Automatic ring-crossing and welding system of double-sided buzzer

A welding system and buzzer technology, applied in the field of double-sided buzzer automatic ring-piercing welding systems, can solve the problems of difficulty in recruiting, scratches on the double-sided buzzer, and the influence of double-sided buzzer welding, and reduce the cost, improve work efficiency, and the effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

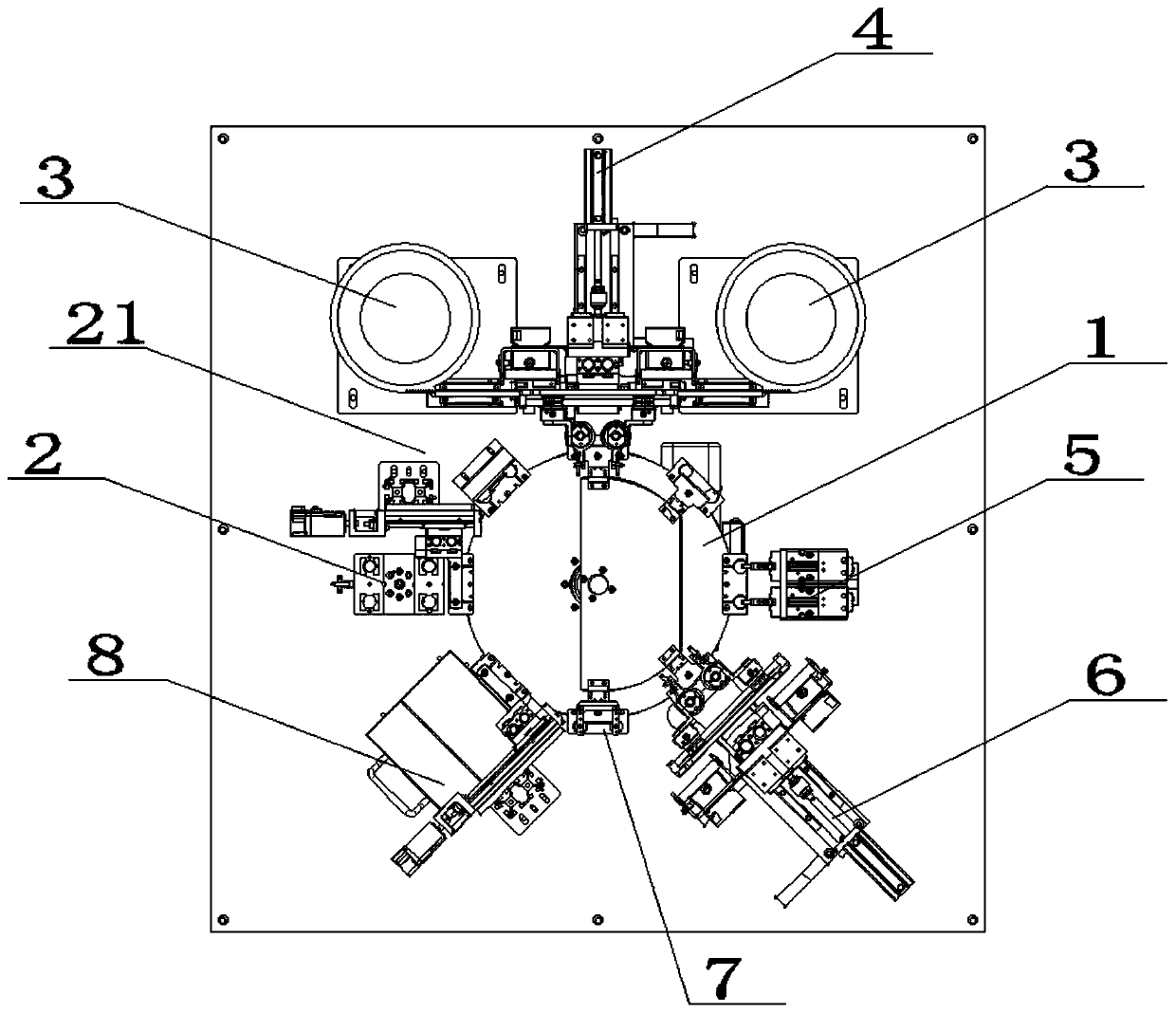

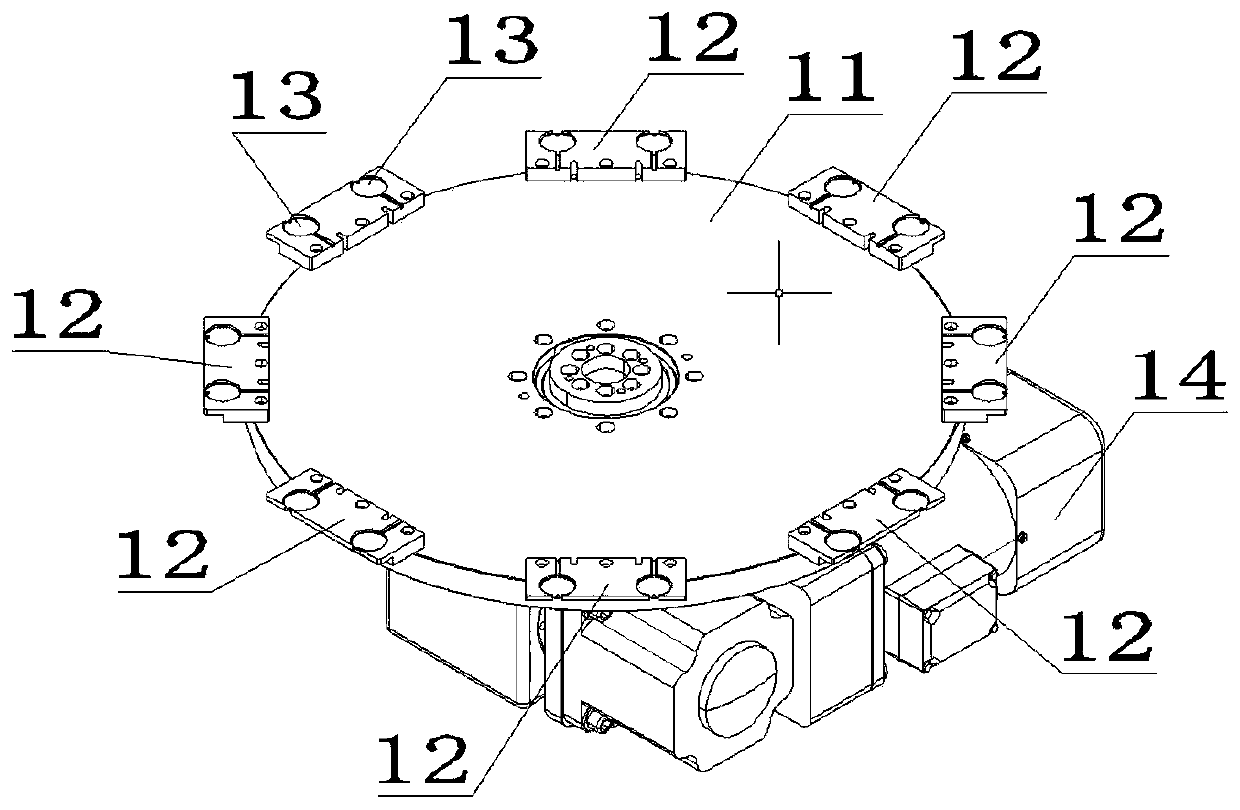

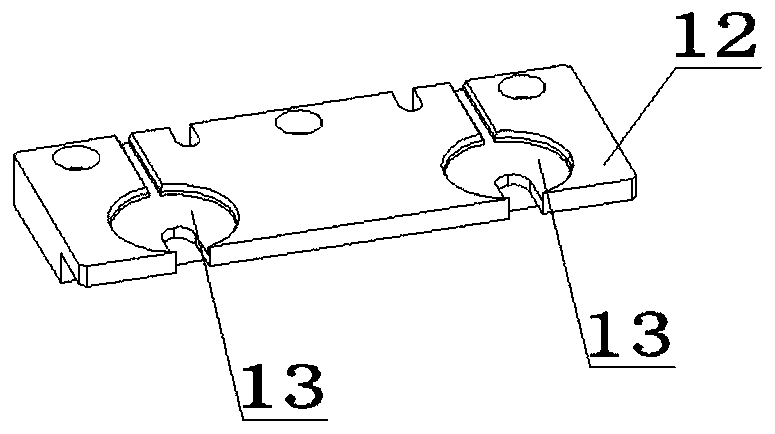

[0035] Embodiment: a kind of double-sided buzzer sheet automatic piercing welding system, as attached figure 1 As shown, the automatic ring-piercing welding system includes a rotating mechanism 1, a feeding mechanism 2, a detection mechanism 21, an inserting ring mechanism 3, a first welding mechanism 4, a turning mechanism 5, a second welding mechanism 6, a testing mechanism 7, and a sorting mechanism 8. The rotating mechanism 1 includes a rotating disk 11 and several positioning pieces 12; the circumferential edge of the rotating disk 11 is equiangularly equipped with positioning pieces 12, the feeding mechanism 2, the detection mechanism 21, the inserting ring mechanism 3, and the first welding mechanism 4 , turning mechanism 5, second welding mechanism 6, testing mechanism 7 and sorting mechanism 8 are installed around the outer circumference of the rotating disk 11 in turn, wherein the inserting ring mechanism 3 and the first welding mechanism 4 jointly align the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com