Knitted fiber sorting process and auxiliary fixture

A knitting and fiber technology, applied in the field of knitting fiber sorting process and auxiliary fixtures, can solve the problems of low carbon fiber orientation and inability to increase thermal conductivity, and achieve the effects of improving thermal conductivity, eliminating air bubbles, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

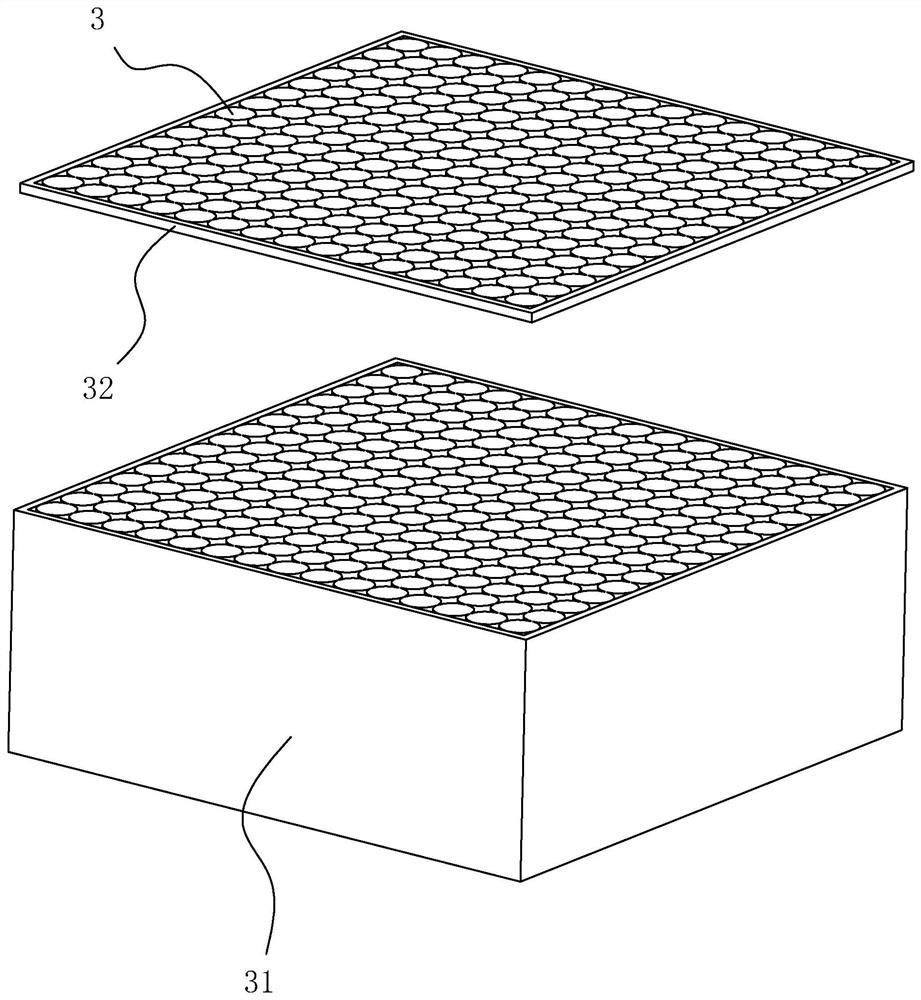

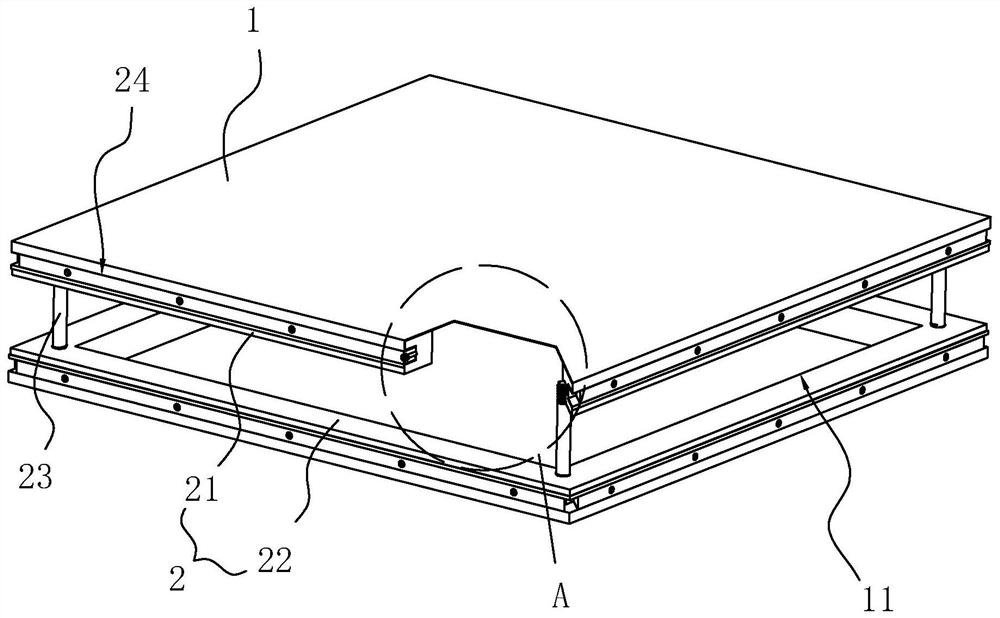

[0044] Attached to the following Figure 1-6 This application will be described in further detail.

[0045] The embodiments of the present application disclose a knitted fiber sorting process.

[0046] refer to figure 1 , the knitted fiber sorting process includes the following steps:

[0047] S1, refer to figure 2 , 3 , adjust the height of the auxiliary fixture 2 according to the thickness of the single-piece thermal conductive gasket for the number of thermal conductive gaskets to be processed, and then use two carriers 1 to cover the top and bottom walls of the auxiliary fixture 2 respectively, and Connect and fix with auxiliary fixture 2. When covering the carrier 1, it is necessary to keep the carrier 1 in the area to be filled 11 hollowed out in the middle of the auxiliary fixture 2 flat.

[0048] S2, refer to image 3 , 5 , the auxiliary jig 2 is installed, and the auxiliary jig 2 with the carrier 1 is installed on the sewing equipment 4 . The sewing equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com