A receiving mechanism capable of automatically collecting pulp output from a pulp press in rolls

A technology of receiving mechanism and pulping machine, which is applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems of high production cost, low production efficiency, inconvenience, etc., and achieve simple and convenient operation, innovative technology level, and change production The effect of method and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

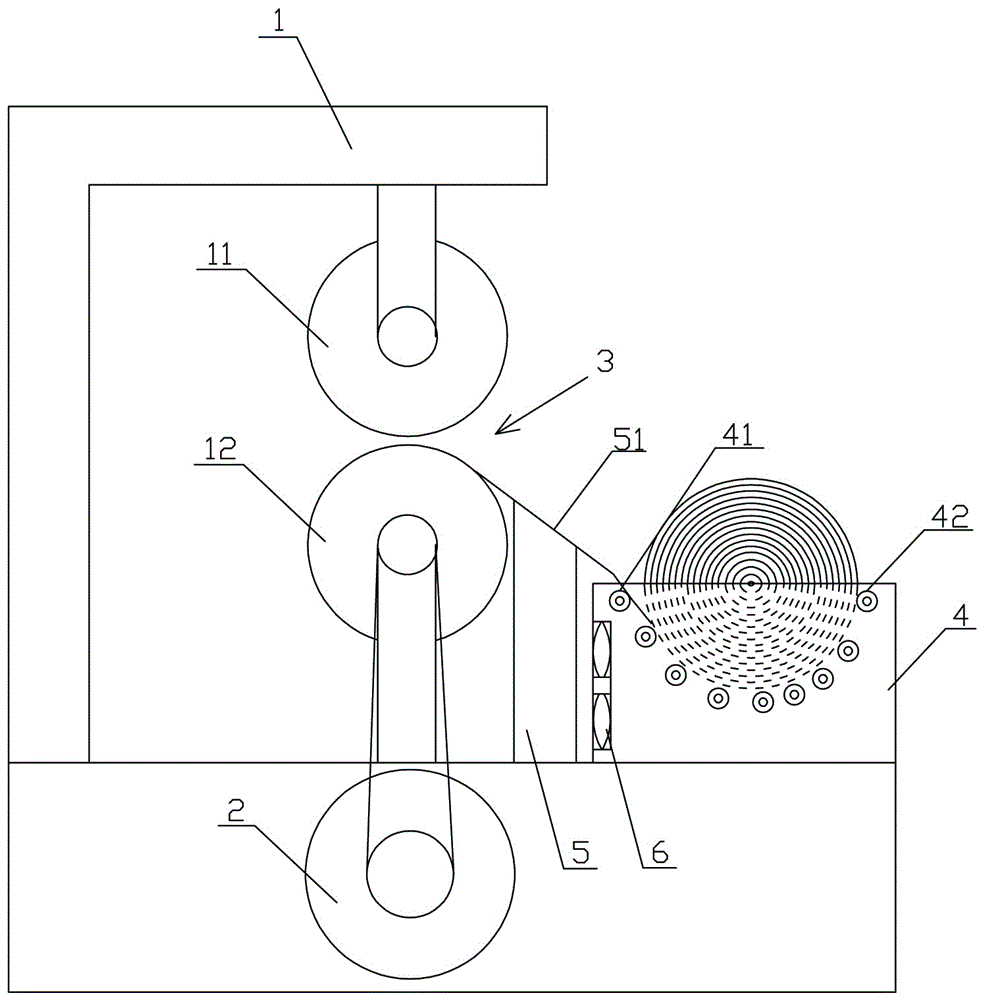

[0021] Such as figure 1 As shown, a rewinding mechanism capable of automatically collecting paper slurry output from a press includes a press roller mechanism 1 of the press and a first drive motor 2 drivingly connected to the press roller mechanism 1 The pressing roller mechanism 1 includes two upper rollers 11 and a lower roller 12 that are matched with the pressing rollers to squeeze materials. The first driving motor 2 is drivingly connected to the lower roller 12, and the upper roller 11 Rotation is driven by the rolling pressure of the lower roller 12. A discharge port 3 is provided between the upper roller 11 and the lower roller 12, and a receiving table 4 is provided below the discharge port 3. A shoveling table 5 is also provided between the discharging port 3 and the receiving table 4. The shoveling table 5 includes a shovel blade 51 arranged obliquely, and the blade edge of the shovel blade 51 is attached to the lower roller. On the roller surface of the wheel 12, a...

Embodiment 2

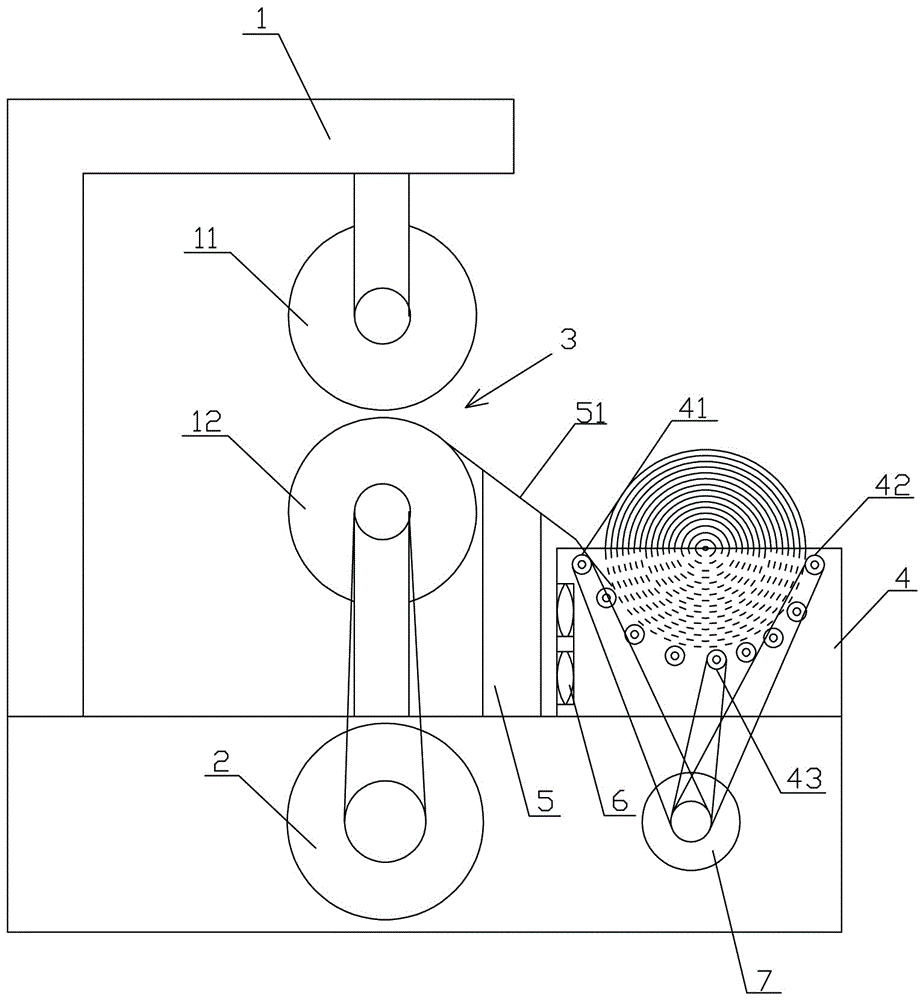

[0025] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that the present invention also includes a second driving motor 7, which is respectively drivingly connected to the first receiving roller 41 and the second receiving roller 42 , And the rotation direction of the first take-up roller 41 and the second take-up roller 42 are the same, and both rotate in a clockwise direction, so that the semi-wet dry pulp entering the receiving table 4 can be better rolled and packed It prevents the semi-wet dry pulp from being blocked when the roll reaches the highest point, which leads to the failure of roll packing, and improves the efficiency of roll packing of the present invention. The other structure is exactly the same as that of the first embodiment, and will not be repeated here.

Embodiment 3

[0027] Such as image 3 As shown, the difference between this embodiment and the first embodiment is that the present invention also includes a second drive motor 7, which is also compatible with the third receiving material at the bottom end of the semi-circular arc section of the receiving platform 4. The roller 43 is drivingly connected, and at the same time, the first receiving roller 41 and the second receiving roller 42 are also respectively drivingly connected with the second driving motor 7, and the first receiving roller 41 and the second receiving roller 42 , The rotation direction of the third take-up roller 43 is the same, and all rotate in a clockwise direction. In this way, the semi-wet dry pulp entering the receiving station 4 can be better packaged in rolls, preventing the semi-wet dry pulp from being blocked when the roll reaches the highest point or the lowest point, resulting in failure of roll packaging. The efficiency of the roll packing of the invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com