Production and extraction technology of L-isoleucine

A technology of isoleucine and extraction process, applied in the direction of biochemical equipment and methods, microorganisms, chemical instruments and methods, etc., can solve the problems of reagent consumption, production waste, increase process complexity and workload, etc., and achieve product saving Cost, increase fermentation yield, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A production and extraction process of L-isoleucine, which comprises the following steps:

[0036] Step 1): Cultivate Corynebacterium glutamicum (CGMCC NO.12153, donated by Tianjin University of Science and Technology) to a concentration of 5×10 8 The CFU / mL seed solution was then inoculated into the fermentation medium according to 10% inoculation amount, and fermented for 72 hours. The fermentation culture conditions were: temperature 30°C, dissolved oxygen 30%, pH 6.5-6.8, to obtain L- Isoleucine fermentation broth; the components of the fermentation medium are: glucose 120 g / L, (NH 4 ) 2 SO 4 20g / L, FeSO 4 ·7H 2 O 0.015 g / L, MgSO 4 ·7H 2 O 0.4 g / L, MnSO 4 ·H 2 O 0.015 g / L, KH 2 PO 4 2.2 g / L, K 2 HPO 4 1.0 g / L, VH 80 μg / L, VB 1 2.5mg / L, Met30mg / L, Glu 20mg / L, Inositol 20mg / L;

[0037]Step 2): Pass the L-isoleucine fermentation broth through a ceramic membrane (20nm) to remove bacterial protein; membrane filtration operating temperature: 45°C, workin...

Embodiment 2

[0045] A production and extraction process of L-isoleucine, which comprises the following steps:

[0046] Step 1): Cultivate Corynebacterium glutamicum (CGMCC NO.12153, donated by Tianjin University of Science and Technology) to a concentration of 5×10 8 CFU / mL seed liquid, then inoculated into the fermentation medium according to 10% inoculation amount, and fermented for 75 hours. The fermentation culture conditions were: temperature 30°C, dissolved oxygen 30%, pH 6.5-6.8, to obtain L- Isoleucine fermentation broth; the components of the fermentation medium are: glucose 160 g / L, (NH 4 ) 2 SO 4 30 g / L, FeSO 4 ·7H 2 O 0.015 g / L, MgSO 4 ·7H 2 O 0.4 g / L, MnSO 4 ·H 2 O 0.015 g / L, KH 2 PO 4 2.2 g / L, K 2 HPO 4 1.0 g / L, VH 80 μg / L, VB 1 2.5mg / L, Met30mg / L, Glu 20mg / L, Inositol 20mg / L;

[0047] Step 2): Pass the L-isoleucine fermentation broth through a ceramic membrane (50nm) to remove bacterial protein; membrane filtration operating temperature: 50°C, working press...

Embodiment 3

[0055] Taking 200L fermentation medium as an example, a total of 6.53kg of L-isoleucine product was obtained. The appearance of the product is white and translucent. The purity is 99.4%.

[0056] The present invention also detects the influence of culture medium and culture time on the concentration of L-isoleucine in the fermentation broth.

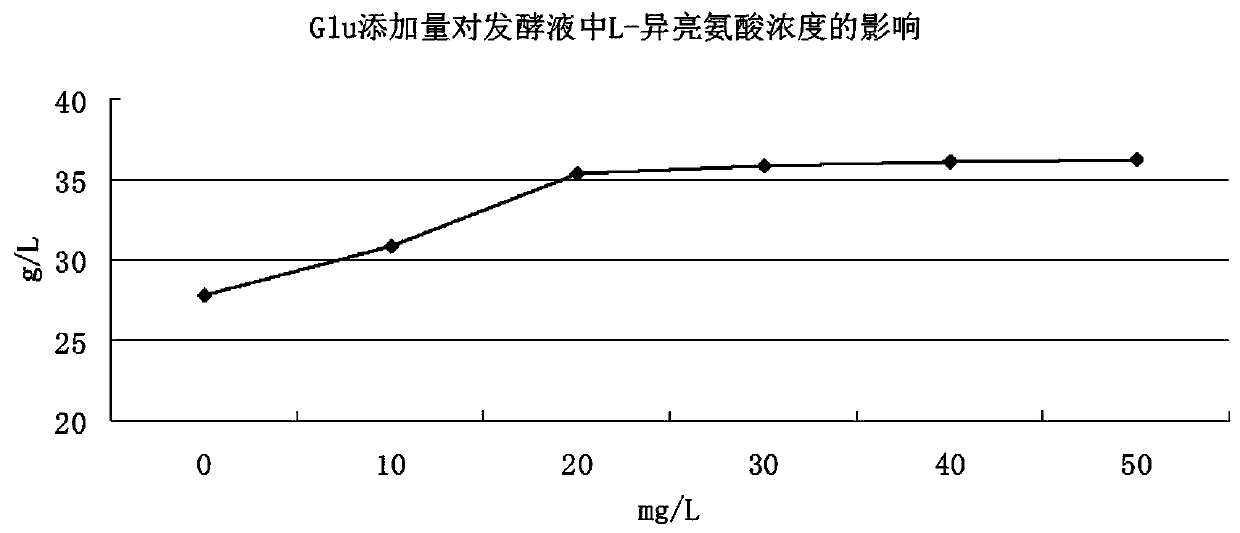

[0057] Taking Example 1 as the experimental group, set the Glu concentration in the medium to 0, 10, 20, 30, 40, 50 (mg / L), such as figure 1 As shown, with the increase of Glu concentration, the output of L-isoleucine increased significantly, when the Glu concentration increased to 20mg / L, the concentration of L-isoleucine did not change significantly, considering the increase in production and economic factors , choose the most appropriate content of 20mg / L.

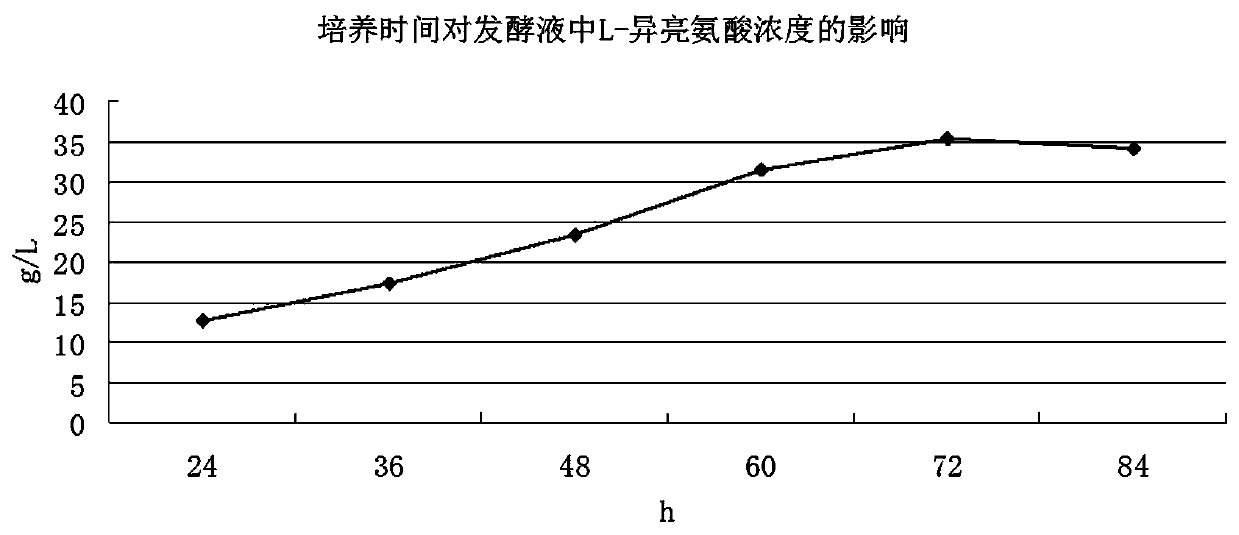

[0058] Set the time of fermentation culture as 24, 36, 48, 60, 72, 84 (h), pass figure 2 Visible, along with the increase of fermentation time, the concentration increase of L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com