Method for manufacturing recyclable resin stamping dies

A stamping die and manufacturing method technology, which is applied in the field of resin stamping die manufacturing, can solve the problems of high environmental requirements, waste, and high cost, and achieve the effects of reducing environmental pollution sources, improving work efficiency, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

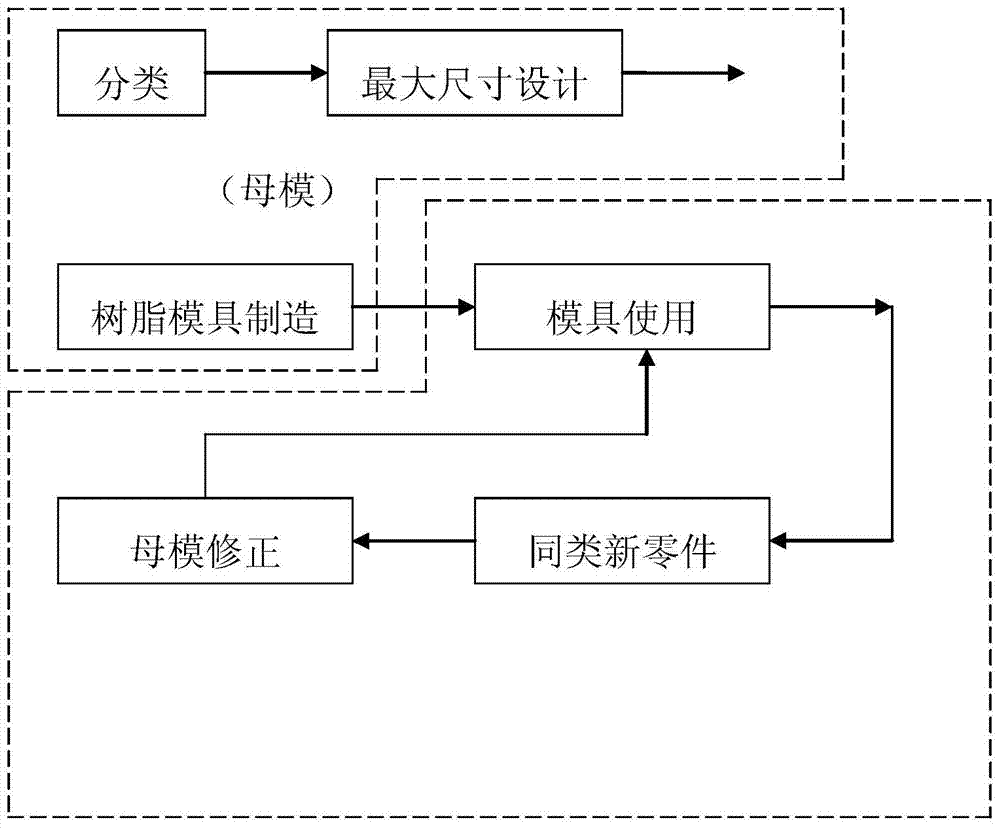

[0040] Such as figure 1 As shown, a manufacturing method of a recyclable resin stamping die, its specific implementation steps are as follows:

[0041] (1) Selection of the master mold: first classify the parts according to the purpose, select the largest size of the same kind of parts to design the mold, and the mold manufactured according to this size is used as the master mold; the master mold is a resin stamping mold for rapid parts, master model for use;

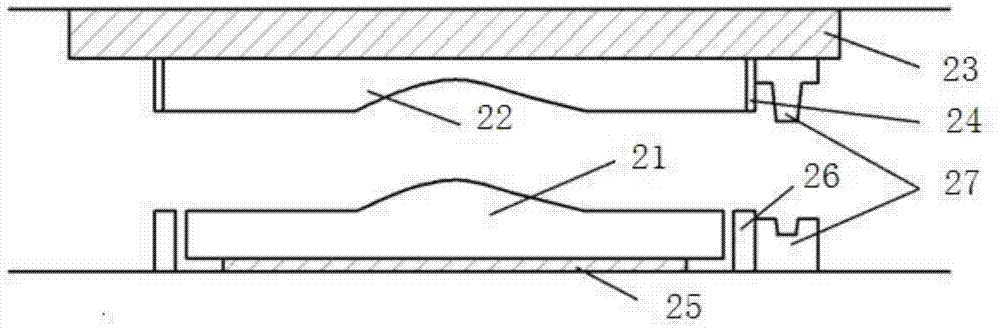

[0042] (2) Refer to image 3 , Determine the correction area: After the master mold is used, after comparing it with the new parts of the same kind, determine the correction area of the master mold according to the difference between the stamping surface shape of the new parts of the same kind and the master mold;

[0043] (3) Refer to Figure 4 , Modification of the punch: use a cutting machine to remove the excess resin material from the protruding part of the punch of the master die until the surface of the punc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com