Novel low-temperature-dried fermented soybean meal preparation method

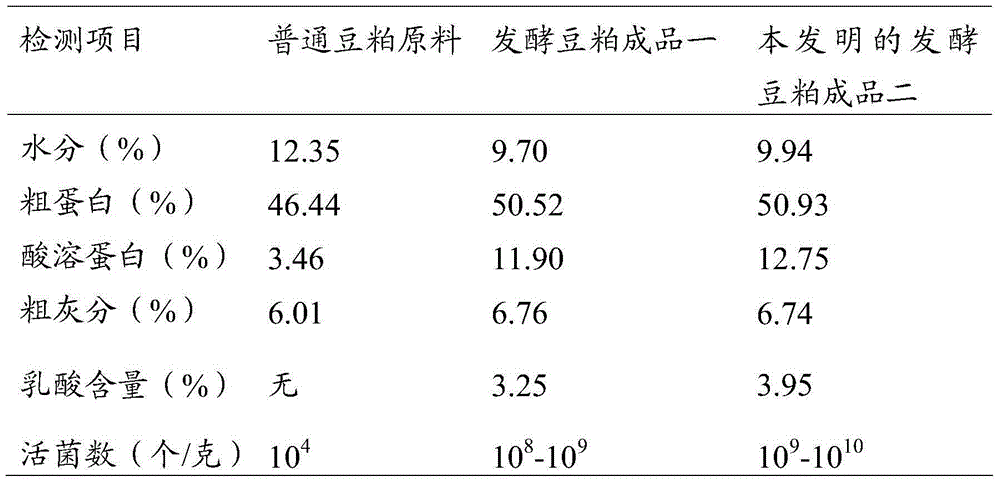

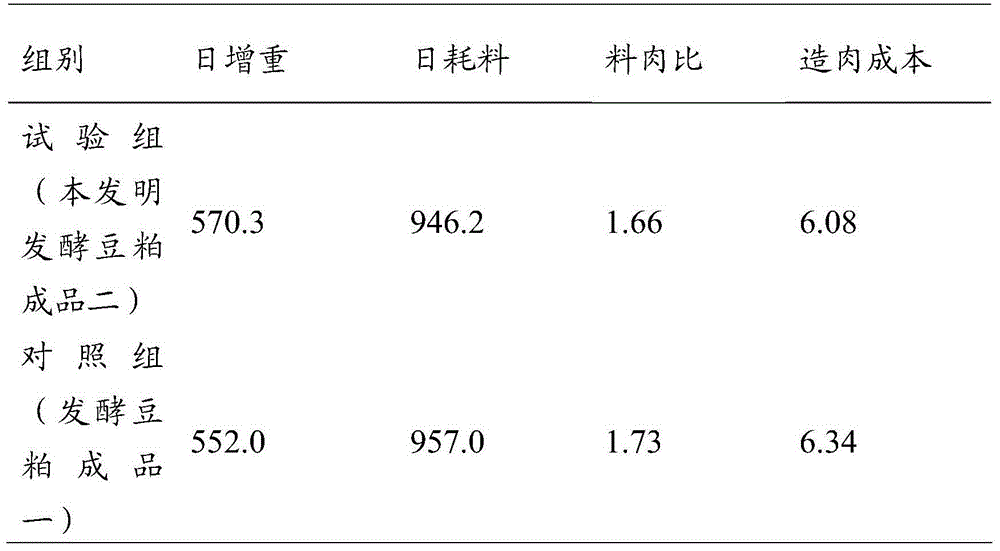

A fermented soybean meal and drying technology is applied in the field of new low-temperature dry fermented soybean meal, which can solve the problems of unfermentable soybean meal feed value, bacterial contamination, loss of heat-sensitive substances, etc., to provide feed and nutritional value, save labor costs, The effect of product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

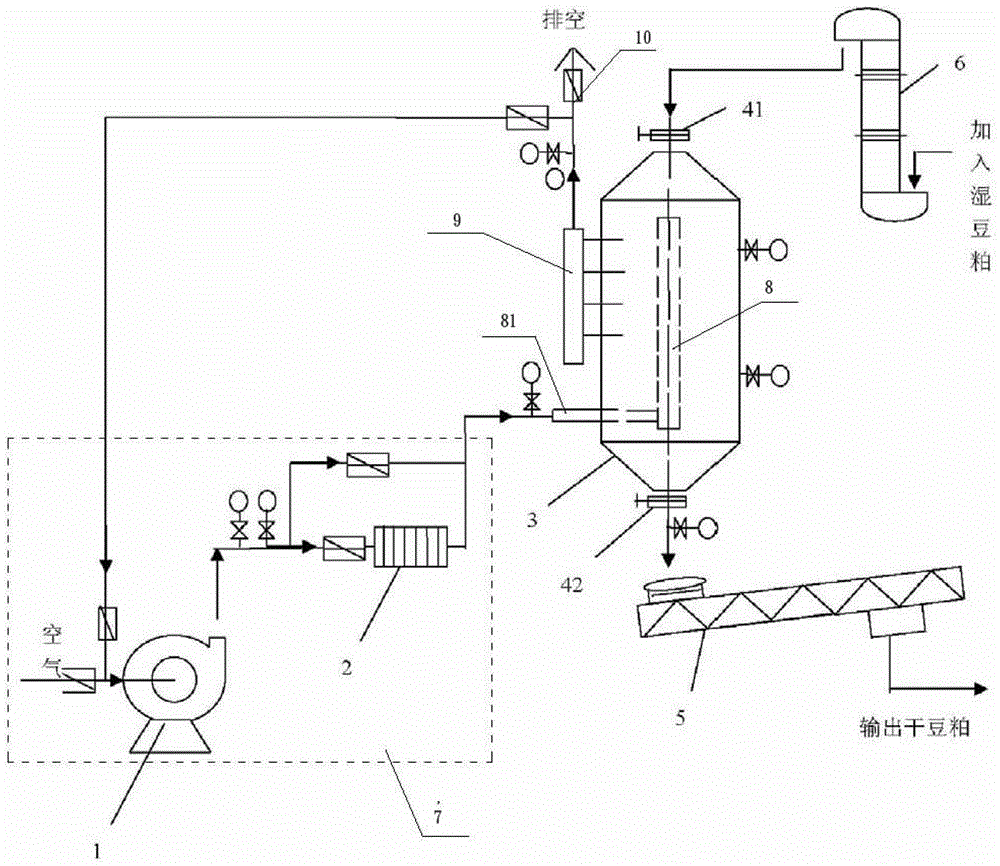

Method used

Image

Examples

Embodiment 1

[0024] Carry out following steps successively to prepare a kind of novel low-temperature dry fermented soybean meal of the present invention:

[0025] Step 1. Inoculate the three strains of Bacillus, lactic acid bacteria and yeast into the solid medium for activation culture respectively; then inoculate the colonies on the solid medium into the seed liquid medium for cultivation, and the culture conditions are as follows: Bacillus The culture temperature is 30-37°C, the rotation speed is 100-200r / min; the lactic acid bacteria are cultured at a constant temperature of 30-35°C, and the yeast are cultured at a constant temperature of 30-35°C; is 3-10%, and the culture conditions are the same as above) for 1-2 days; Bacillus bacterium liquid, lactic acid bacteria bacterium liquid and saccharomyces bacterium liquid are prepared for fermentation; : 3-7*10 9 pcs / g, lactic acid bacteria: 5-10*10 9 pcs / g, yeast: 3-8*10 8 pcs / g.

[0026] Step 2, taking the bacterial liquid prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com