work efficiencyDomestic articlesMedical equipmentEngineering

The invention discloses a production equipment of plastic products for medical equipment, which comprises a machine platform, a feeding device, a conveying device arranged on the machine platform, a plastic substrate adsorption and transfer device successively erected on the conveying device, and a sponge ball adding device , Disinfectant dripping device and aluminum foil paper hot-melt device, the conveying device includes a conveying track, a number of conveying carriers slidably arranged on both inner sides of the conveying track, a carrier rear push mechanism arranged at one end of the front of the conveying track, and a conveying The carrier front push mechanism at one end of the track rear, the carrier right push mechanism located behind the left end of the conveying track, and the carrier left push mechanism located in front of the right end of the conveying track. An embedding groove for embedding the plastic base is provided on the protruding block. Realize the operation of adding sponge balls, dripping disinfectant and hot-melt aluminum foil paper to the plastic substrate on the conveying carrier. The invention also discloses a production method of the plastic product for medical equipment.

Owner:东莞顶钧塑胶模具有限公司

Method for extracting and recovering hemicelluloses in squeezed waste alkalis

The invention relates to a method for extracting and recovering hemicelluloses in squeezed waste alkalis, belongs to the chemical fiber making industry field, and especially belongs to the processing field of the squeezed waste alkalis in the viscose fiber production making process. Hemicelluloses in the squeezed waste alkali are recovered through neutralizing, precipitating, filtering and drying steps. The method adopts alkalescence as a neutralizing end point, and the polymerization degree of the hemicelluloses is high, so the recovery rate can reach above 80%. The finally obtained hemicelluloses comprise 95% or more of the hemicelluloses (oven dry) and 0.5% or less of ash, and can be sold directly or exploited as a next-step synthesis raw material.

Owner:YIBIN GRACE GROUP CO LTD +2

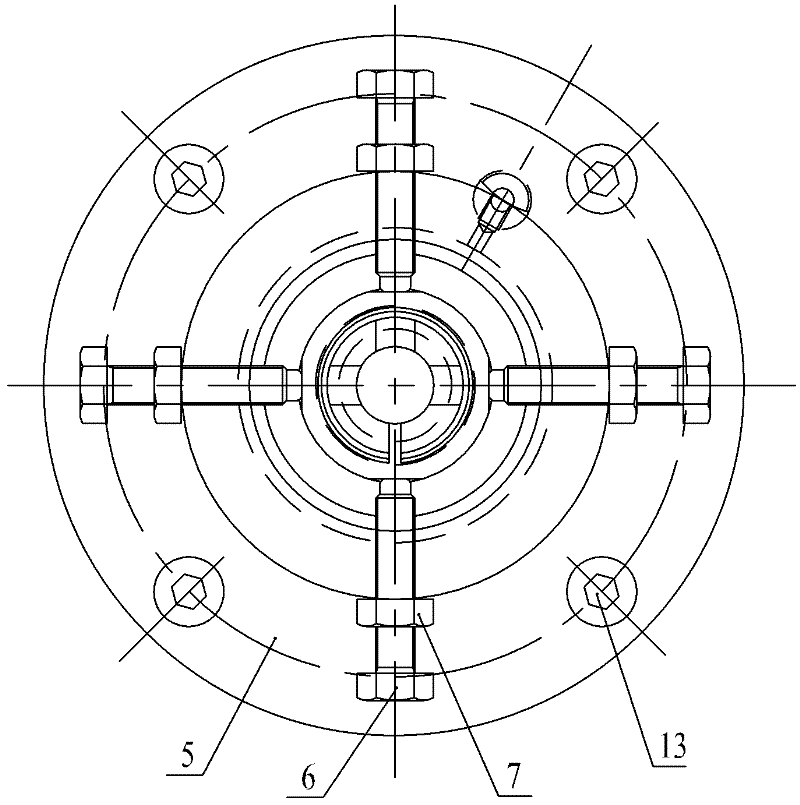

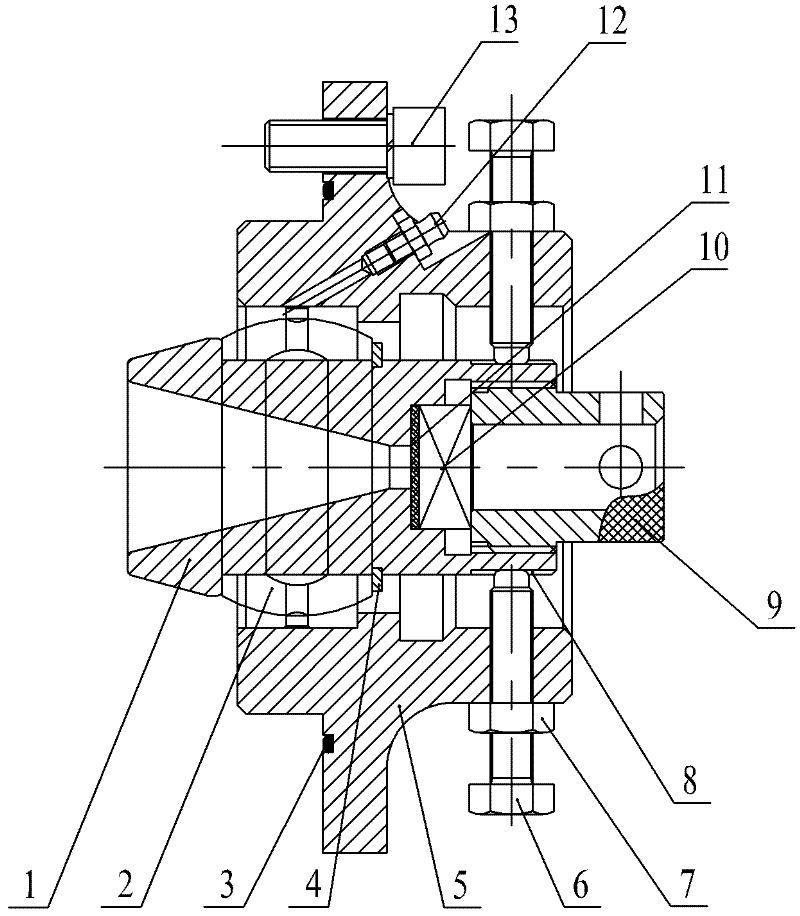

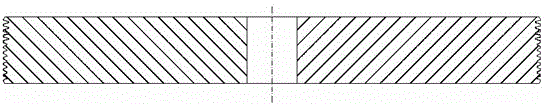

Die box component of wire drawing machine

The invention relates to a die box component for reducing the drawing diameter of a metal wire on a water tank wire drawing machine. The die box component comprises a die holder, a die sleeve, a joint bearing, a wire drawing die, a die pin and a limit screw, wherein the die holder is fixedly arranged on a tank body of the wire drawing machine; the die sleeve is arranged in the die holder through the joint bearing, and is provided with a shaft retainer ring for limiting the axial movement of the die sleeve in the joint bearing; the head end of the die sleeve is provided with a conical wire inlet; the tail end of the die sleeve is provided with a concave cavity; the wire drawing die is arranged in the concave cavity, and is compressed and fixed through the hollow die pin; the outer wall of the tail part of the die sleeve is provided with a limit groove; the tail part of the die holder is provided with the limit screw; and the inner end of the limit screw is pressed in the limit groove, and is used for limiting the rotation of the die sleeve. The die box component has a skillful, compact and reasonable structure; and the wire drawing die is arranged through the joint bearing, and can be finely adjusted in a certain angle range according to the height of the metal wire, so that the metal wire is prevented from being damaged, the final product quality is improved, and the service life of the die box component is prolonged.

Owner:WUXI CHANGXIN TECH

Lithium battery pole piece slitting burr detector

InactiveCN107192719AReduce sizeAvoid internal short circuitOptically investigating flaws/contaminationUsing optical meansPole pieceEngineering

The invention relates to a lithium battery pole piece slitting burr detector. The detector consists of a baseplate, a side bracket, a hand wheel, a screw rod, a screw nut, a transition frame, a guide pillar, a sliding bearing, an up-down adjustment bracket, a fixed ring, a microscope and a clamp plate group. On the baseplate, the screw rod passes through the side bracket through a bearing seat, one end of the screw rod goes through the side bracket and is connected to the hand wheel, the screw nut is in threaded engagement with the screw rod, and is fixedly connected in the transition frame, the guide pillar is parallel to the screw rod and passes through the side bracket on both sides of the baseplate, the guide pillar passes through the transition frame through the sliding bearing, the up-down adjustment bracket perpendicular to the baseplate is fixedly connected to the transition frame, the fixed ring is connected to the up-down adjustment bracket through a clamp seat, the microscope is fixedly sleeved on the fixed ring, the baseplate is provided with the clamp plate group that is parallel to the screw rod and is used for clamping a pole piece, and corresponding to a position above the clamp plate group, the microscope is in a state of mobile measurement of pole piece cut burr along the clamp plate group direction.

Owner:JIANGSU SUNPOWER

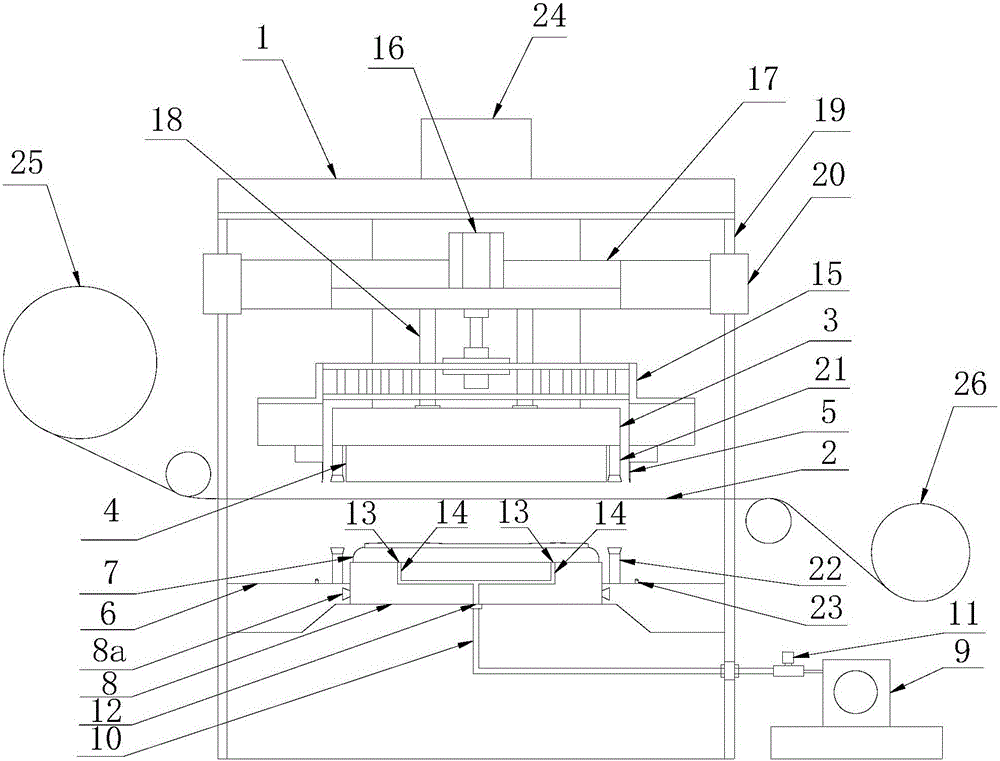

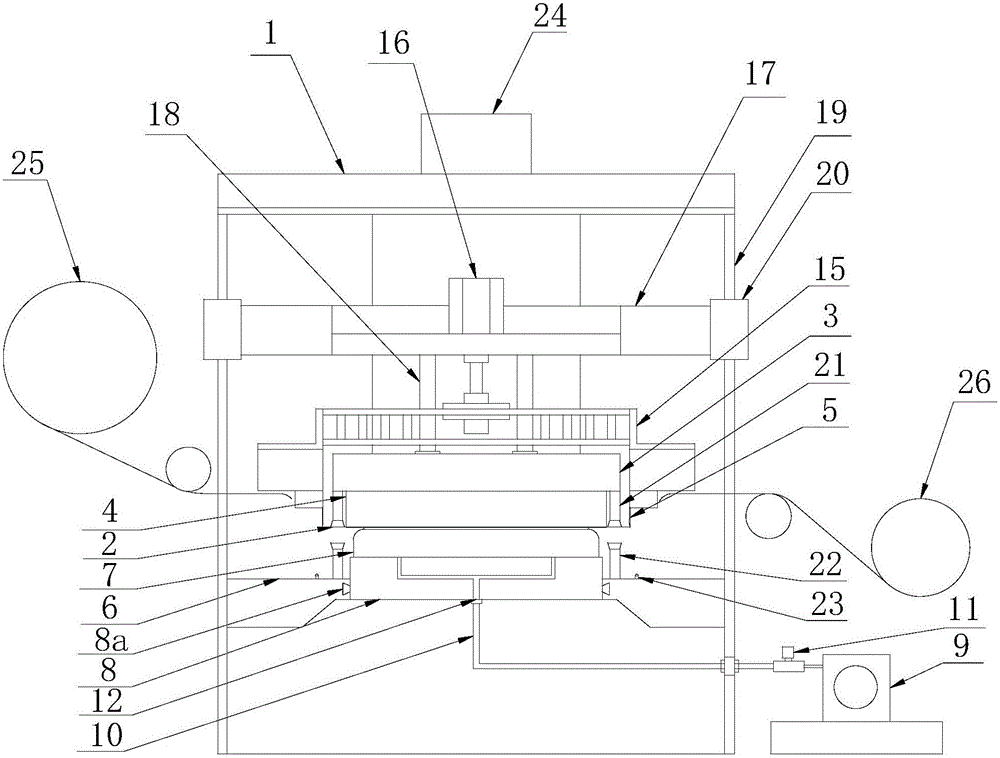

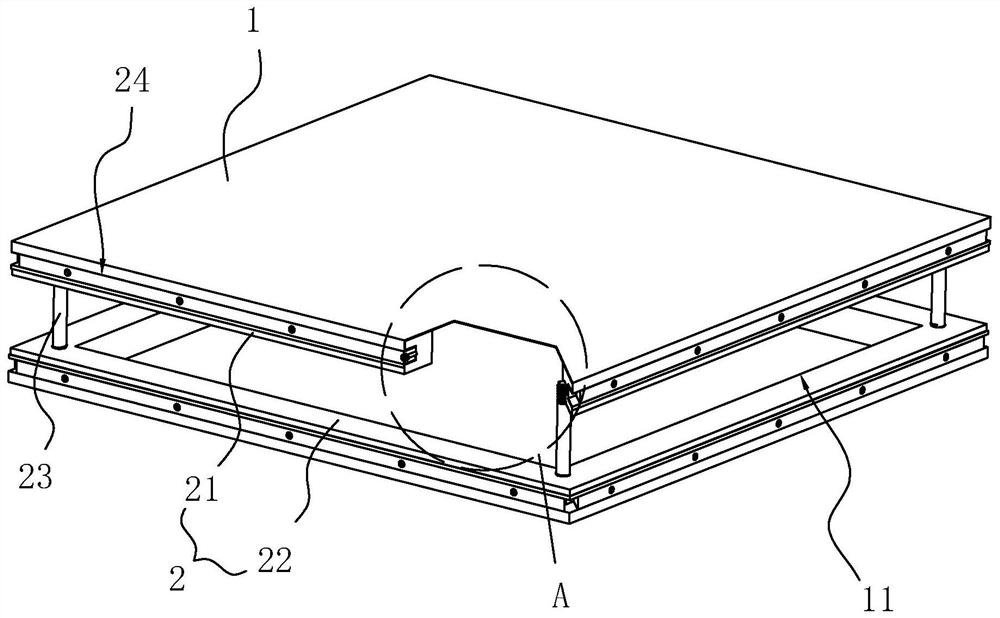

Heat transfer film automatic alignment transfer printing device suitable for flexible substrate

The invention discloses a heat transfer film automatic alignment transfer printing device suitable for a flexible substrate. A substrate positioning mechanism in conventional equipment is mainly improved, and an air cushion type supporting mechanism is used for replacing an original rigid platen. The air cushion type supporting mechanism comprises a silicone rubber air bag cushion opposite to a heat transfer film pressing plate and an air charging device for charging air into the silicone rubber air bag cushion. The silicone rubber air bag cushion is suitable for supporting and being attached to the flexible substrate, especially when the heat transfer film pressing plate drives a cut-off heat transfer film to be pressed downwards, a PLC controls the air charging device to charge air into the silicone rubber air bag cushion so that the silicone rubber air bag cushion can expand and squeeze the flexible substrate, enough feedback force is provided to ensure the attaching closeness and matching precision of the heat transfer film and the flexible substrate together with the upper pressing plate, the product quality of the heat transfer printing process of the flexible substrate is greatly improved, the rejection rate is reduced, and cost is reduced for enterprises.

Owner:苏州锦安新材料科技有限公司

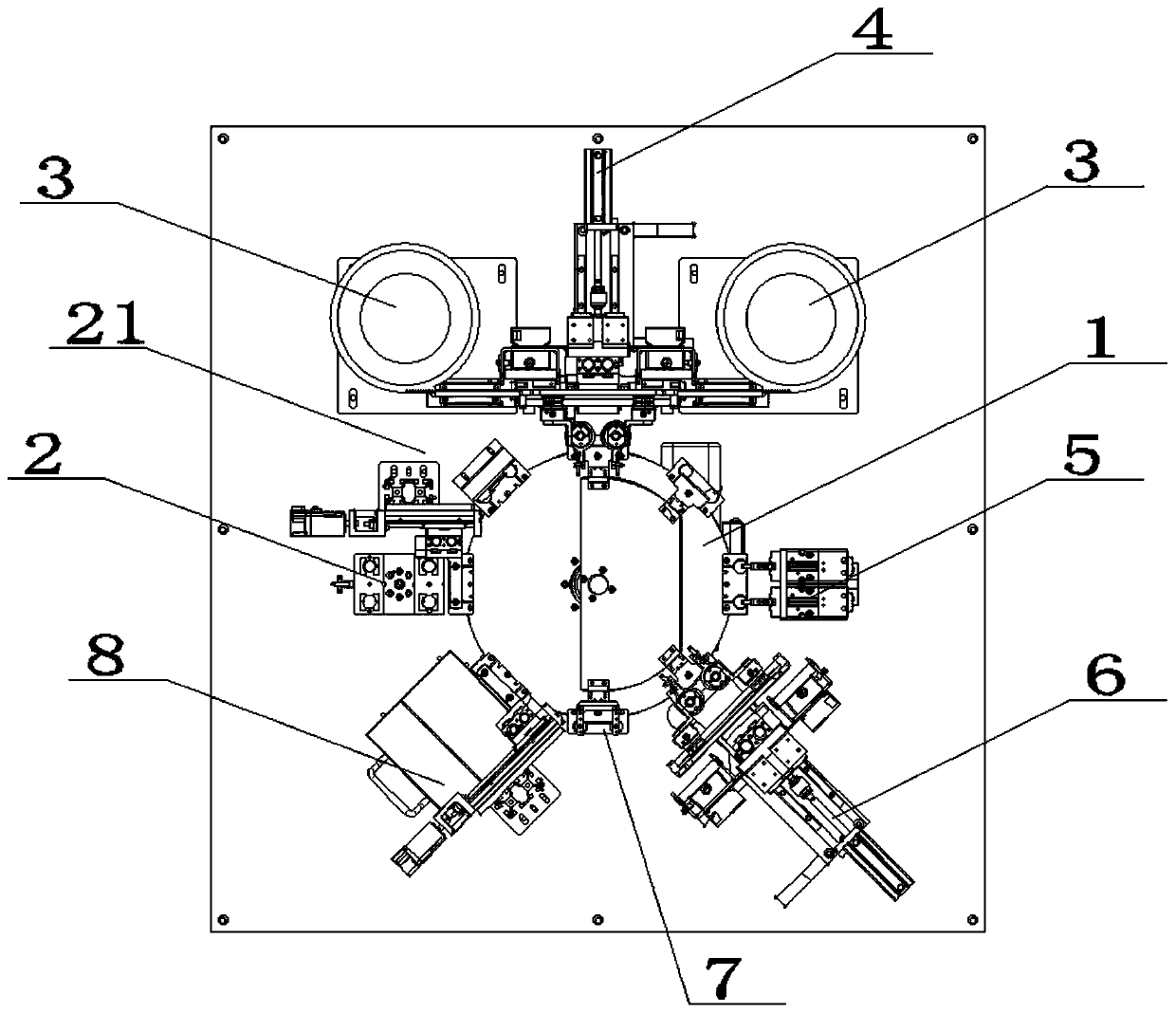

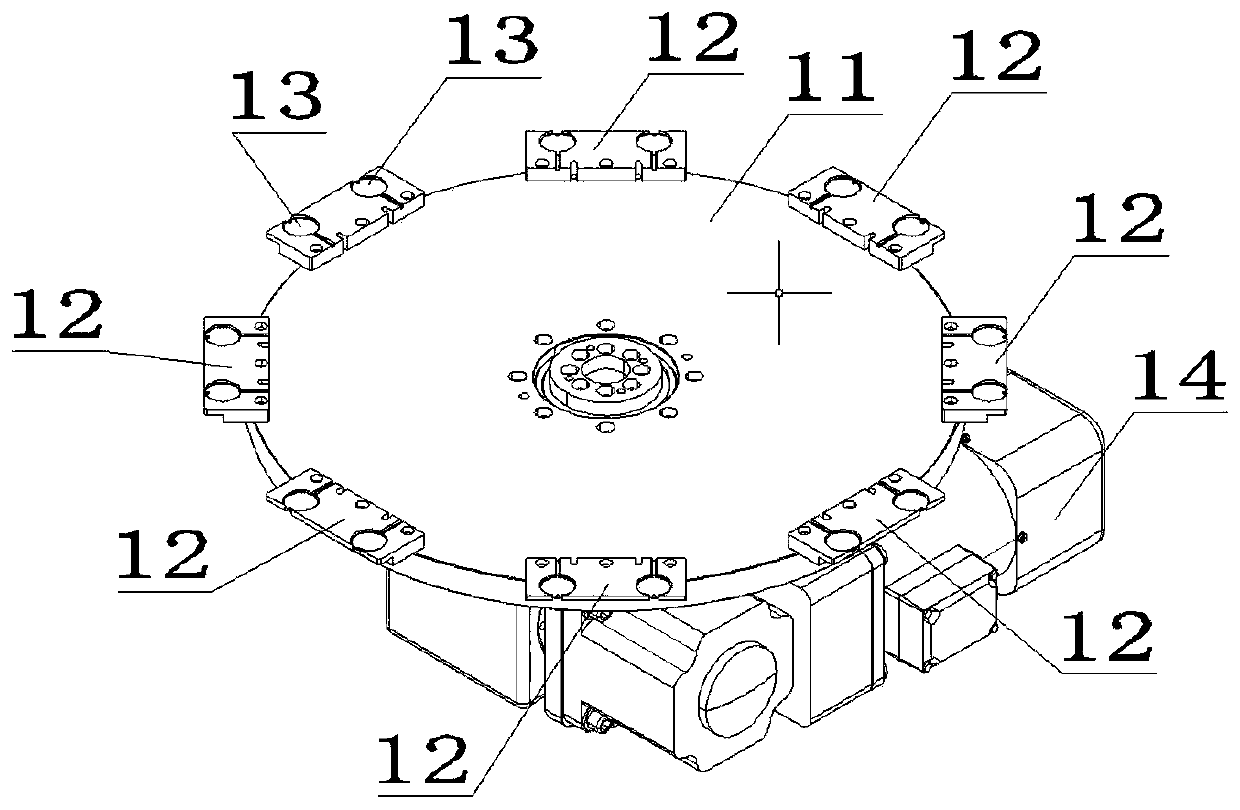

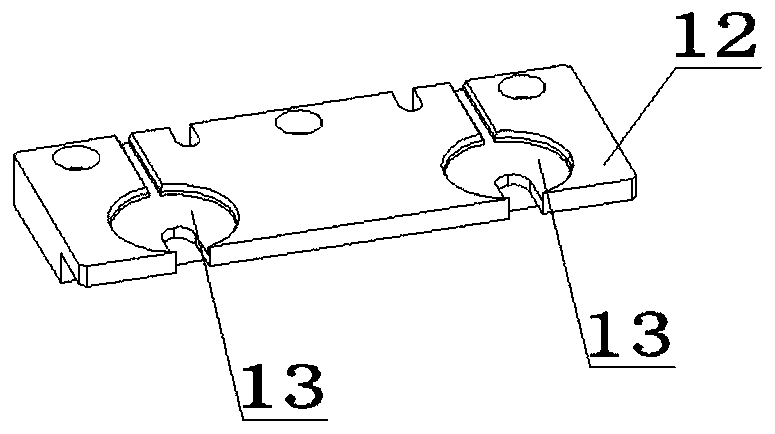

Automatic ring-crossing and welding system of double-sided buzzer

PendingCN111545861AAvoid product qualityImprove work efficiencySortingMetal working apparatusIndustrial engineeringBuzzer

The invention discloses an automatic ring-crossing and welding system of a double-sided buzzer. The automatic ring-crossing and welding system of the double-sided buzzer comprises a rotating mechanism, a feeding mechanism, a ring inserting mechanism, a first welding mechanism, an overturning mechanism, a second welding mechanism, a testing mechanism and a sorting mechanism. The feeding mechanism places the double-sided buzzer on a locating sheet. The ring inserting mechanism opens a closed welding ring, and the double-sided buzzer located on the locating sheet crosses the welding ring. The twosides of the double-sided buzzer achieve welding with the welding ring through a first welding mechanism and a second welding mechanism. A welded finished product undergoes welding insulating property through a testing mechanism. The sorting mechanism conducts qualified and unqualified sorting classification on the products according to the testing results of the testing mechanism, places the qualified products into a qualified product storage bin and places the unqualified products in an unqualified product storage bin. Through cooperation between a rotating disk and the mechanisms, the automatic ring-crossing and welding system of the double-sided buzzer achieves automatic ring crossing, welding and insulating property testing of the double-sided buzzer, product quality can be better controlled, and cost is lowered.

Owner:江苏波速传感器有限公司

Method for reducing viscosity of titanium dioxide slurry

The invention relates to a method for reducing viscosity of titanium dioxide slurry, and belongs to the technical field of production of titanium dioxide. The technical problem to be solved by the invention is to provide the method for reducing the viscosity of the titanium dioxide slurry. The method grinds a raw product of titanium dioxide to reach a fineness of not more than 40 meshes, and performs the pulping dispersion. The method can screen and classify grinded materials through controlling related process parameters of rolling, pressing and milling, changes the fineness of pulping materials to increase the concentration of the titanium dioxide slurry and to reduce the viscosity thereof, improves the quality of the titanium dioxide slurry, improves the grinding efficiency, and improves the abrasive material quality and the final product quality. The method is simple in operation, high in implementability, capable of not changing traditional medium powder equipment, suitable for popularization and broad in application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Multifunctional pipe machine

ActiveCN108262580AIncrease production capacityImprove welding qualityWelding/cutting auxillary devicesDesign optimisation/simulationProduction lineProduction effect

The invention provides a multifunctional pipe machine. The multifunctional pipe machine comprises a control module, a cloud server, a display module, a speaker, a pipe winding module, a second mechanical arm, a first mechanical arm, a laser scanning device, a welding gun and a camera; and the control module is respectively connected with the cloud server, the display module, the speaker, the pipewinding module, the second mechanical arm and the first mechanical arm. The multifunctional pipe machine has the following beneficial effects: a production line is digitally rebuilt through a three-dimensional scanner; production line parameters are dynamically adjusted to achieve optimal production effects; the quality of welding spots is comprehensively judged through welding spot three-dimensional models and welding spot videos; and the welding gun is dynamically controlled for repair welding, so that the welding quality is improved, and the final product quality is improved.

Owner:重庆近江智信汽车零部件有限公司

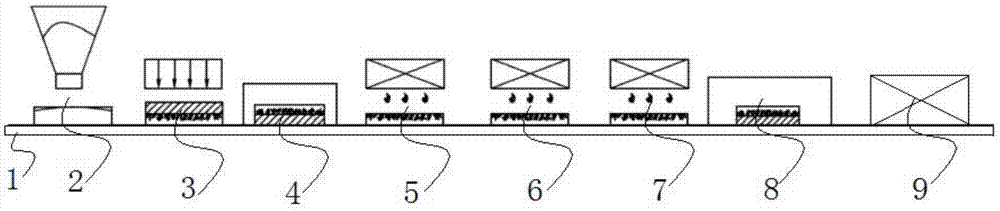

Manufacturing system and manufacturing process for stone-like ceramic tile with vivid stone imitation effect

PendingCN107199629AProtection stabilityNice appearanceCeramic shaping plantsFeeding arrangmentsBrickManufacturing technology

The invention relates to a manufacturing system and a manufacturing process for a stone-like ceramic tile with a vivid stone imitation effect. The manufacturing system comprises a material distributing device, a pressing device, a biscuiting device, a bottom-layer glaze pouring device, an ink-jet printing device, a surface layer glaze spraying device, a firing device and a cutting polishing device which are sequentially connected through a conveyor belt. Compared with the prior art, the manufacturing system has the advantages that processes of pouring glaze, spraying ink and spraying glaze are adopted to sequentially prepare a glaze bottom layer, a color layer with the stone-like effect and a glaze protective surface layer on a brick blank surface layer, so that the problem that insufficient color and luster or over-burning is caused as an ink-jet material is affected by a temperature in a firing process is overcome; and meanwhile, the glaze protective surface layer can protect stability of pattern color of ink-jet 3D printing, so that a final product has a relatively fine condition in aspect of external perception and interior quality.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD

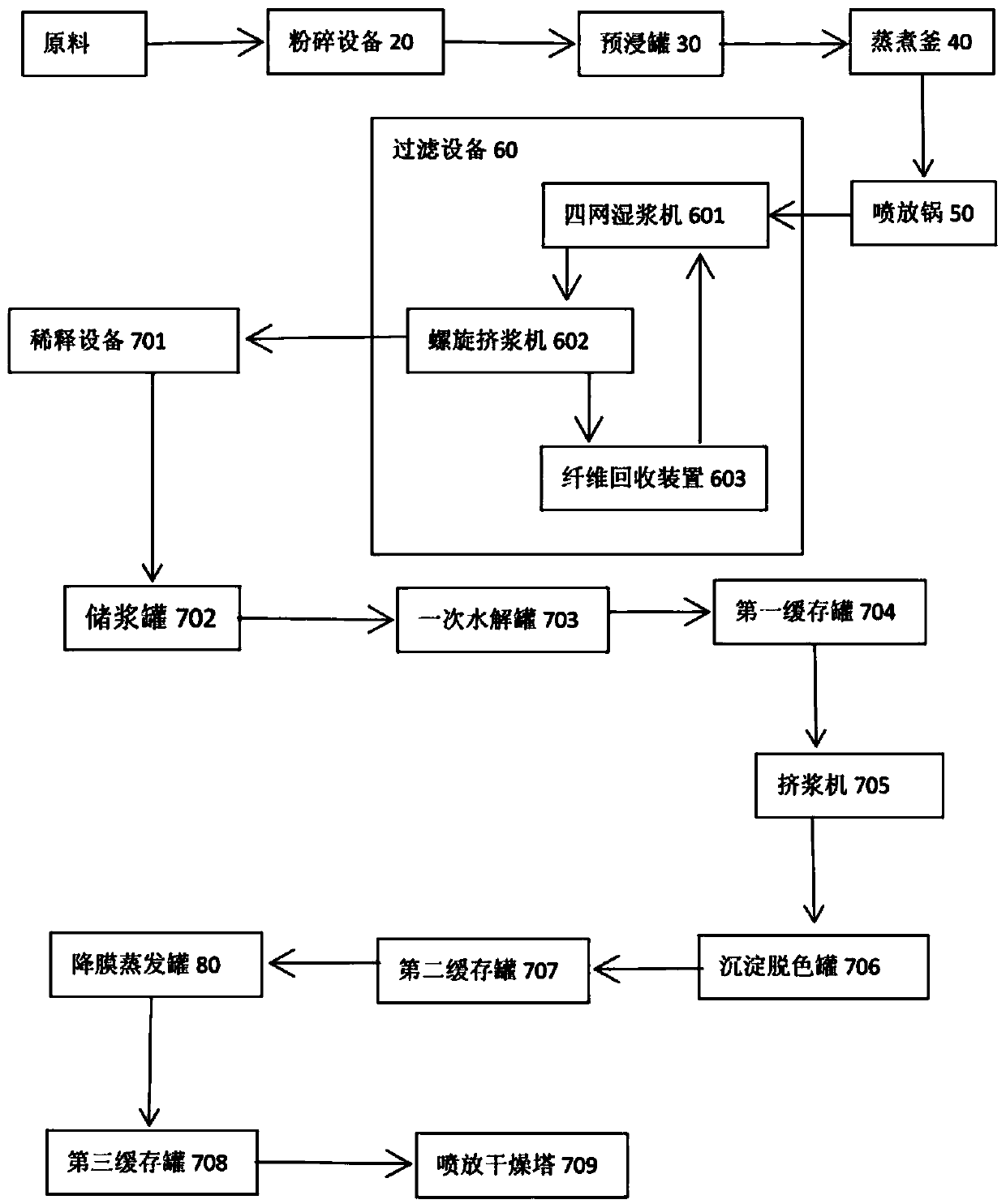

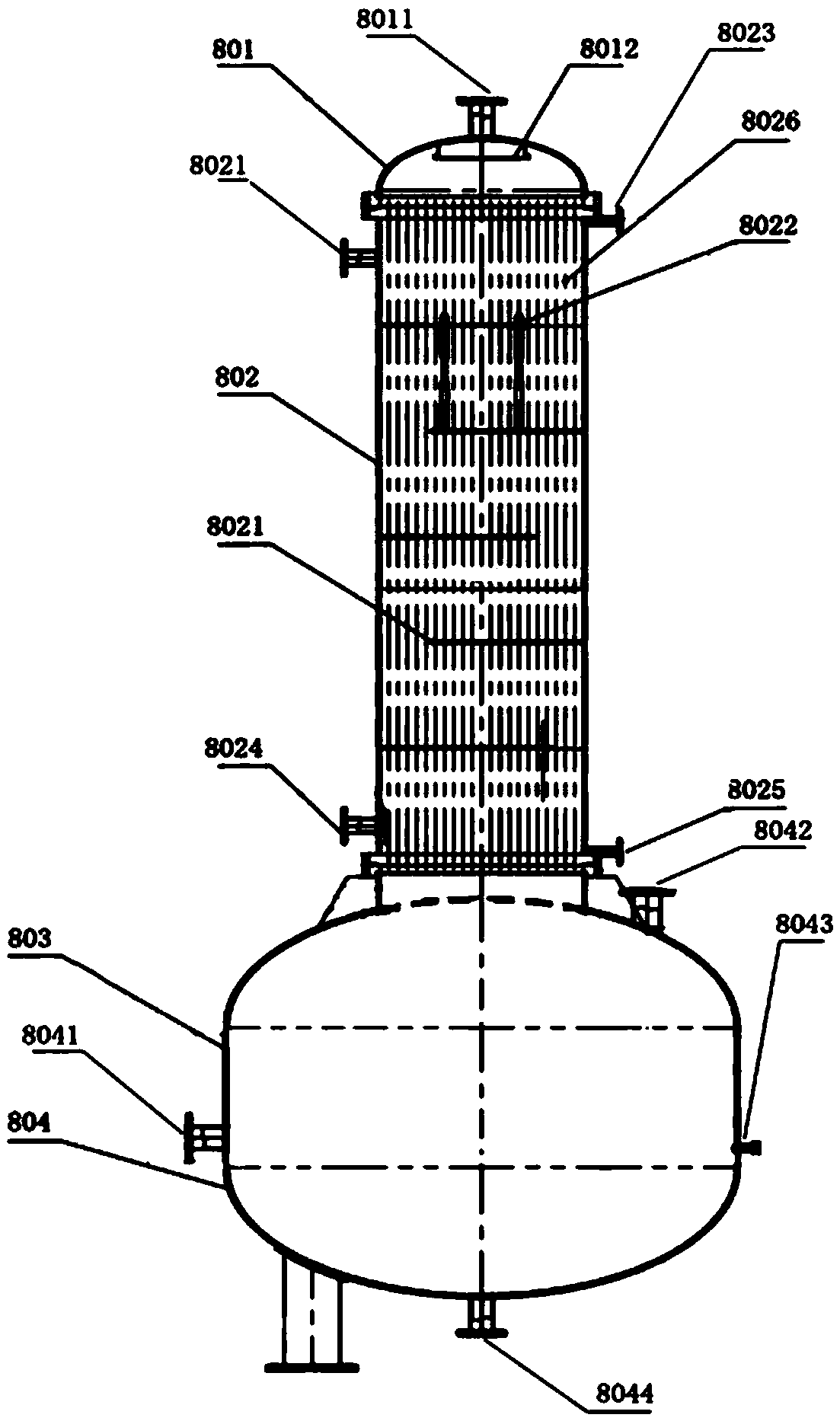

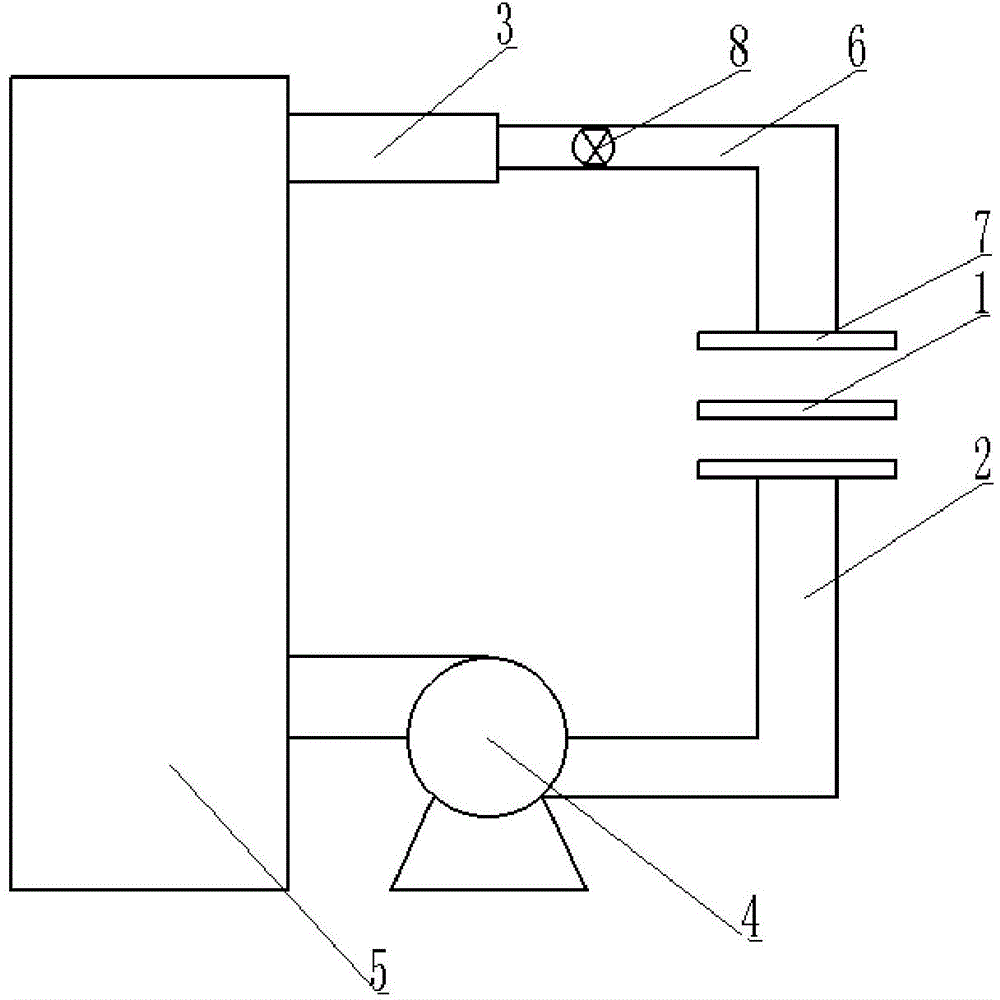

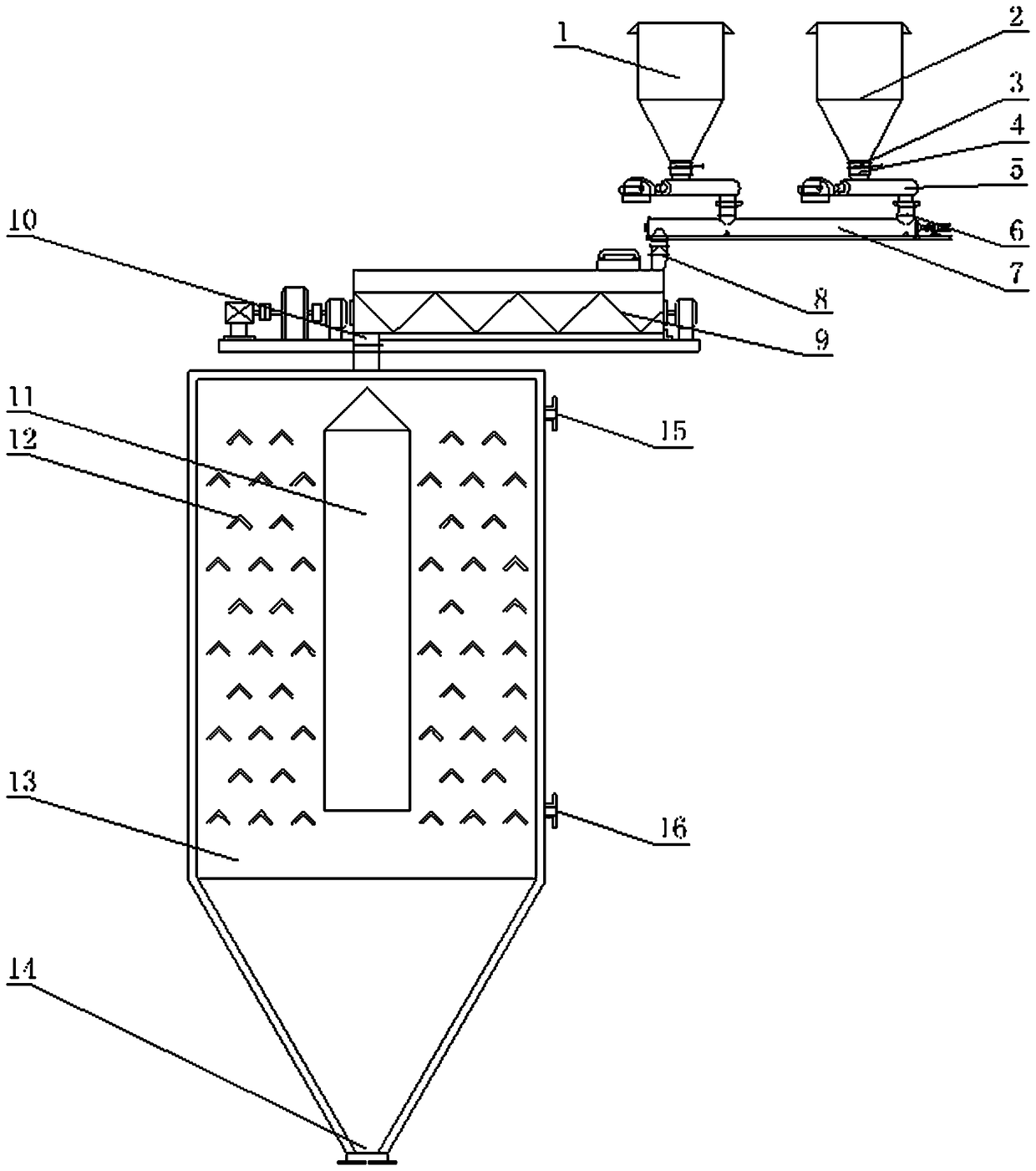

Equipment for preparing xylooligosaccharide

InactiveCN105505768AControllable reaction processImprove final product qualityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSlurry

The invention discloses equipment for preparing xylooligosaccharide. The equipment comprises smashing equipment, a preimpregnation tank, a cooking kettle, a blow tank, filtering equipment, diluting equipment, a slurry storage tank, a one-time hydrolysis tank, a first buffering tank, a slurry extrusion machine, a precipitating and decoloring tank, a second buffering tank, a falling-film evaporator, a third buffering tank and a blowing drying tower. According to the equipment for preparing the xylooligosaccharide, every stage of a reaction is directly buffered through one buffering tank, therefore, the whole reaction process is more controllable, and the quality of the final product is higher; in addition, the equipment of every stage is designed according to the characteristics of the product, and therefore the quality of the final product is higher.

Owner:FUJIAN HONG YU AN BIOTECH

Low pollution vanadium settling iron-removing wet zinc smelting method

ActiveCN100374592CHigh recovery rateReduce consumptionProcess efficiency improvementAcid concentrationZinc smelting

Owner:CHIFENG ZHONGSE ZINC IND CO LTD +1

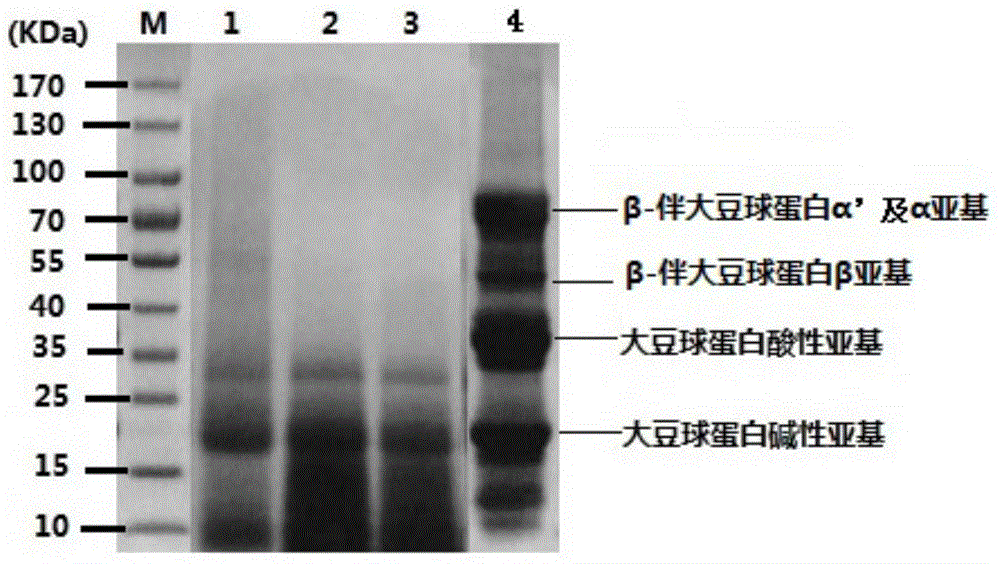

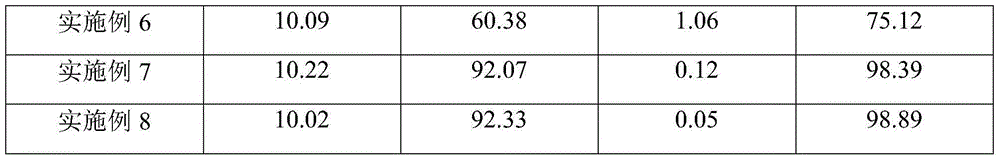

Fermented soybean peptides with low lipophilicity protein and production method of fermented soybean peptides

InactiveCN105410330AImprove qualityBreak through the shortcomings of easy settlementVegetable proteins working-upFood preparationSulfiteLipophilicity

The invention provides a production method of fermented soybean peptides with low lipophilicity protein. The production method comprises the following steps of (i) preparing fermented soybean protein from fermented soybean meal to obtain a fermented soybean protein solution; (ii) extracting the fermented soybean peptides from the fermented soybean protein solution to obtain an extracting solution of the fermented soybean peptides; (iii) adding sulfite into the extraction solution of the fermented soybean peptides, adjusting a pH value, performing solid-liquid separation so as to remove lipophilicity protein to obtain supernate of the fermented soybean peptides with low lipophilicity protein; and (iv) drying the supernate of the fermented soybean peptides with low lipophilicity protein to obtain the fermented soybean peptides with low lipophilicity protein.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Non-woven fabric lapping machine air supply mechanism

The invention discloses a non-woven fabric lapping machine air supply mechanism comprising a lapping machine curtain net; an air suction path is arranged below the lapping machine curtain net, and an air inlet path is arranged above the curtain net; the air suction path is connected with an air suction fan; an air suction fan pipe is connected with an air-conditioning processing chamber; an air-conditioning processing chamber pipe is connected with an air inlet pipe; the end of the air inlet pipe is provided with a plurality of branch air inlet tubes; air outlets of the branch air inlet tubes respectively face the lapping machine curtain net, and are respectively provided with an air uniform plate; a control valve is respectively arranged on each branch air inlet tube. Compared with the prior art, multi-air paths are employed to match with air uniform plates of different air outlet angles, and the machine can be opened and closed at any time according to production needs, thus improving net uniformity and intensity; the air uniform plates are prepared by honeycomb bore plates and ventilation plates of different bore density, so air force can be divided to form even air supply, and thus improving final production quality.

Owner:重庆九天无纺布有限公司

Curry steak and production method thereof

InactiveCN107874144AImprove qualityImprove final product qualityFood ingredientsSodium bicarbonateCarrageenan

The invention discloses a curry steak. The curry steak is characterized by comprising the following components in parts by weight: 100 parts of upper parts of chicken legs, 0.5 to 1 part of table salt, 1.2 to 2 parts of white granulated sugar, 0.6 to 0.7 part of aginomoto, 0.2 to 0.35 part of black pepper particles, 0.1 to 0.2 part of chili powder, 0.5 to 0.15 part of curry powder, 0.3 to 0.45 part of chicken paste, 25 to 40 parts of water, 0.6 to 1 part of soy sauce, 0.2 to 0.5 part of carrageenan, 0.3 to 0.45 part of mashed garlic, 0.1 to 0.3 part of citric acid, 0.12 to 0.25 part of inclusion garlic powder, 0.38 to 0.47 part of dashi no moto, 0.4 to 0.6 of spices, 3 to 5 parts of starch, 0.05 to 0.1 part of sodium hydrogen carbonate, 0.2 to 0.3 part of sodium tripolyphosphate, 0.15 to 0.25 part of sodium pyrophosphate, and 0.1 to 0.15 part of sodium hexametaphosphate. By adopting the technical scheme, the curry steak has the following beneficial effects that the curry powder enablesthe steak to have unique flavor; and in addition, by adding the auxiliary materials such as the citric acid, dashi no moto, sodium hydrogen carbonate, sodium tripolyphosphate, sodium pyrophosphate and sodium hexametaphosphate, the quality of the upper parts of chicken legs can be effectively improved, and the quality of the final product can be improved.

Owner:诸城外贸有限责任公司

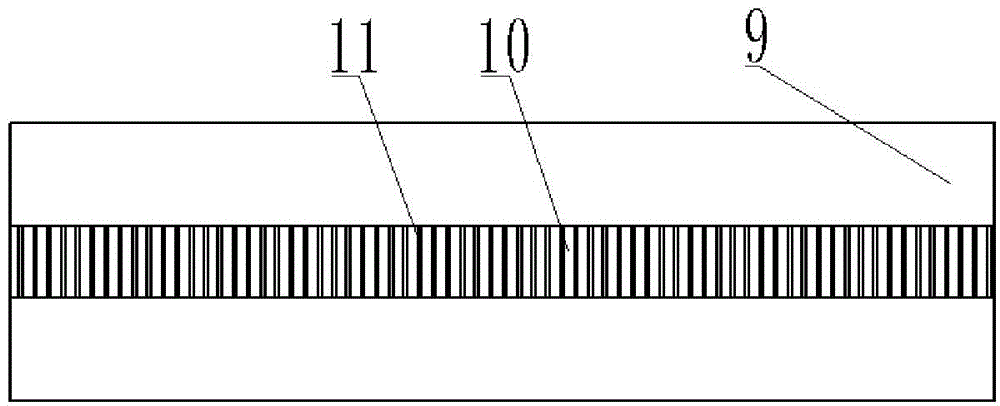

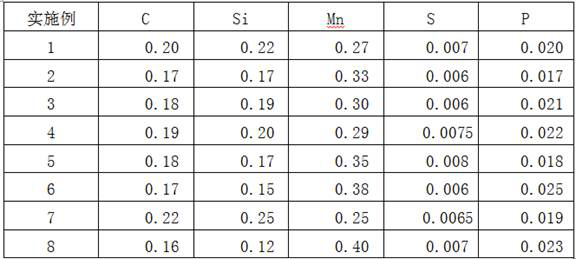

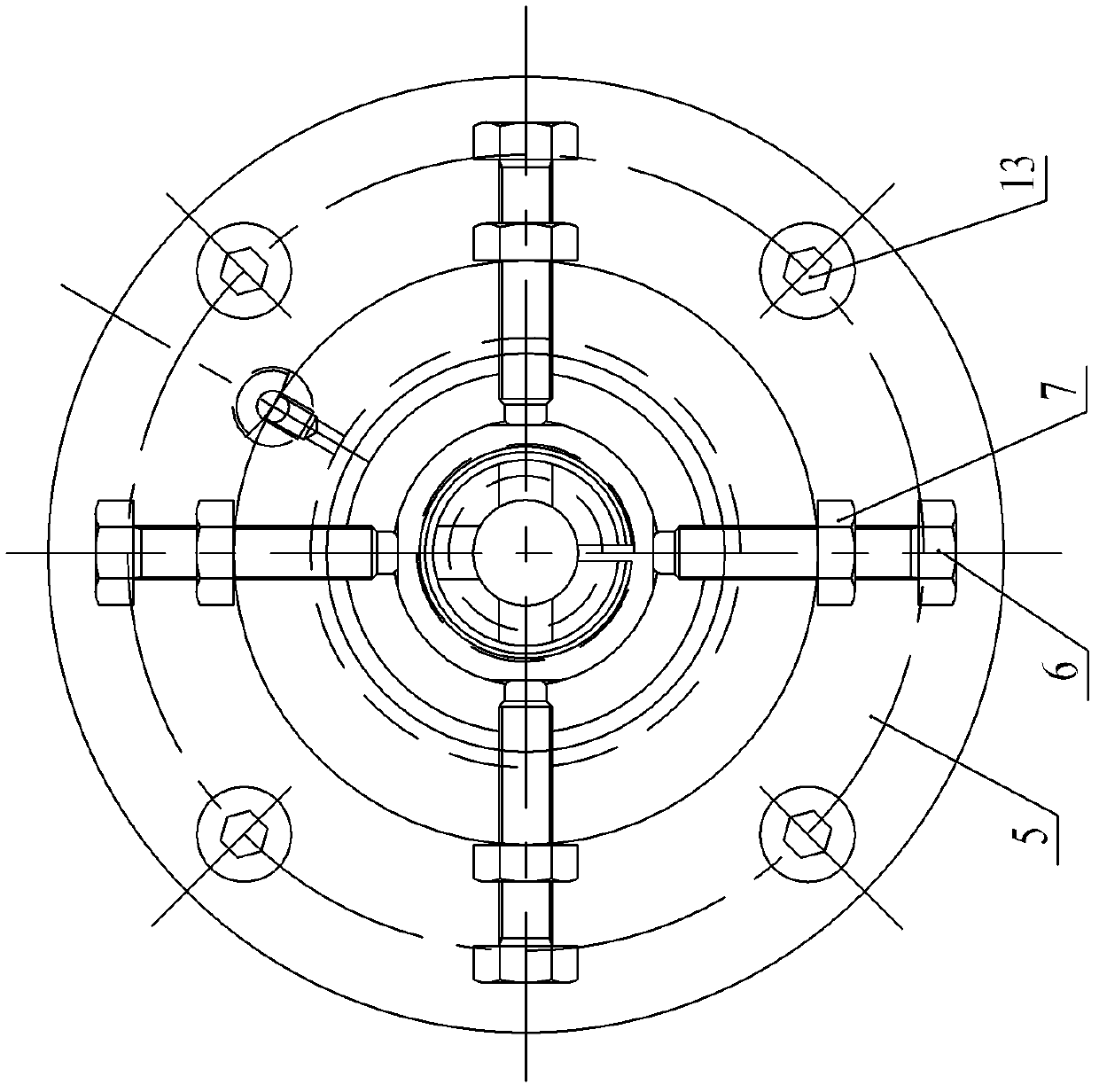

A continuous casting process for medium-carbon structural steel with low-sulfur content directly in converter

ActiveCN111041148BGood product qualitySolve nozzle nodulation and product surface defectsManufacturing convertersArgon flowThin slab

The invention discloses a process for continuous casting of medium-carbon structural steel with low sulfur content directly on a medium-thin slab. The pretreatment of molten iron uses the process of spraying magnesium powder. Lime powder of 3-7kg / t steel is added in advance in the iron ladle to control The composition of the end point of the converter is: C≥0.06%, S≤0.012%, P≤0.022%, and the end point temperature is 1670~1680°C; during the tapping process, ferrosilicon is used for deoxidation, silicon blending, high carbon ferromanganese blending manganese, and reasonable feeding is controlled Sequence and ladle argon stirring intensity, so that the final S of molten steel is ≤0.008%; control the continuous casting casting speed at 1.6-1.8m / min, use argon blowing stopper rod and argon blowing nozzle, and control the argon flow rate at 3-6L / min. The invention realizes the continuous casting process of medium-carbon structural steel with low sulfur content by blowing argon into the converter and solves the technical problems of nodules and product surface defects in the casting process of the medium-thin slab continuous casting process. The products produced The quality is good and meets the standards and user requirements.

Owner:TANGSHAN IRON & STEEL GROUP +1

Preparation method for raw material used for printing ink

The invention provides a preparation method for a raw material used for printing ink. The preparation method comprises the following steps: subjecting 60 to 90 parts by weight of deionized water, 100 to 150 parts by weight of mixed monomers and the first part of a composite emulsifier to pre-emulsification for 1 to 2 h so as to prepare a pre-emulsion; adding the second part of the composite emulsifier, 30 to 50 parts by weight of deionized water and 0.3 to 0.7 part by weight of sodium bicarbonate into a reaction vessel equipped with a stirrer, a thermometer, a reflux condensing tube and a constant-pressure dropping funnel, carrying out stirring and heating to 83 to 85 DEG C, and adding 3 to 15 wt% of the pre-emulsion and 1 / 3 of an initiator; and when a blue phase occurs, adding the rest pre-emulsion and an aqueous solution of the rest initiator drop by drop within 3 to 4 h, carrying out heating to 86 to 89 DEG C, maintaining the temperature for 3 to 5 h, then carrying out cooling to 42 to 45 DEG C, adjusting a pH value to 7 by using ammonia water and then carrying out filtering and discharging. The raw material prepared in the invention has good water dispersibility and improves the final product quality of the printing ink.

Owner:衡阳唯美印务有限公司

Die box component of wire drawing machine

Owner:WUXI CHANGXIN TECH

A chamfering grinding wheel and chamfering method for processing thick-layer epitaxial silicon single wafer

ActiveCN103394982BHigh edge contour accuracyConsistent edge qualityEdge grinding machinesSlip lineMicrometer

The invention relates to a chamfering grinding wheel for machining a silicon single crystal wafer for thick-layer epitaxy, and a chamfering method. The diameters of coarse chamfering grooves of the grinding wheel are 120-150 micrometers less than the thickness of the wafer; half angles are 18-22 degrees; the depths are 900-1100 micrometers; the diamond sizes are 600-1000#; the diameters of fine chamfering grooves are 160-180 micrometers less than the thickness of the wafer; half angles are 11 degrees; the depths are 1400-1600 micrometers; the diamond sizes are 1000-2000#; the rotating speed of the coarse chamfering grinding wheel is 2500-5000rpm; machining is conducted for 1-2 rings; the rotating speed of the wafer is 16-20mm / s; the rotating speed of the fine chamfering grinding wheel is 3000-5000rmp; machining is conducted for 2-4 rings; and the rotating speed of the wafer is 10-15mm / s. The edge chamfering is conducted on the wafer by adopting the chamfering grinding wheel, so that the accuracy of an edge contour is high, the consistency of the edge quality is good, and the problem of a slip line due to the defect of the edge of the silicon wafer in a growth process of the thick-layer epitaxy is solved effectively.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

A kind of industrial grade calcium hydroxide production equipment and its production process

The invention relates to industrial grade calcium hydroxide production equipment which comprises carbide slag bin, a lime bin, a feeding screw reamer, a dual-shaft stirrer and a digestion bin. The carbide slag bin and the lime bin are communicated with the feeding screw reamer. An outlet of the feeding screw reamer is communicated with a dual-shaft stirrer feeding inlet of the dual-shaft stirrer. A dual-shaft stirrer discharging outlet of the dual-shaft stirrer is communicated with the digestion bin. A discharging outlet is formed in the lower portion of the digestion bin. The digestion bin is sealed. According to the industrial grade calcium hydroxide production equipment, a traditional calcium hydroxide production technology is changed, a large amount of industrial waste carbide slag is utilized, calcium oxide is added to be mixed and stirred, the novel industrial grade Ca(OH)2 production technology is formed through procedures such as digestion of the digestion bin, a large amount of carbide slag can be utilized with low cost, the technology is widely applied to projects such as power plant desulfuration, and the technology is of special significance in China as the world first calcium carbide production country.

Owner:范洪喜

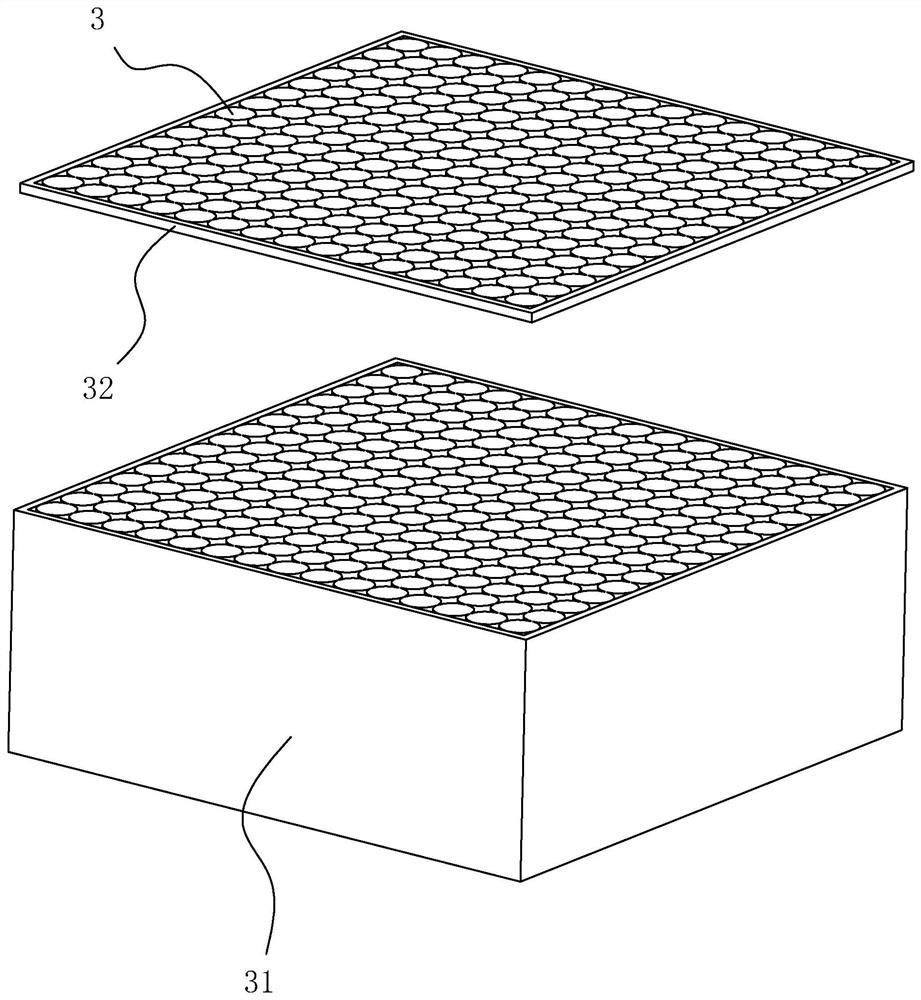

Knitted fiber sorting process and auxiliary fixture

ActiveCN112936929BImprove efficiencyImprove thermal conductivityFlat articlesFiberMechanical engineering

The present application relates to a knitted fiber sorting process and an auxiliary jig, which includes the following steps: S1, installing two layers of carriers on the auxiliary jig in parallel; S2, placing the auxiliary jig on the sewing equipment, and aligning the needles vertically Carrier; S3. The sewing equipment knits the full carrier vertically back and forth between the two layers of carriers; S4. Put the full carrier and auxiliary fixture into the container, pour the liquid colloid to heat and solidify; S5. Place the carrier along the edge of the effective part Cut out the prefabricated product; S6, cut the prefabricated product into a plurality of semi-finished products; S7, grind both sides of the semi-finished product to obtain the finished product. The fiber filaments in the finished thermal pad are parallel to each other in the thickness direction of the finished product and perpendicular to the horizontal direction, which greatly improves the use efficiency of the fiber filaments. At the same time, the two use surfaces of the finished thermal pad are directly connected through the fiber filaments. It has the effect of improving the thermal conductivity of the thermally conductive gasket.

Owner:SHENZHEN HFC SHIELDING PRODS CO LTD

Novel low-temperature-dried fermented soybean meal preparation method

ActiveCN103315143BReduce labor costsImprove labor efficiencyAnimal feeding stuffHeat sensitiveSoybean meal

Owner:ANHUI TECH BANK BIO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com