Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Change the production method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

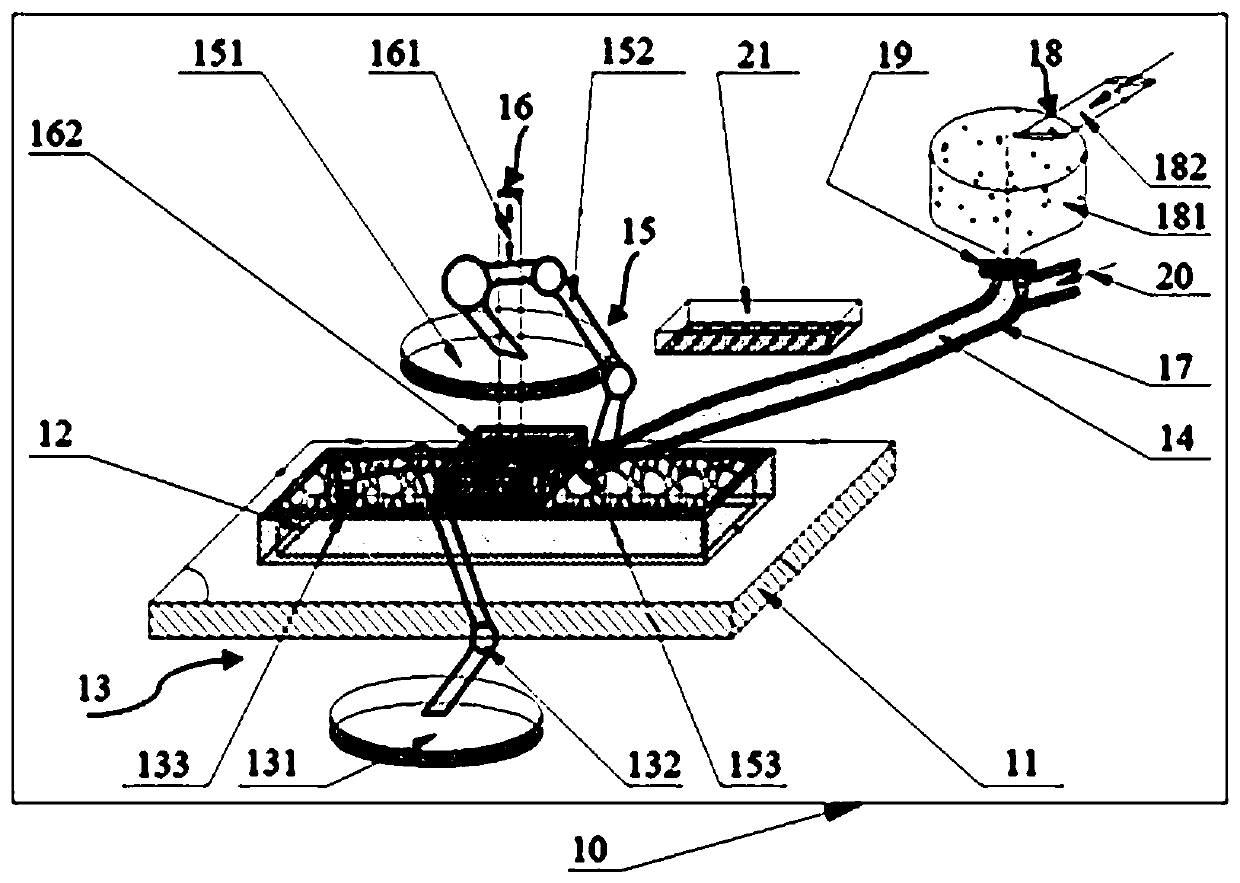

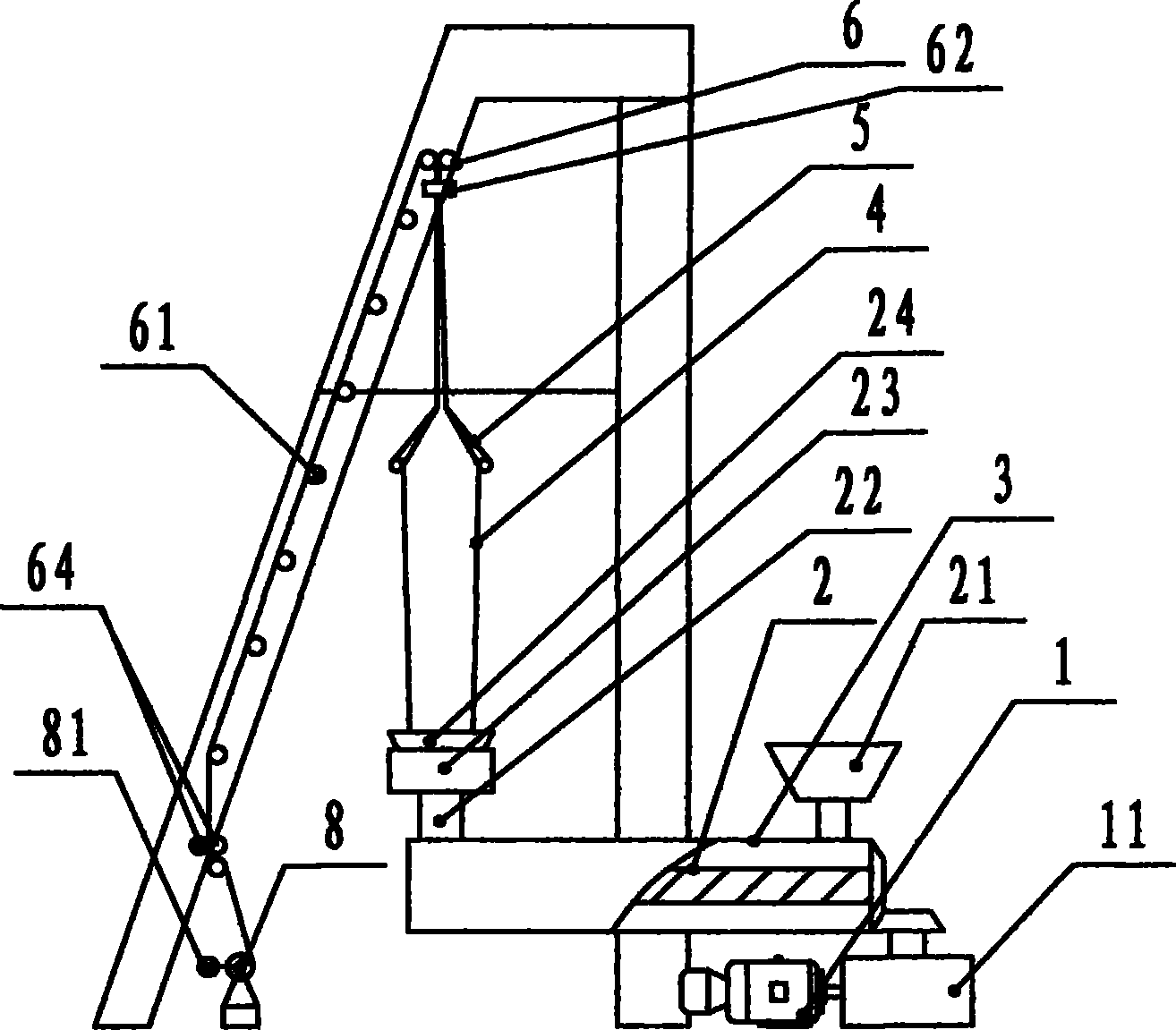

Method and system for high speed laser directly writing of diffraction light change image

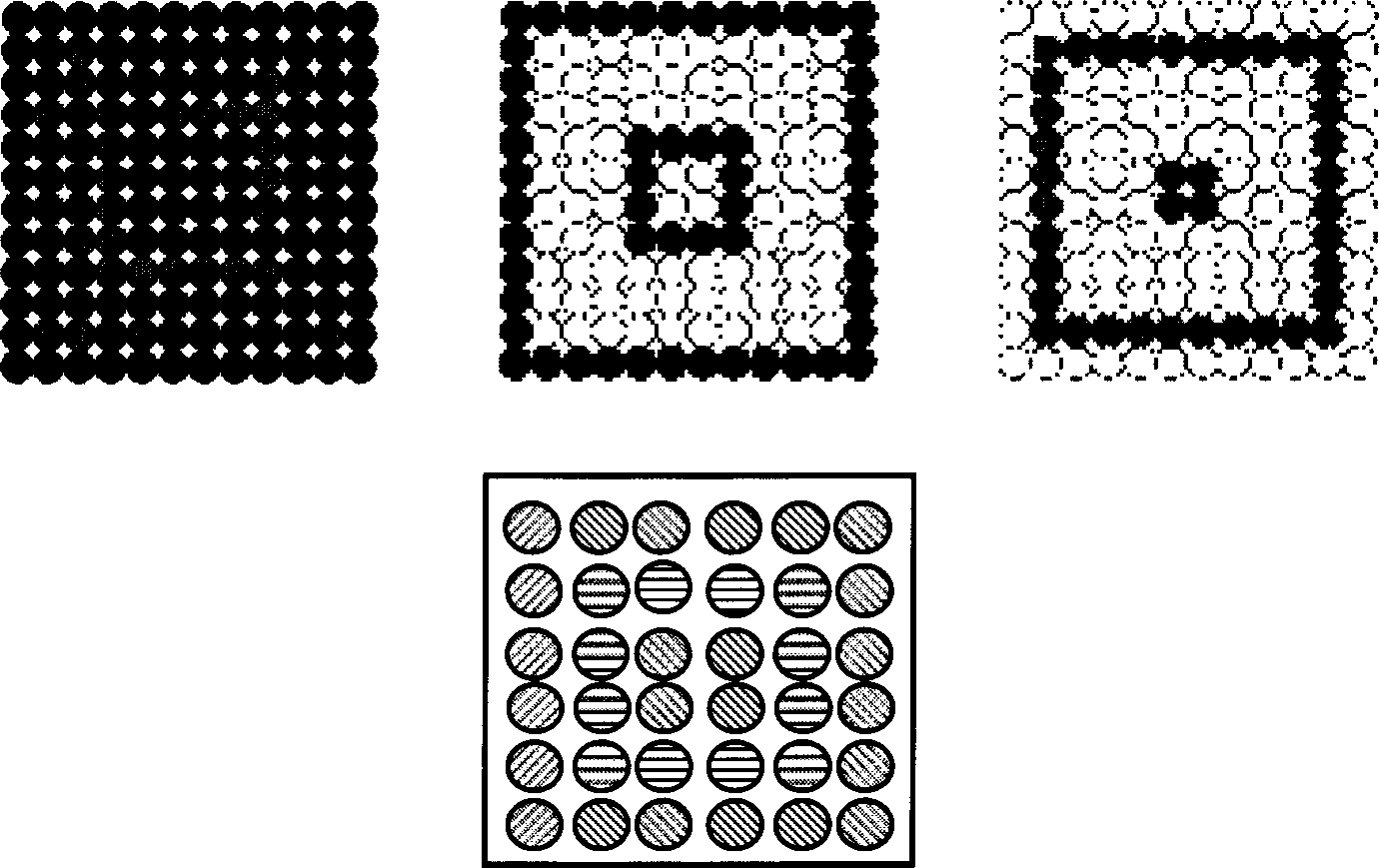

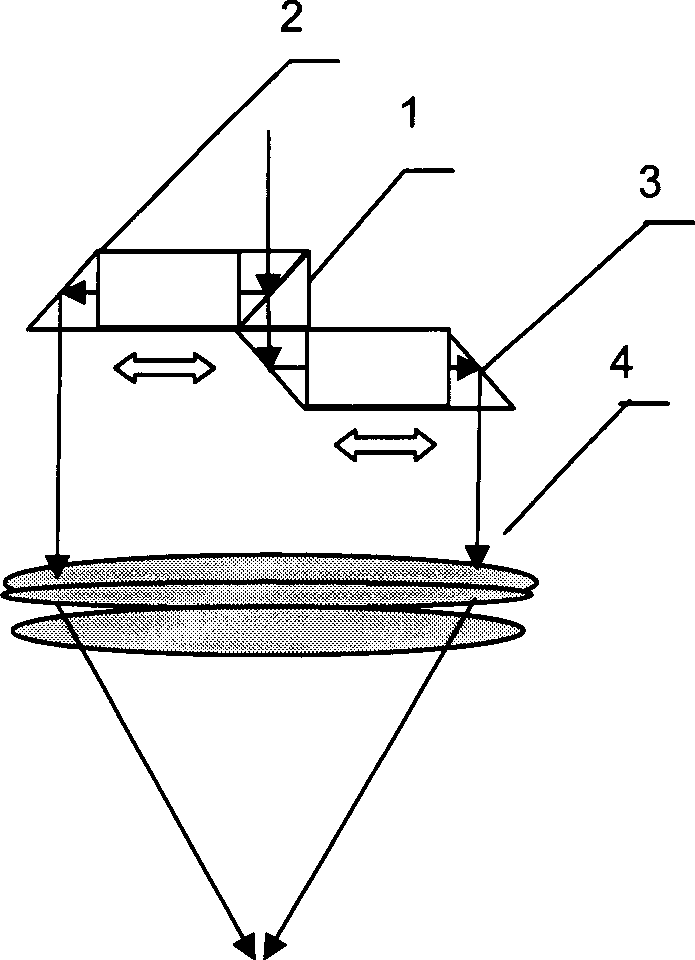

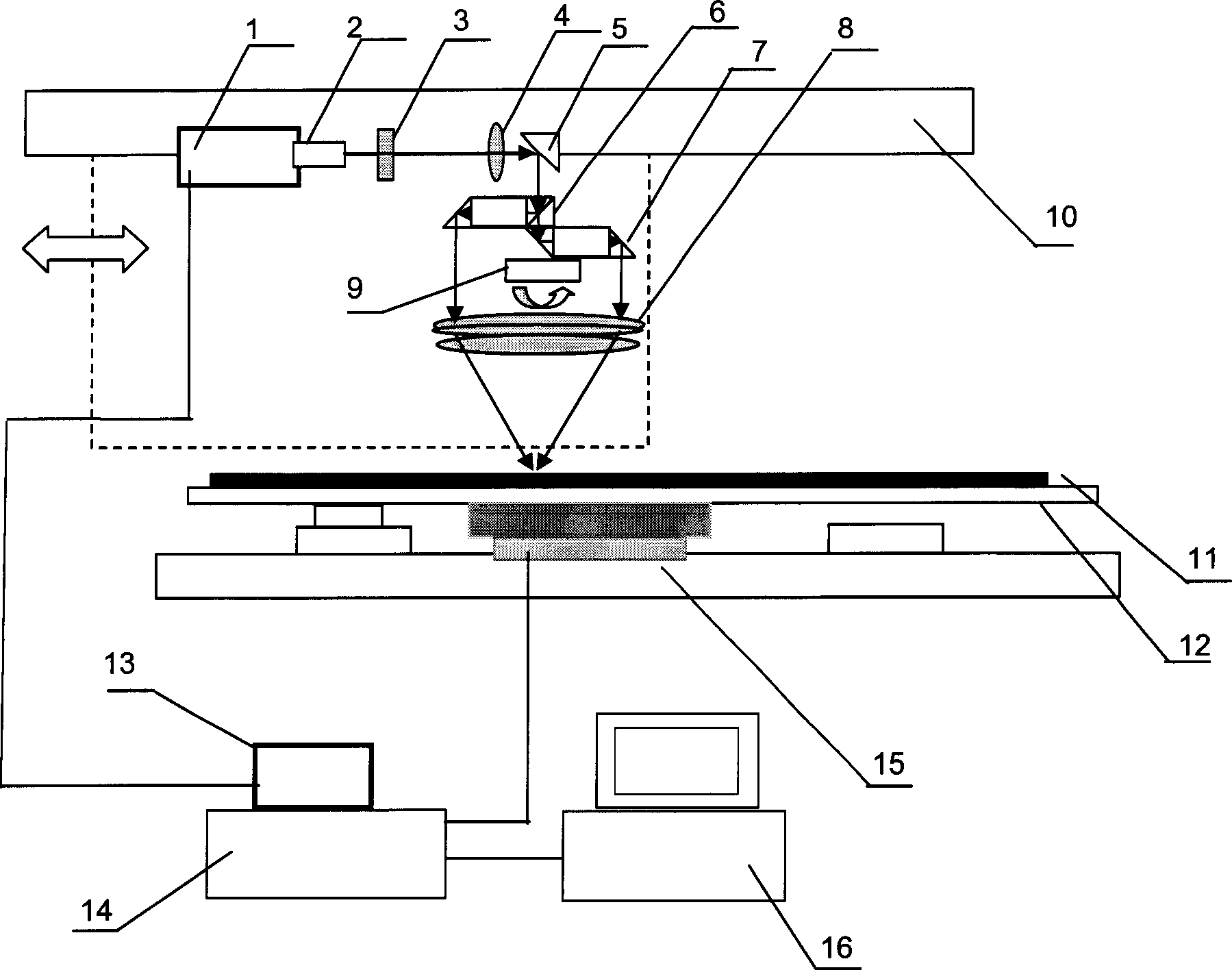

ActiveCN1786748ADistance controlEasy to adjustDiffraction gratingsNon-linear opticsGratingBeam splitting

The invention relates to diffracted light image changing high speed laser write through method. It includes the following steps: do electrostatic image for incidence parallel light reaches beam-splitting element though diaphragm; gathering the beam-slitting light to produce interference fringe optical field; orderly photoengraving interference fringe with different trend to form micro light grating image. Its features are that it is adopted solid state ultraviolet laser to produce laser beam; and it is used TTL signal control to realize laser beam pulse output; the two sets of the laser beam have zero optical path difference; optical system and photoresist dry plate are moved on two one dimension directions which are vertical with each other; photolithography is adopted continual motion, continual pulse exposing type. Thus the invention realizes high speed laser write through photolithography system to make diffracted light changing image original edition manufacturing shorten between many hours to seventeen hours. It really enters industrialization application period, and is the important breakthrough of digitalization advanced manufacturing technique in laser holographic technique field.

Owner:SUZHOU UNIV +1

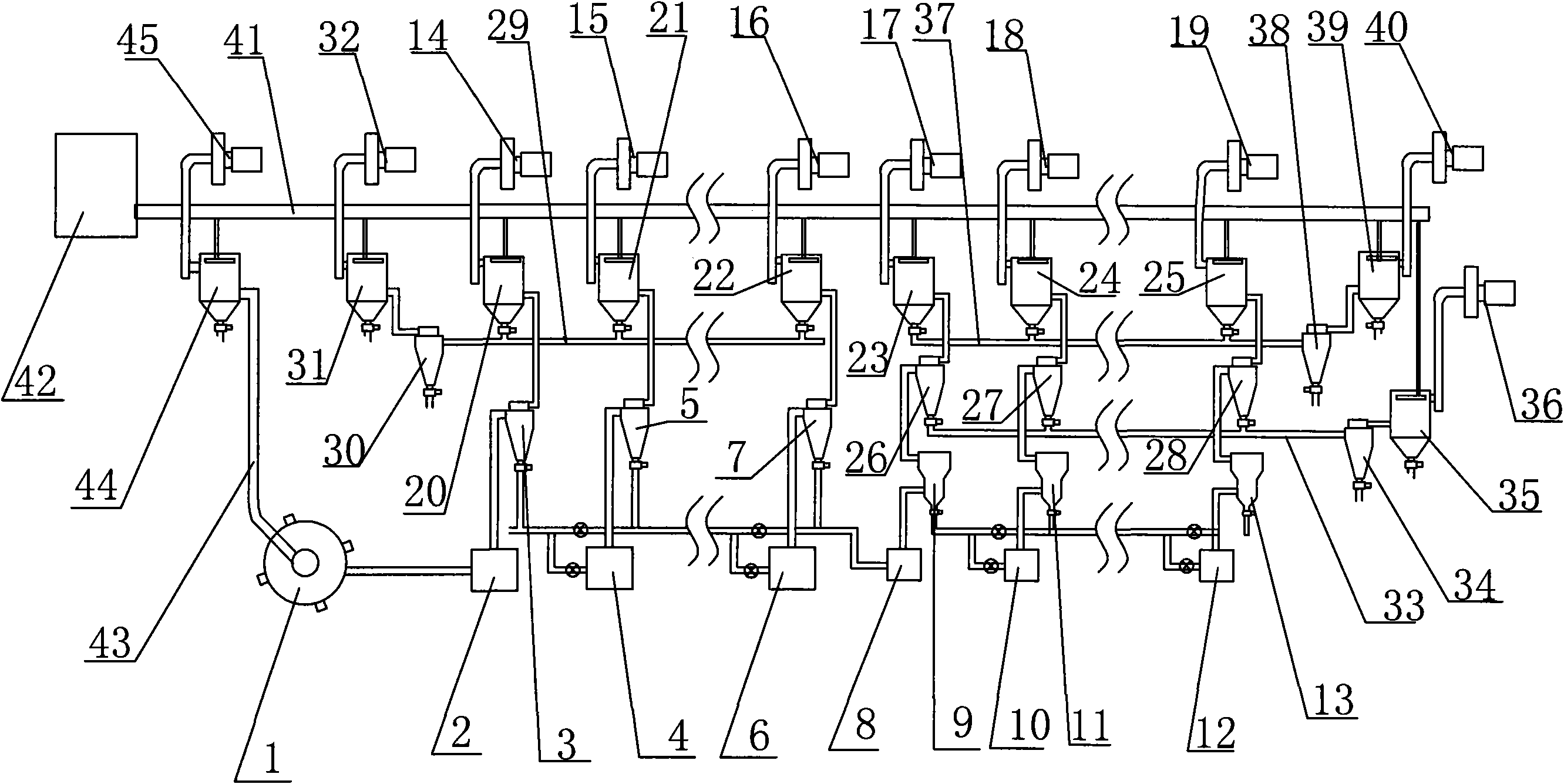

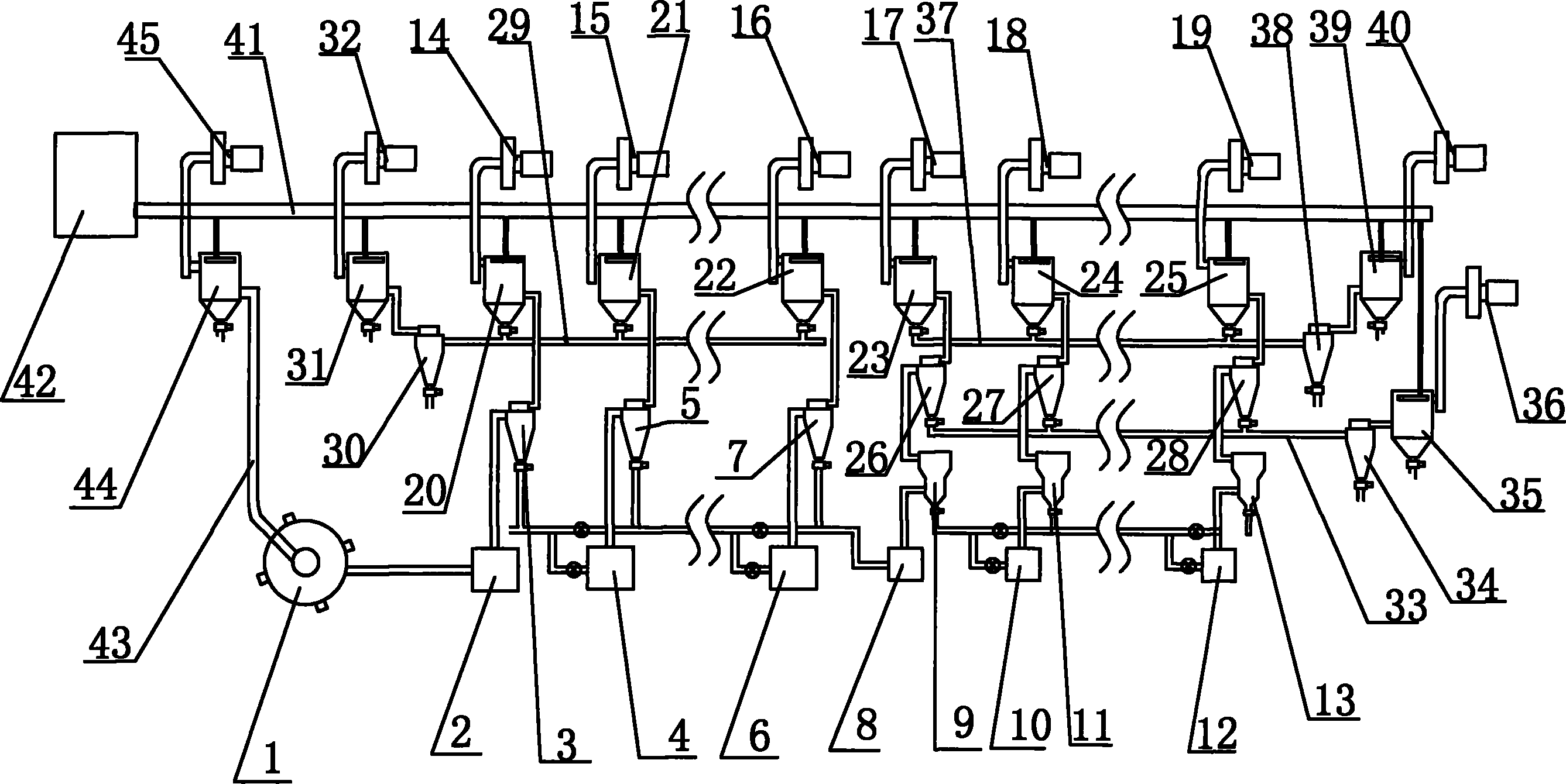

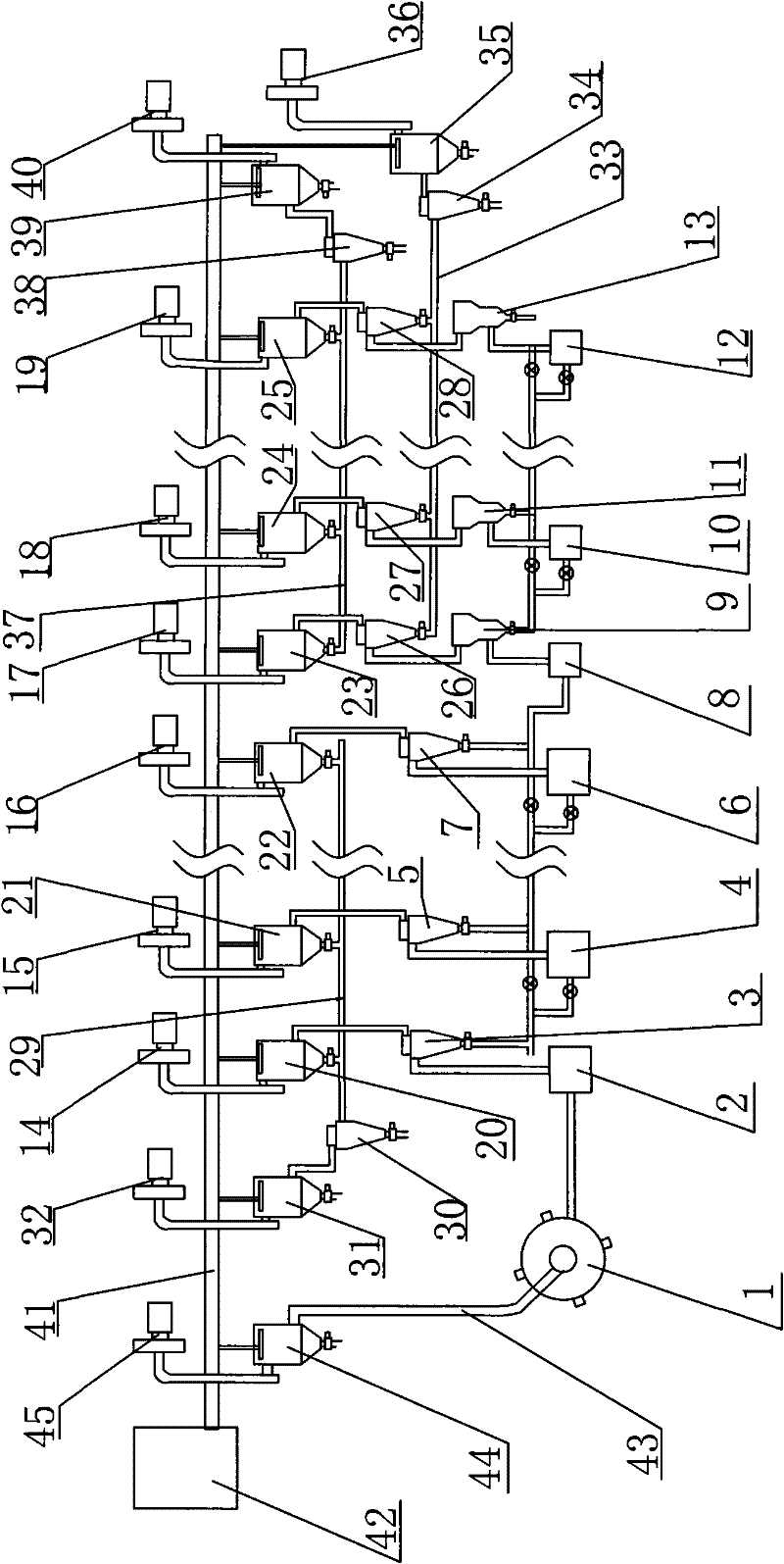

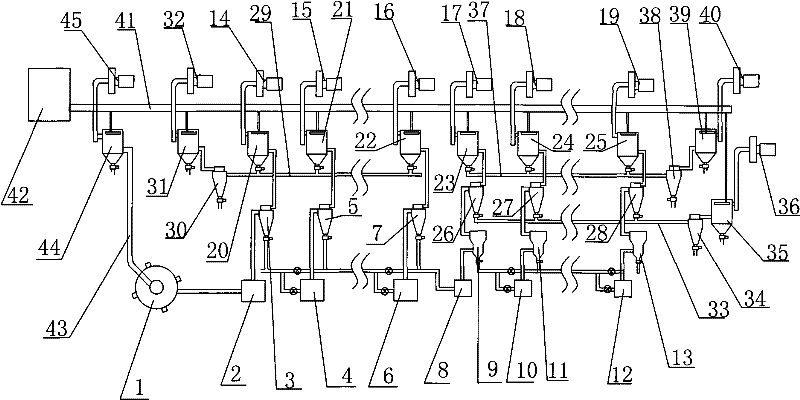

Automatic spheroidization device for producing spherical graphite

The invention discloses an automatic spheroidization device for producing spherical graphite, which mainly comprises an automatic material supply device, a powder system, a spheroidization system, a dust recovery system and a material collection system, wherein materials enter the powder system from the automatic material supply device and after being processed, and enter the spheroidization system and the material collection system in turn; the whole process is carried out in a sealed pipe in sequence; a vacuum exhaust fan is used for providing power; and in a production process, the efficiency is high and no pollution is generated. The device can realize the fully-automatic control in a whole process from material supply to powder making to spheroidization to separation to product recovery to dust recovery; the prepared graphite powder is spherical material; the surface of the graphite powder has openings; the values, which are preset before production, of the tap density, specific surface area and size distribution can be achieved; the product quality is stable; the yield can be improved by more than three times; over 40 percent of energy can be saved; over 60 percent of cost can be saved; and dust leakage and high noise are prevented.

Owner:LUOYANG GUANQI INDAL & TRADE

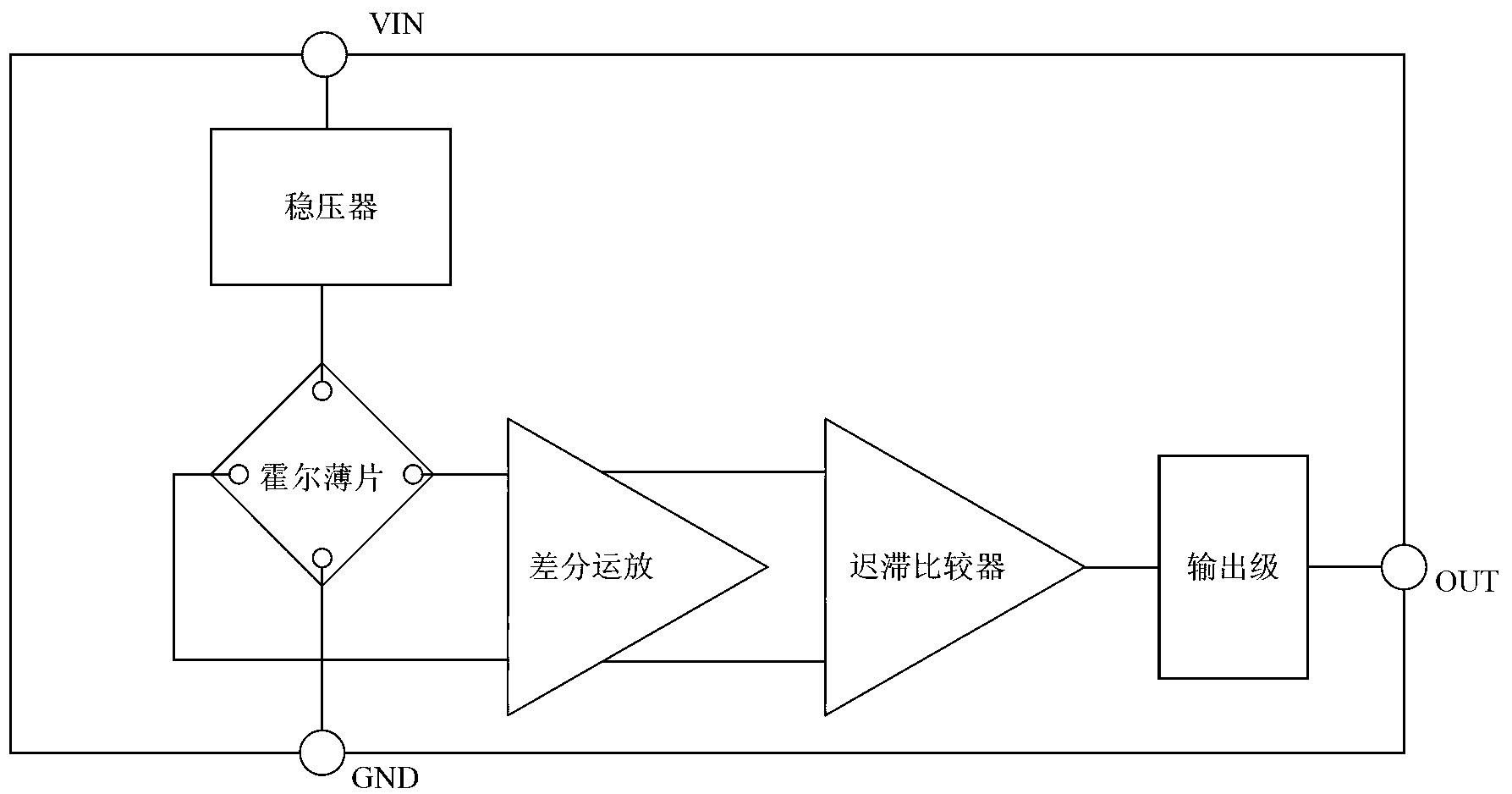

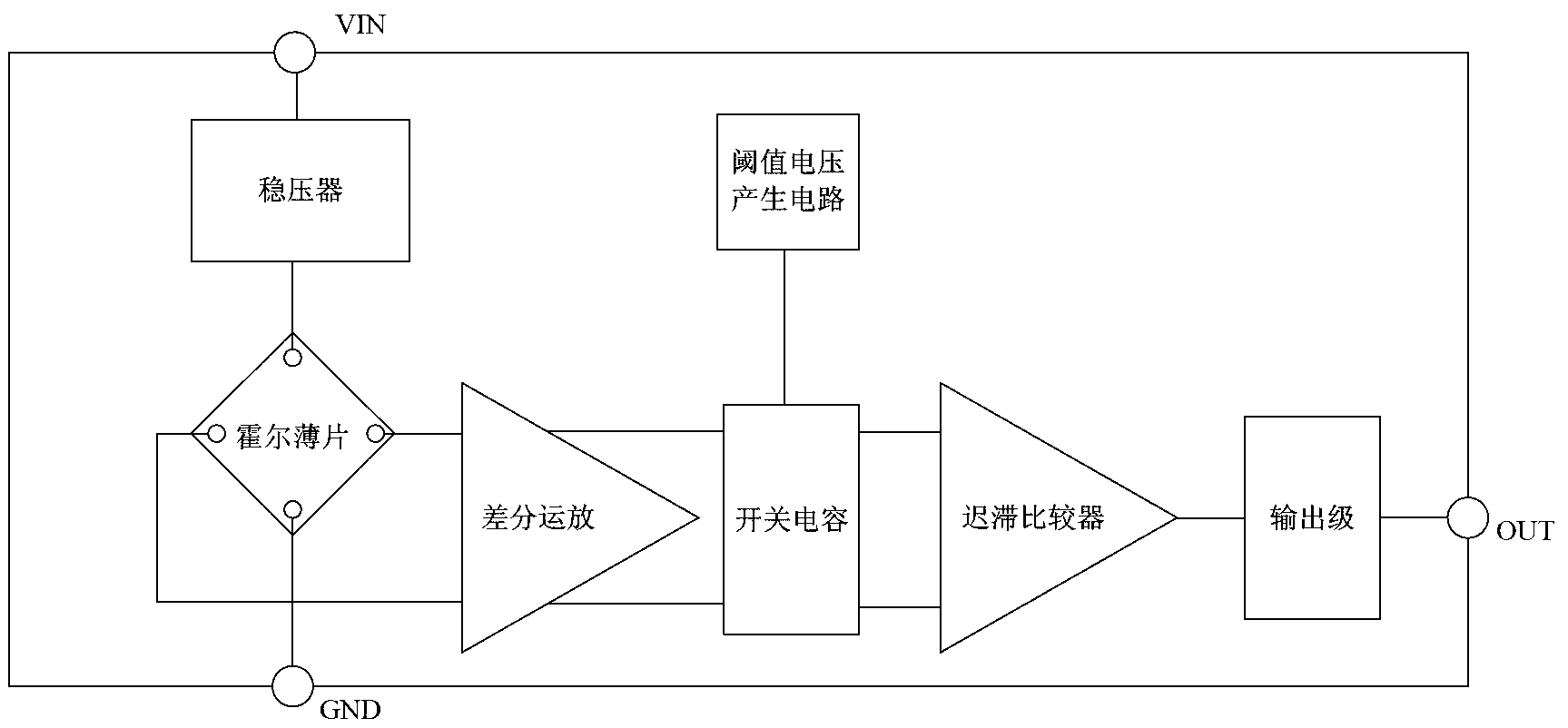

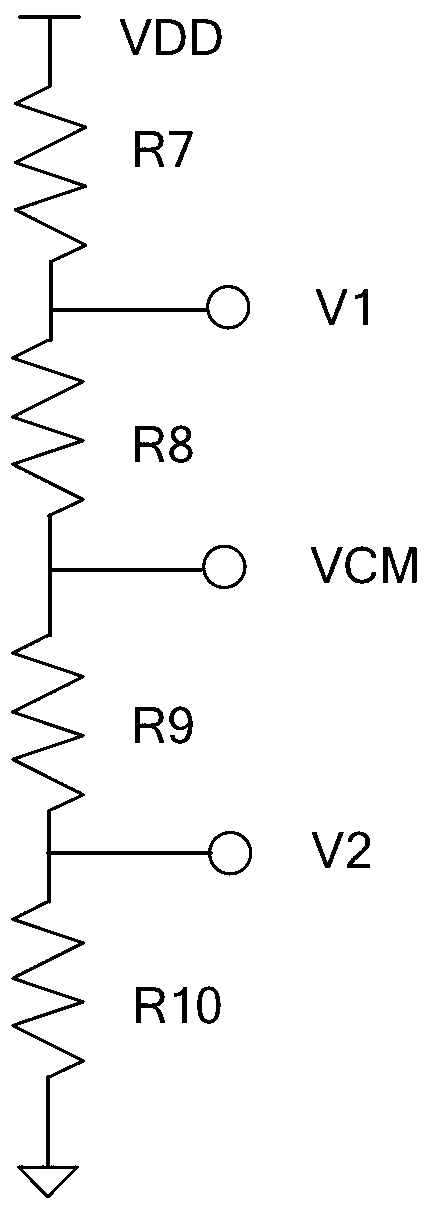

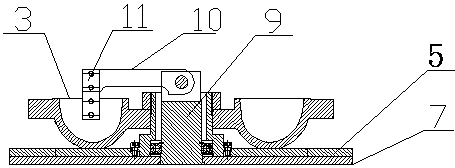

Temperature compensating circuit and temperature compensating method for switch-type Hall sensor

ActiveCN103248345AChange the production methodLower requirementElectronic switchingTemperature coefficientCapacitance

The invention discloses a temperature compensating circuit and a temperature compensating method for a switch-type Hall sensor. The temperature compensating circuit comprises a Hall chip, a differential amplifier, a switched capacitor circuit, a voltage stabilizer and a hysteresis comparator, wherein a reference current generating circuit and a threshold voltage generating circuit are connected in series between the voltage stabilizer and the switched capacitor circuit, and are used for generating reference current and threshold voltage to be provided to the hysteresis comparator; and the hysteresis comparator is used for comparing an amplified Hall induced voltage with a threshold voltage value, and outputting a discrimination result to an output stage. According to the temperature compensating circuit and the temperature compensating method, the reference current generating circuit module is added, the threshold voltage generating way is changed, the temperature compensating accuracy is higher, the influence of nonlinearity of a resistance temperature coefficient is eliminated, undifferentiated high-accuracy compensation can be realized on each temperature value, the requirement on a used process line is lowered, a resistor of a specific positive-negative temperature coefficient is not needed, and the selection range of the process line is expanded for a design engineer.

Owner:CROSSCHIP MICROSYST

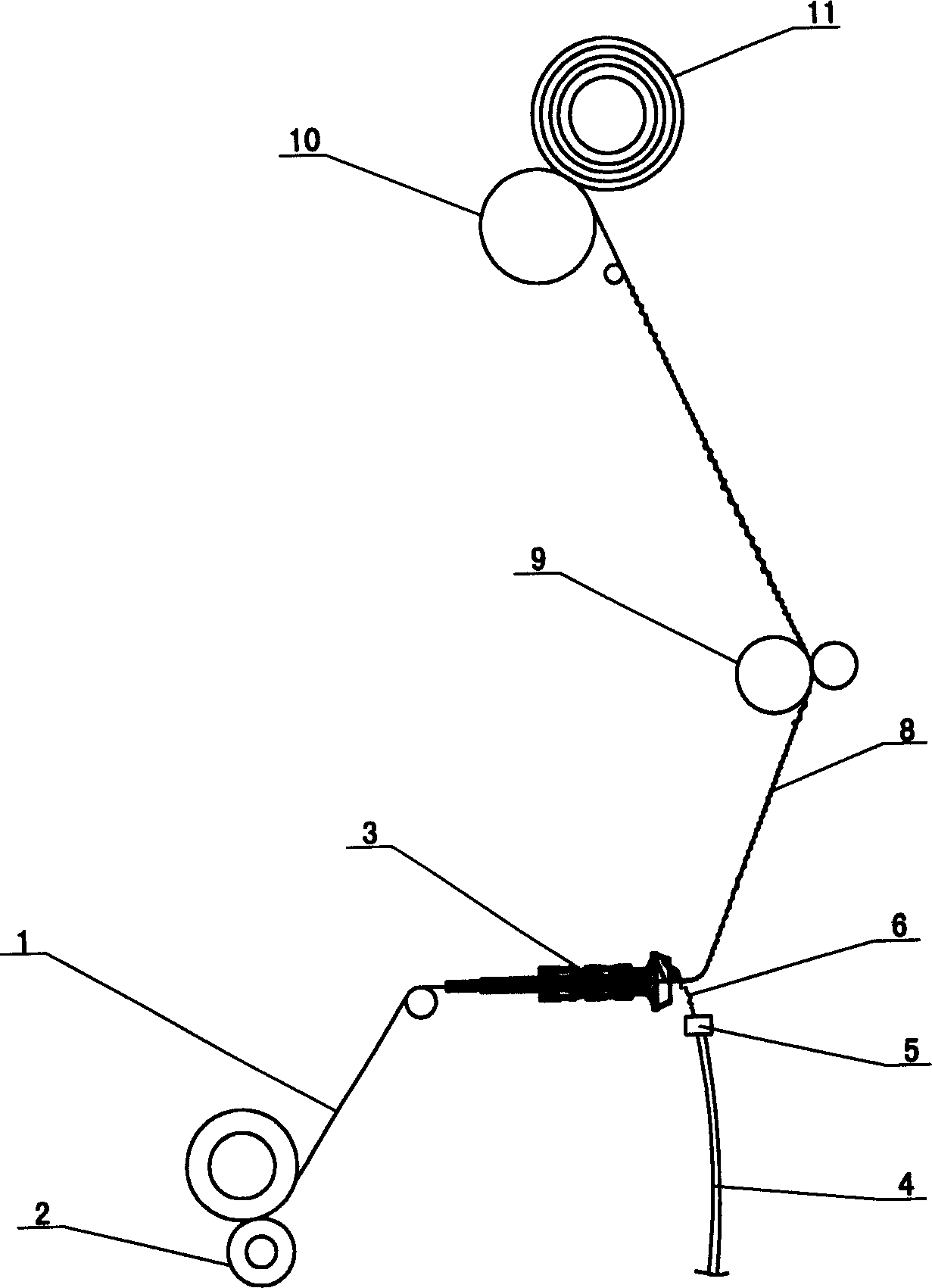

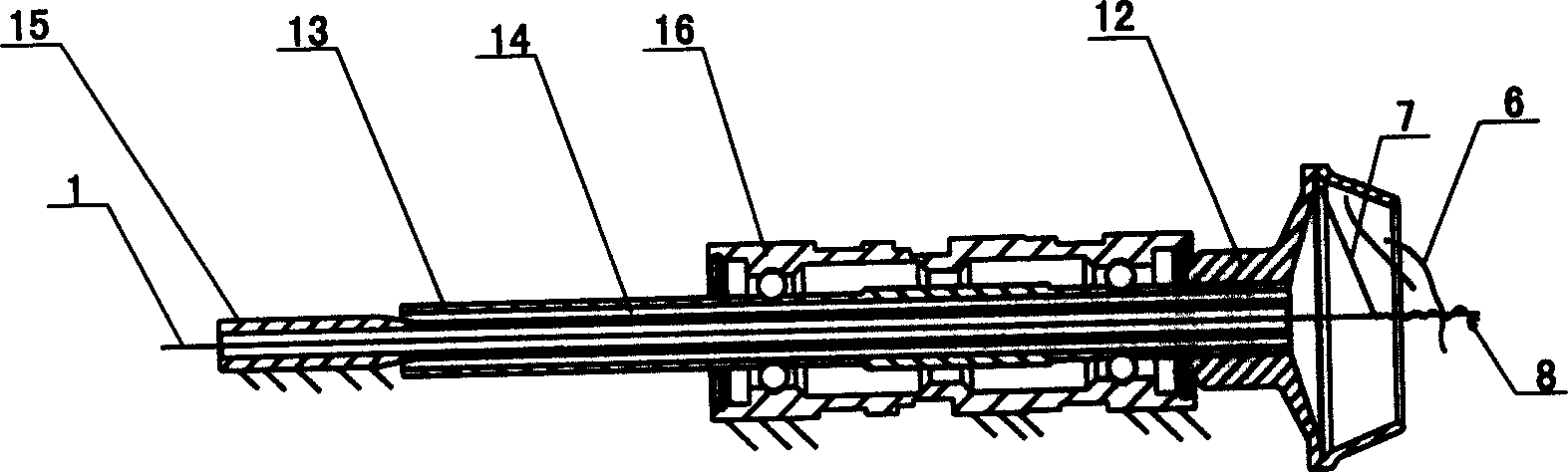

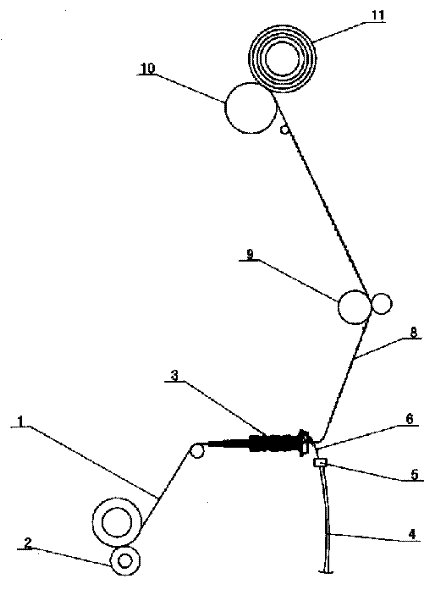

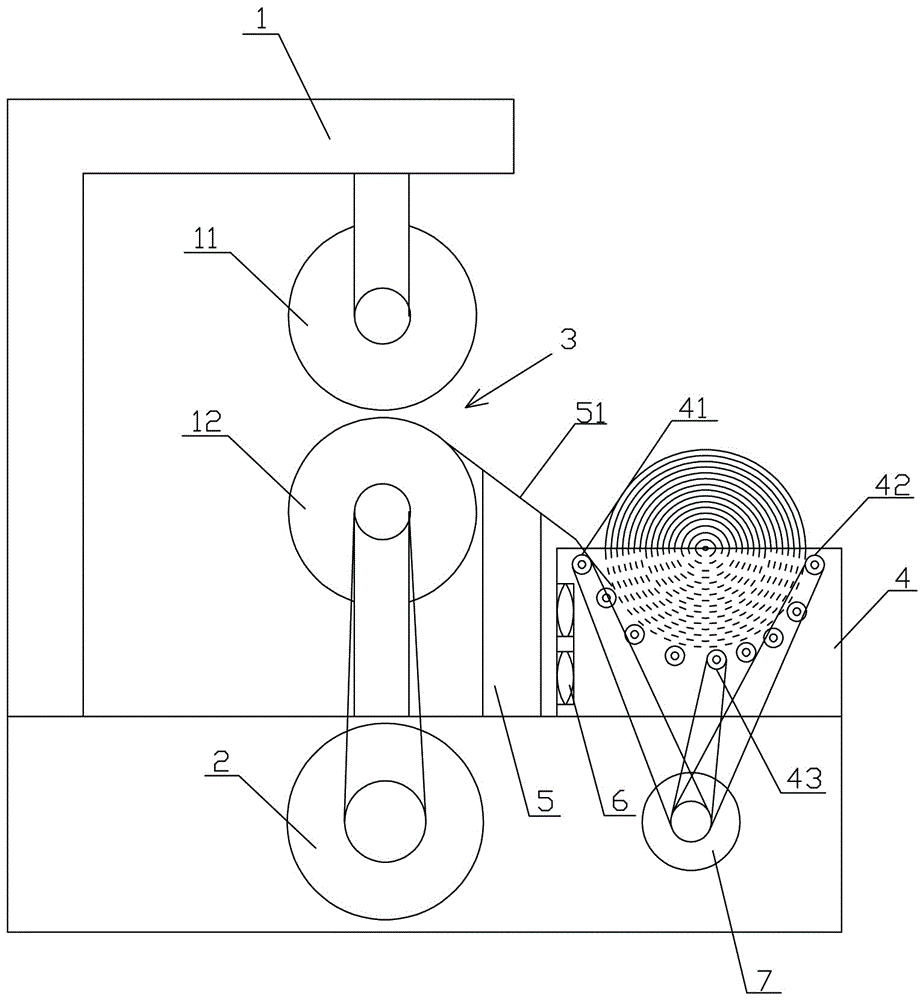

Coated yarn spinning method and apparatus

InactiveCN1468989ASimple equipment structureIngenious ideaContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

Owner:浙江日发控股集团有限公司

Double-layer composite production method for plastic film sheet material on blowfilm machine and equipment thereof

ActiveCN101220181AImprove softnessIncrease die temperatureFlat articlesLow-density polyethylenePlastic film

The invention relates to the field of fine chemical products, in particular to a producing method of double-layer composition of plastic film sheet on a plastic film blowing machine. The invention pertains to a plastic film sheet, the compositions of which are 5-65 percent of low density polyethylene and 95-35 percent of acetic acid. Difference of the producing method of the invention with the existing plastic film is that: the temperature of a die head of the plastic film blowing machine is 150 to 170 DEG C, which causes that the plastic film blown in drum shape can be directly compacted into bundles without cutting, namely, two layers of film are hot pressed into one layer. The invention has the advantages that: the tenderness of the plastic film is increased by changing the compounding formula of the plastic film, and the viscidity of the film is also increased by enhancing the temperature of the die head; the originally separated two layers of film are closely compacted into a whole; due to the invention, the modification to the existing device is little, and the production cost is lowered. By using a small scale device for producing thick plastic film sheet, machine consumptions in production process can also be reduced and the cost is prevented from increasing due to the composing by glue and environment pollution.

Owner:福州永鑫塑料包装用品有限公司

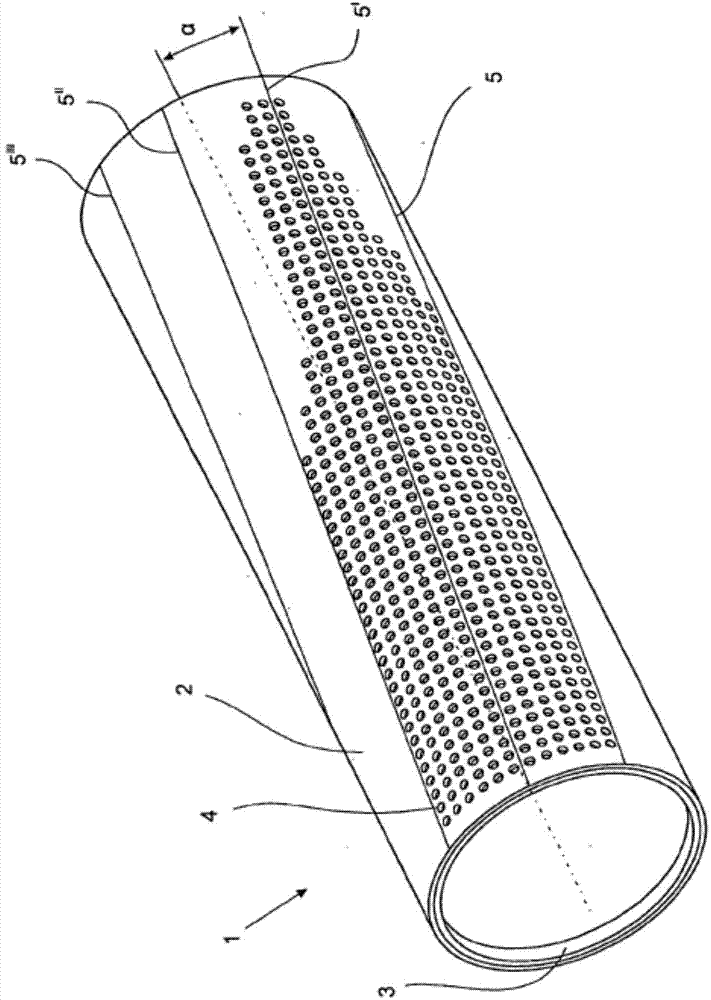

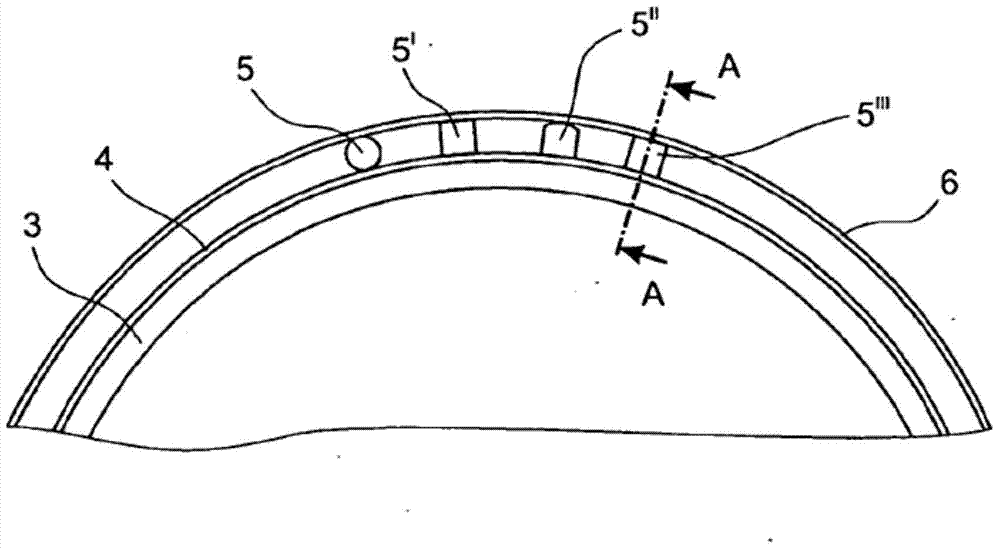

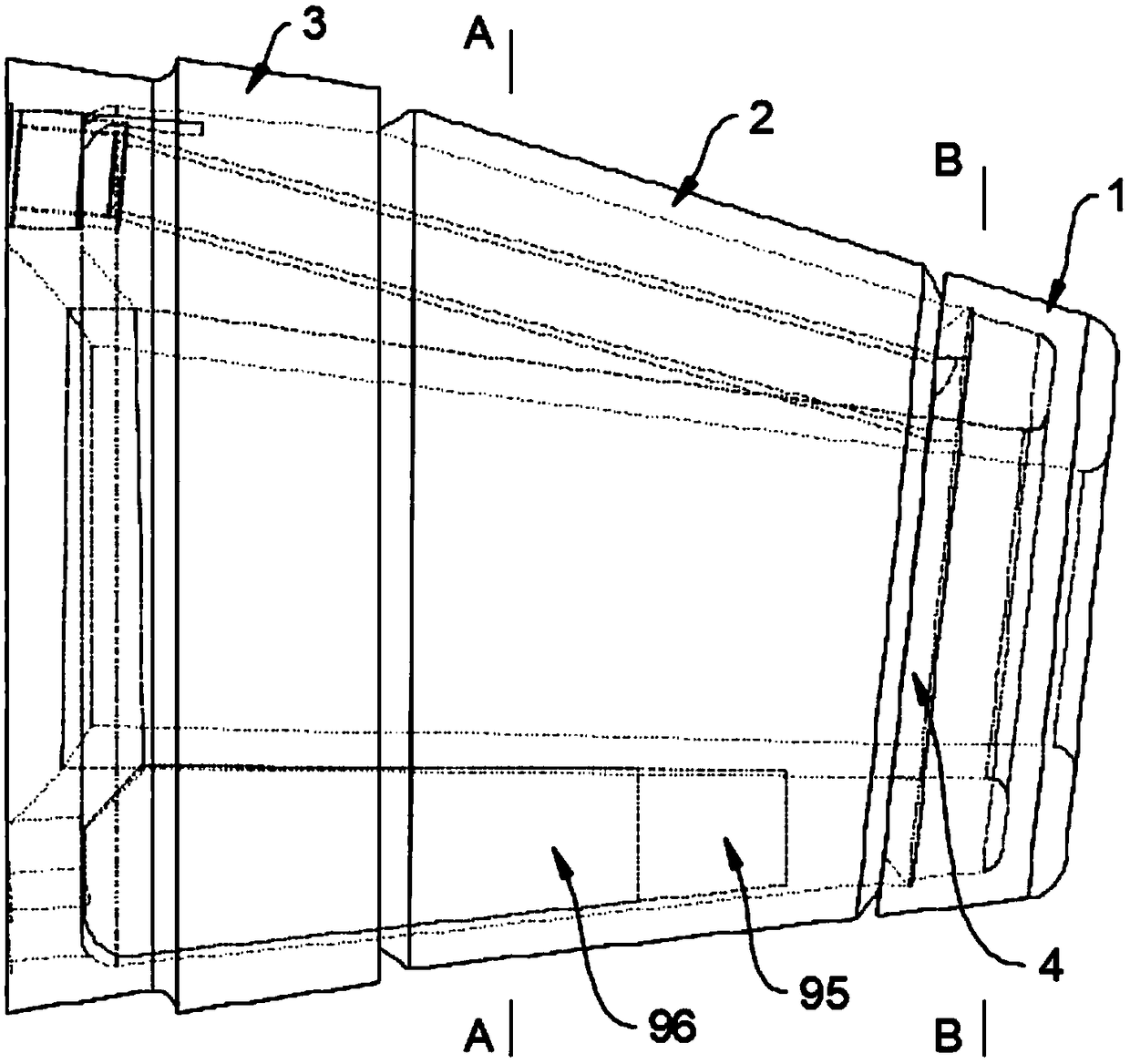

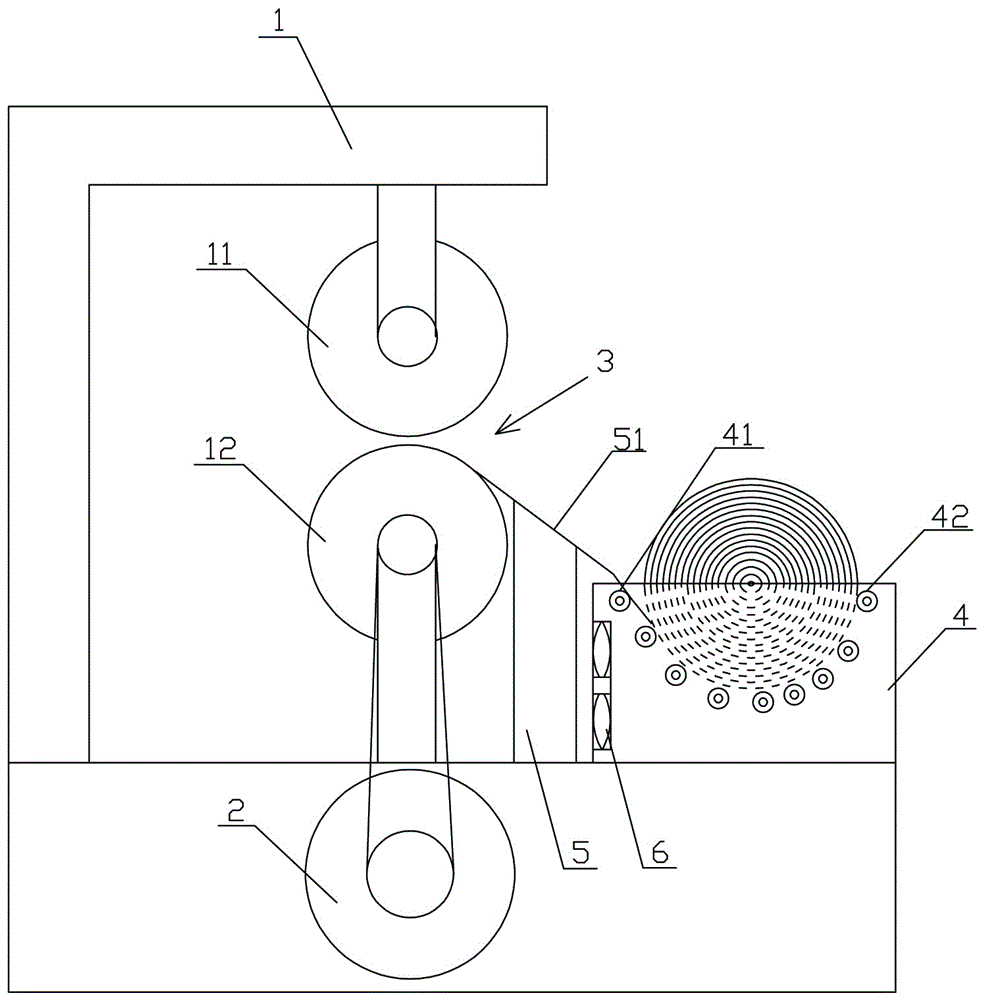

Device for hydrodynamically strengthening nonwovens, wovens or knitted fabrics

ActiveCN104204326AManufacturing flexibilityInexpensive and long-lasting connectionsDrying machines with progressive movementsNeedling machinesEngineeringAngle alpha

The invention relates to a device for hydrodynamically strengthening nonwovens, wovens or knitted fabrics, comprising a base drum (1), which has a plurality of bore holes (4) and on which a structural drum (6) is arranged at a spacing, wherein the distance between the base drum (1) and the structural drum (6) can be produced with a plurality of wires (5, 5', 5", 5"',...) that are arranged on the surface of the base drum (1) and are at least partially integrally joined to the base drum (1), the wires (5, 5', 5", 5"',...) being arranged parallel to each other on the surface of the base drum (1), characterised in that the wires (5, 5', 5", 5"',...) are arranged on the surface of the base drum (1) at an angle alpha of 5° to 45°, preferably 15° to the longitudinal axis of the base drum (1).

Owner:TRUETZSCHLER GRP SE

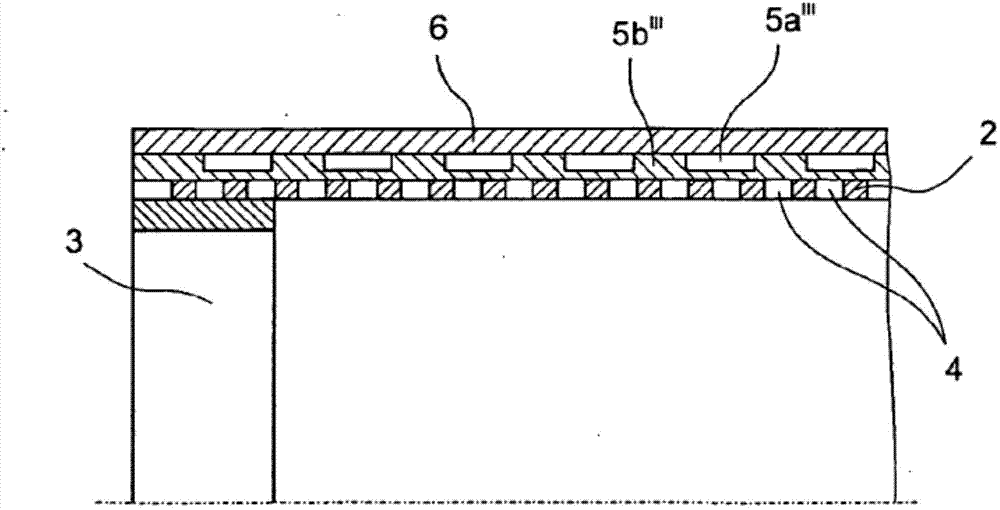

Method for making standard mandarin speech micro-courseware based on TTS technology

ActiveCN105679120AImprove work efficiencyShorten the timeElectrical appliancesSpeech soundAudio frequency

The invention discloses a method for making standard mandarin speech micro-courseware based on TTS technology. The method adopts a standard mandarin-Camtasia Studio-PPT recorder screen model, that is, an MCP model. The MCP model is constructed with the following steps: 1) making micro-courseware scripts in a PPT format; 2) generating a standard mandarin audio and carrying out synchronous training: converting an explanation text into the standard mandarin audio through the TTS technology, and adjusting the explanation text to obtain a correct pronunciation effect; 3) carrying out Camtasia studio audio and video synchronous recording to generate an audio and video record file; and 4) carrying out later-stage editing: editing the micro-courseware through Camtasia studio. The method realizes direct recording of the micro-courseware scripts through a PPT and explaining word mode, so that the effect that what you see is what you get is realized; TTS-based automatic standard mandarin dubbing is realized; micro-courseware automatic recording is realized; the audio is free of noise; the audio and video are synchronous; and micro-course group making efficiency and teaching quality are improved.

Owner:右江民族医学院 +1

Blast furnace cooling tuyere

Disclosed is a blast furnace cooling tuyere. The blast furnace cooling tuyere comprises a front cap, a middle cap and a rear cap, wherein a cavity structure is enclosed by the front cap, the middle cap and the rear cap. A partition plate is arranged between the front cap and the middle cap to divide the cavity structure into a front cavity and a rear cavity. A cooling water inlet pipe and a cooling water outlet pipe are arranged in the rear cavity. The partition plate is provided with a partition plate water inlet hole and a partition plate water outlet hole. The cooling water inlet pipe and the cooling water outlet pipe communicate with the partition plate water inlet hole and the partition plate water outlet hole correspondingly. The front cavity is internally provided with a front cavity partition plate, and the front cavity partition plate is positioned between the partition plate water inlet hole and the partition plate water outlet hole. The cooling capability of a tuyere small sleeve can be improved, and the hidden danger of water leakage caused by a traditional casting structure can be eliminated, so that the service life of the tuyere can be prolonged, and the service quality and the combustion rate are improved.

Owner:常州市武进长虹结晶器有限公司 +1

High-temperature-resistant hydraulic cylinder manufacturing technology

InactiveCN104014985AIncrease profitImprove high temperature resistanceFluid-pressure actuatorsManufacturing technologyMaterials science

A high-temperature-resistant hydraulic cylinder manufacturing technology comprises the following steps of (1) material selection, (2) product machining and (3) technology design. A material of a hydraulic cylinder is selected according to the pressure of a working medium and the size of a working cylinder. 40 forged steel or 45 forged steel or carbon steel STKM13C can be selected as the material of the hydraulic cylinder and a piston rod can be made of S45C carbon steel. Seamless cold drawing is conducted on the surface of the hydraulic cylinder, high-accuracy inclination intersecting boring is conducted on the inner diameter portion, the tolerance of the inner diameter ranges from H7 to H9, the surface roughness ranges from 0.8 S to 2.0 S, and the tension strength is over 5.2 MPa. Grinding and hard chroming are conducted on the outer diameter portion of the piston rod, the tolerance of the appearance ranges from f7 to f8, the surface hardness is over HV700, the surface roughness ranges from 0.8 S to 1.6 S, and the chroming thickness is 20 micrometers. According to the high-temperature hydraulic cylinder manufacturing technology, the hydraulic cylinder is good in high-temperature-resistant performance, the service life of a sealing device of the hydraulic cylinder can be prolonged, the number of needed spare parts is small, the number of replacement periods can be reduced, and therefore the labor intensity of workers is relieved; the structure is simple and the hydraulic cylinder is safe and reliable.

Owner:LIUZHOU WEILISHI HYDRAULIC DEVICE

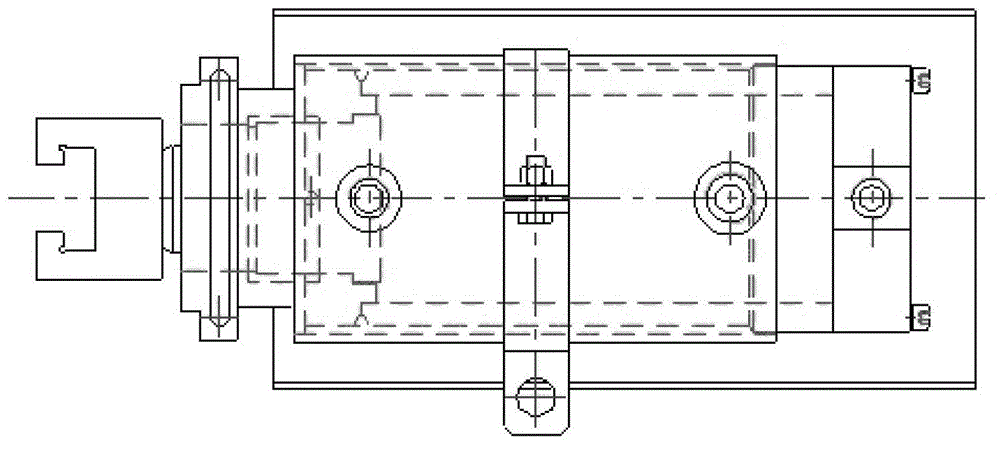

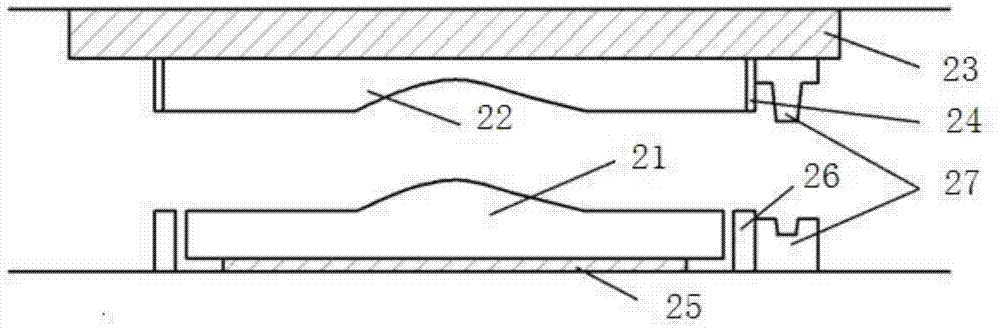

Forming die used for thin walled pipe faucet water outlet nozzle

InactiveCN103658398AChange the production methodSave social energyShaping toolsEjection devicesPunchingThin walled

The invention discloses a forming die used for a thin walled pipe faucet water outlet nozzle. The forming die comprises a lower bottom plate and an upper bottom plate. The upper bottom plate and the lower bottom plate are provided with an upper clamping block and a lower clamping block respectively, wherein the upper clamping block and the lower clamping block are mutually matched and used for clamping a workpiece placed between the upper bottom plate and the lower bottom plate. The upper clamping block is movably installed on the upper bottom plate through third compression springs, a forming punch is arranged on one side of the lower clamping block, located below a water outlet nozzle forming pipe wall of the workpiece and installed on the lower bottom plate, a guiding fixed base is arranged on one side of the forming punch, and a certain gap is kept between the forming punch and the guiding fixed base to form a punching groove. The guiding fixed base is fixedly installed on the lower bottom plate, and a forming concave die is formed over the guiding fixed base in a matched mode and fixedly installed on the upper bottom plate. Due to the fact that the water outlet nozzle is formed through the die in a punching mode, a traditional casting or welding mode does not need to be adopted for producing the faucet water outlet nozzle, social energy is saved, and besides the mode of manufacturing the faucet water outlet nozzle is changed.

Owner:JODEN INC

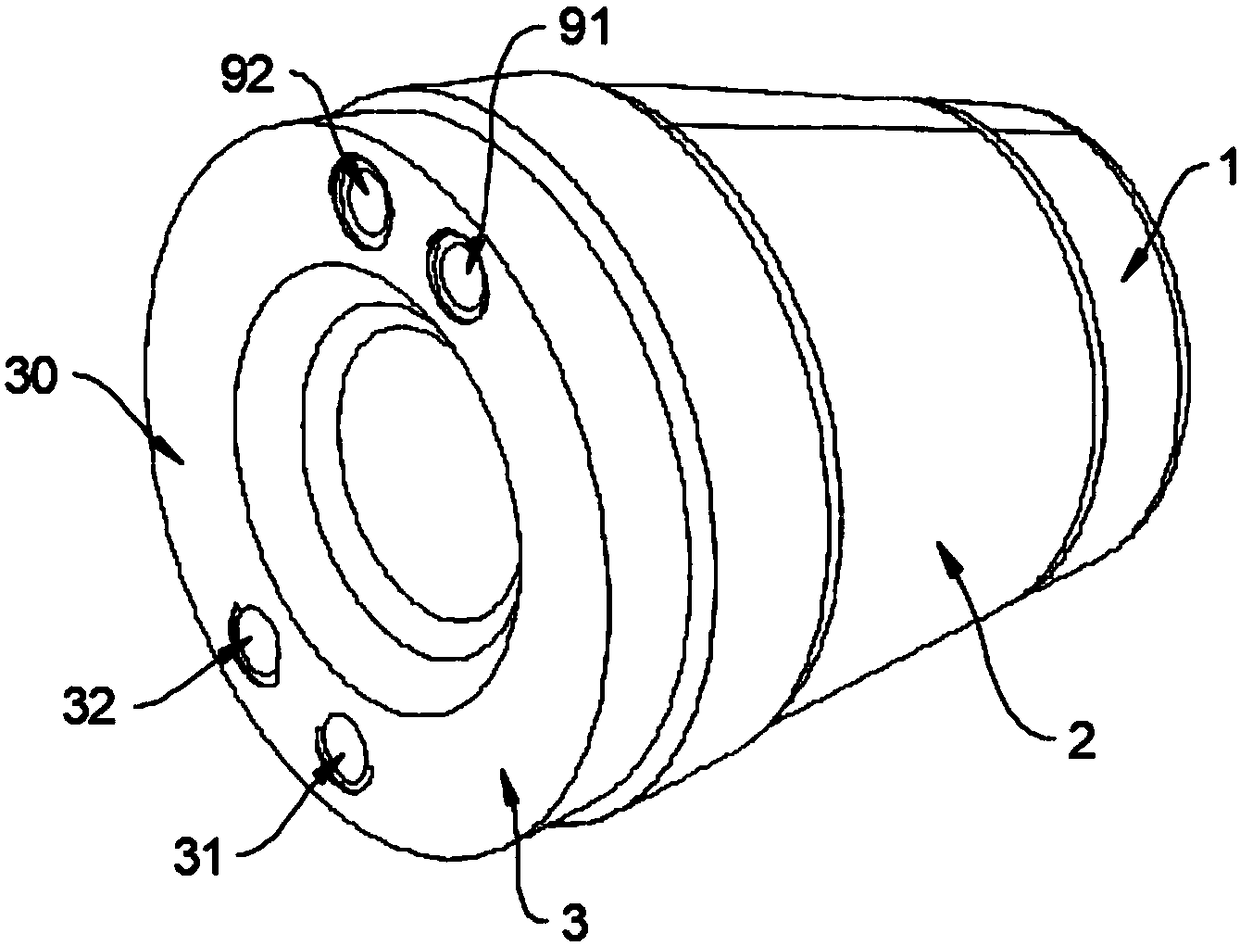

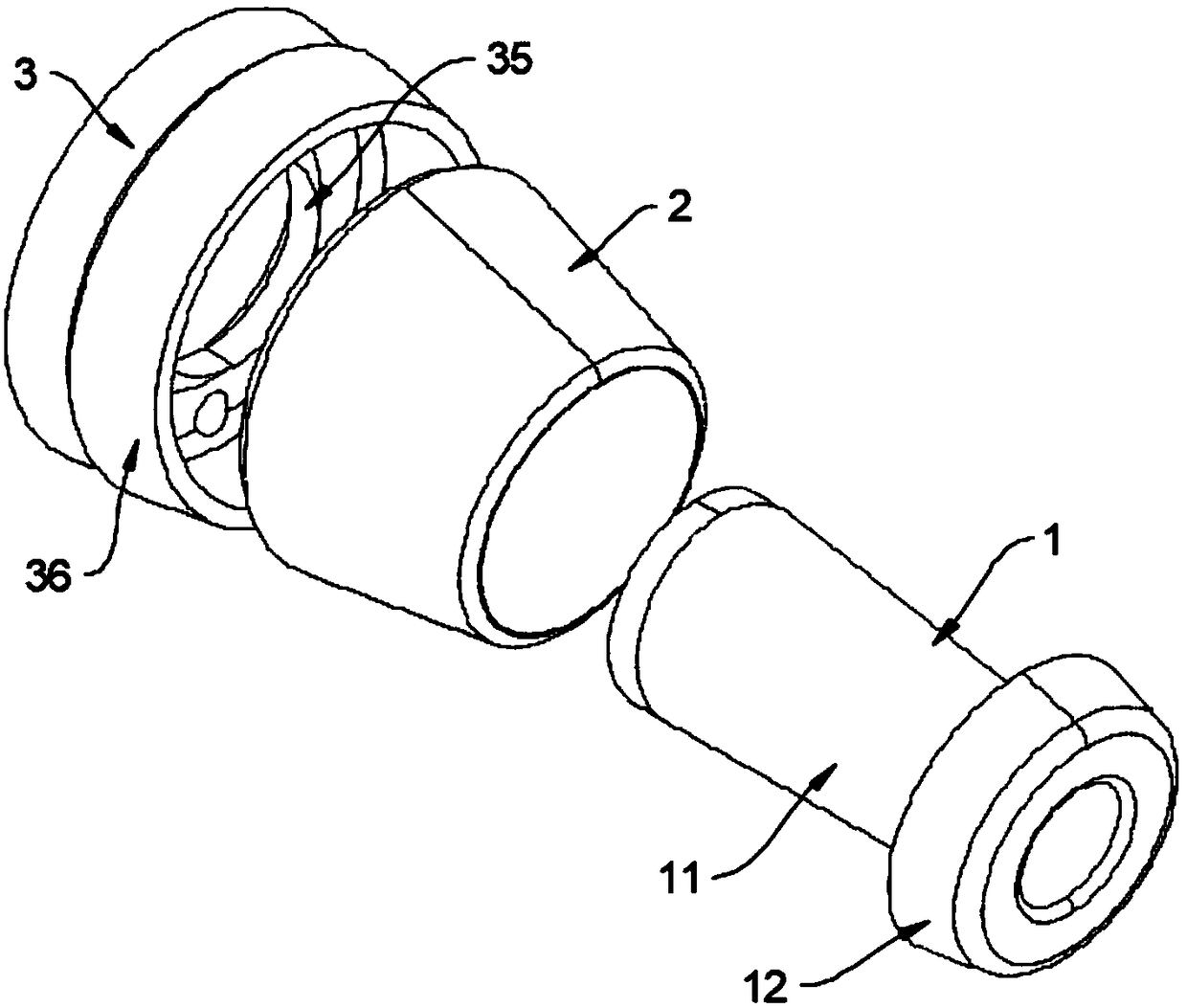

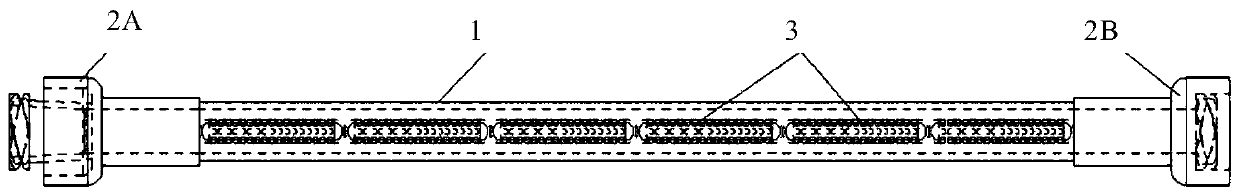

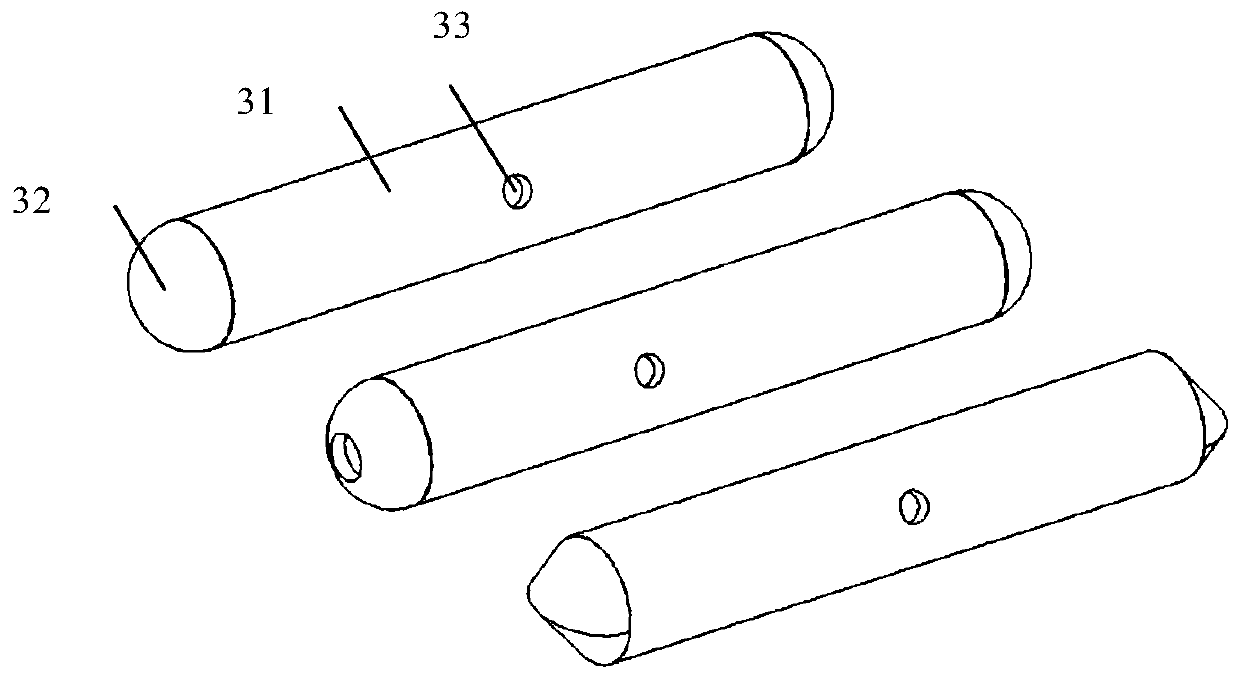

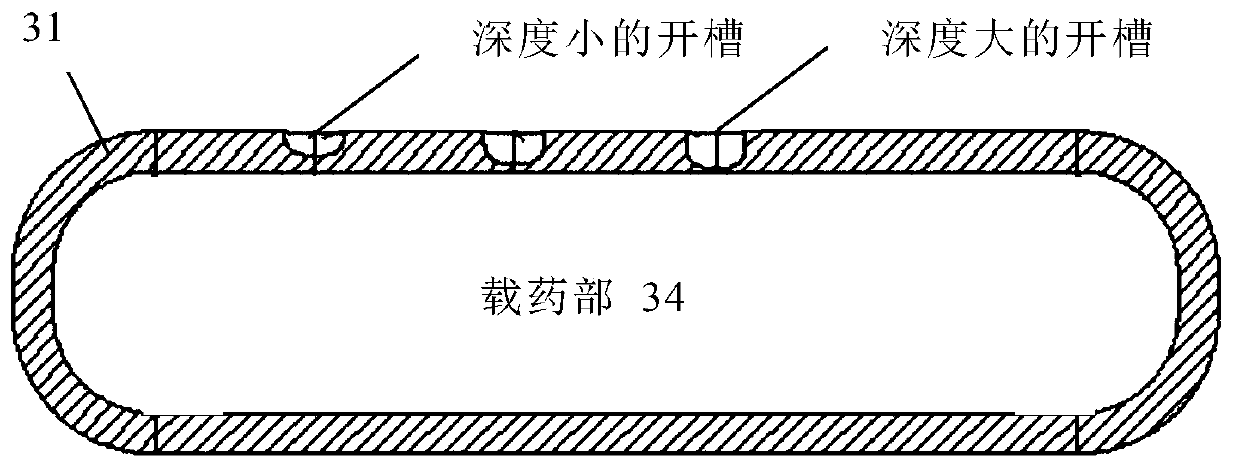

Drug-loaded particles, catheter with drug-loaded particles and implantation system

PendingCN111437265ARelease precision controlGood curative effectPowder deliveryMedical devicesCurative effectEngineering

The present invention discloses drug-loaded particles. The particles comprise a biodegradable housing (31), and a drug-loaded portion (34) arranged inside the housing and used for being implanted intoin-vivo tissues via a puncture needle (5), the drug-loaded portion (34) comprises a drug, and the housing is closed and designed to form an opening through a wall thickness of the housing at a predetermined time. The drug-loaded particles provided by the embodiment of the invention have a relatively large size, can be directly implanted into in-vivo tissues, and does not need to pass through a blood vessel. Moreover, drug-loaded particles containing different drugs can be implanted through one-time puncture and needle insertion, so that the different drugs are promoted mutually, and the curative effect is improved. According to the invention, different drug-loaded particles can have different drug release speed curves respectively, and a plurality of drug-loaded particles with different drug release speed curves can be implanted at one time, so that accurate control of drug release can be realized.

Owner:MEDESSENCE LIFESCIENCES SUZHOU INC

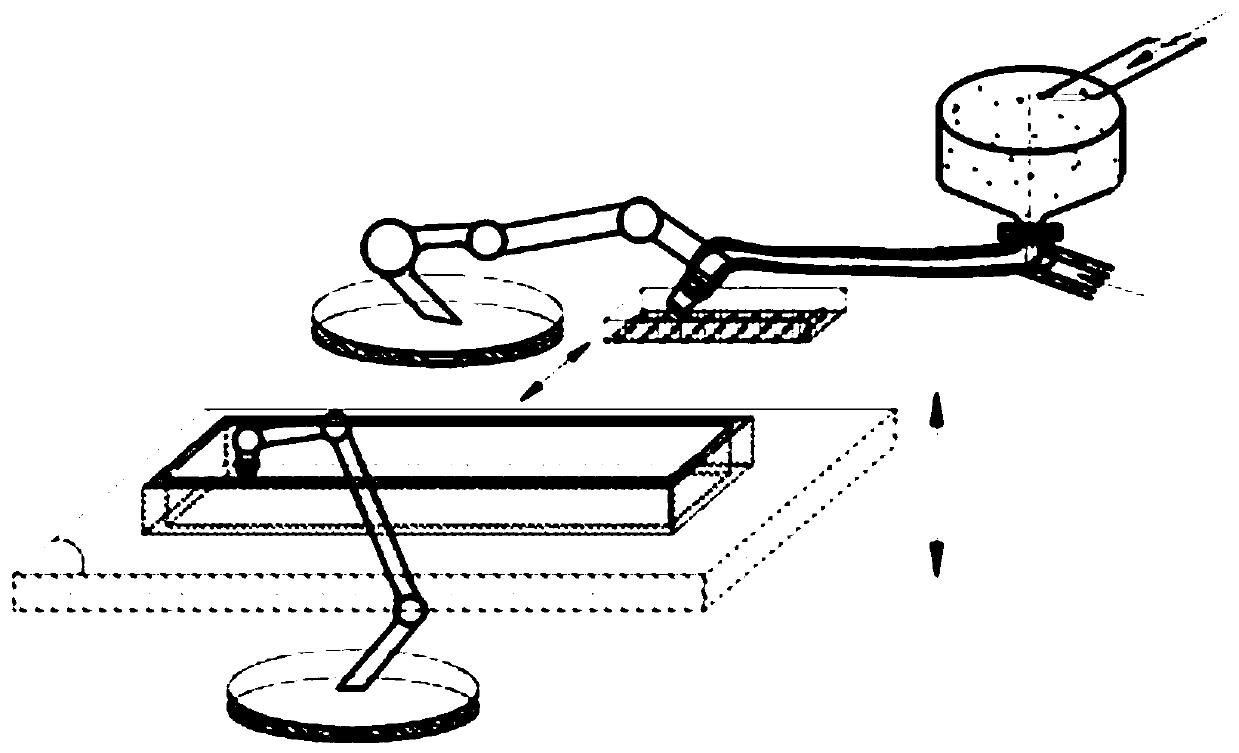

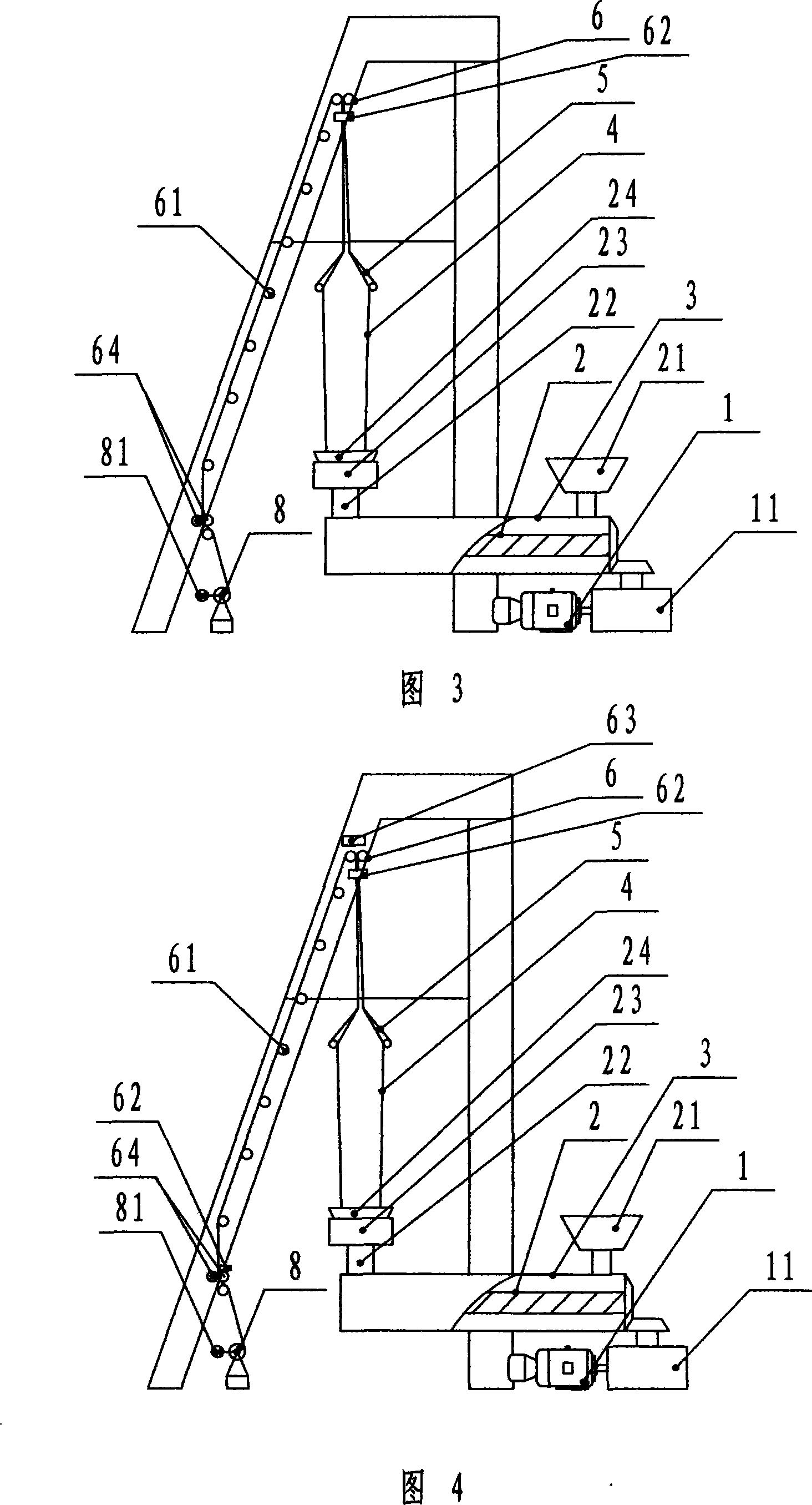

Jacket type composite additive manufacturing device

InactiveCN111468724AStrong connectionImprove sufficiencyAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing cost reductionPipe

The invention discloses a jacket type composite additive manufacturing device. The jacket type composite additive manufacturing device comprises a sealed forming cabin and a base arranged in the sealed forming cabin, wherein a jacket deposition forming device is arranged on one side of the base, a casting forming device is arranged on the other side of the base, an extruding / forging / rolling mechanical auxiliary device is arranged over the base, the casting forming device is connected with a metal smelting device through a flow guide pipe, the metal smelting device communicates with the flow guide pipe through a flow control element, and when metal liquid in a jacket is cooled to the proper pressure machining temperature, the metal liquid in the jacket is subjected to combined machining through the device. According to the jacket type composite additive manufacturing device, through the casting forming device, conventional wire and powder base metal is replaced with large-block base metal, the sufficiency of metal metallurgy is improved through the metal smelting device, a deposited blank is subjected to three-way extrusion stress, the action mode of an existing deposition and one-dimensional composite additive forming device is changed, the consistency and stability of a structure and performance of a formed component are greatly improved, the manufacturing efficiency is greatly improved, and the manufacturing cost is reduced.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Mushroom sauce and its making method

The present invention relates to a kind of mushroom sauce and its preparation method. Its raw material composition includes (by weight portion) 70-90 portions of mushroom extract, 0.1-0.5 portion of pepper, 0.05-0.5 portion of star anise, 3-7 portions of amino of star anise, 3-7 portions of amino acids, 0.03-0.09 portion of citric acid, 0.004-0.008 portion of edible colouring matter, 1-2 portions of sodium 5'-inosinate, 1-2 portions of sodium 5'-guanylate, 3-12 portions of granulated sugar, 1-2 portions of old ginger and 14-17 portions of edible salt. Said invention also provides the concrete steps of its preparation method.

Owner:赵持勤 +1

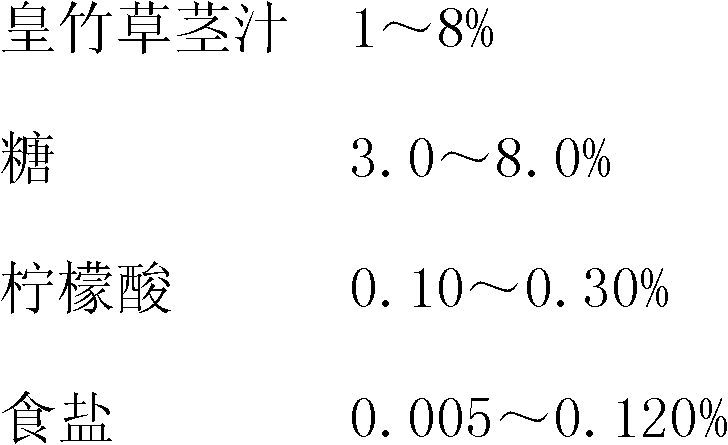

Pennisetum hydridum sports drink

InactiveCN102715608APromote absorptionChange the production methodFood preparationNutrientPhysical exercise

The present invention provides a Pennisetum hydridum sports drink, which consists of the following components by mass percentage: 1-8% of Pennisetum hydridum stalk juice, 3.0-8.0% of sugar, 0.10-0.30% of citric acid, 0.005-0.120% of salt and the balance of water. According to the present invention, a Pennisetum hydridum stalk juice is used to substitute an additive potassium salt, and added with a proper amount of white granulated sugar, citric acid, salt and water to blend and produce a plant sports drink. The sports drink contains health care components such as natural plant vitamins, minerals and flavonoids, complies with sports drink standard of GB15266, and has nutrients and other components to fit physiological characteristics of exercise or physical activity groups, so as to supplement moisture, electrolyte and energy for the body and be absorbed quickly; besides, the sports drink is added with no pigment, essence or antiseptic, and is natural and healthful. According to the invention, a production mode of blending sports drink with food additives for most sports drinks in the current market is changed, therefore the Pennisetum hydridum sports drink provided by the present invention is beneficial for public health.

Owner:ZHUHAI JINLVZHOU AGRI DEV

Snowy moon cake at room temperature

Owner:HUNAN JINZHIYUAN FOOD

Snowy moon cake

The invention relates to a snowy moon cake. The snowy moon cake is composed of a cake crust and stuffing. The stuffing is wrapped by the cake crust. The cake crust mainly includes, by weight, 100-150 parts of cooked glutinous rice flour, 25-35 parts of powdered sugar, 750-900 parts of syrup, 65-140 parts of animal oil and fat, 420-700 parts of vegetable fat and 4-8 parts of emulsifying agents. The snowy moon cake has the advantages of not needing hot processing and being capable of being preserved at a normal temperature.

Owner:SHANGHAI DOILLY OIL FOODS

Low-fat-content Xinjiang naan bread and preparation method thereof

The invention relates to low-fat-content Xinjiang naan bread and a preparation method thereof, and belongs to the field of food processing. The low-fat-content Xinjiang naan bread is mainly prepared from the following raw materials in parts by weight: 500 parts of flour, 5-15 parts of hypsizygus tessellates powder, 1-3 parts of active dry yeast, 1-4 parts of salt, 3-6 parts of sugar and 200-300 parts of water. Compared with conventional Xinjiang naan bread, the low-fat-content Xinjiang naan bread disclosed by the invention has the following advantages: the hypsizygus tessellates powder is added in the raw materials while grease is omitted, so that the prepared low-fat-content Xinjiang naan bread is rich in nutrition, and has health-care effects; moreover, the low-fat-content Xinjiang naan bread is low in fat content, healthy and prolonged in shelf life. Although the raw materials of the low-fat-content Xinjiang naan bread disclosed by the invention contain no grease, the crispness of the low-fat-content Xinjiang naan bread is comparable to the crispness of the Xinjiang naan bread added with grease, or the crispness of the low-fat-content Xinjiang naan bread is even better. In addition, the addition of the hypsizygus tessellates powder is capable of improving the coloring capacity of the Xinjiang naan bread, so that the baking time is thereby shortened. An oven is utilized to replace the pit as a baking device according to the preparation method; and during the baking processes, a technological means of using high heat first and using low heat later is utilized, so that the problems of excessive dryness and excessive hardness of the surface of the Xinjiang naan bread are effectively solved.

Owner:UNIV OF JINAN

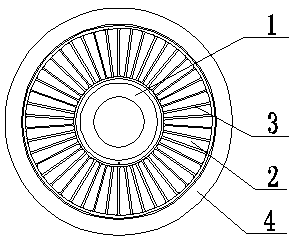

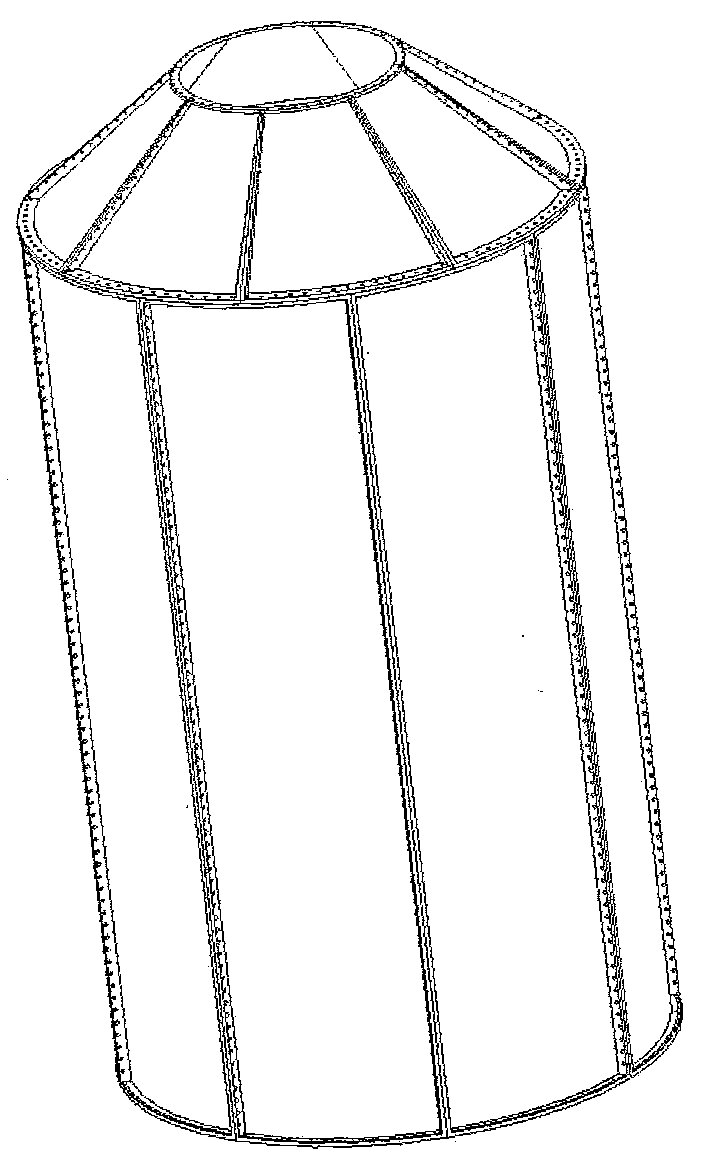

Fluid coupling rotor and production method thereof

ActiveCN108443450AReduce frictionEnough machining allowanceFluid gearingsFluid couplingForm processing

The invention provides a fluid coupling rotor and a production method thereof. The fluid coupling rotor comprises an inner flange plate, an annular turbine cavity, a blade and an outer flange plate. The inner flange plate and the annular turbine cavity are connected integrally. The blade and the annular turbine cavity are welded. The outer flange plate and the annular turbine cavity are welded. The annular turbine cavity is formed by die forging. The inner flange plate, the annular turbine cavity, the blade and the outer flange plate are made of stainless steel. The production method comprisesthe steps of material selection, initial shaping, die forging modeling, forming processing of the annular turbine cavity and blade welding. The traditional rotor structural connection mode is changed, pollution hazards to the environment due to the production process are reduced, and energy consumption is lowered. The fluid coupling rotor obtained by the production method is good in smooth flatness, regular in structure, high in precision and large in material improvement space, the rotor is repairable, production cost is lowered greatly, and energy is saved.

Owner:DADAO SOFT STAR MACHINERY CO LTD

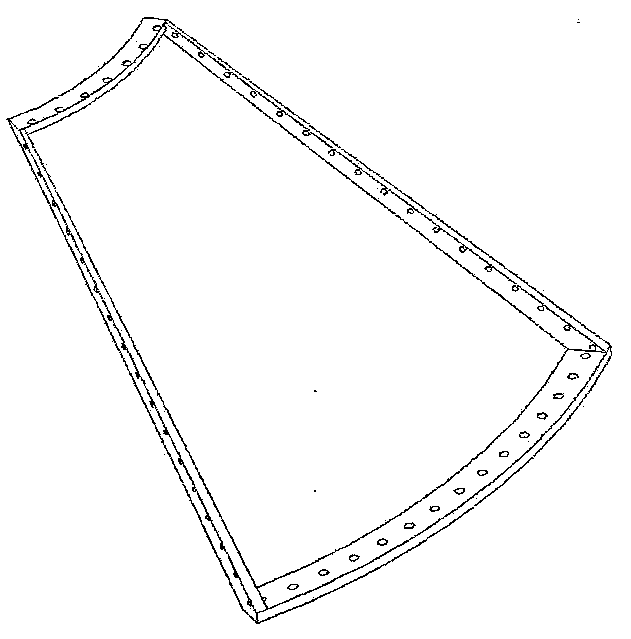

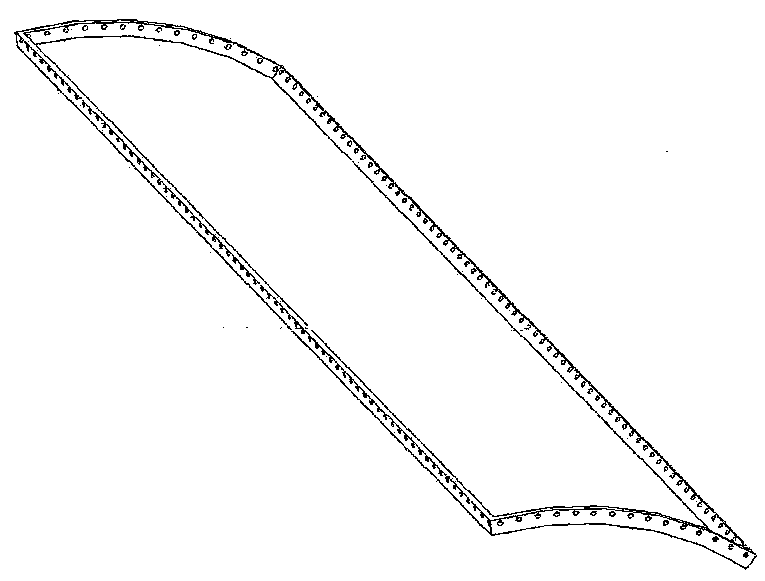

Large chemical equipment assembled by plate-shaped modules with anticorrosion liners and manufacturing method of chemical equipment

InactiveCN103691383ALow costQuality assuranceLarge containersChemical/physical/physico-chemical processesProduction lineComputer module

The invention discloses large chemical equipment assembled by plate-shaped modules with anticorrosion liners and a manufacturing method of the chemical equipment. The chemical equipment comprises the metal plate-shaped modules with flanges at the peripheries, wherein the metal plate-shaped modules are connected through bolts; the anticorrosion liner layers are lined on the inner surfaces and the flange sealing surfaces of the metal plate-shaped modules. According to the chemical equipment, a conventional design and manufacture concept is broken through, and any lined equipment with the diameter more than 4 m can be designed into large integral equipment assembled by a plurality of plate-shaped modules, so that the equipment can be manufactured on a production line in a manufacture enterprise and assembled on site, and the effects of reducing the cost and guaranteeing the quality are achieved.

Owner:潘兆金

Oil used for manufacturing of ice rind mooncake

The invention relates to an oil used for manufacturing of an ice rind mooncake. The oil mainly comprises the following components by weight: 10 to 20 parts of animal fat, 65 to 105 parts of plant fat and 1 to 2 parts of an emulsifier. The oil used for manufacturing of the ice rind mooncake has the following advantages: with the oil, the wrapper of the mooncake has good plasticity and processability, and the ice rind mooncake can be stored at normal temperature.

Owner:SHANGHAI DOILLY OIL FOODS

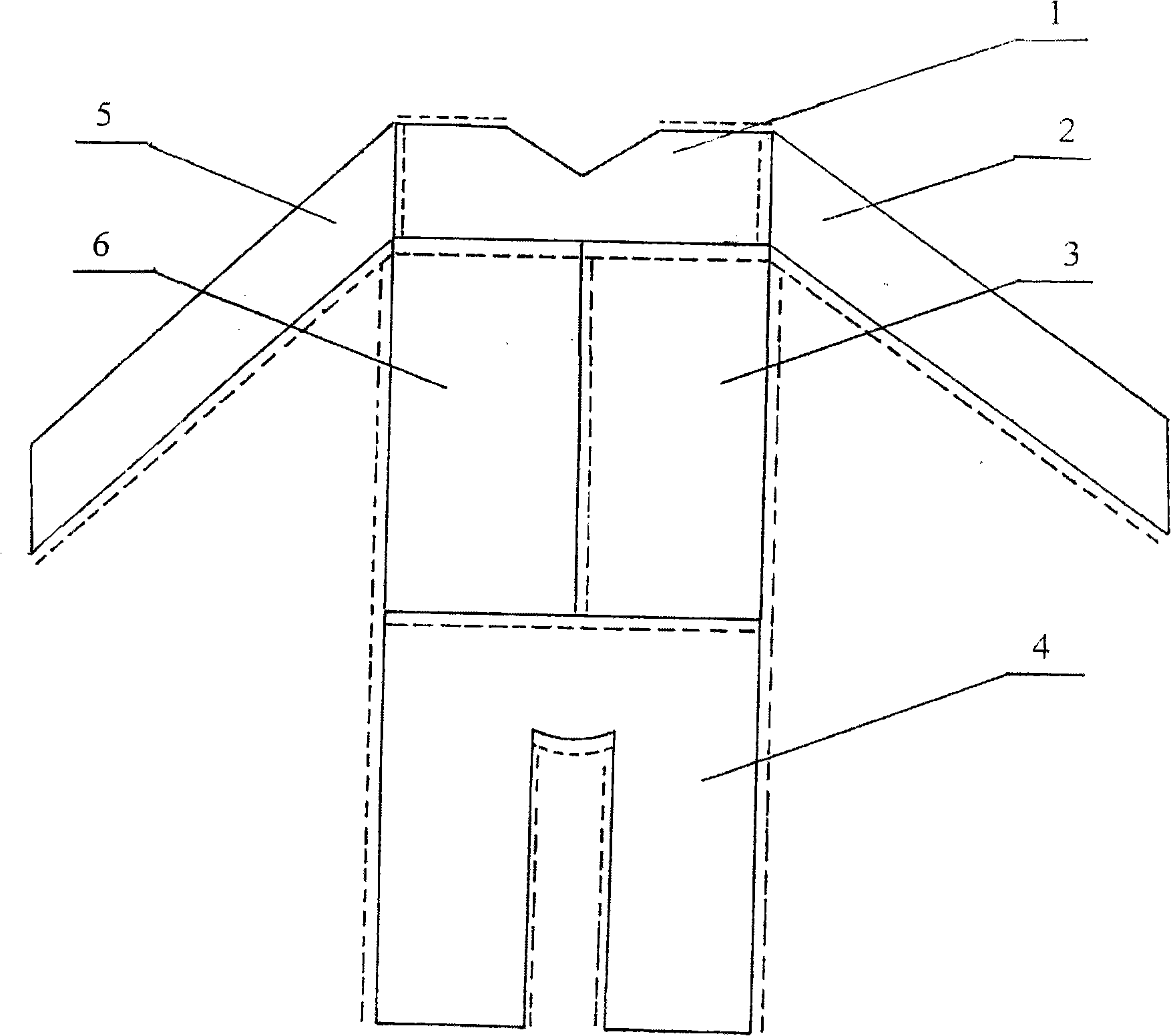

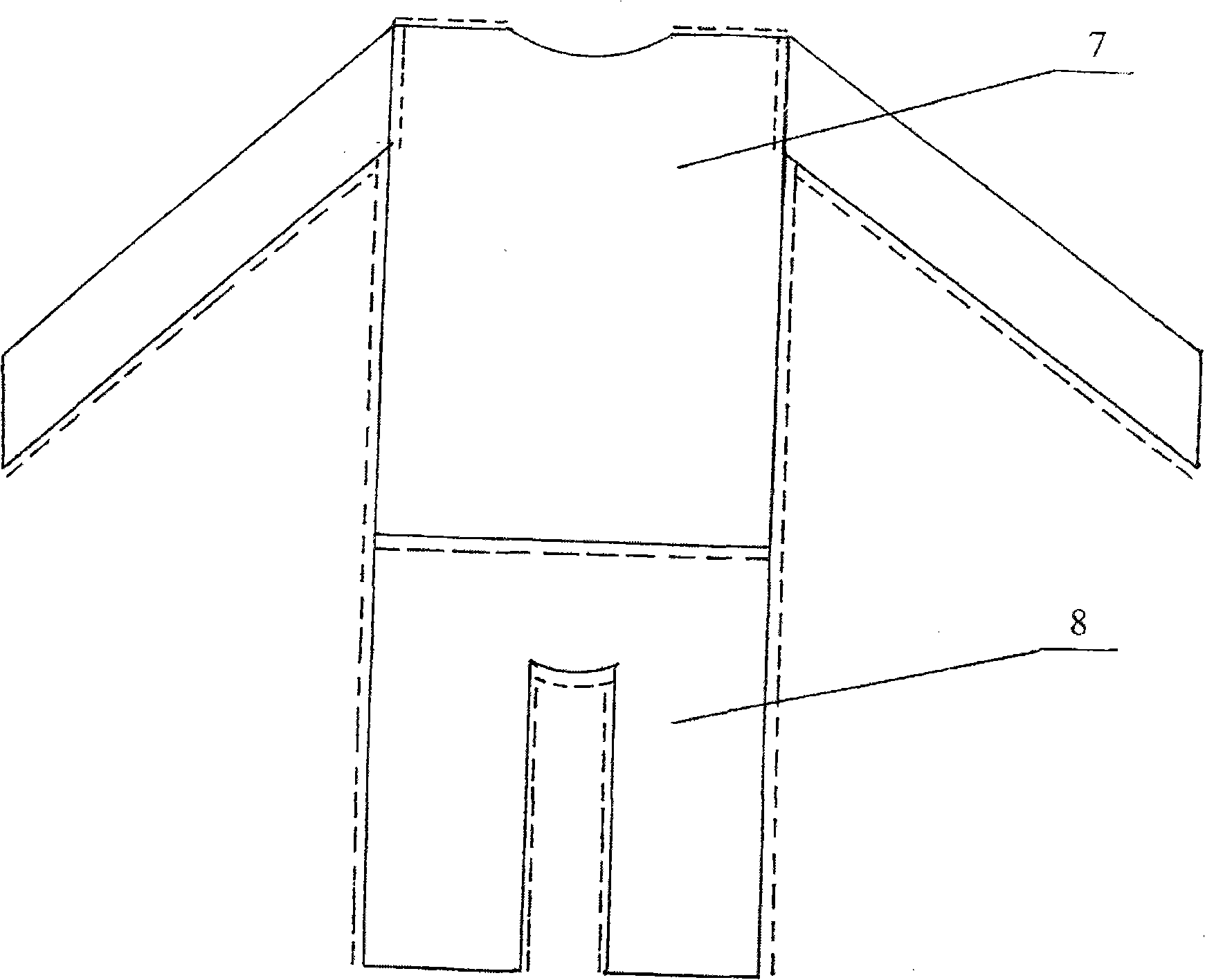

Clothes convenient for putting on and off

InactiveCN101357001AEasy to makeMeet the requirements for putting on and taking offGarmentsVertical edgeEngineering

The invention relates to a costume which is conveniently worn and taken off. The costume comprises an upper garment front upper piece, an upper garment front left piece, an upper garment front right piece, an upper garment rear piece, an upper garment left sleeve piece, an upper garment right sleeve piece, a lower garment front piece and a lower garment rear piece. The costume is characterized in that: the upper garment front upper piece is respectively connected with the upper garment front left piece, the upper garment front right piece, the upper garment left sleeve piece and the upper garment left sleeve piece; the lower garment front piece is respectively connected with the upper garment front left piece and the upper garment front right piece; the upper garment rear piece is respectively connected with the upper garment left sleeve piece, the upper garment right piece, the upper garment front left piece, the upper garment front right piece and the upper garment front upper piece; the vertical edges of the upper garment left sleeve piece and the upper garment right sleeve piece are respectively connected. After cloth is cut into pieces needed by making a garment, the outer edge of each piece is respectively wrapped by needles; after being wrapped, the connection places among all the pieces are not sewed by the needle but connected by a zipper, a plastic adhesive strip, a knot, etc. The invention provides a brand-new method for making the garment with simple process.

Owner:惠金龙

Polyphenyl sandwich light architectural material and its production method

InactiveCN1559794ASmall sizeBig moduleConstruction materialSolid waste managementBrickHazardous substance

A polybenzene sandwich building material with light weight is prepared from magnesium oxide, plant ash, powdered coal ash, assistant (efficient water-decreasing agent NB, penetrant OS15, emulsifier OP-10 and melamine), and solution of magnesium chloride (or sulfate). Its advantages are light weight, and low cost.

Owner:谢涛

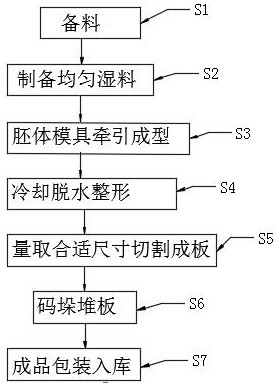

Fly ash plate and preparation method thereof

The invention discloses a fly ash plate which is composed of the following materials in parts by weight: 80 parts of fly ash, 15 parts of PVC, 5 parts of a coupling agent, 50 parts of polyvinyl chloride, 5 parts of triethanolamine, 10 parts of a calcium-zinc composite stabilizer, 5 parts of a foaming regulator, 0.5-10 part of NC, 2 parts of PE wax, 3-5 parts of NNO, 1 part of JY-0, 15 parts of silane, 5 parts of a diffusant, and 15 parts of water. The fly ash plate is simple in structure, convenient to operate, reasonable in design, free of formaldehyde, zero in release, free of radiation, free of pollution and free of bulging, has the characteristics of moisture prevention, mildew prevention, water prevention, insect prevention, corrosion prevention, static prevention, flame retardance, impact resistance, deformation resistance, wear resistance, easiness in cleaning and the like, is energy-saving, environment-friendly and stable in quality, can be recycled and reused, and has wide application prospects. The fly ash plate can be widely applied to the fields of office, civil use, hotels, schools and other furniture, decoration boards and the like, can replace natural wood and composite boards, and meets the national environment-friendly and healthy industrial development direction and the policy requirements of local governments.

Owner:新疆远疆环保科技有限公司

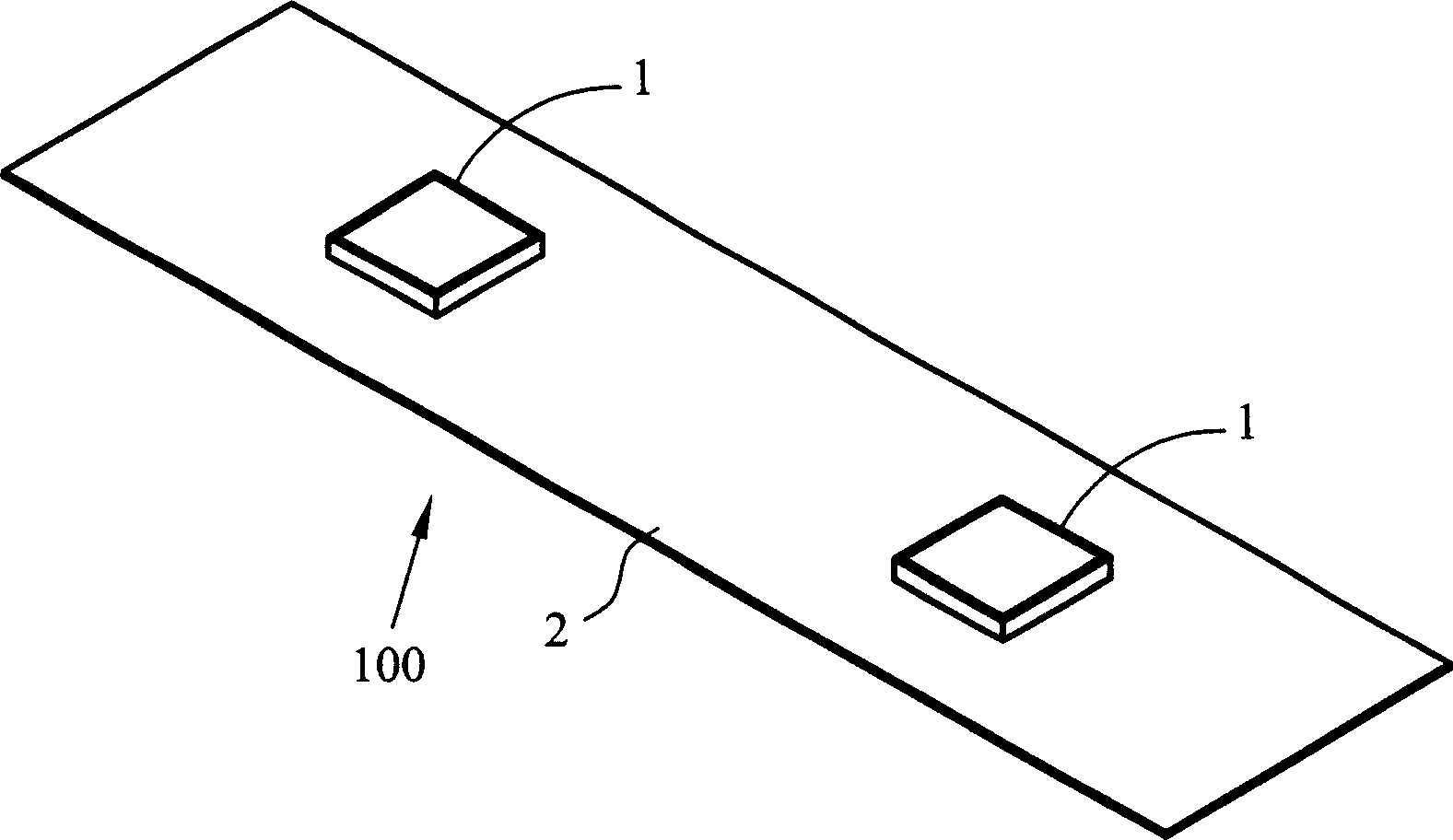

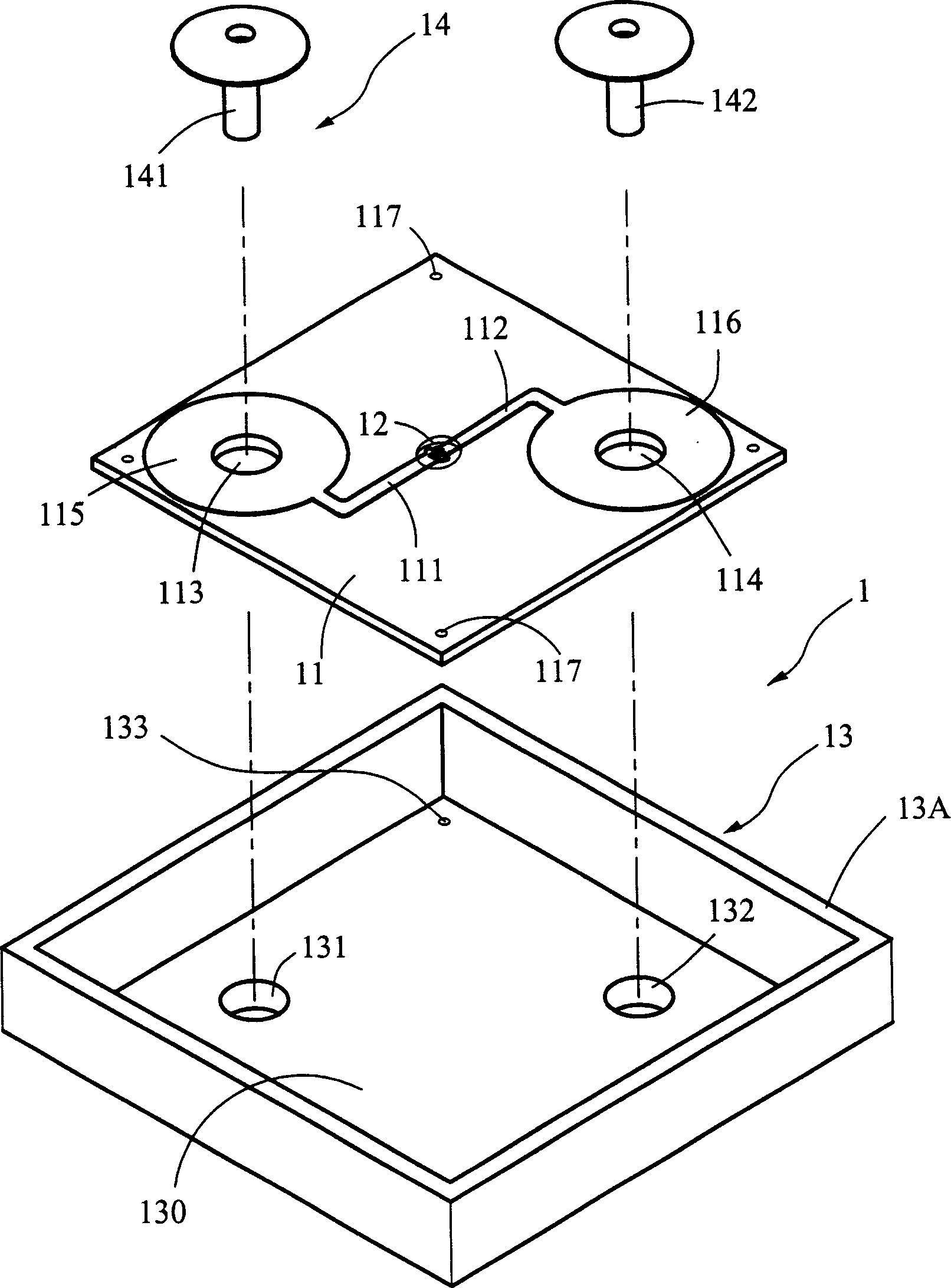

Lamp body structure for reflecting device and its manufacturing method

InactiveCN1641722AChange the production methodChange the structureIdentification meansEngineeringEconomic benefits

The invention provides a lamp body of the light-reflectance apparatus and its manufacture method. It comprises that a base plate, it is set complex number through holes; a LED lamp bank, it is set on the base plate; a base seat, it has space, and complex number fixed holes are set in it; a rivet set, it comprises complex number rivets, the rivet is drilled through the through hole and the fixed hole, and fixedly welded on the former, and it realizes electrical property connection with the LED lamp bank; a filling rubber, it is filled in the space of the base seat. This can make the lamp body of the light-reflectance apparatus has the modularization design. Thus, the manufacture and assemble of the light-reflectance apparatus have the better economic benefit.

Owner:HAYASHIBARA CO LTD

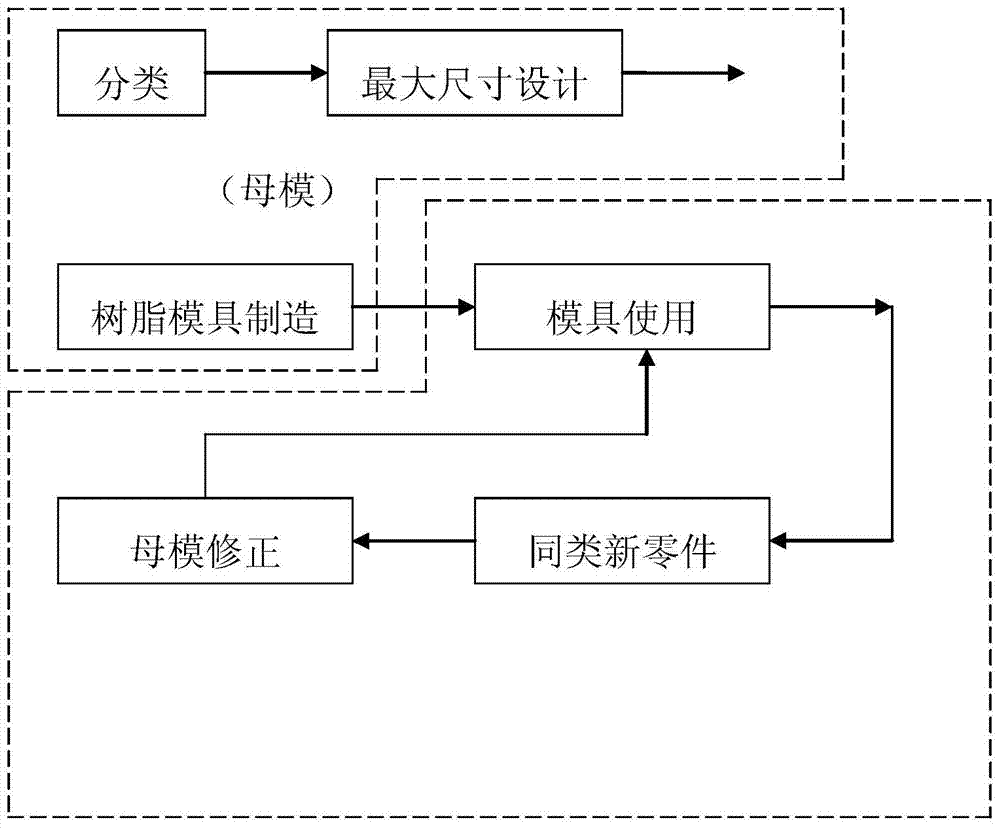

Method for manufacturing recyclable resin stamping dies

The invention discloses a method for manufacturing recyclable resin stamping dies. The method mainly aims to solve problems of single use, high manufacturing cost and incapability of being repaired in case of damage of an existing stamping die. The method includes selecting female dies; comparing like novel components to the female dies to determine correction areas; correcting the female dies; preparing resin materials and filling the female dies with the resin materials; machining new dies to obtain the new dies on the basis of the female dies. The method has the advantages that purposes of locally modifying and integrally updating resin stamping dies can be achieved on the premise that the integral structures of the resin stamping dies are not changed, and accordingly the dies can be recycled.

Owner:SHENYANG CHINA AVIATION MERITT IND CO LTD

Venison fungus dessert and preparation method thereof

InactiveCN103027243AImprove immunityEnhance immune functionFood preparationBiotechnologyAdditive ingredient

The invention relates to a dessert and a preparation method thereof and in particular to a dessert mixed by meat and edible fungi and a preparation method thereof. The venison fungus dessert is mainly composed of a wrapper, venison and edible fungi, wherein the edible fungi comprise at least one of matsutake mushroom, pleurotus eryngii, pleurotus nebrodensis and boletus; the mass percentage of each component is as follows: 15-30% of venison, 30-60% of edible fungi and the balance of wrappers. The invention also provides a method for preparing the venison fungus dessert. With the adoption of the venison fungus dessert and the preparation method thereof, the defect that the traditional dessert has no a dietary therapy function is overcome, the venison fungus dessert has herbal cuisine efficiency, the traditional preparation method of the venison is changed, nutrition ingredients of the venison, the fungi and pumpkin are sufficiently used, and the product has the efficiencies of radiation resistance, cancer resistance and blood pressure reduction.

Owner:SNTO TECH GRP

Double-layer composite production method for plastic film sheet material on blowfilm machine and equipment thereof

ActiveCN101220181BGood flexibilityIncrease stickinessFlat articlesLow-density polyethyleneAcetic acid

The invention relates to the field of fine chemical products, in particular to a producing method of double-layer composition of plastic film sheet on a plastic film blowing machine. The invention pertains to a plastic film sheet, the compositions of which are 5-65 percent of low density polyethylene and 95-35 percent of acetic acid. Difference of the producing method of the invention with the existing plastic film is that: the temperature of a die head of the plastic film blowing machine is 150 to 170 DEG C, which causes that the plastic film blown in drum shape can be directly compacted into bundles without cutting, namely, two layers of film are hot pressed into one layer. The invention has the advantages that: the tenderness of the plastic film is increased by changing the compoundingformula of the plastic film, and the viscidity of the film is also increased by enhancing the temperature of the die head; the originally separated two layers of film are closely compacted into a whole; due to the invention, the modification to the existing device is little, and the production cost is lowered. By using a small scale device for producing thick plastic film sheet, machine consumptions in production process can also be reduced and the cost is prevented from increasing due to the composing by glue and environment pollution.

Owner:福州永鑫塑料包装用品有限公司

Automatic spheroidization device for producing spherical graphite

The invention discloses an automatic spheroidization device for producing spherical graphite, which mainly comprises an automatic material supply device, a powder system, a spheroidization system, a dust recovery system and a material collection system, wherein materials enter the powder system from the automatic material supply device and after being processed, and enter the spheroidization system and the material collection system in turn; the whole process is carried out in a sealed pipe in sequence; a vacuum exhaust fan is used for providing power; and in a production process, the efficiency is high and no pollution is generated. The device can realize the fully-automatic control in a whole process from material supply to powder making to spheroidization to separation to product recovery to dust recovery; the prepared graphite powder is spherical material; the surface of the graphite powder has openings; the values, which are preset before production, of the tap density, specific surface area and size distribution can be achieved; the product quality is stable; the yield can be improved by more than three times; over 40 percent of energy can be saved; over 60 percent of cost can be saved; and dust leakage and high noise are prevented.

Owner:LUOYANG GUANQI INDAL & TRADE

A receiving mechanism capable of automatically collecting pulp output from a pulp press in rolls

ActiveCN104911941BEasy to operateChange the production methodPaper-making machinesEngineeringPulp and paper industry

Owner:福建铙山科技有限公司

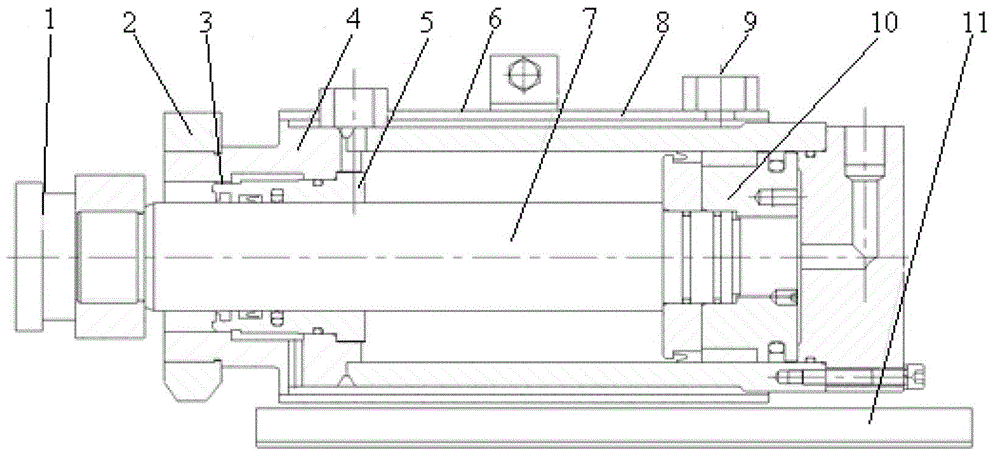

Coking experimental coke oven and coking experimental method

ActiveCN108659863BThe same heightGuaranteed accuracyRetortsCoke oven detailsThermodynamicsProcess engineering

The invention relates to an experimental coke oven and experimental method for coking. The experimental coke oven for coking comprises a coke oven support, an experimental coke oven, a pressurizing device and a detection device, wherein the experimental coke oven is composed of an oven wall, an oven chamber, an oven cover, an oven bottom tray and a heating element; the oven bottom tray is connected with a vertical rod of the coke oven support through a rocking arm and a lifting device, and can rotate around the vertical rod under the driving of the rocking arm and vertically move up and down under the driving of the lifting device; the pressurizing rod of the pressurizing device penetrates the oven cover to connect to a pressurizing plate which is pressed on a coal sample; the detection device comprises a temperature sensor, a pressure sensor and a displacement sensor; and the top of the oven cover of the experimental coke over is provided with a waste gas chimney. The experimental coke oven and experimental method of the invention can perform conventional coking experiments and pressurized coking experiments; the accuracy of the coke quality predicted by the experimental coke ovencan be guaranteed; and the reliability of the experimental coke oven in guiding coke production process reaches a new height.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com