Method for producing citric acid through complete cassava fermentation

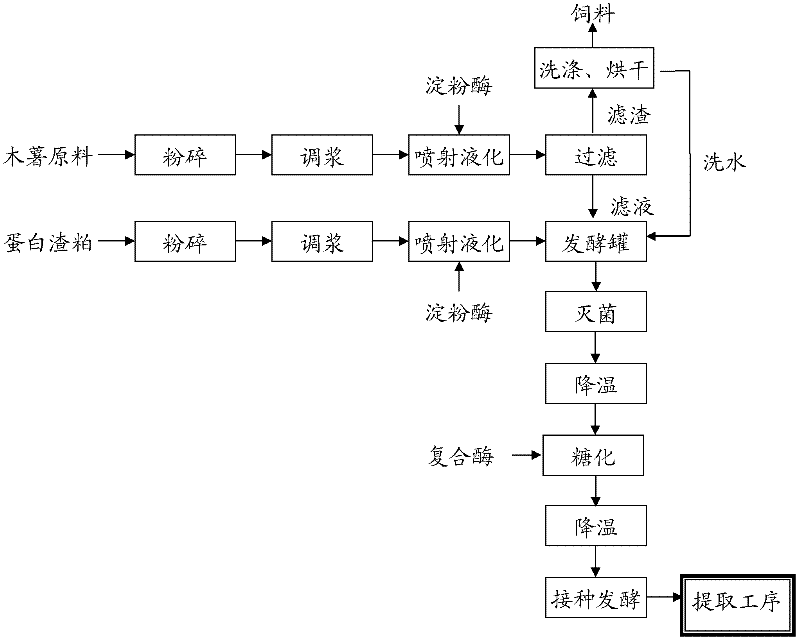

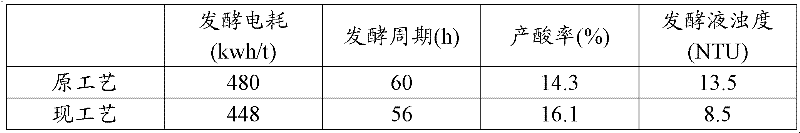

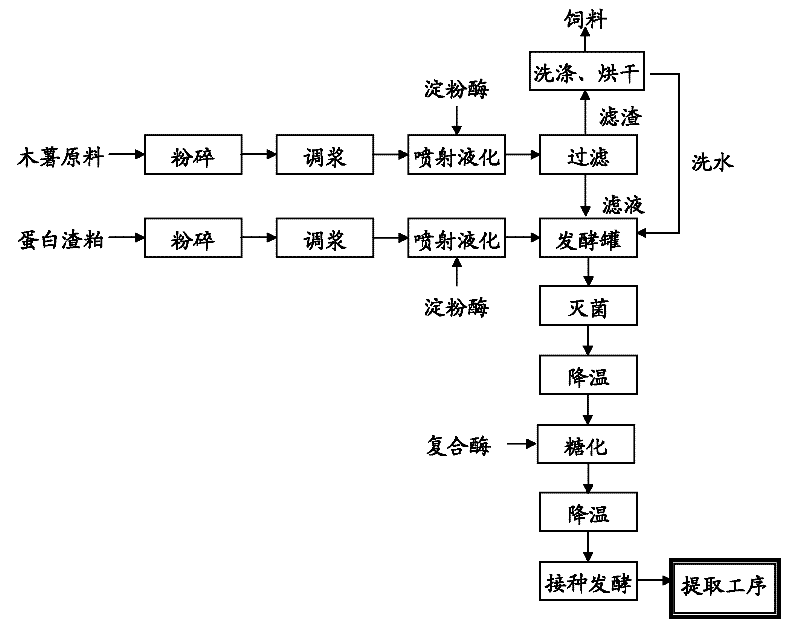

A technology of citric acid and cassava, which is applied in the field of fermentation to produce citric acid, can solve the problems of incomplete saccharification, low concentration of fermentation substrate, and long fermentation cycle, and achieve the goal of improving the quality of the final product, increasing the conversion rate of fermentation, and shortening the fermentation cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for cassava fermentation to produce citric acid, the main steps of which include:

[0041] (1) Take cassava raw material 3000kg, be ground into cassava flour, cross 60 mesh sieves;

[0042] (2) Add water to the pulverized cassava flour, and adjust the pulp. The mass ratio of cassava flour to water is 1:3

[0043] (3) Add high-temperature α-amylase for liquefaction; the jet liquefaction temperature is 90° C., the maintenance time is 2 hours, and the amount of amylase added is 0.3‰ of the cassava flour quality;

[0044] (4) the cassava pulp after liquefaction is filtered by adopting a pressurized drum filter, the filtrate is retained, and the filter residue is made into feed;

[0045] (5) Take by weighing 100kg of protein dregs (35% protein content) produced by corn processing in our company's citric acid production process, and pulverize it, and the pulverized corn dregs particle size is 0.5-0.9mm;

[0046] (6) Add water to the pulverized protein slag, adjust ...

Embodiment 2

[0054] A method for cassava fermentation to produce citric acid, the main steps of which include:

[0055] (1) Take cassava raw material 3000kg, be ground into cassava flour, cross 60 mesh sieves;

[0056] (2) Add water to the pulverized cassava flour, and adjust the slurry, the mass ratio of cassava flour and water is 1: 3;

[0057] (3) adding high-temperature α-amylase for liquefaction; the jet liquefaction temperature is 100° C., the maintenance time is 1 h, and the amount of amylase added is 0.2‰ of the cassava flour quality;

[0058] (4) the cassava pulp after liquefaction is filtered by adopting a pressurized drum filter, the filtrate is retained, and the filter residue is made into feed;

[0059] (5) Take by weighing 115kg (protein content 30%) of waste residue from the corn processing industry purchased from outside, pulverize it, and the particle diameter of waste residue after pulverization is 0.5-0.7mm;

[0060] (6) Add water to the crushed waste residue, adjust t...

Embodiment 3

[0068] A method for cassava fermentation to produce citric acid, the main steps of which include:

[0069] (1) Take cassava raw material 3000kg, be ground into cassava flour, cross 60 mesh sieves;

[0070] (2) Add water to the pulverized cassava flour, and adjust the slurry, the mass ratio of cassava flour and water is 1: 3;

[0071] (3) adding high-temperature α-amylase to carry out liquefaction; the jet liquefaction temperature is 105°C, the maintenance time is 1h, and the addition of amylase is 0.4‰ of the quality of cassava flour;

[0072] (4) The cassava pulp after liquefaction is filtered by adopting a chamber filter press, retaining the filtrate, and the filter residue is made into feed;

[0073] (5) Weigh 200kg of protein sprayed fiber or DDGS or corn germ meal (about 18% protein content) in the corn processing industry, and pulverize it, and the pulverized protein slag particle size is 0.1-0.5mm;

[0074] (6) Add water to the pulverized protein slag, adjust the slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com