Low pollution vanadium settling iron-removing wet zinc smelting method

A zinc hydrometallurgy and low-pollution technology, applied in the direction of improving process efficiency, etc., can solve problems such as loss of zinc and valuable metals, unfavorable alum slag storage, difficult operation, etc., to enhance the ability to remove impurities , Improve metal recovery rate and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

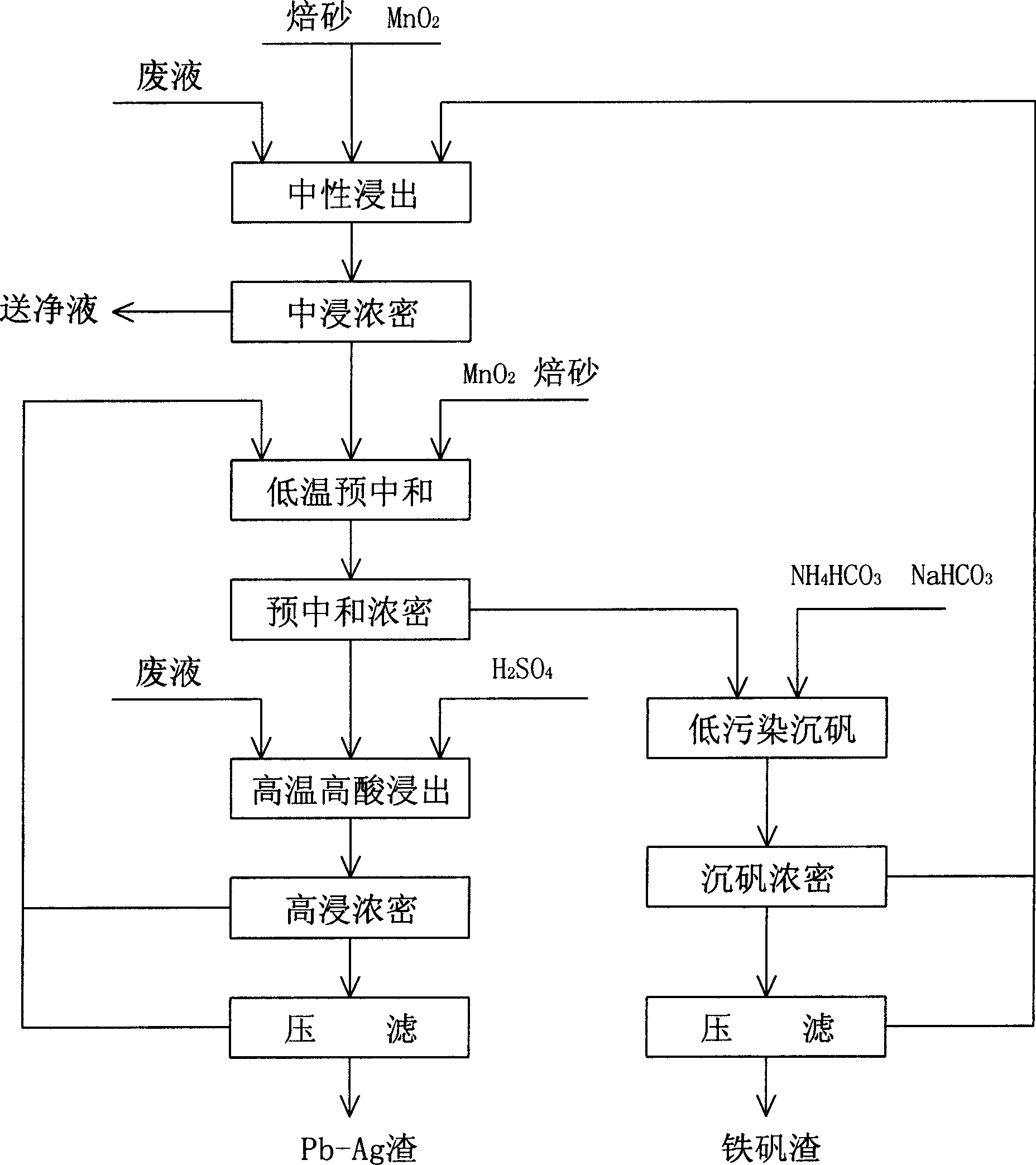

[0037] Embodiment 1: as figure 1 As shown, the present invention's low-pollution sinking alum and iron-removing zinc hydrometallurgy method mainly comprises four processing steps:

[0038] (1) Neutral leaching: Pour the sinking alum overflow solution and waste electrolyte into the oxidation tank continuously, and add manganese dioxide according to the ferrous content, control the acidity to 40-50g / L, and control the iron content to 1-2g / L. The liquid and calcined sand in the oxidation tank are poured into the intermediate immersion tank continuously, the pH of the ore slurry in the intermediate immersion tank is controlled to be 5.0-5.4, the solid-liquid ratio is 1:12-14, the temperature is 65-72°C, and the time is 1-1.2h. Neutral leaching overflow liquid and neutral leaching underflow liquid are produced through intermediate leaching thickening.

[0039] (2) Low-temperature pre-neutralization: Put the neutral leaching underflow liquid and the high-temperature high-acid lea...

Embodiment 2

[0042] Embodiment 2: process step is identical with embodiment 1, and process parameter is as follows:

[0043] (1) Neutral leaching: control the solid-liquid ratio of 1:8~10, the initial acidity is 35~40g / L, the iron content is controlled at 1~2g / L, the pH of the pulp in the intermediate leaching tank is 4.8~5.2, and the temperature is 55~ 65 ℃, time 1.5 ~ 2h.

[0044] (2) Low-temperature pre-neutralization: control the solid-liquid ratio to 1:6-8, the initial acidity is 35-38g / L, the final acidity is 9-15g / L, the reaction temperature is 55-62°C, and the reaction time is 1.2-1.5h.

[0045] (3) High-temperature and high-acid leaching: control the solid-liquid ratio to 1:6-9, the initial acidity is 140-150g / L, the final acidity is 55-65g / L, the reaction temperature is 90-95°C, and the reaction time is 3.8-4.2h.

[0046] (3) Low-pollution sinking alum for iron removal: control the solid-liquid ratio to 1:8-10, the initial acidity is 10-12g / L, the end-point Fe≤2g / L, the reaction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com