Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Avoid excessive erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

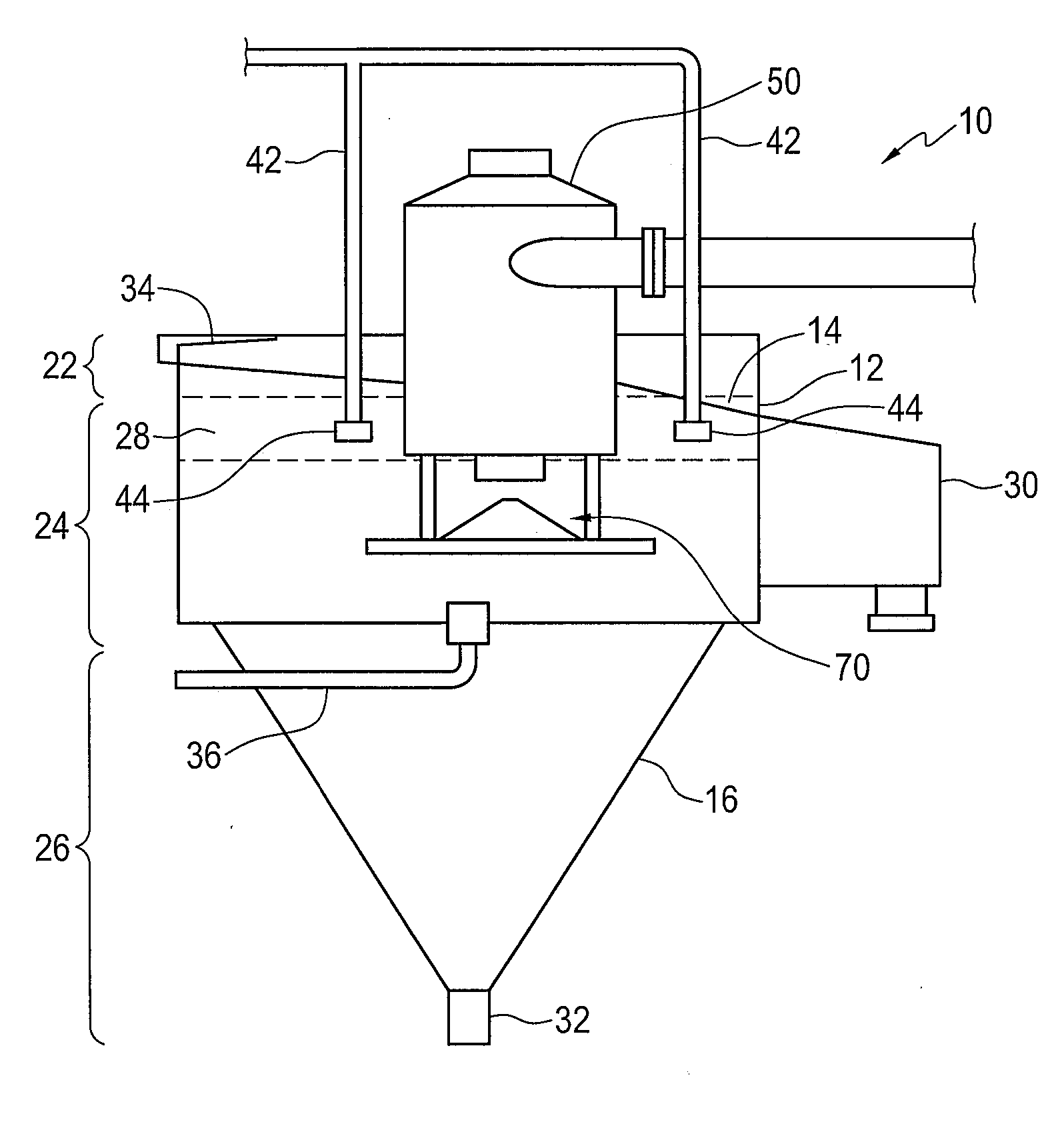

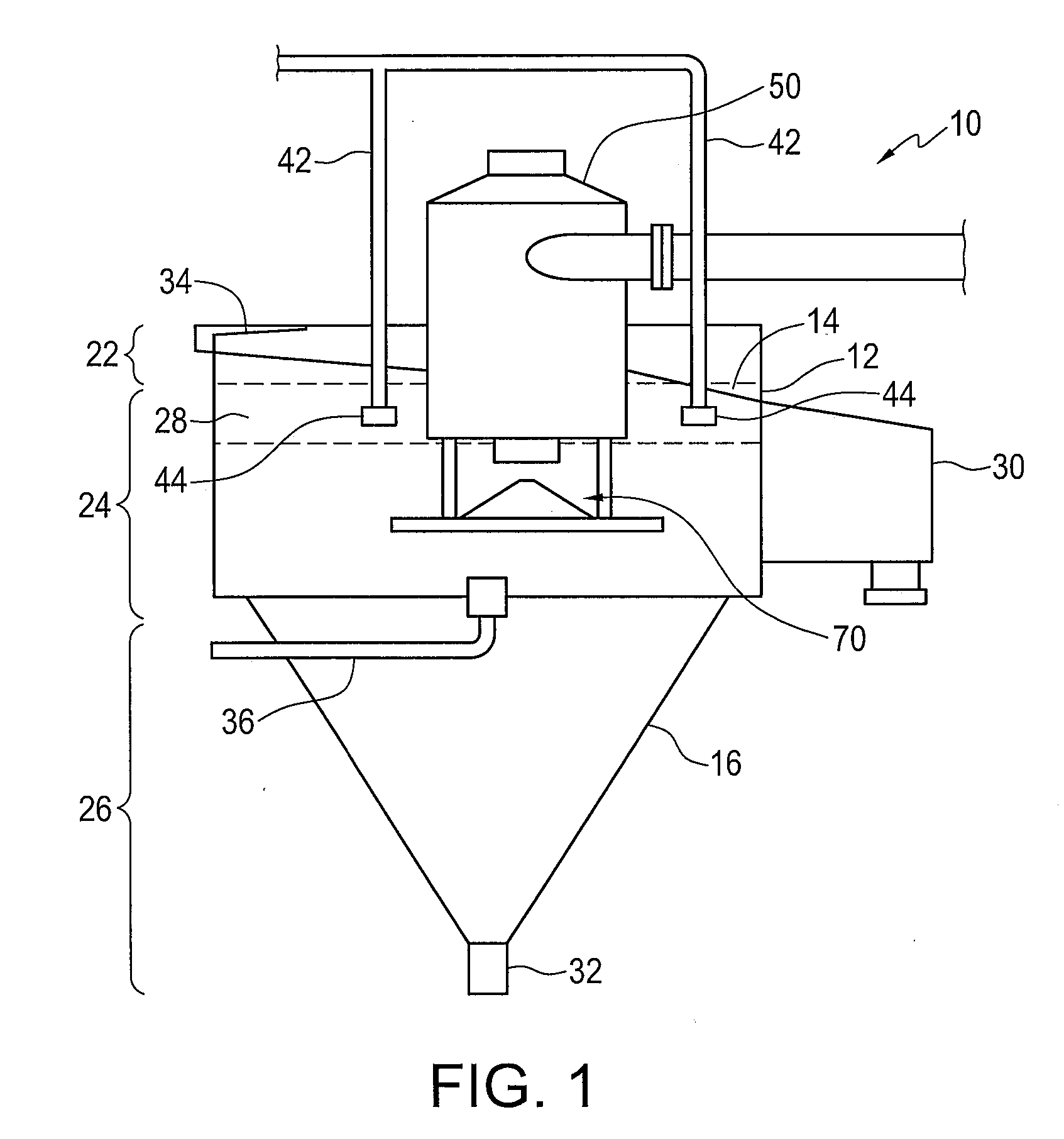

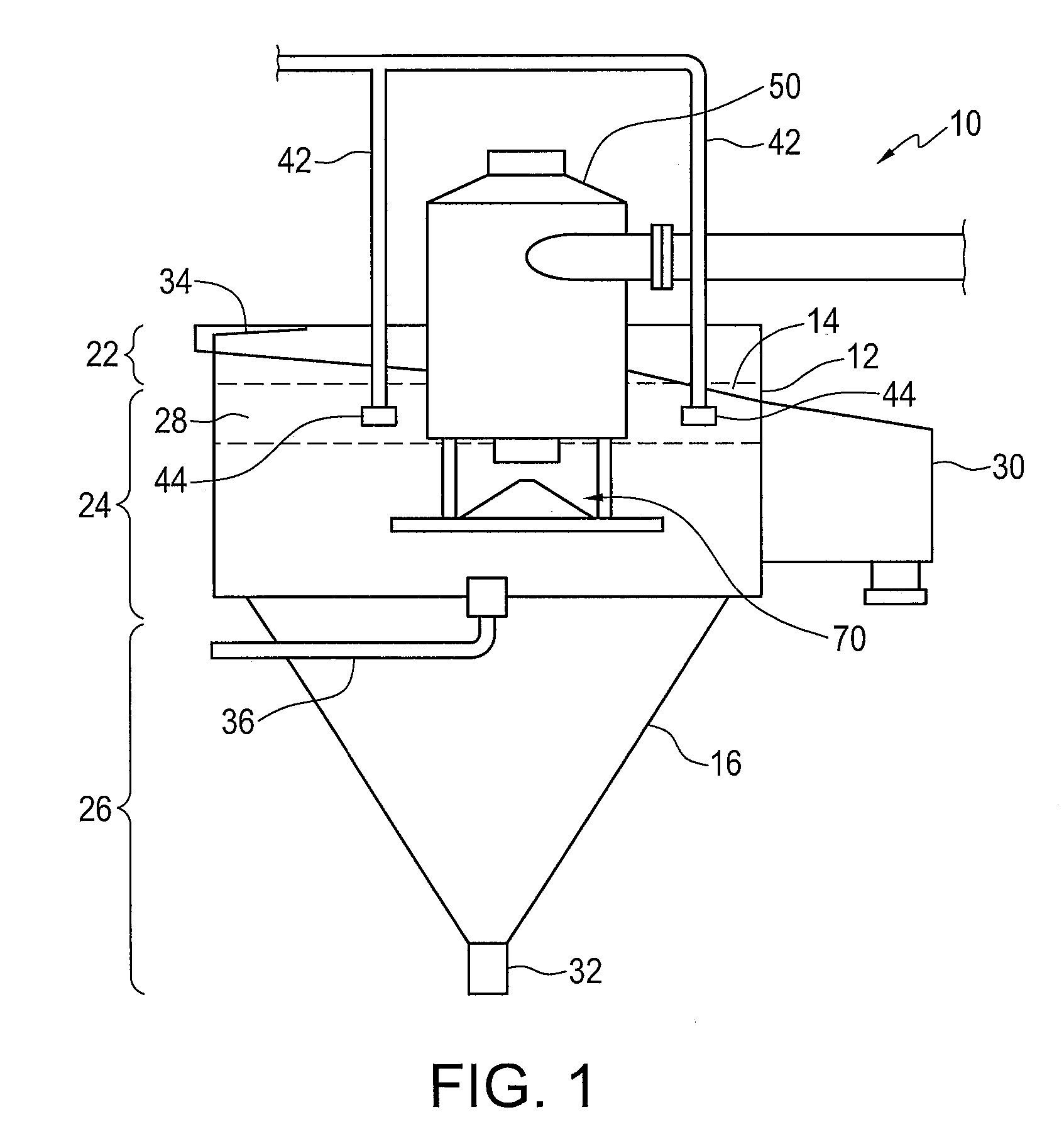

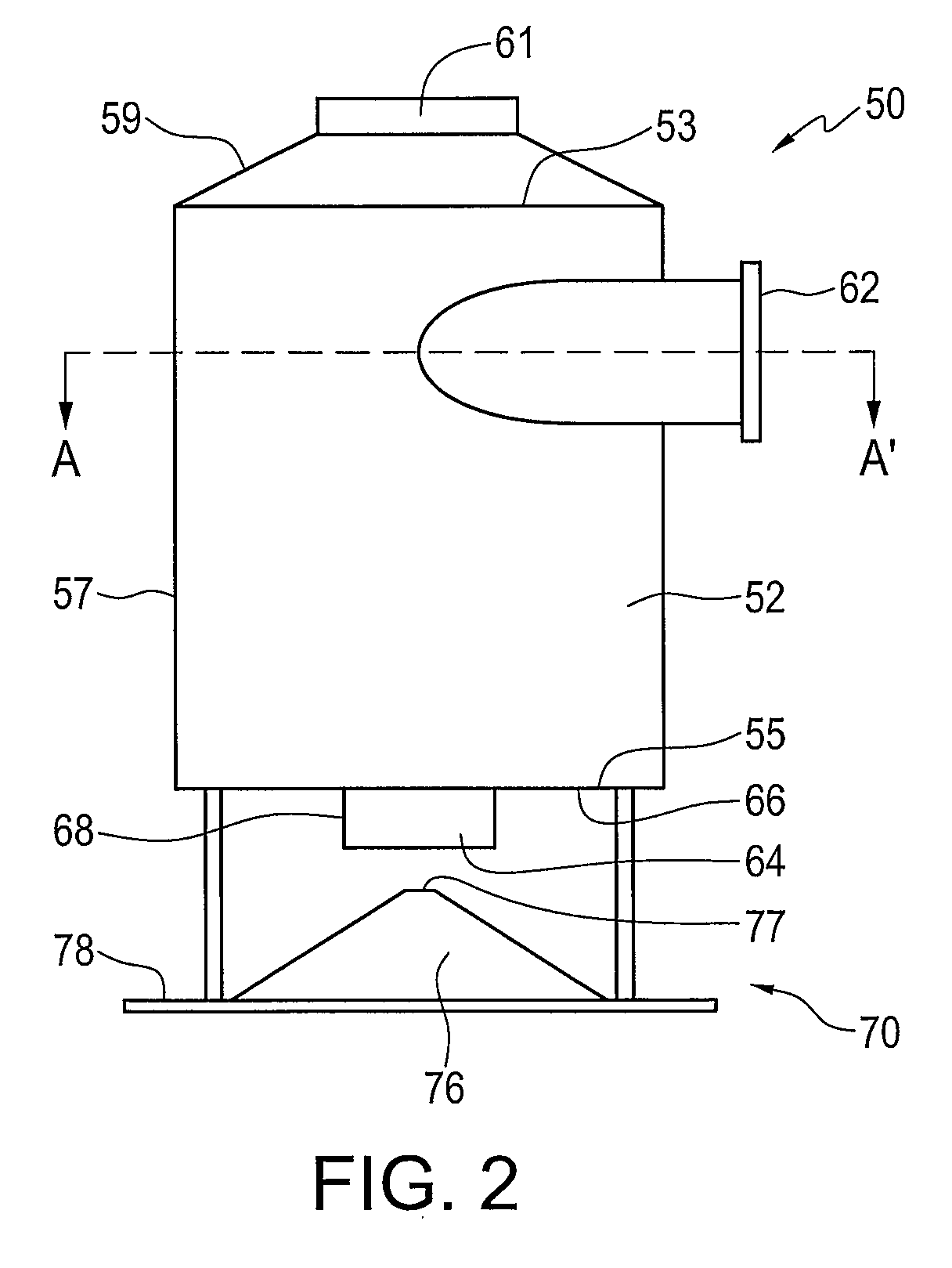

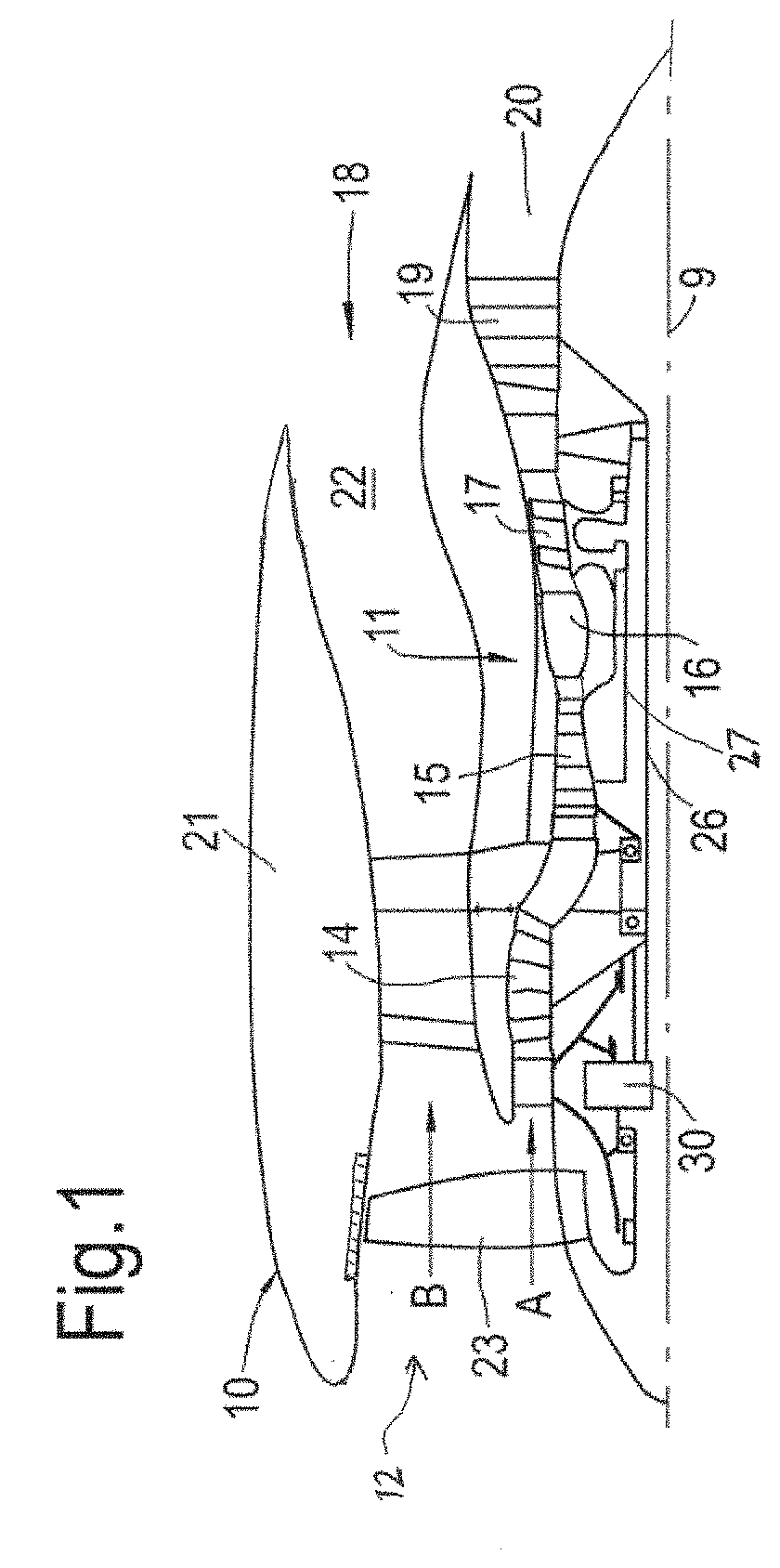

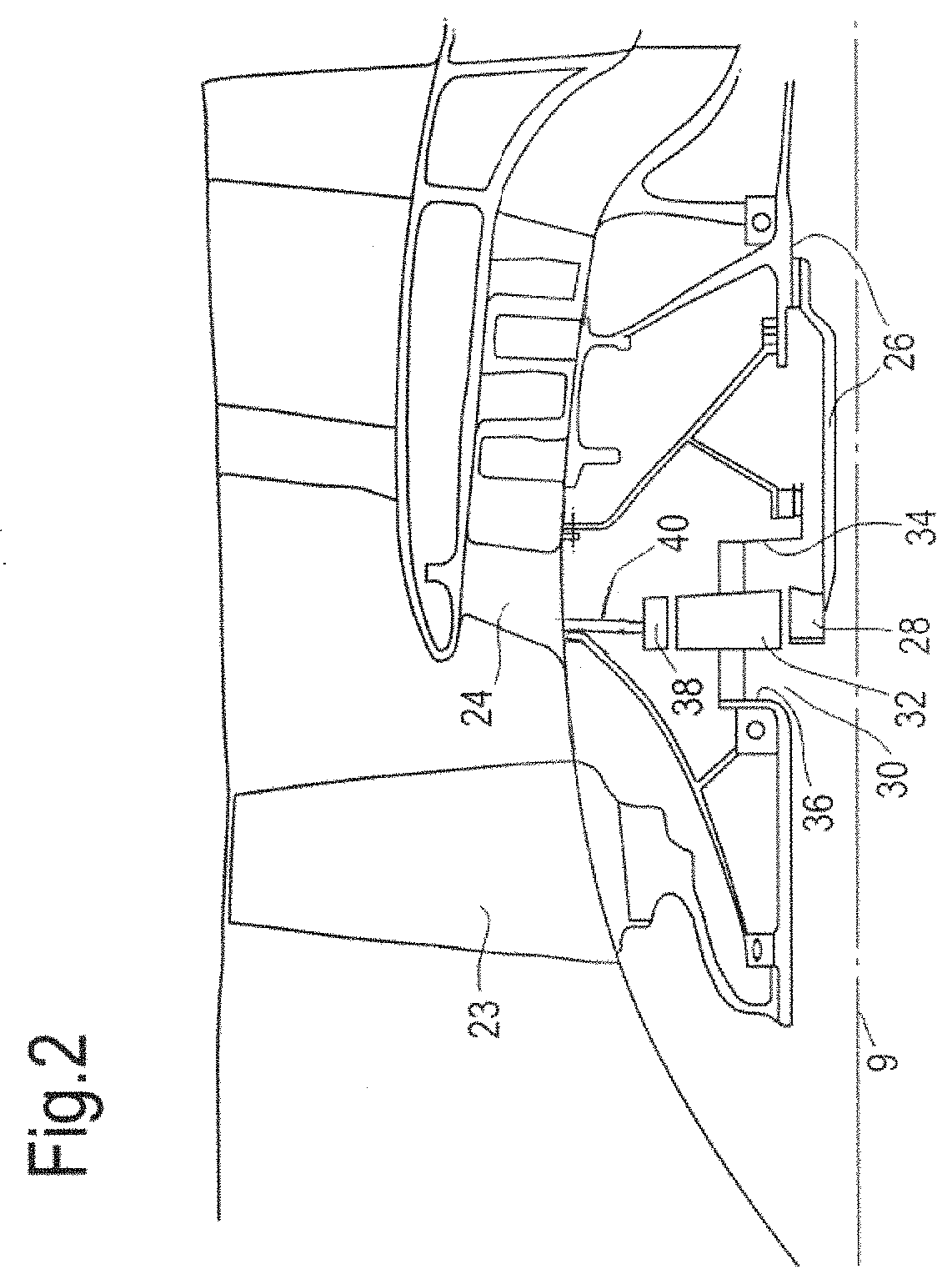

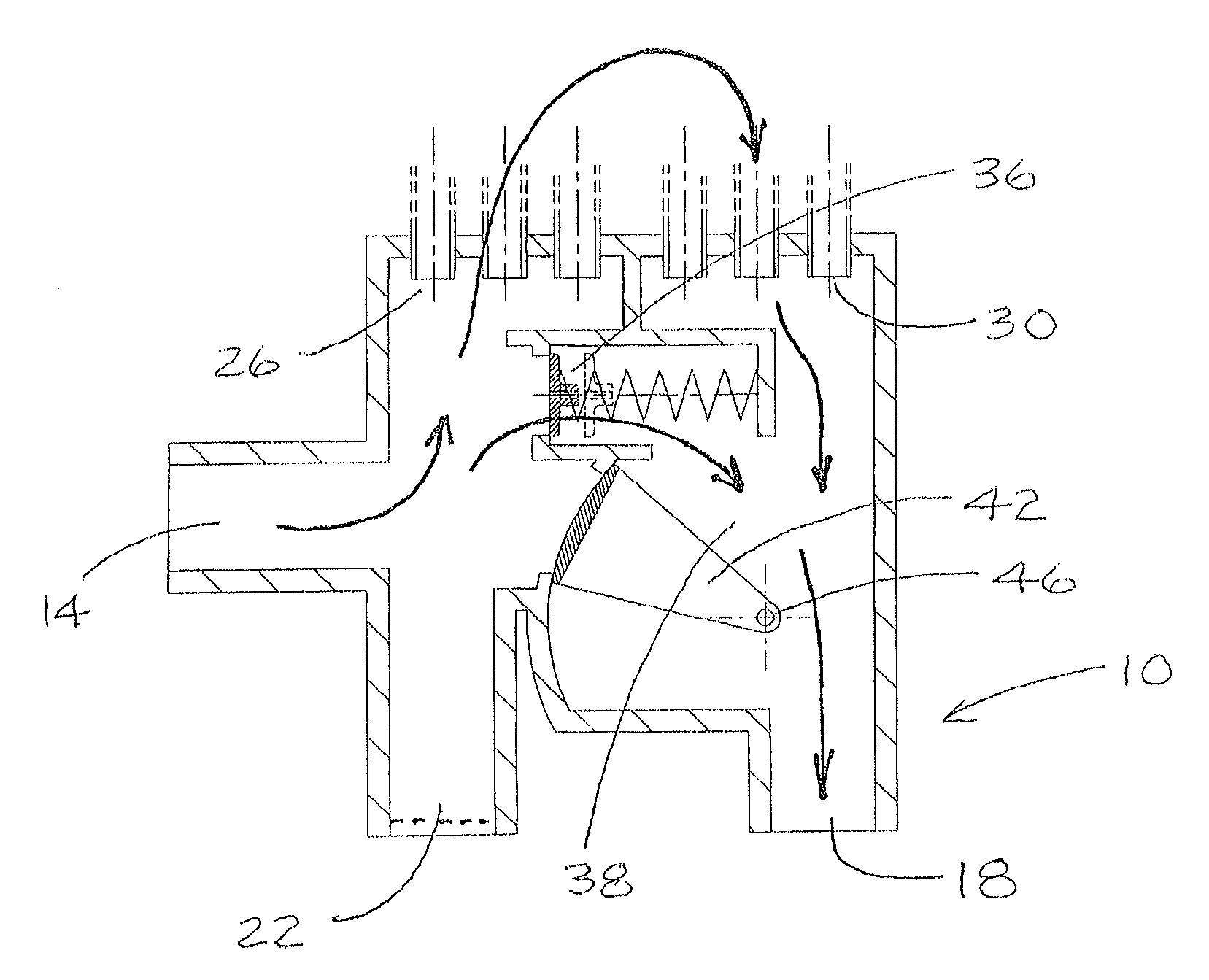

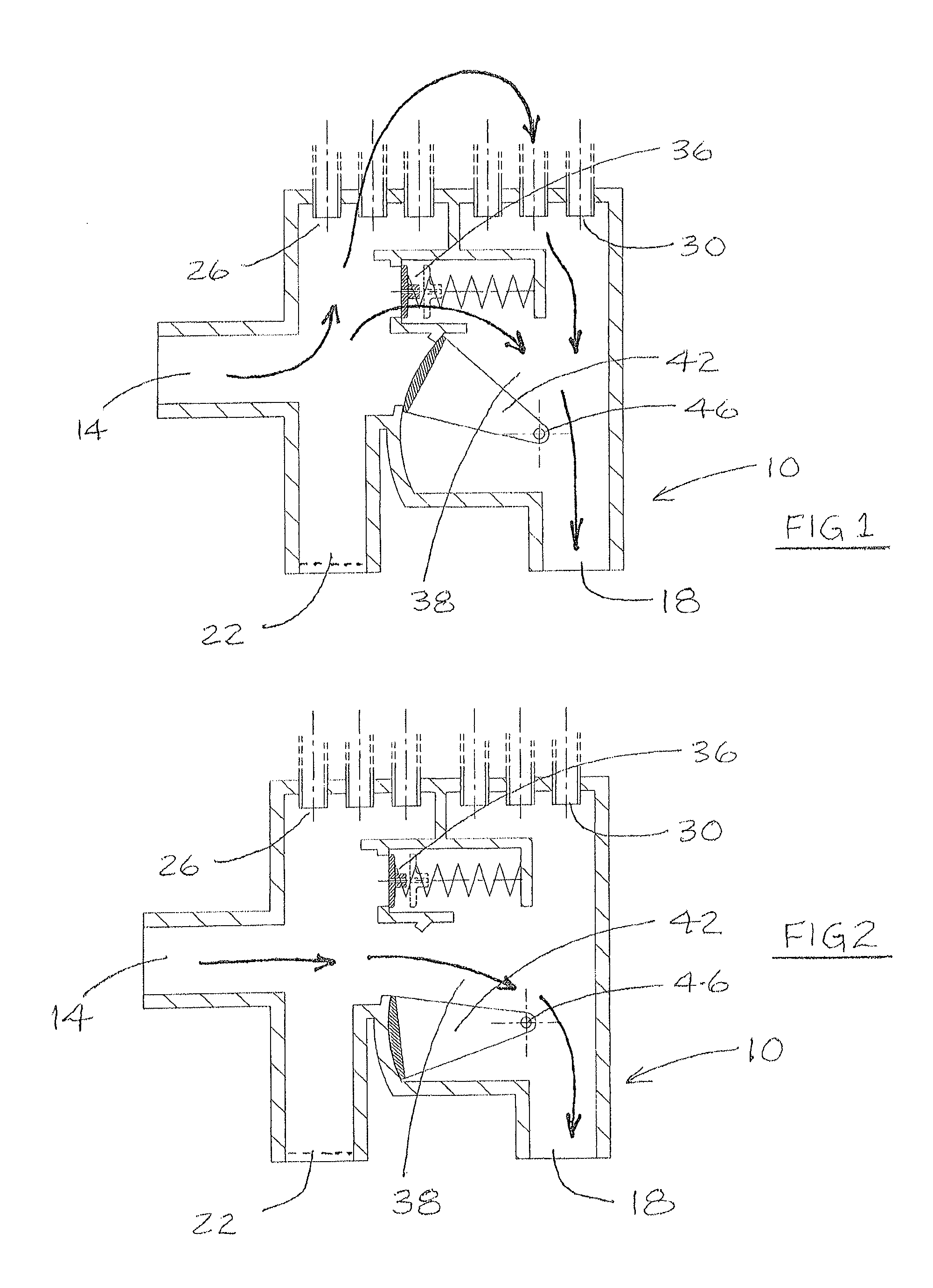

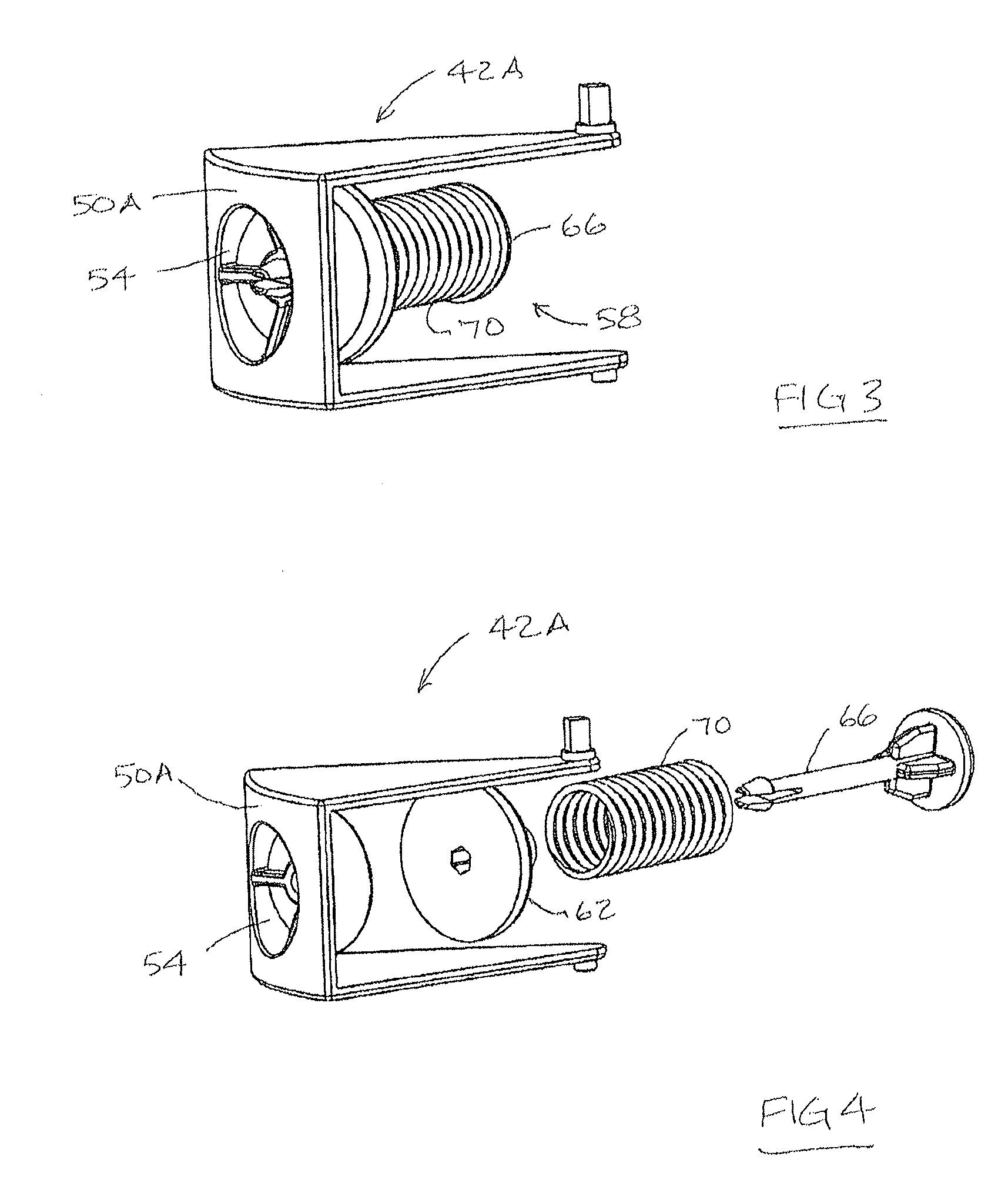

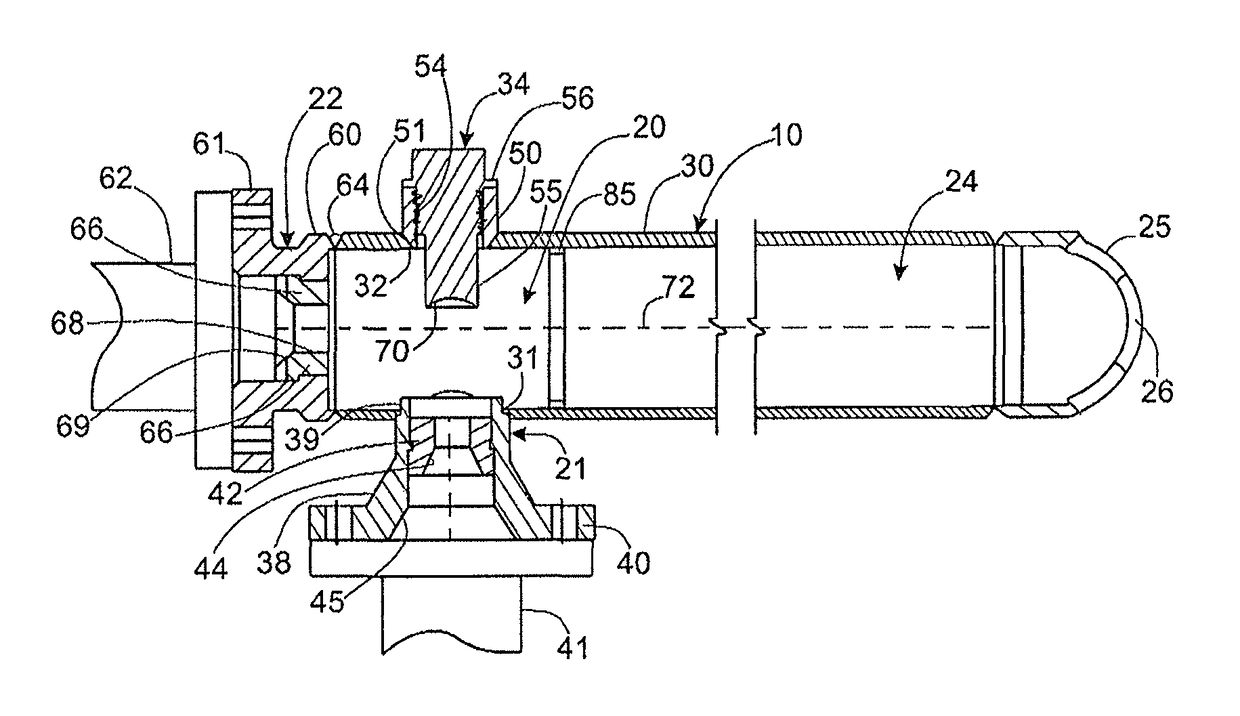

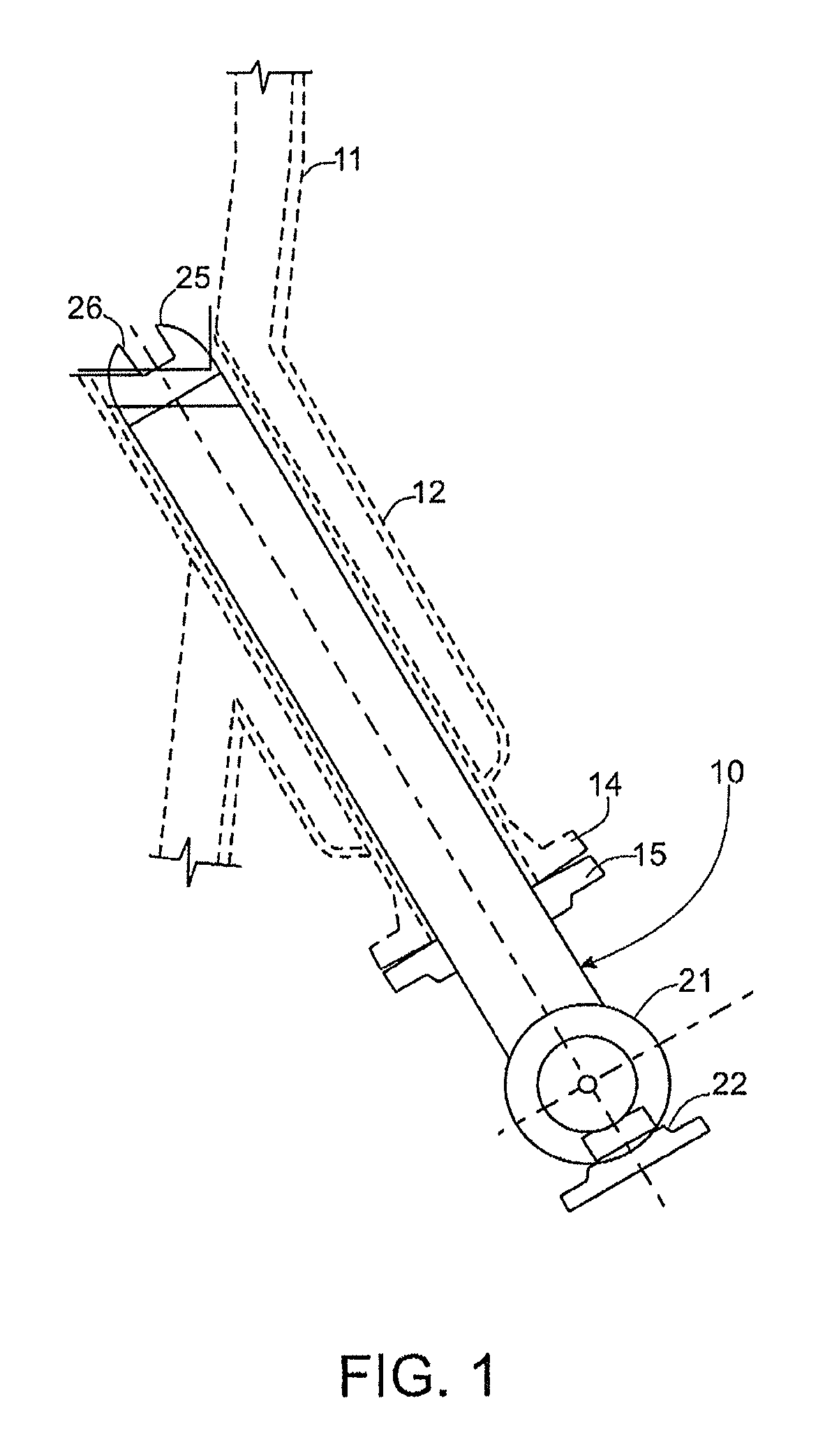

Feedwell for a gravity separation vessel

InactiveUS20110062090A1Evenly distributedReduce momentumWater/sewage treatmentLiquid displacementSlurryGravity separation

A feedwell for a gravity separation vessel for introducing a feed stream such as oil sand slurry to the gravity separation vessel is provided comprising a walled member having an upper perimeter edge, a lower perimeter edge and a substantially continuous wall extending from the upper perimeter edge to the lower perimeter edge; an inlet for introducing the feed stream into the walled member positioned adjacent the substantially continuous wall; and a bottom floor having an opening and extending generally beneath the lower perimeter edge; whereby a perimeter of the opening is less than a perimeter of the walled member.

Owner:SYNCRUDE CANADA LTD

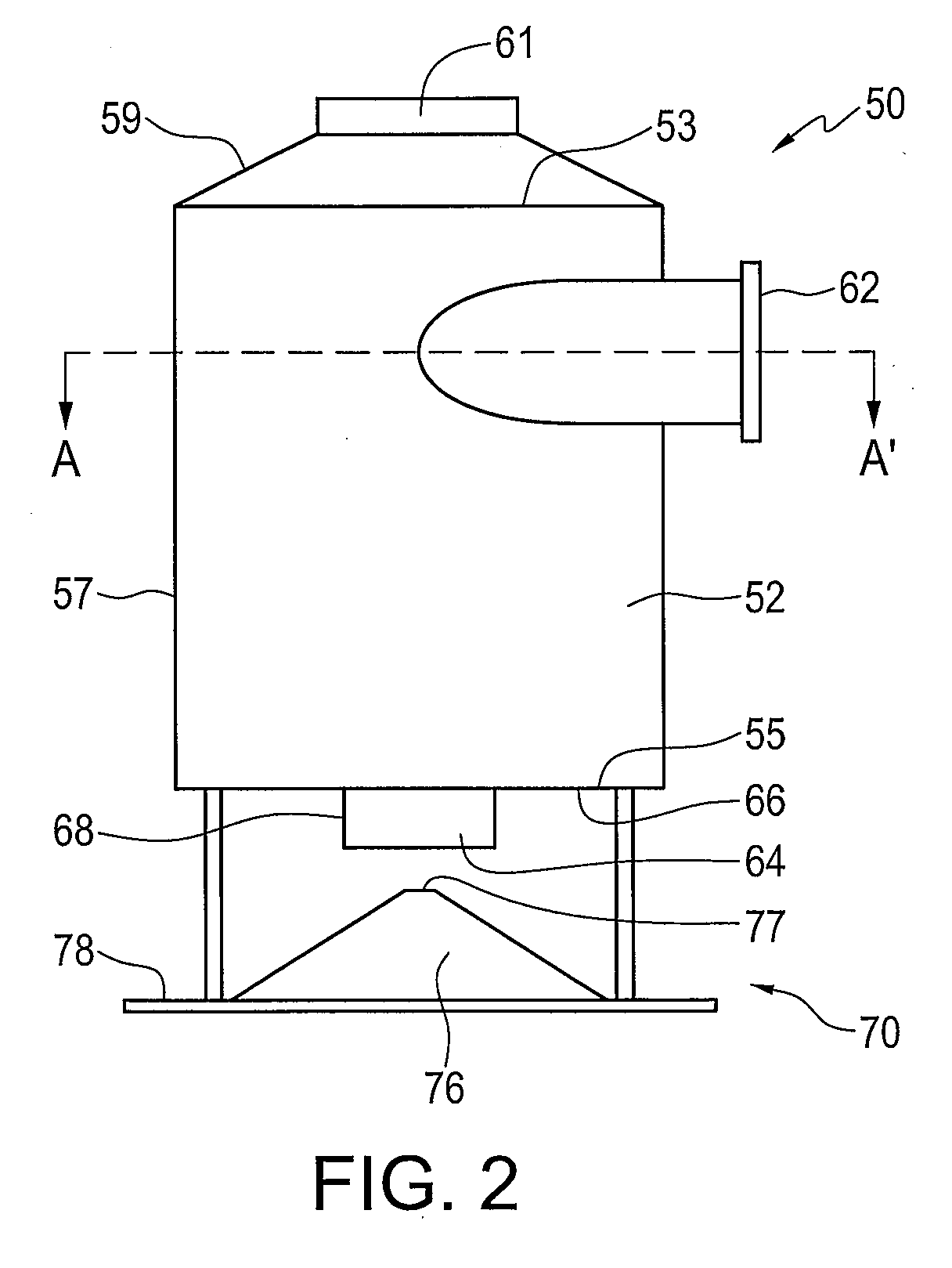

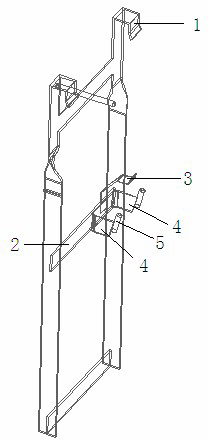

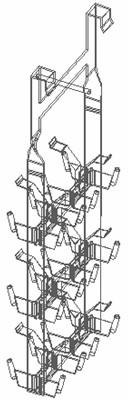

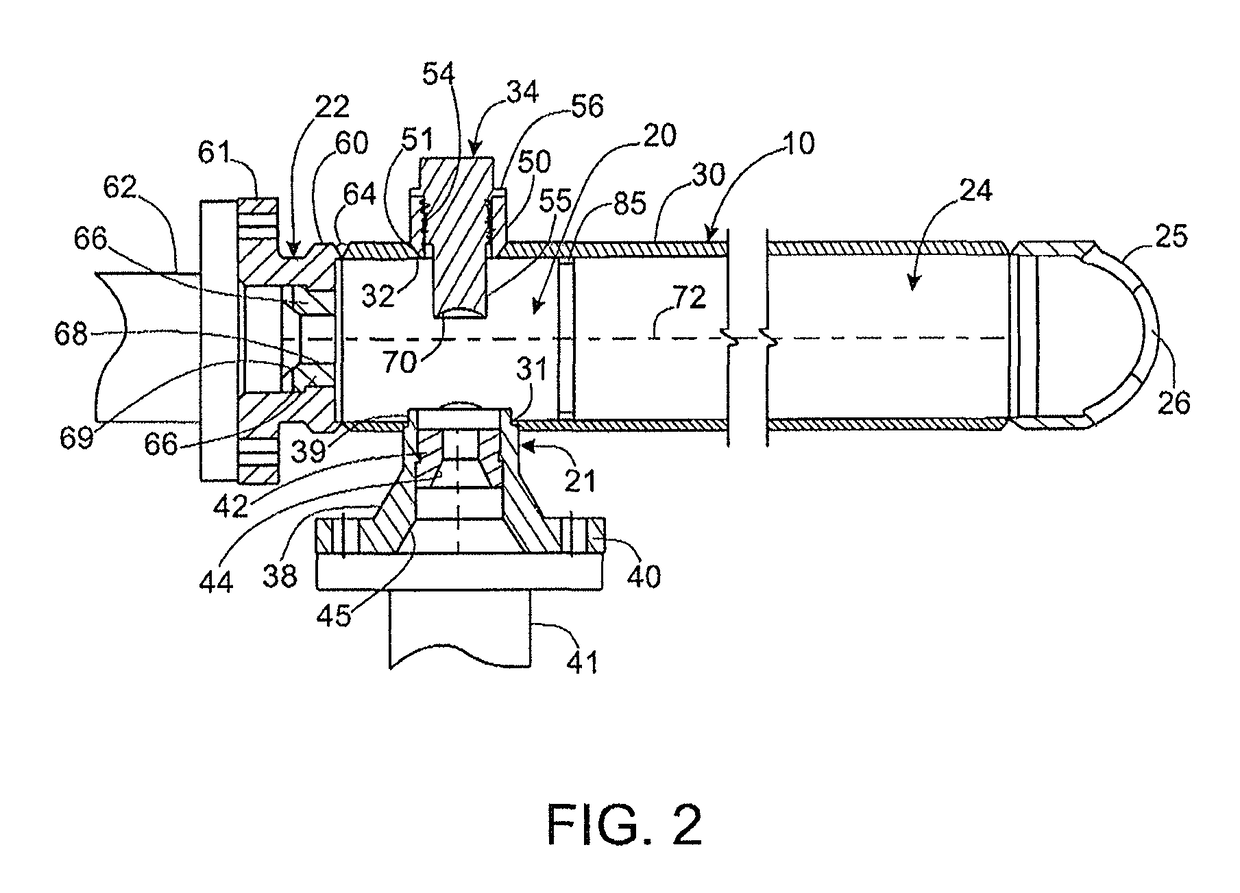

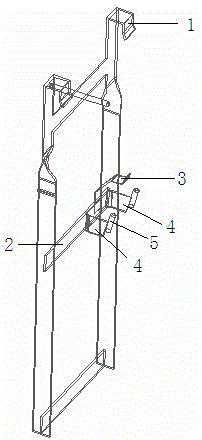

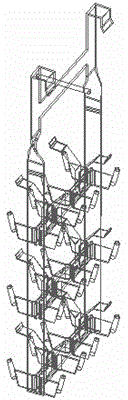

Jet type torsional impact drilling tool

ActiveCN103774983AIncreased torque averageReduce stick-slipReciprocating drilling machinesConstructionsWorking lifeWell drilling

The invention relates to a jet type torsional impact drilling tool. The jet type torsional impact drilling tool comprises an upper connector, an outer shell, a float valve, a valve seat spreader plate, a jet element, a jet spreader plate, a punch hammer, an impact transmission cylinder and a spring. The upper connector is fixedly connected with the outer shell, the outer shell is fixedly connected with the impact transmission cylinder, the float valve, the valve seat spreader plate, the jet element, the jet spreader plate and the spring are located in the outer shell, and the punch hammer is arranged in the transmission cylinder. According to the jet type torsional impact drilling tool, the attachment jet element generates alternating jet to drive the punch hammer to swing left and right, and the punch hammer collides with and impacts on the transmission cylinder to make underground torque greatly fluctuate; compared with a conventional drilling mode, the mean value of the torque of an underground drill bit is increased, the torque of the underground drilling tool is made to greatly fluctuate at high frequency in the drilling process, the stick slip phenomenon of the drill bit is alleviated, the probability of bit bouncing is reduced, and drilling efficiency is improved. The drilling tool is fewer in movable parts and quick-wear parts, long in normal work life, and high in safe reliability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Deoxidation method for converter tapping molten steel

The invention discloses a deoxidation method for converter tapping molten steel. The deoxidation method comprises the steps of: firstly adding a deoxidizer into a ladle before the converter tapping, wherein the addition amount of the deoxidizer is 1.75-4.0kg per ton of tapping molten steel; then tapping at 1660-1700 DEG C and blowing argon to the bottom of ladle at the same time; adding a deep deoxidizer when the tapping molten steel accounts for 30%-40% of the total molten steel, and carrying out deep deoxidation, wherein the addition amount of the deep deoxidizer is 0.5-2.5kg per ton of tapping molten steel, and the addition of the deep deoxidizer is finished before that the tapping molten steel accounts for 75% of the total molten steel. The deoxidation method disclosed by the invention has the advantages that the pre-deoxidation is finished by mainly adopting relatively cheap deoxidizer such as carbon powder, SiC and CaC2 and final deoxidation is finished by cooperating with the deep deoxidizer; and the deoxidizer can effectively reduce the oxidation property of the slag on the surface of the molten steel, is beneficial to reducing the oxidation loss of alloying element and reducing the oxidation erosion of the slag to the refractory, and significantly improves the yield of the alloying element.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Preparation method for high-dispersity carbon fiber

InactiveCN104562299AGood dispersionChange surface wettabilityArtificial filament chemical after-treatmentDispersityFiber

The invention belongs to the technical field of preparation methods of carbon fibers, and particularly relates to a preparation method for a high-dispersity carbon fiber. The preparation method mainly solves the technical problem that conventional carbon fibers are low in strength, and is low in dispersity during preparation processes, and is characterized by comprising the steps of oil applying and bunching, short cutting, pre-non-melting treatment, penetrant spraying, non-melting treatment, high heat treatment and starching. The preparation method has the advantages that the strength of the carbon fiber is high, and the dispersity of the carbon fiber in the preparation process is good.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

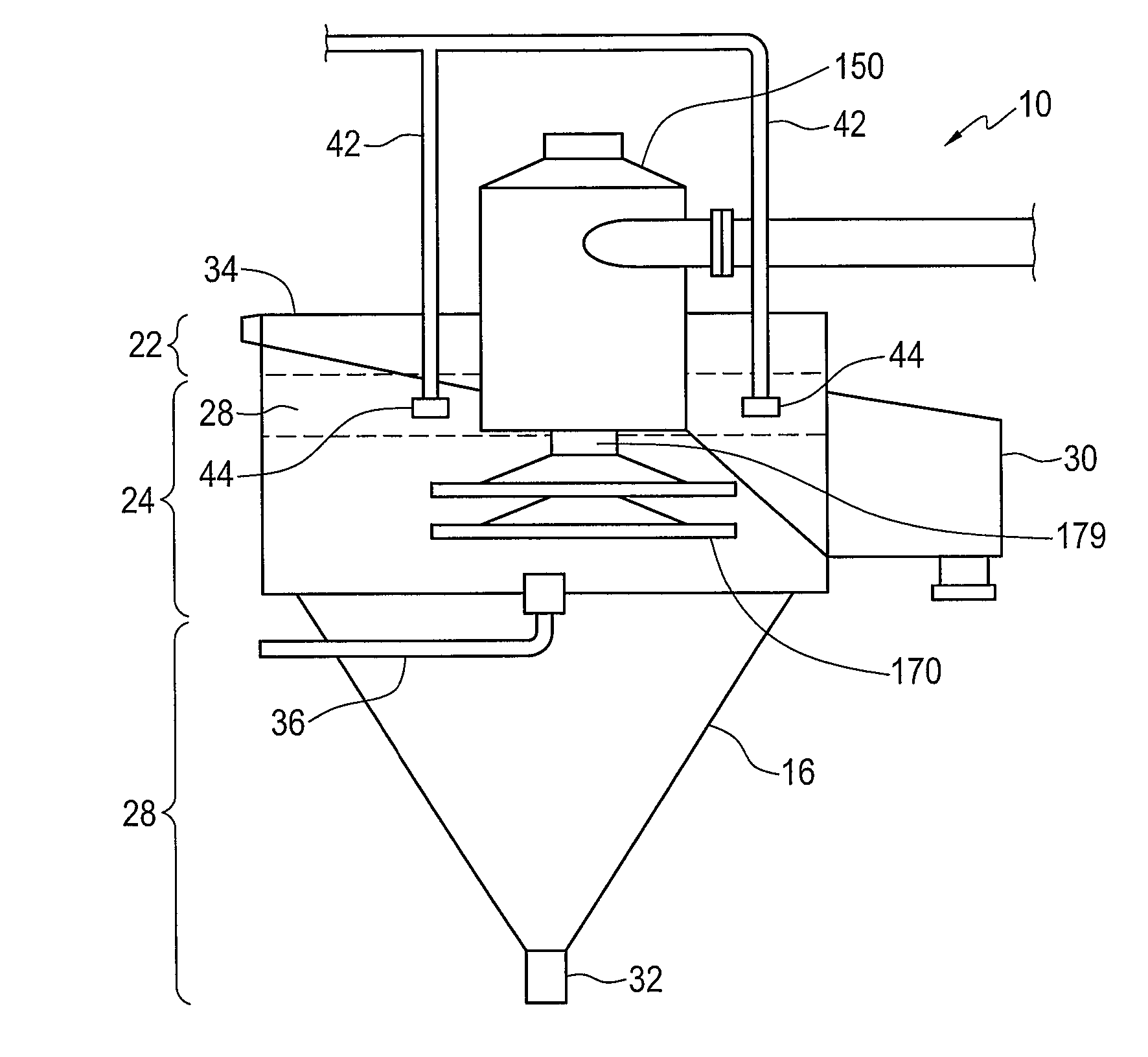

Feedwell for a gravity separation vessel

InactiveUS8550258B2Evenly distributedReduce momentumSettling tanks feed/dischargeWater/sewage treatmentSlurryGravity separation

A feedwell for a gravity separation vessel for introducing a feed stream such as oil sand slurry to the gravity separation vessel is provided comprising a walled member having an upper perimeter edge, a lower perimeter edge and a substantially continuous wall extending from the upper perimeter edge to the lower perimeter edge; an inlet for introducing the feed stream into the walled member positioned adjacent the substantially continuous wall; and a bottom floor having an opening and extending generally beneath the lower perimeter edge; whereby a perimeter of the opening is less than a perimeter of the walled member.

Owner:SYNCRUDE CANADA LTD

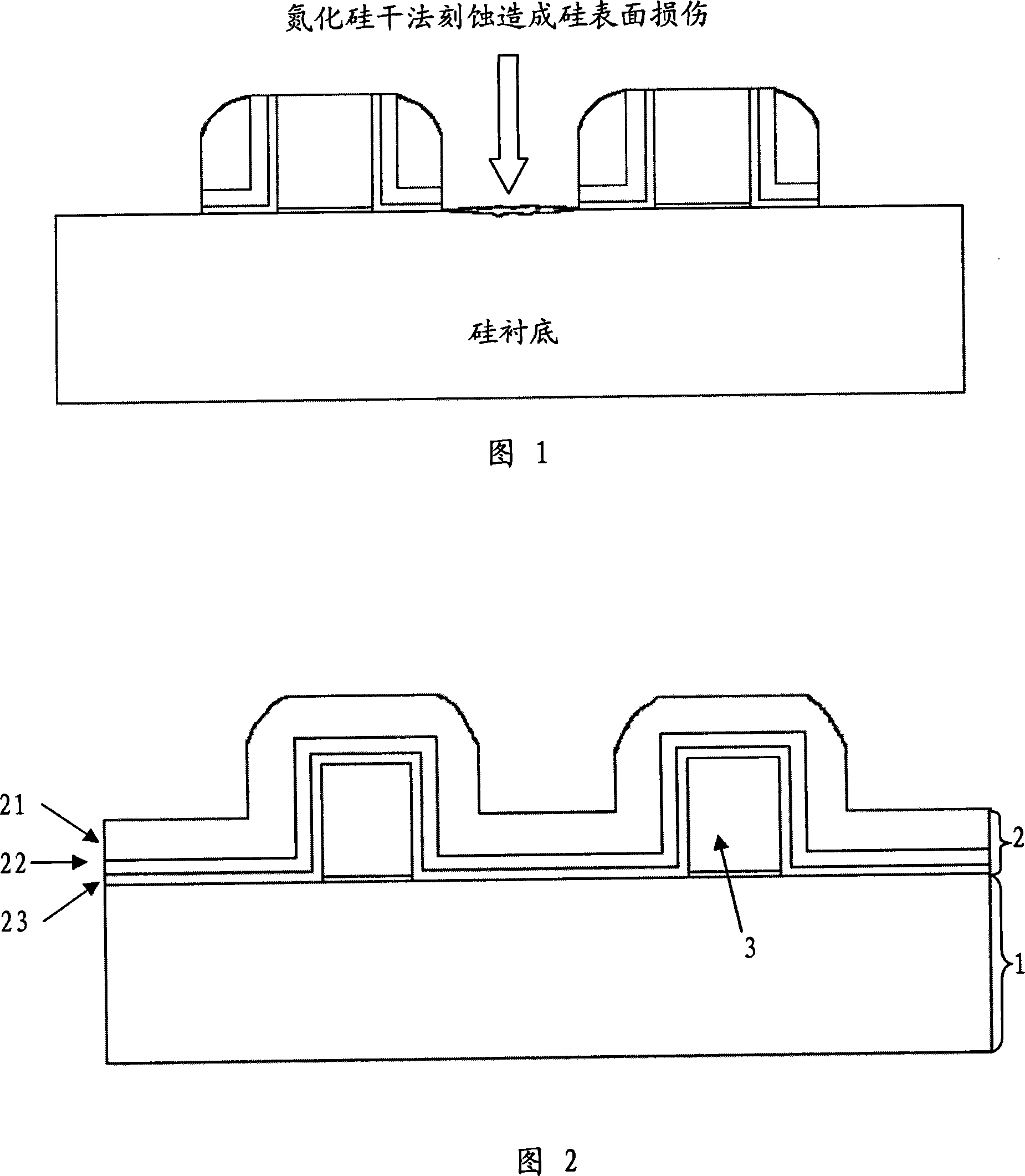

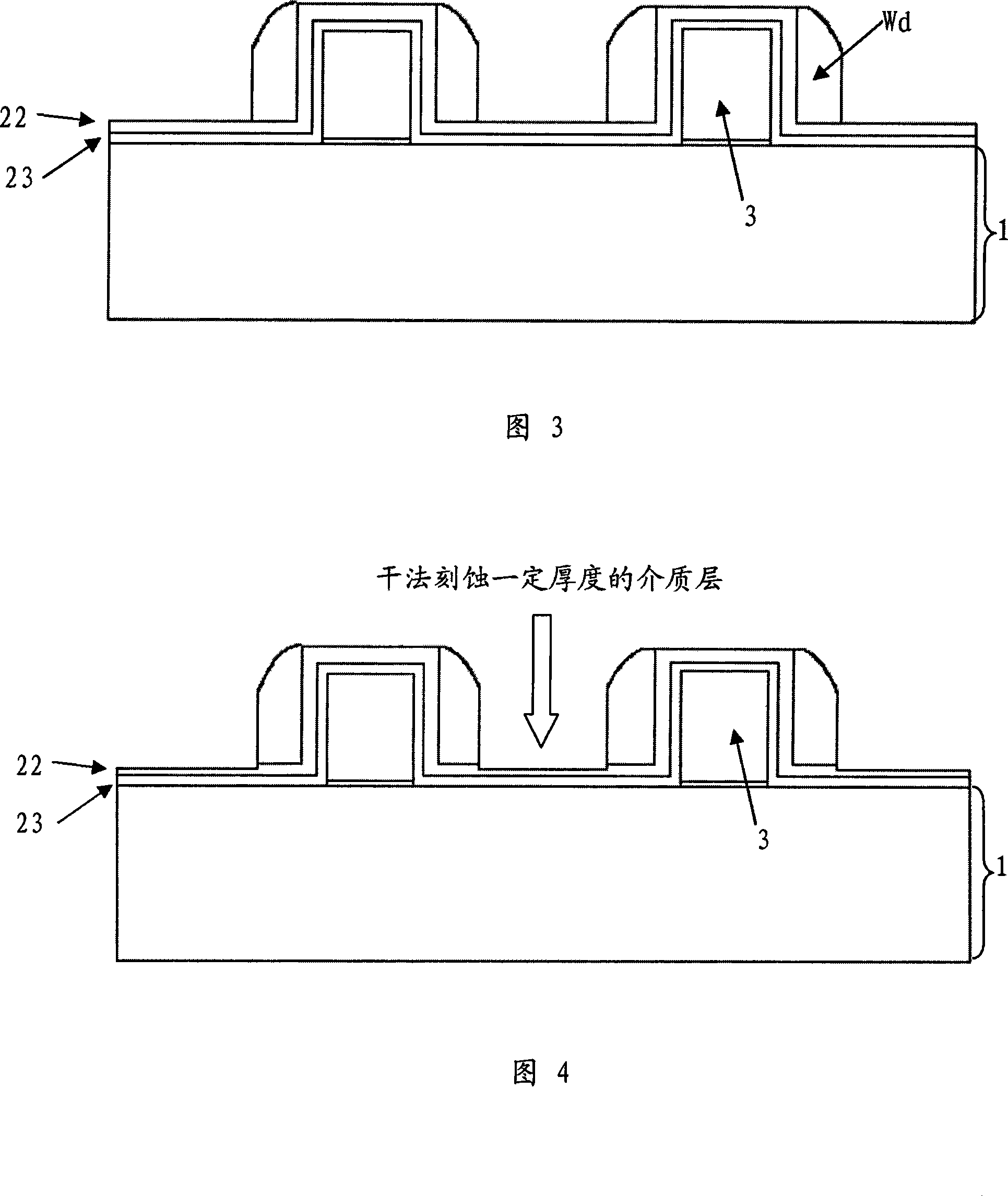

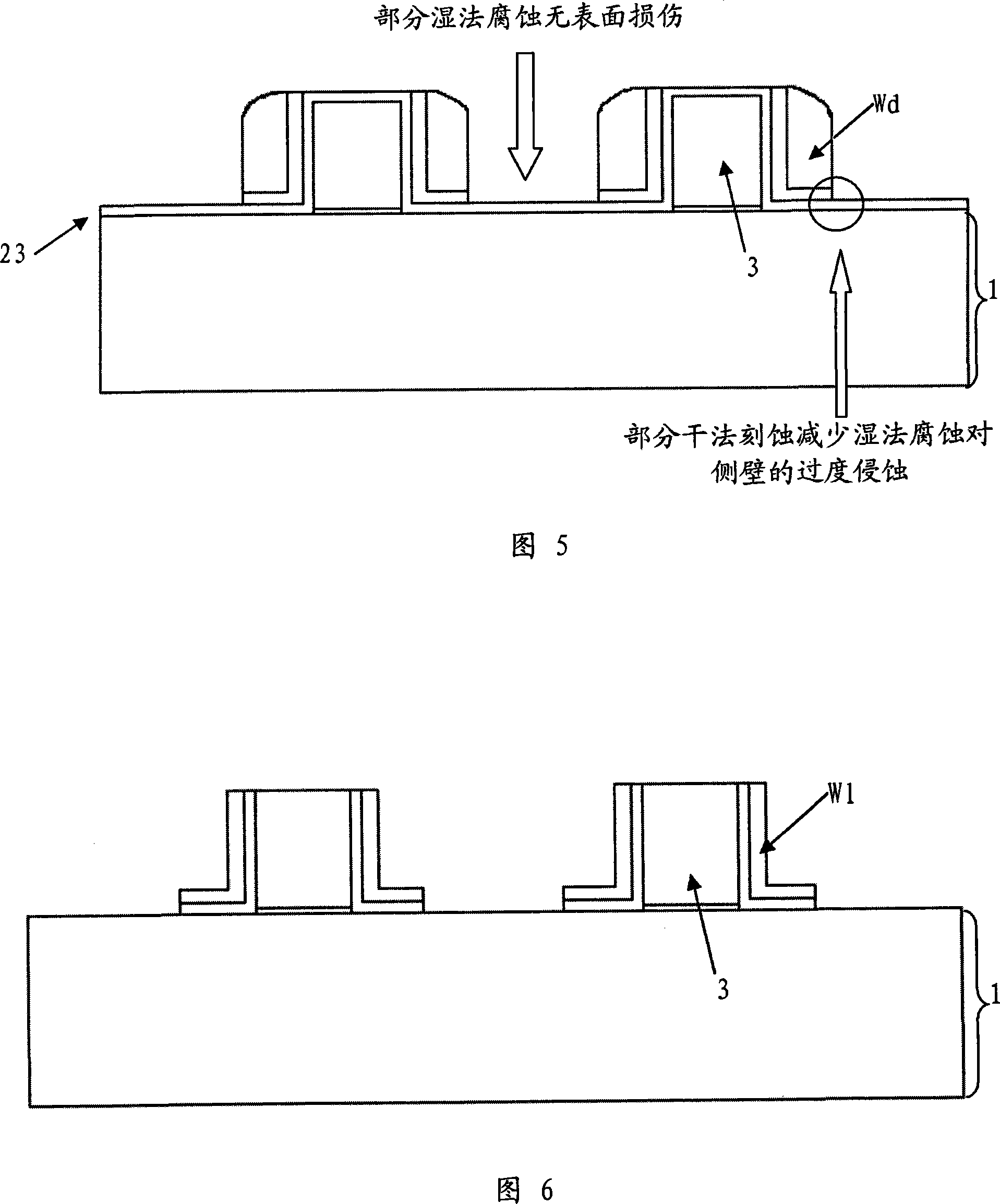

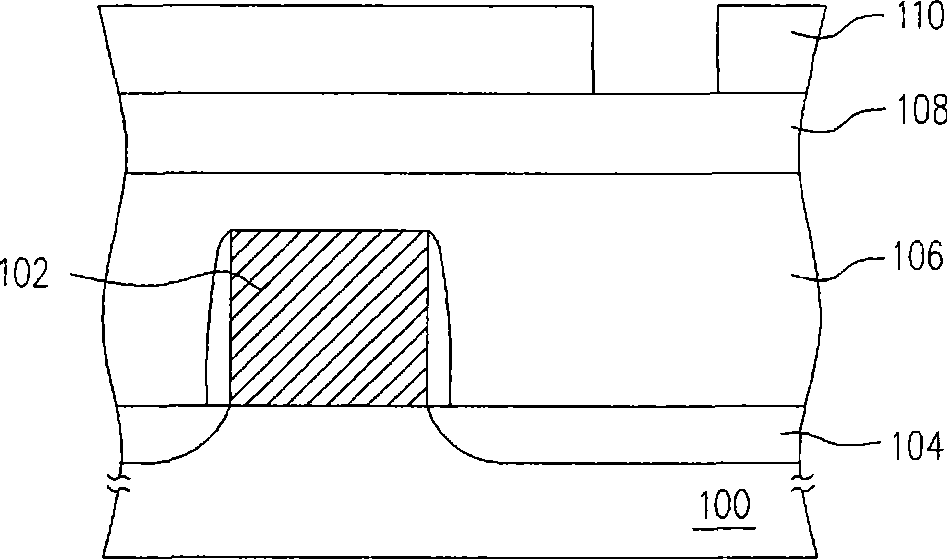

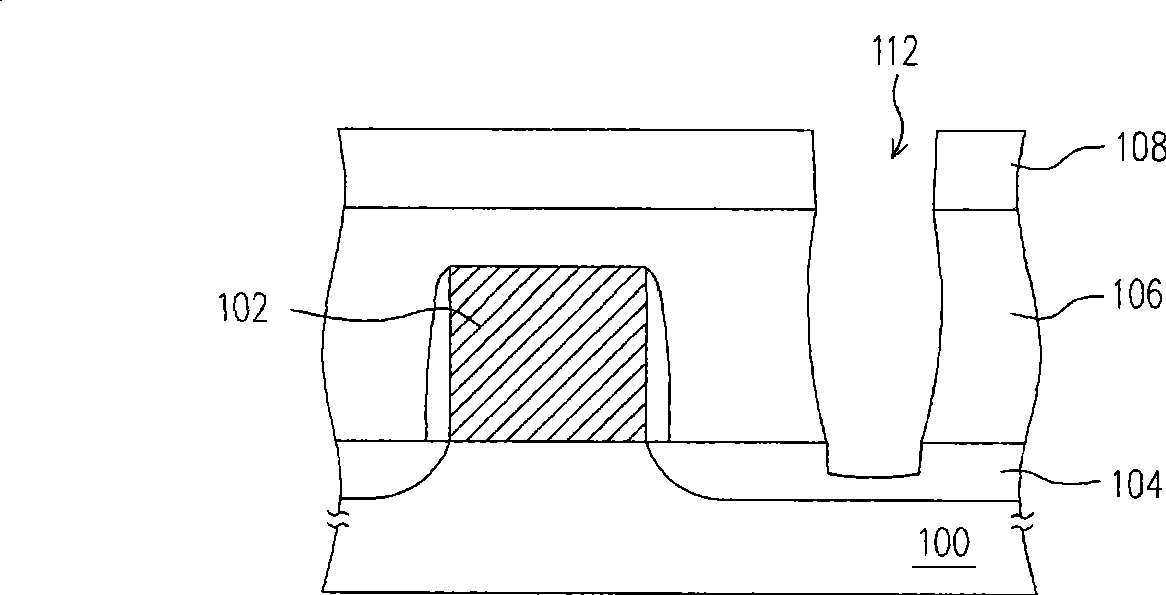

Forming method of L-shaped side wall

InactiveCN101197264AAvoid excessive erosionAvoid damageSemiconductor/solid-state device manufacturingSemiconductor devicesDielectric layerDry etching

The invention discloses a method for reducing substrate surface damage in the L-shaped side wall forming technology and a corresponding forming method for an L-shaped side wall. A partial dry etching and a partial wet corrosion is used to replace the prior dry etching to process a dielectric layer, thus reducing the damage on the substrate surface during etching process. The specific steps are asfollows: forming the L-shaped side wall from a composite dielectric layer which is deposited on the substrate, wherein, the composite dielectric layer comprises a sacrifice layer, a dielectric layer and an oxidized layer. The method for reducing the substrate surface damage is used for etching process of the composite dielectric layer. The method comprises the following steps: removing the dielectric layer which is exposed outside and has certain thickness by the dry etching; and removing the dielectric layer which is exposed outside and has remaining thickness by the wet corrosion.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

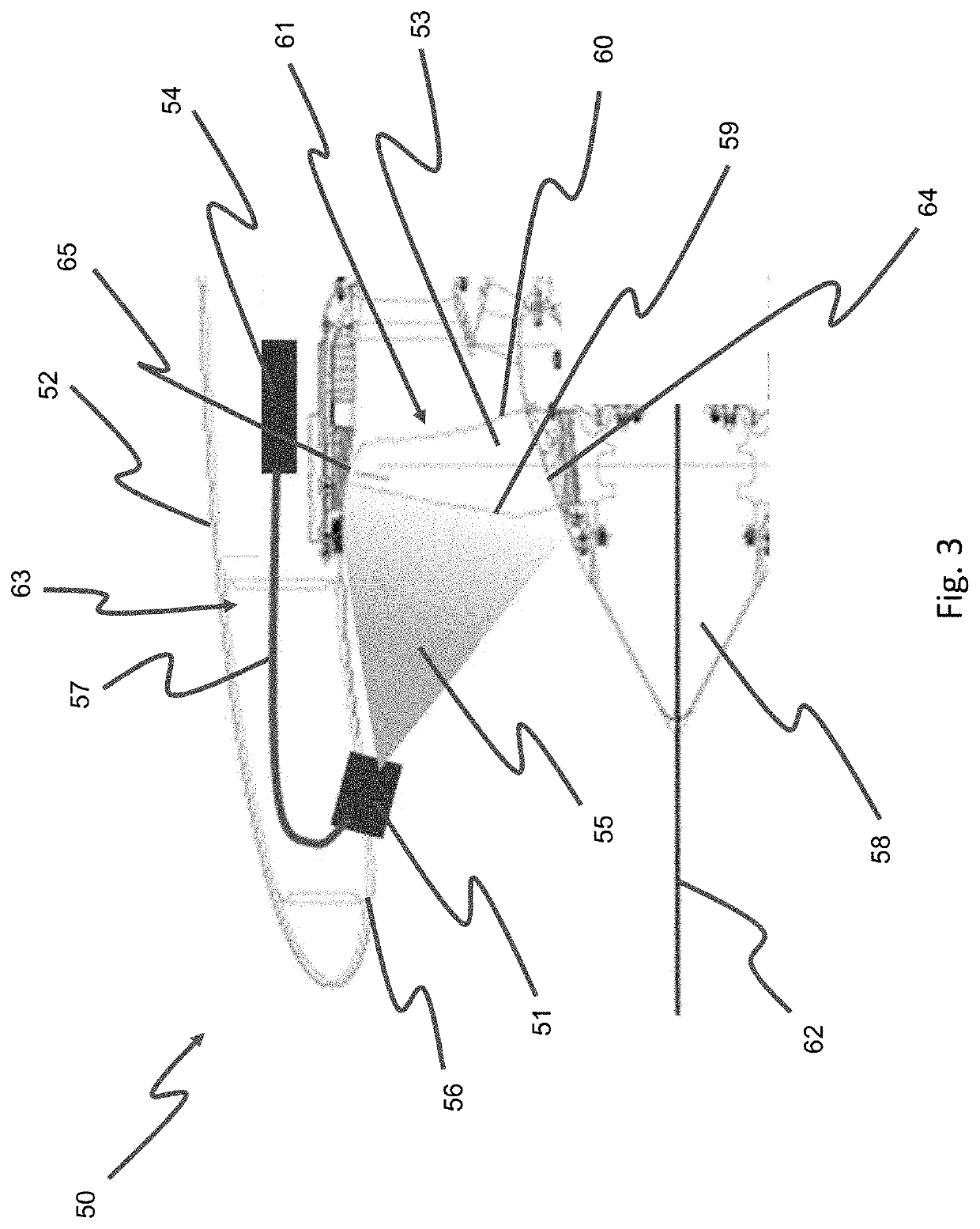

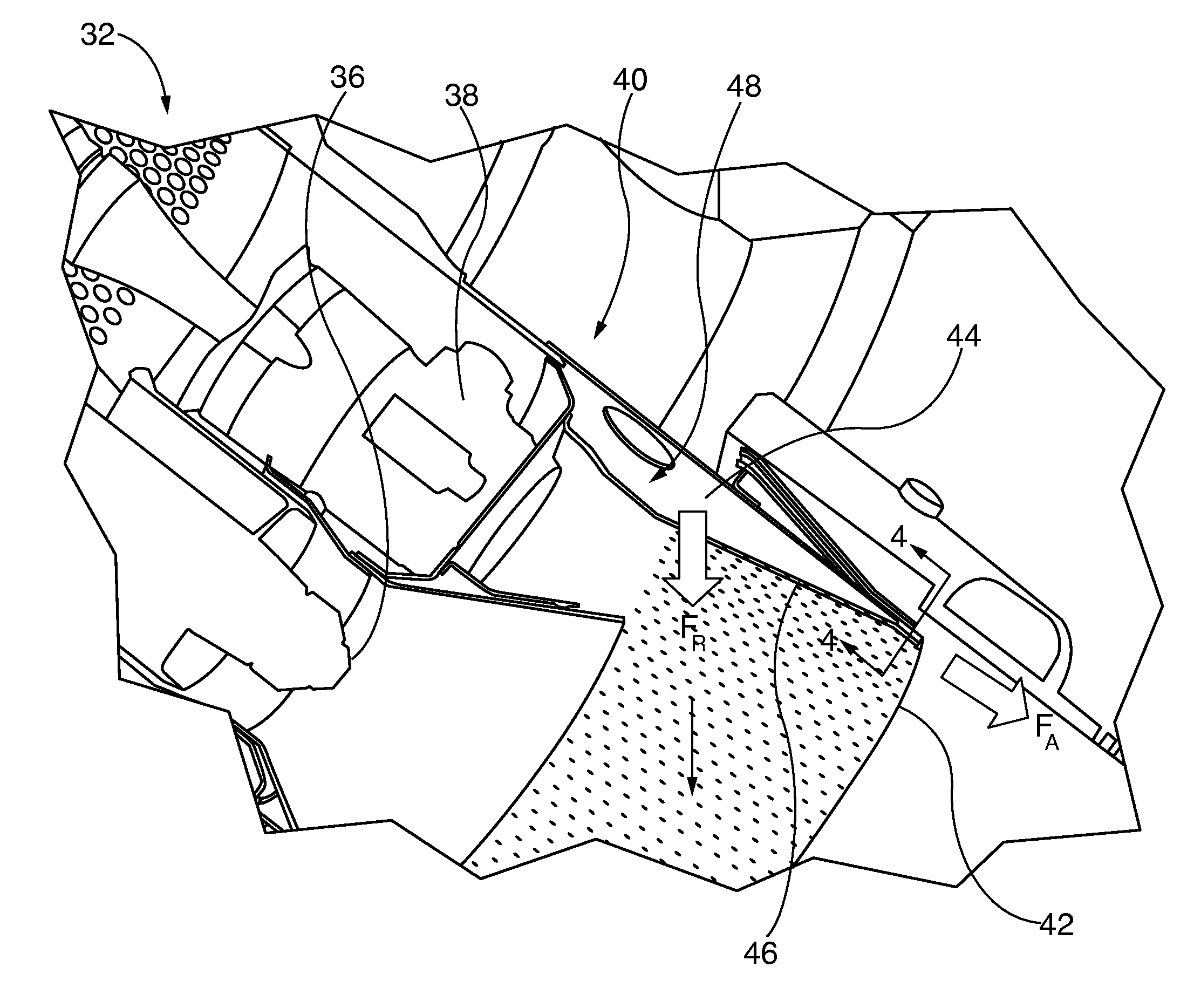

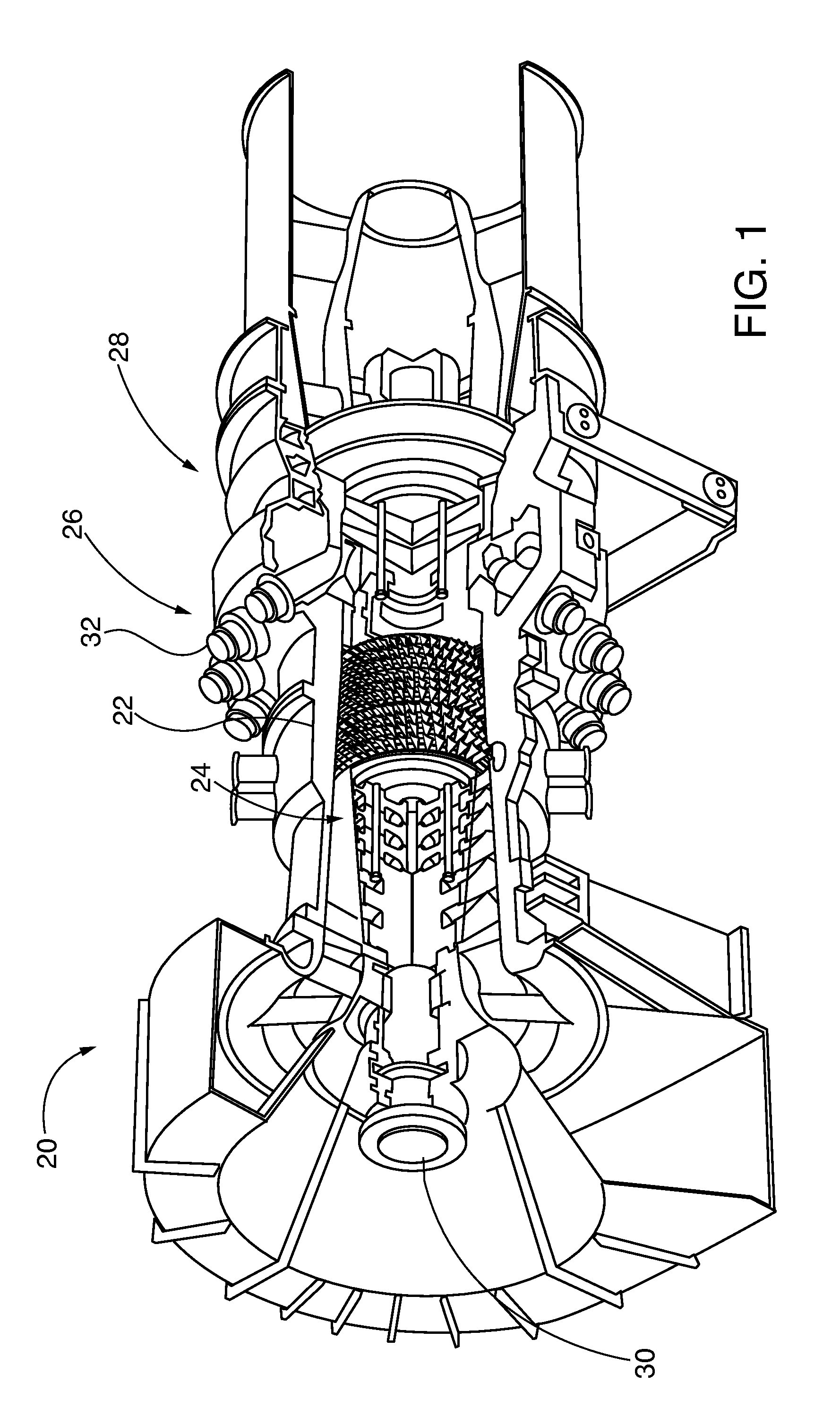

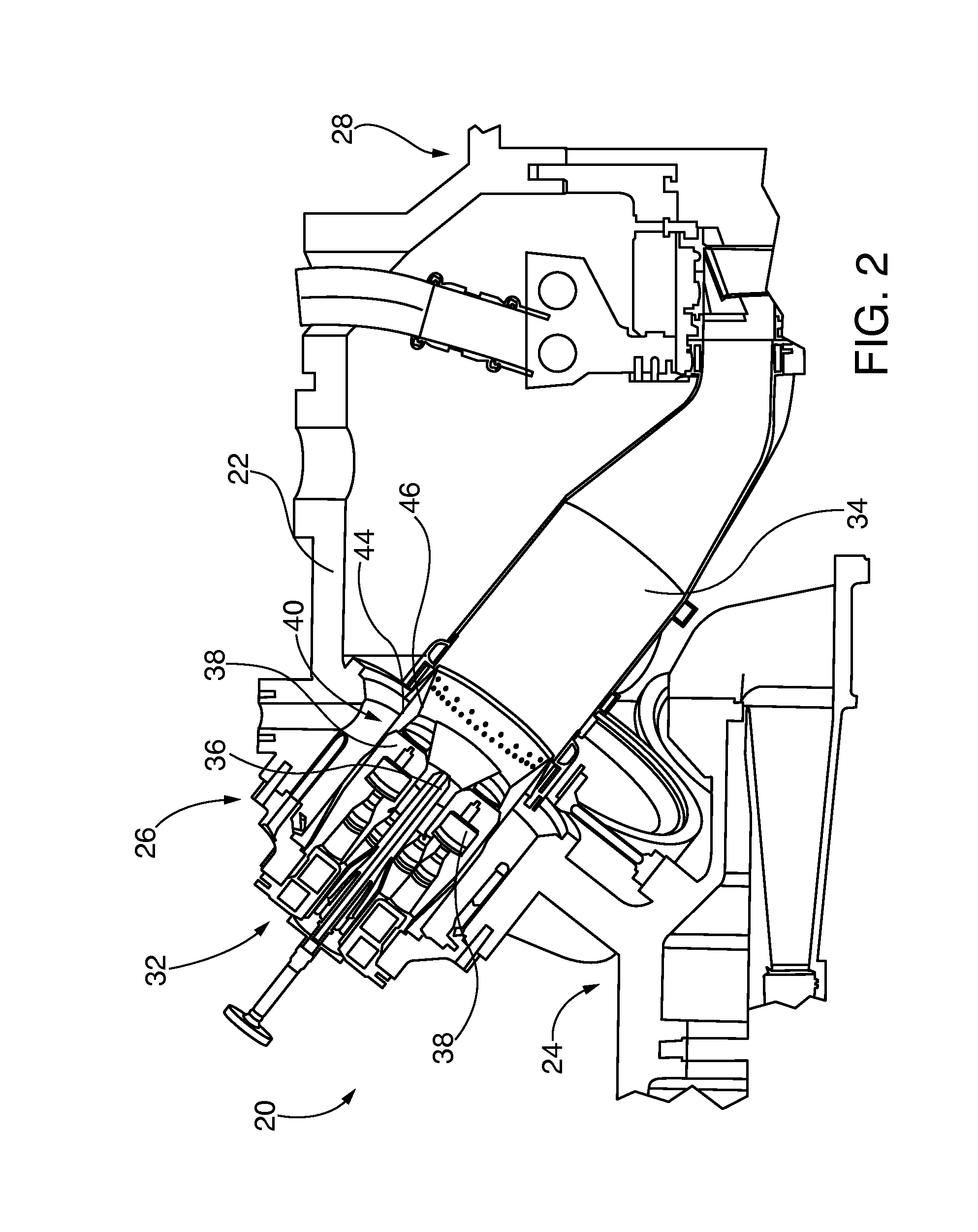

Method of detecting rotor blade damage

InactiveUS20200056501A1Visible damageAvoid excessive wearImage enhancementImage analysisGeometric modelingStructural engineering

A method of detecting rotor blade damage on a gas turbine engine is provided comprising the steps of taking an image of a rotor blade, processing the image to produce a blade profile using an edge detection algorithm and determining a rotor blade error by comparing the blade profile with a geometric model of a corresponding blade.

Owner:ROLLS ROYCE PLC

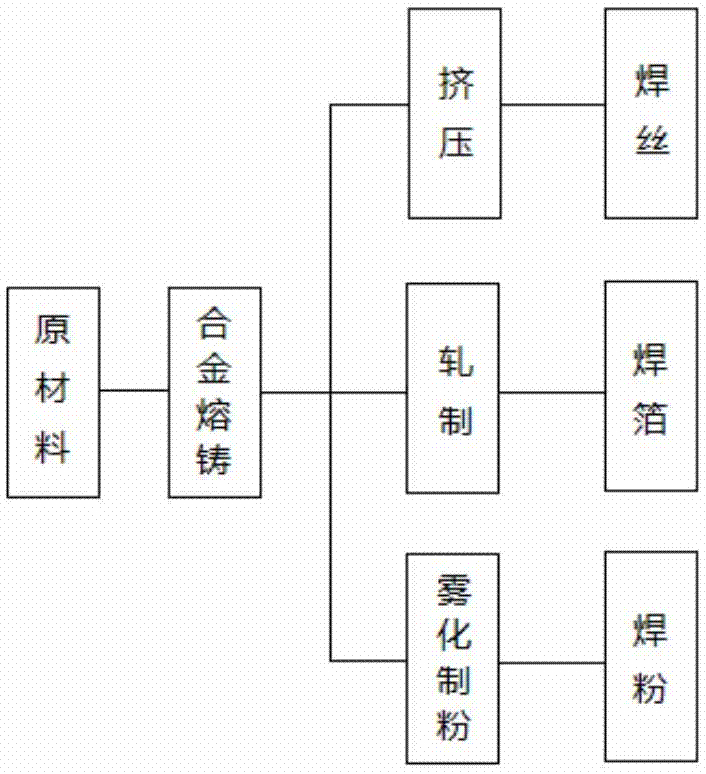

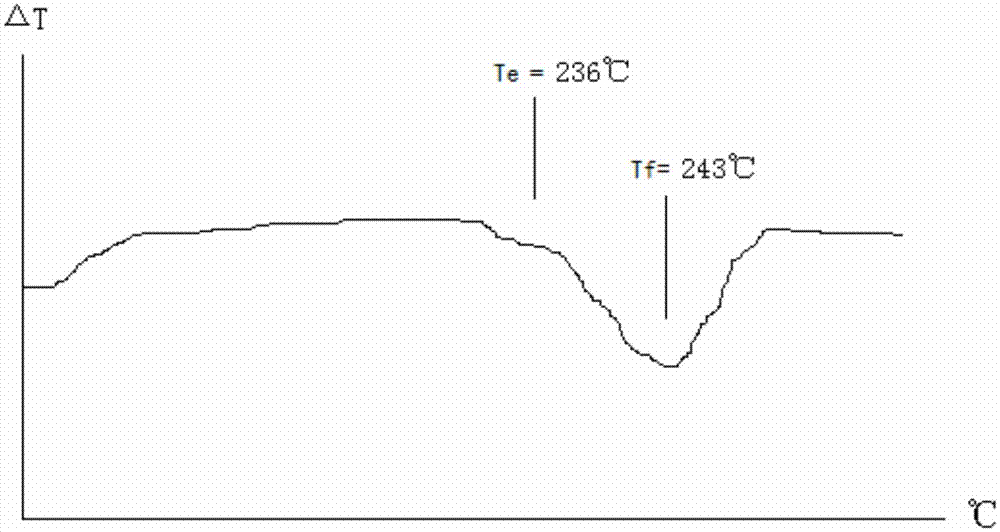

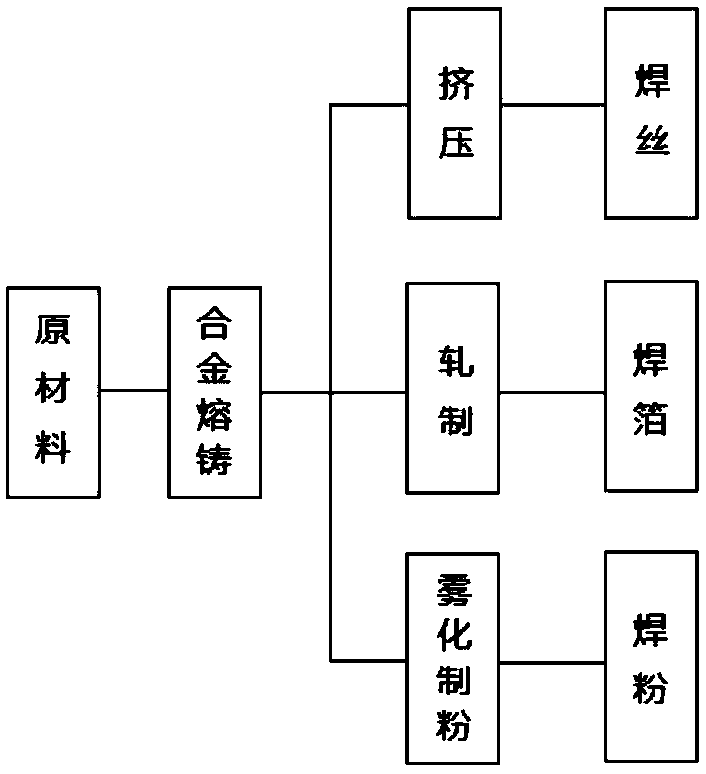

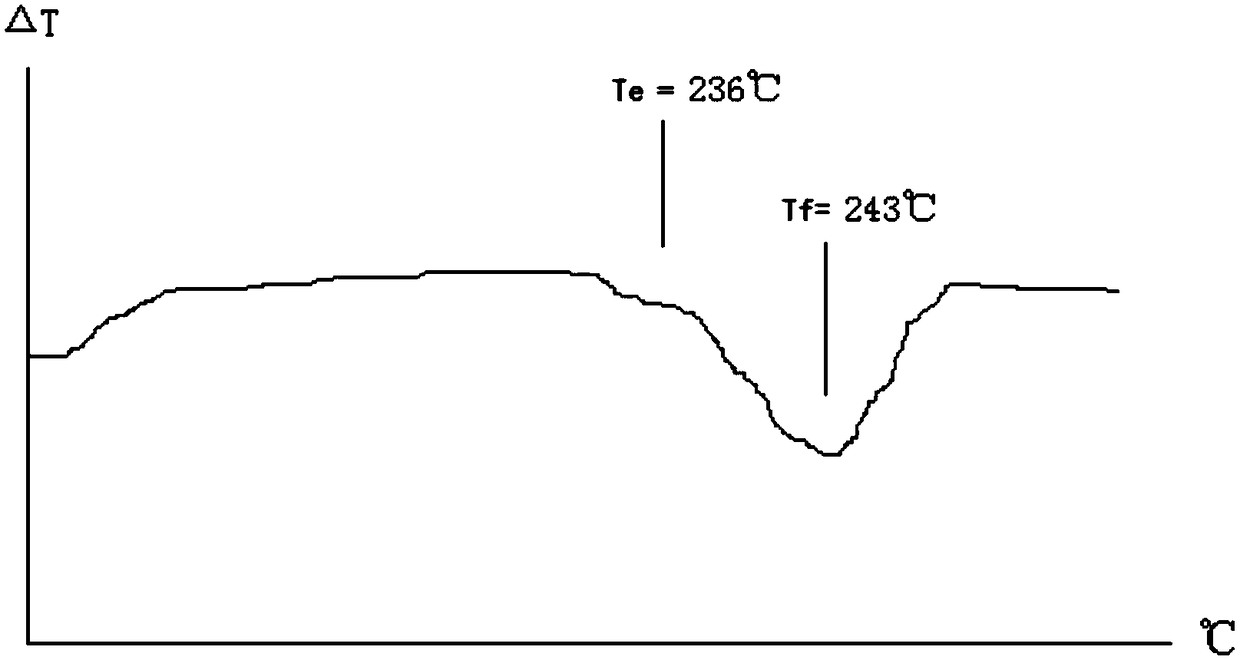

Pb-Sn-Sb-Ag alloy brazing filler metal and manufacturing method thereof

ActiveCN104741819AAvoid excessive erosionInhibit erosionWelding/cutting media/materialsSoldering mediaSolderingFiller metal

Pb-Sn-Sb-Ag alloy brazing filler metal is mainly used for soldering of metal coatings of an electronic device. The brazing filler metal comprises, by weight, 15.5-16.5wt % of Sn, 7.0-8.0wt% of Sb, 0.01-1.2wt% of Ag and the balance of Pb. The brazing filler metal is moderate in melting temperature, has excellent wettability for the metal coatings, and is good in brazing process and applicable to soldering of silver (alloy) coatings, gold coatings and copper of electronic devices, and thermal impact resistance of brazing seams is good.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH +1

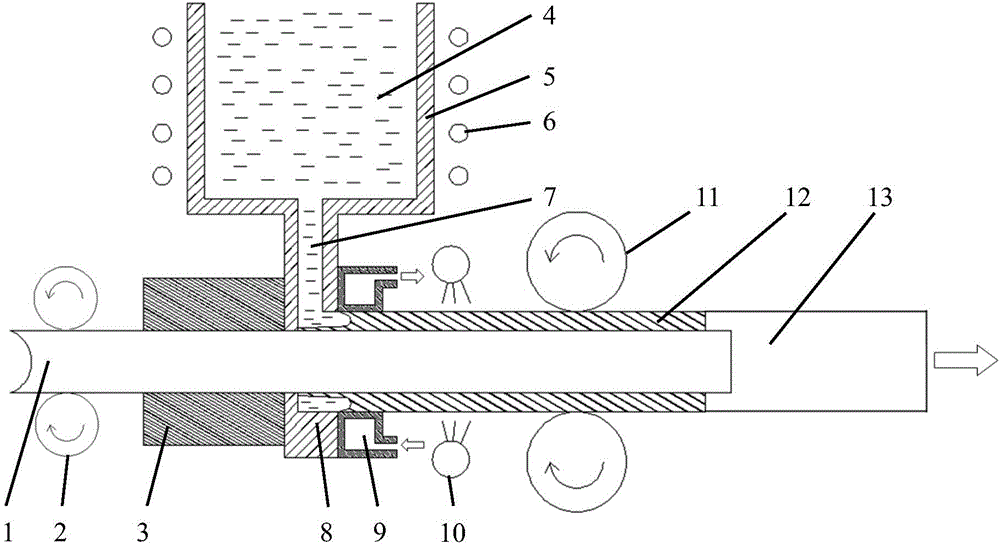

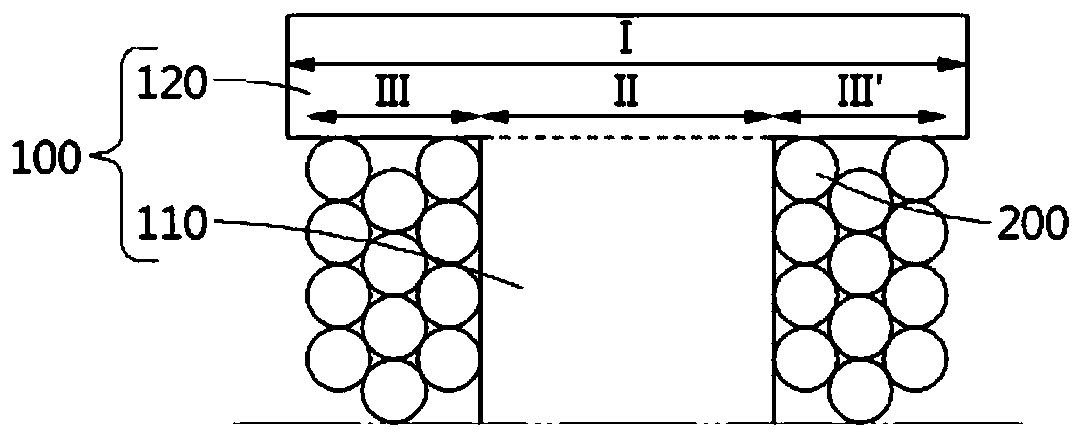

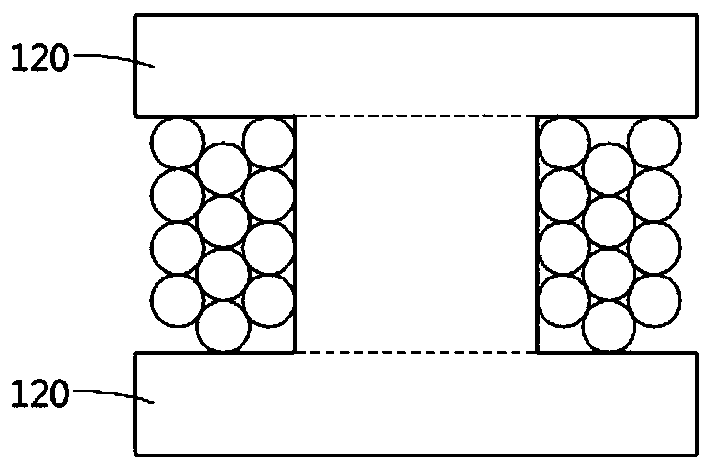

A solid/liquid composite horizontal continuous casting forming equipment and method for coating material

The invention discloses clad material solid / liquid composite horizontal continuous casting and forming equipment and method, and belongs to the technical field of clad material continuous casting. According to the clad material solid / liquid composite horizontal continuous casting and forming equipment and method, the measures that a core material protection device, a flow guide pipe, an inversion solidification device and the like are adopted and mounted below a crucible, core materials are not heated in advance, the inversion solidification device with small capacity is designed, the core materials are prevented from penetrating through clad layer melt metal for a long time, the melt metal flows out from the bottom of the crucible by relying on self-weight, and the size of the inversion solidification device and the size of a water-cooled crystallizer are controlled effectively are taken, the high quality clad materials of needed shapes and sizes are formed through horizontal continuous casting, and the equipment and the method are especially suitable for horizontal continuous casting forming of the large-size clad materials which are hard to reel up and has the melting point of the clad layer metal lower than that of the core material metal. The equipment and method have the advantages that the equipment is simple in structure, parts are easy to replace, operation and maintenance are convenient to carry out, layout is reasonable and compact, production efficiency is high, investment is small, automatic control is easy to achieve, large-scale industrial production is facilitated, the procedure of the forming process is short, energy is saved, environment is protected, efficiency is high, cost is low, the combination freedom of the clad layer metal and the core material metal is large, and the prepared clad materials are good in quality and performance.

Owner:UNIV OF SCI & TECH BEIJING

Production process of aluminized laser paper

ActiveCN108103850AImprove low temperature resistanceAvoid excessive erosionFlexible coversWrappersPaper productionLaser patterning

The invention relates to the technical field of packaging bag paper production, in particular to a production process of aluminized laser paper. The production process comprises the following steps: 1) coating a release agent on a substrate to form a release layer; 2) drying the substrate coated with a release material; 3) imprinting a dried film so that the surface of the substrate can have a laser pattern; 4) conducting vacuum aluminum plating on the substrate, and then conducting protected layer coating on a specified position; 5) immersing the substrate coated with the protected layer in an alkaline liquid pool for aluminum washing and drying again; 6) conducting spot-coating on the surface of the substrate, then compounding the substrate and base paper through a compound device and then drying again; 7) curing composite paper, peeling off the substrate, and transferring the laser pattern to the surface of the base paper. After the release agent is used on the substrate, the durability, compression resistance, solvent resistance, and low temperature resistance are improved, and at the same time, and an alkaline solution can be effectively prevented from excessively eroding thesubstrate when aluminum is washed.

Owner:湖北华源包装有限公司

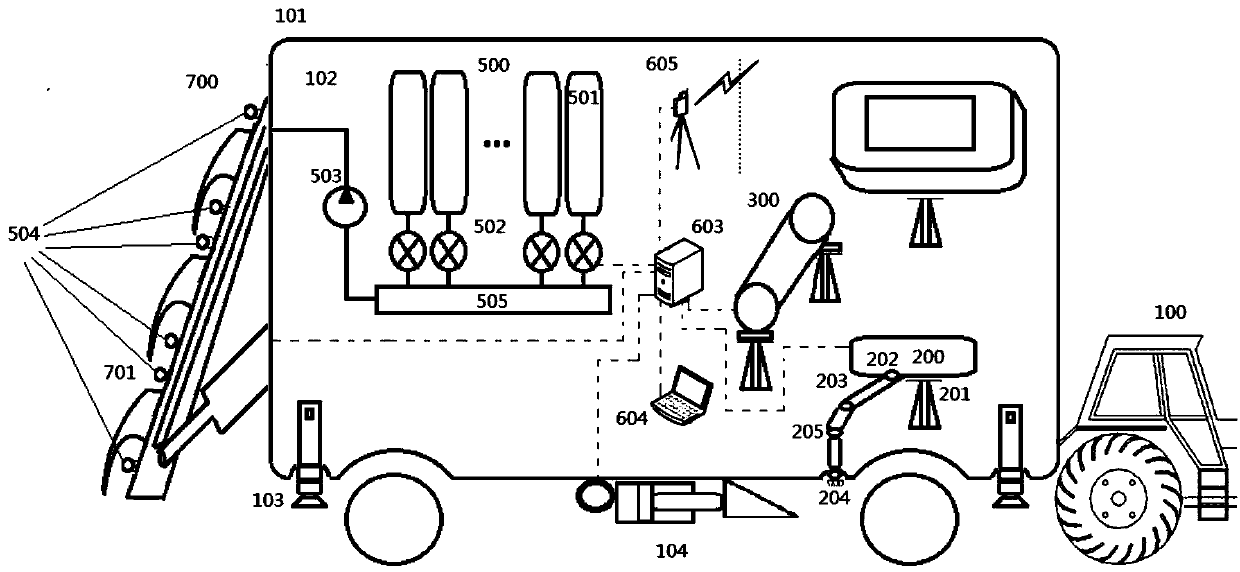

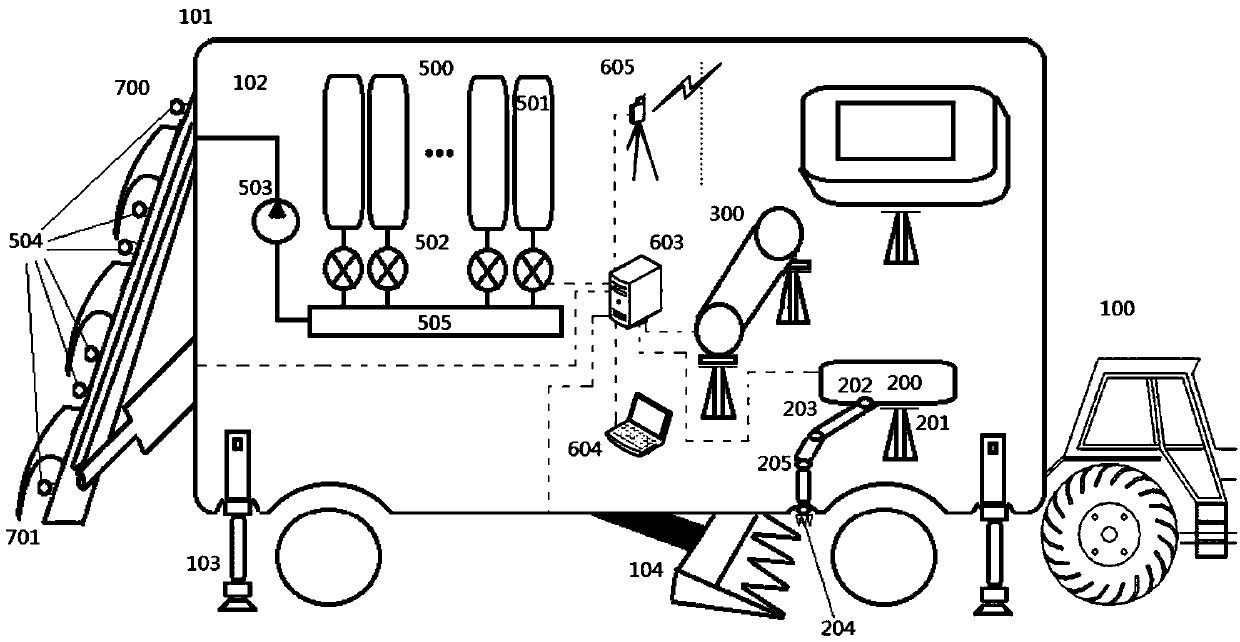

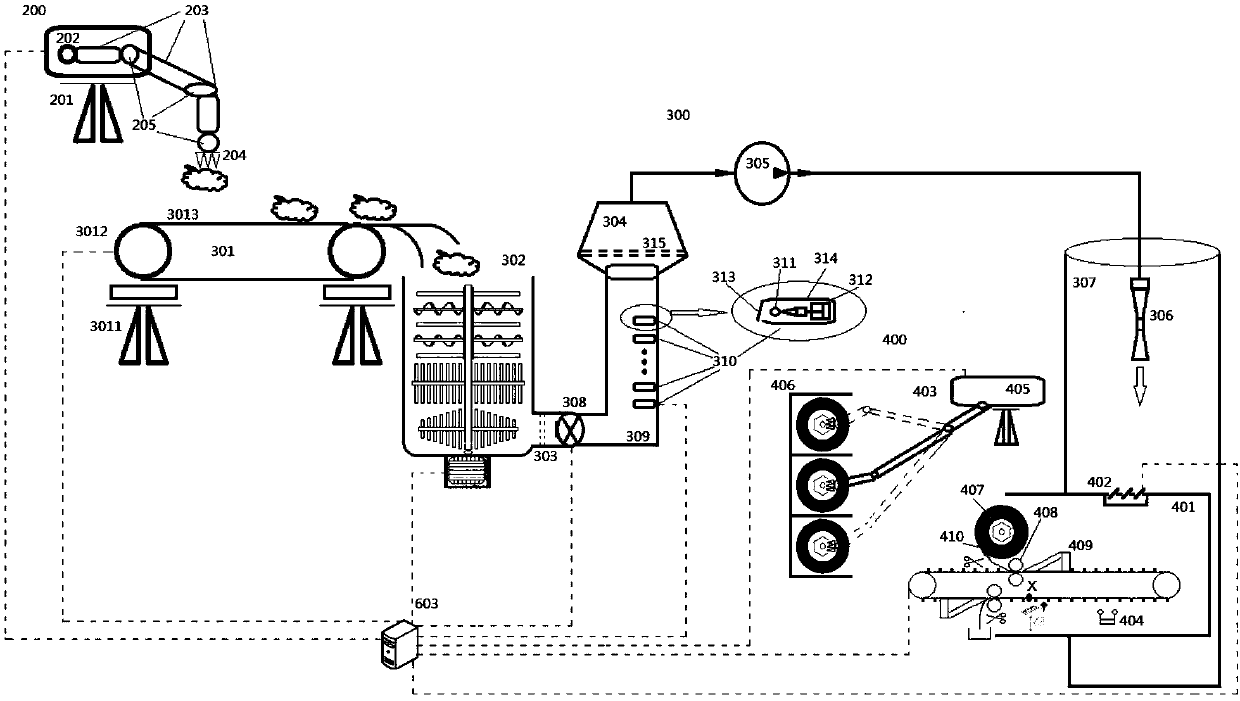

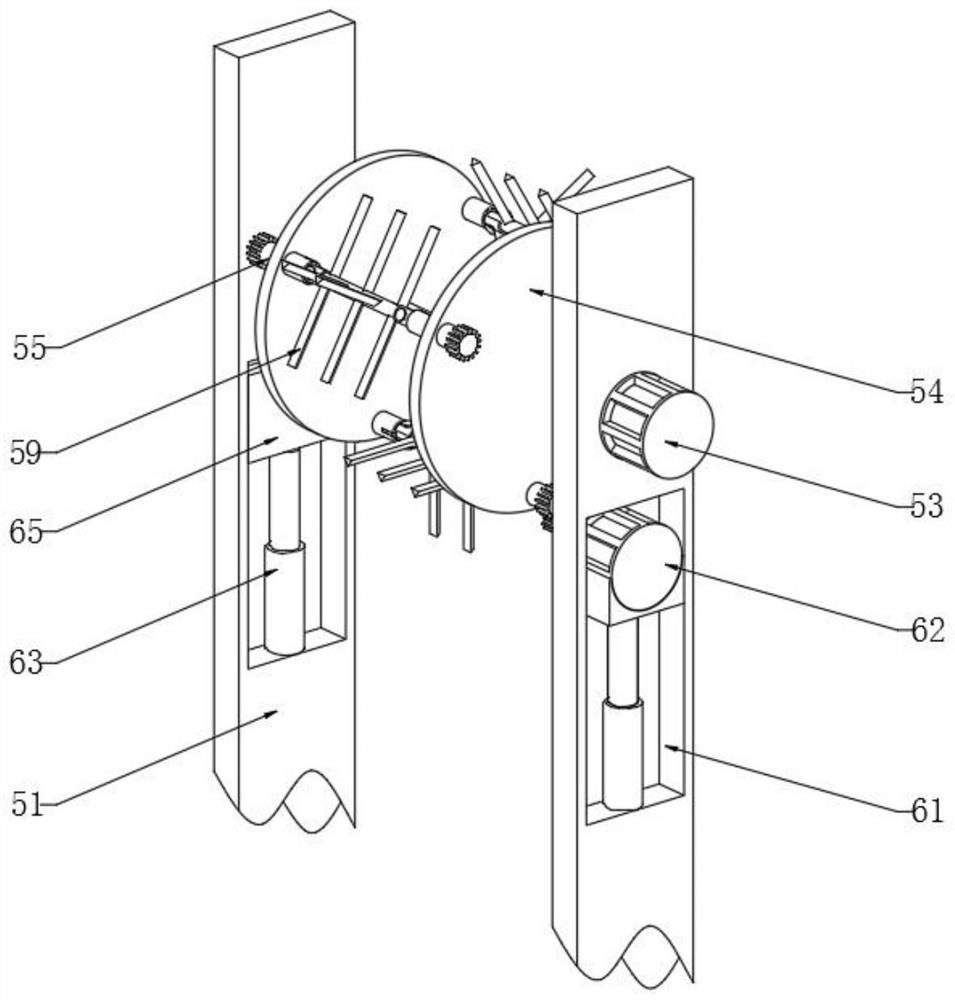

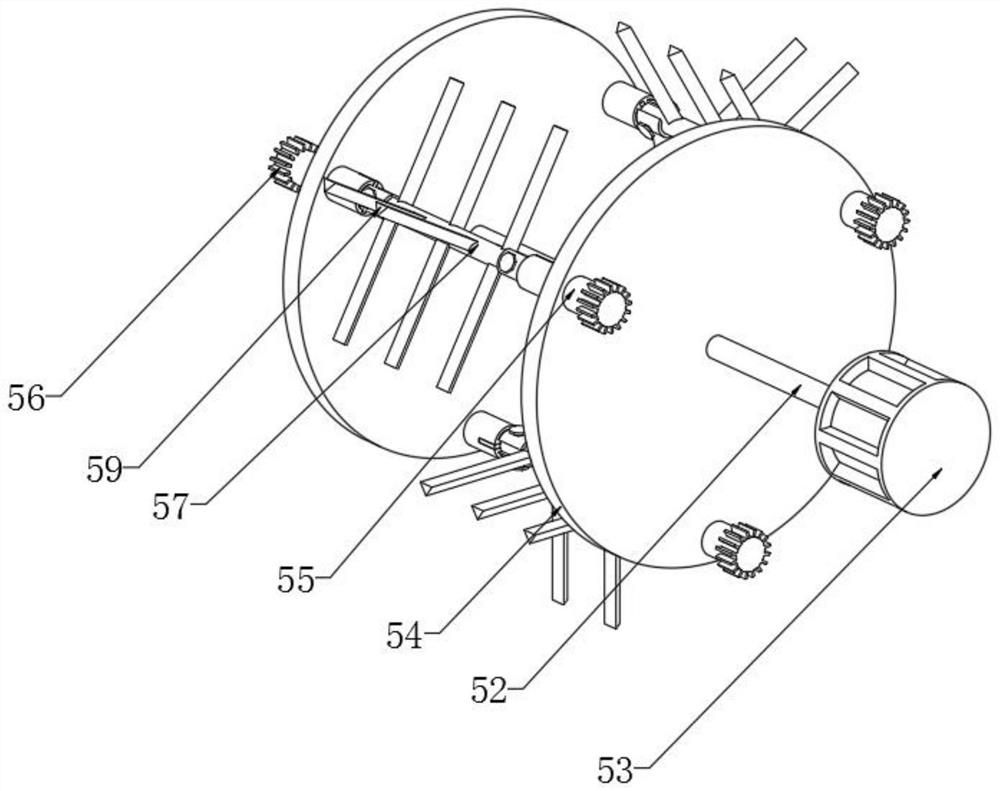

Saline-alkali soil treatment system and method

PendingCN109565988AConvenience to workHigh degree of automationSpadesSoil lifting machinesAlkali soilEngineering

The invention relates to a saline-alkali soil treatment system and method. The saline-alkali soil treatment system comprises movable transportation equipment, a soil shoveling assembly, a soil collection assembly, a soil component fluidization assembly, a test paper analysis and test system, an adjusting liquid distribution assembly and a soil turning assembly, wherein an inductor assembly is arranged in an inductor channel, the inductor assembly has two states, the first state is the work state in which the system is in contact with to-be-tested soil, and the second state is the state in which an inductor is protected and does not work; the test paper analysis and test system comprises a test paper conveying mechanism which can be used for conveying, replacing and recovering a test paperroll. According to the saline-alkali soil treatment system and method, the system can be driven to land needing saline-alkali soil treatment at any time according to requirements, soil can be detectedand treated at the same time, the automation degree is high, remote operation can be achieved, and therefore operators and later personnel can work more conveniently and save labor.

Owner:中国盐业总公司盐业地质勘查大队

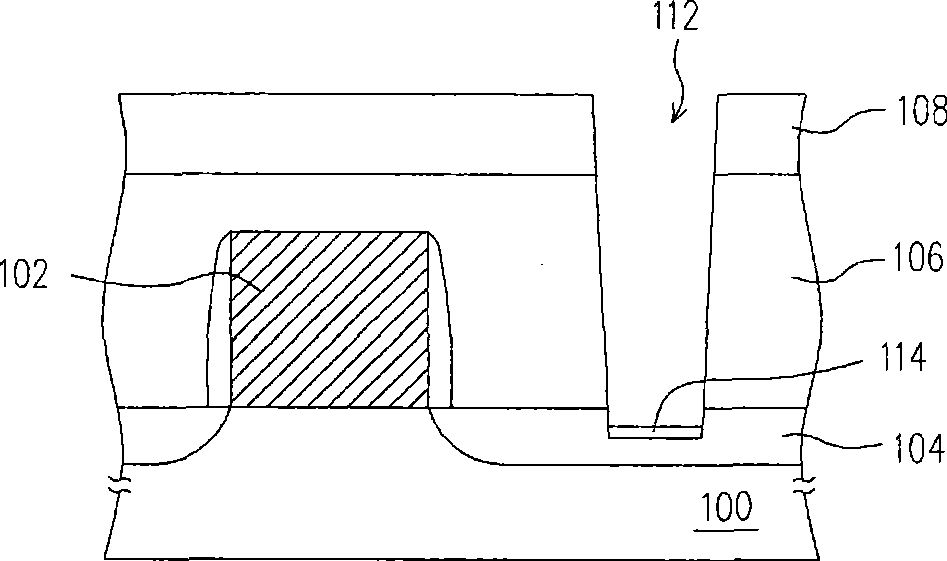

Method for manufacturing contact window for reducing contact resistance

InactiveCN101399221AAvoid formingAvoid excessive erosionSemiconductor/solid-state device manufacturingElectrical conductorEngineering

The invention provides a preparation method for a contact window that reduces contact resistance. Firstly, a substrate, on which a protective layer and a dielectric layer are successively formed, is provided. Afterward, a dry etching process is carried out so as to remove a part of the dielectric layer, thus forming an opening which exposes a part of the protective layer. Then, a wet cleaning process is performed. After that, a dry cleaning process is performed so as to remove the protective layer positioned at the bottom of the opening, and a conductor layer is formed in the opening afterward.

Owner:POWERCHIP SEMICON CORP

Gas turbine engine combustor basket with inverted platefins

ActiveUS20150292742A1Extended service lifeFacilitates inclusionContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

A gas turbine engine combustor basket has nested outer and inner liners that are separated by a gap at their respective distal downstream ends for passage of cooling air between the liners. Radially inwardly projecting platefins formed on an inner circumferential surface of the outer liner maintain the cooling air passage gap. In some embodiments effusion cooling through holes are formed in the inner liner outer circumference, oriented in the air passage gap between the fins, so that cooling air passes through the effusion holes into the cooling air passage gap.

Owner:SIEMENS ENERGY INC

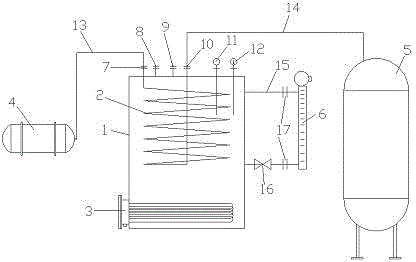

Electrical heating liquid ammonia evaporator with uniform heating effect

The invention provides an electrical heating liquid ammonia evaporator with a uniform heating effect. The electrical heating liquid ammonia evaporator comprises a tank body, a coil pipe, an electrical heater, a liquid ammonia steel cylinder, a cylinder and a liquid level meter, wherein a liquid ammonia inlet, an air outlet, a demineralized water inlet, a gas ammonia outlet, a thermal resistor and a thermometer are sequentially arranged on the tank body, so that abnormal overhigh pressure of the equipment can be avoided; the coil pipe is arranged inside the tank body; the electrical heater is arranged at the bottom of the tank body; the liquid level meter is fixedly arranged on the tank body; the liquid ammonia steel cylinder and the cylinder are connected with the tank body by virtue of a pipeline, so that heating is uniform. By utilizing demineralized water for direct heating, the temperature can be increased to 70 DEG C, the conversion efficiency is improved, and the service life is prolonged. The phenomena such as extremely high noise, vibration and deformation under various loads are avoided, excessive washout for parts at the shell inlet and inside the shell is avoided, the evaporator is safe, reliable and wide in application range, and the service life of the product is effectively prolonged.

Owner:ZHENJIANG DONGFANG ENERGY SAVING EQUIP

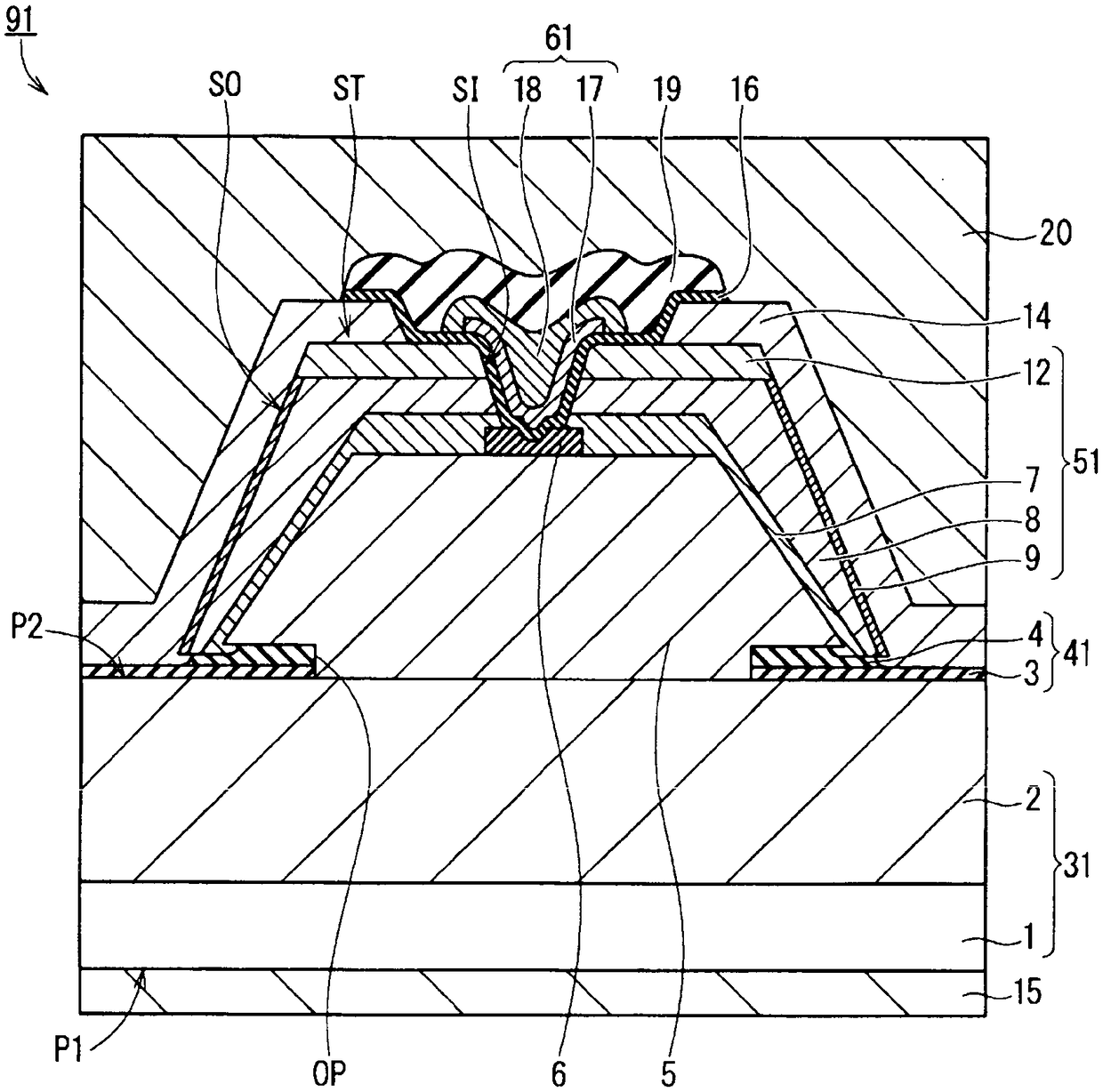

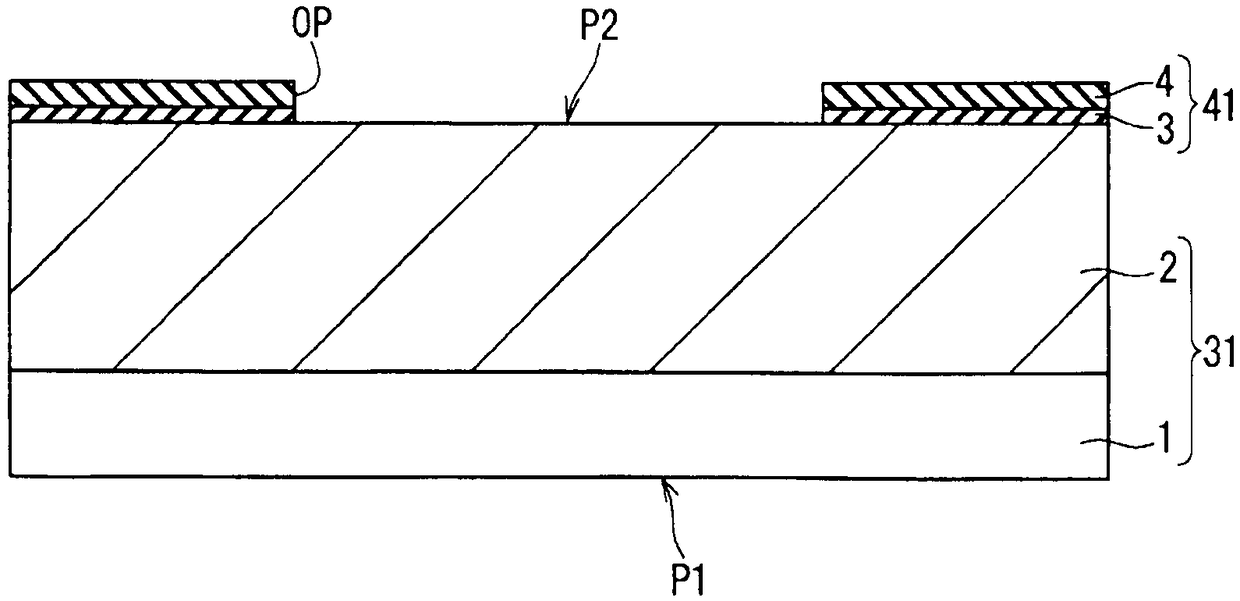

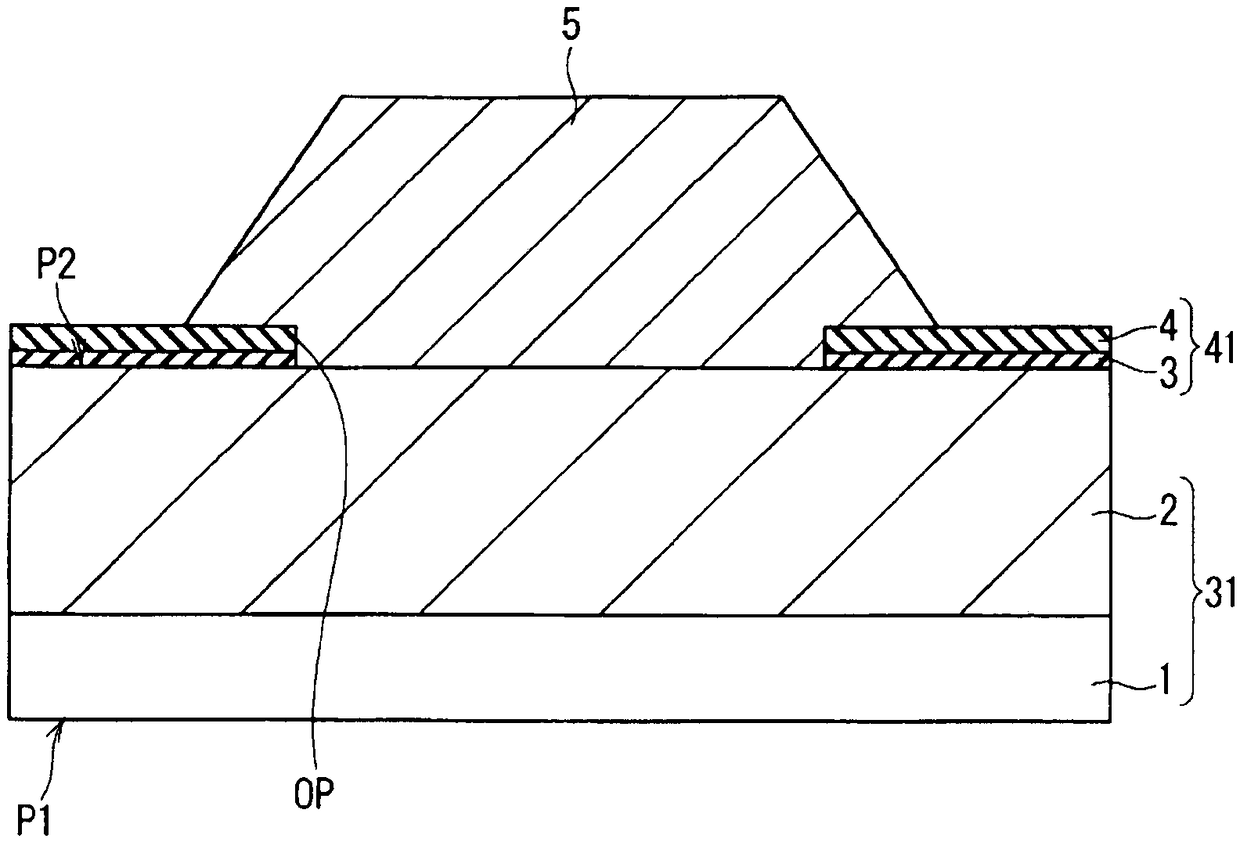

Semiconductor device and method for manufacturing semiconductor device

ActiveUS10784350B2High activityAvoid excessive erosionSemiconductor/solid-state device manufacturingDiodeDevice materialContact layer

A first insulating layer is disposed on a second surface of a semiconductor substrate, and has an opening. A second insulating layer is disposed on the second surface and separated from the first insulating layer. A stack includes, in sequence on the second surface, a side n-type epitaxial layer and first and second p-type epitaxial layers that are made of a gallium-nitride-based material. The stack has an outer side wall having a portion formed of the second p-type epitaxial layer, an inner side wall extending from the second insulating layer, and a top surface. The n-type contact layer is disposed on the top surface. The source electrode portion is in contact with the n-type contact layer on the top surface, and is in contact with the second p-type epitaxial layer on the outer side wall. A gate insulating film is disposed on the inner side wall.

Owner:MITSUBISHI ELECTRIC CORP

Method for oxidizing brake master cylinder

The invention discloses a method for oxidizing a brake master cylinder, which comprises the following steps of: 1, hanging, namely hanging the brake master cylinder to a rack special for oxidizing the brake master cylinder; 2, performing weak acid oil removal treatment; 3, preparing anode oxidizing tank liquor; 4, performing anode oxidization treatment; and 5, taking out the brake master cylinder, cleaning, and performing enclosed drying treatment. The brake master cylinder treated by the method meets the industrial requirements on quality such as film thickness, roughness, hardness and the like.

Owner:JIANGSU RUIER LONGDING IND CO LTD

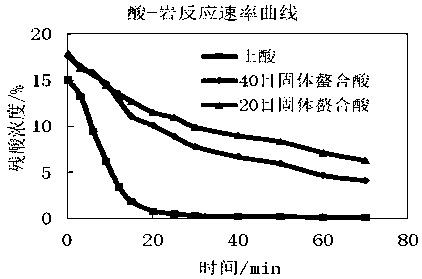

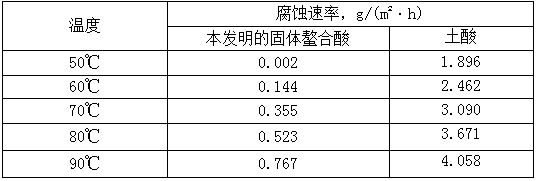

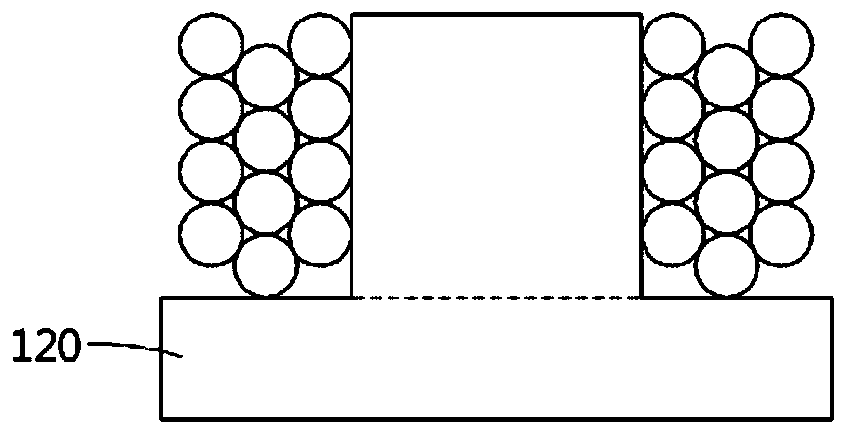

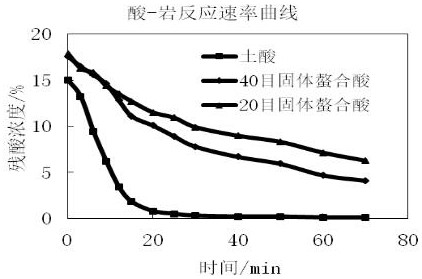

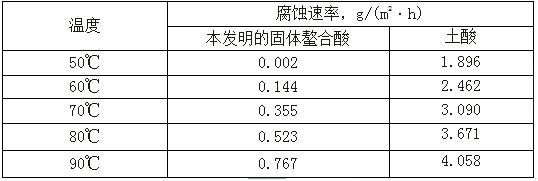

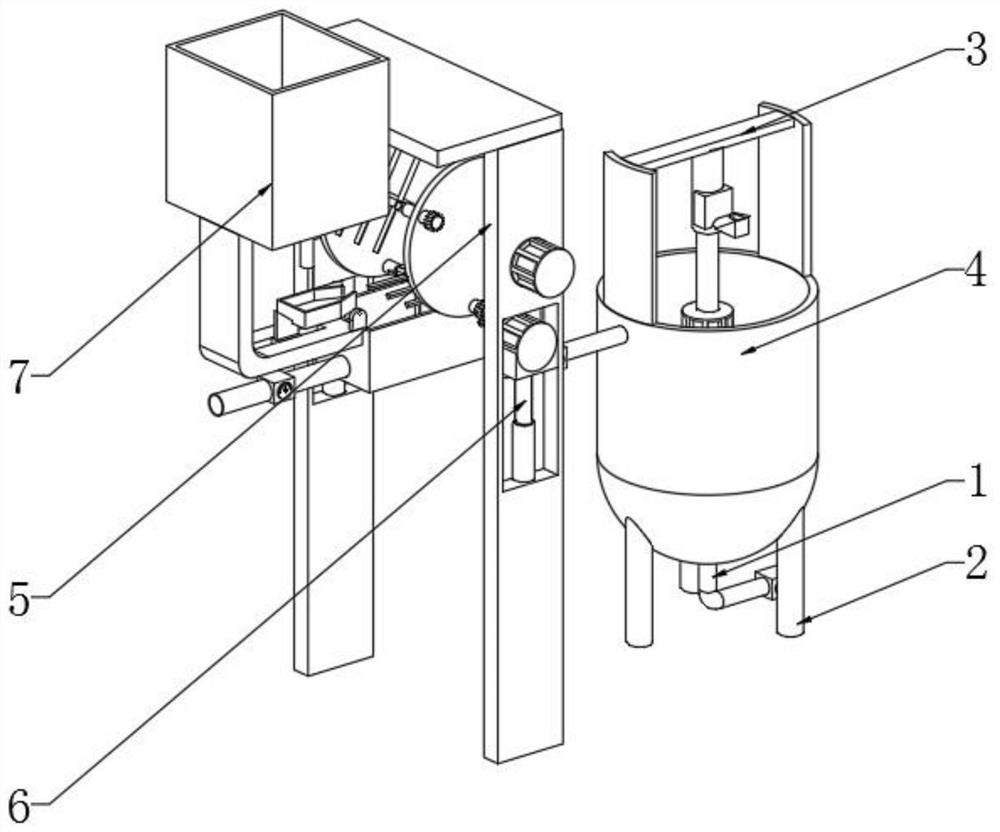

Solid chelate acid for augmented injection of water injection wells and preparation method thereof

ActiveCN109021950AIncrease salienceSelf-corrosion is smallDrilling compositionEnvironmental hazardRADIUS

The invention discloses a solid chelate acid for the augmented injection of water injection wells and a preparation method thereof, which relate to the technical field of depressurization and augmented injection of water injection wells of oilfields. The solid chelate acid for the augmented injection of water injection wells consists ofis prepared from the following materials in percentage by weight: 30 to 40 percent of a main agent, 20 to 30 percent of an auxiliary agent, 10 to 15 percent of an intensifier, 3 to 8 percent of an activator, 2 to 3 percent of an inhibitor, 5 to 10 percent of a stabilizer and 15 to 30 percent of a binder. By adopting the invention, potential safety and environmental hazards in the process of transportation, storage and use in plugging removal by acidification, the slow release rate of acid liquor is greatly increased, the radius of plugging removal is broadened, plugging removal deep in a water injection well is benefittedfacilitated, and the effective rate of depressurization and augmented injection measures for water injection wells is increased.

Owner:SHAANXI YOUBANG PETROLEUM ENG TECH CO LTD

Seedling raising method for coral trees

ActiveCN109757270AImprove permeabilityPromote degradationGrowth substratesCulture mediaAcid etchingRadicle

The invention provides a seedling raising method for coral trees, and belongs to the technical field of planting of coral trees. The seedling raising method for the coral trees comprises the followingsteps: 1) pretreatment: sterilizing coral tree seeds in a potassium permanganate solution at the temperature of 36-38 DEG C; 2) acid etching: carrying out acid etching on the pretreated coral tree seeds by using a mixed concentrated sulfuric acid solution containing diethyl ether; 3) hormone treatment: soaking the coral tree seeds subjected to acid etching in an ethanol solution containing indoleacetic acid and fluorenylmethanol; 4) low-temperature stratification germination acceleration: carrying out wet-cold stratification germination acceleration on coral tree seeds by using 3-5-year-oldpine sawdust; and 5) sowing: after carrying out sterilization and deinsectization treatment on a seedling substrate, sowing seeds, sprouting and growing into seedlings. The seedling raising method forthe coral trees has the beneficial effects that the method is easy to implement, the coral tree seeds in a dormant state can be effectively awakened, growth and development of radicles can be stimulated, sprouting of the radicles can be accelerated, the sprouting rate of the seeds can be increased, sprouting can be accelerated, sprouted seedlings are robust, and the transplanting survival rate ishigh.

Owner:日照新睿招商发展有限公司

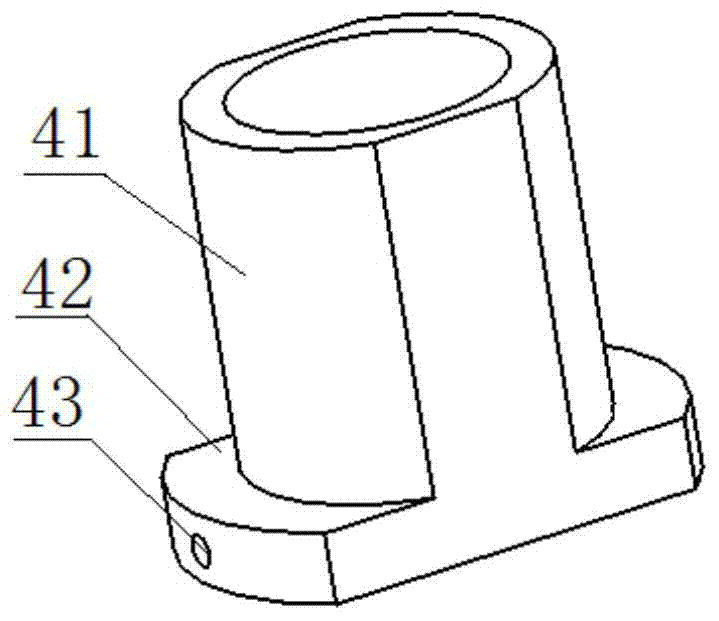

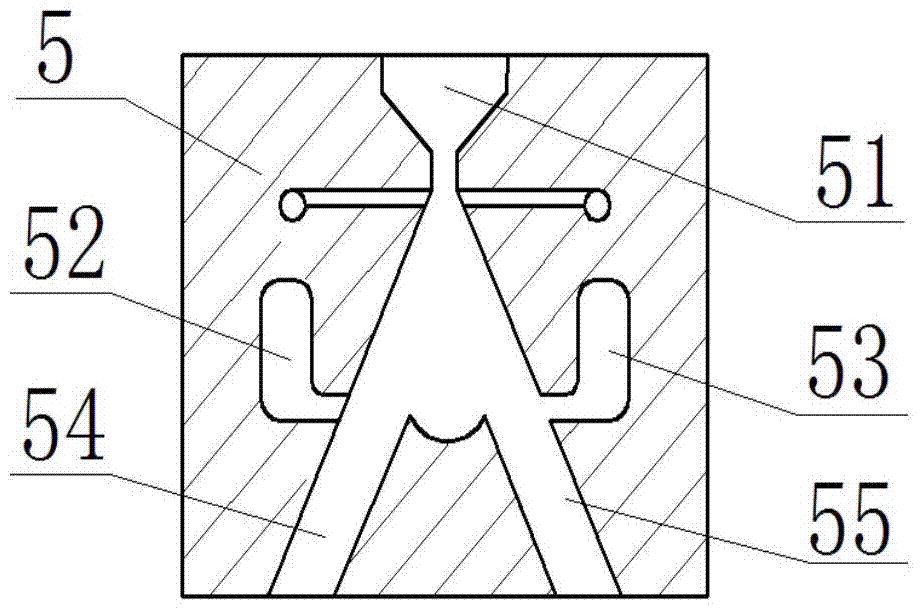

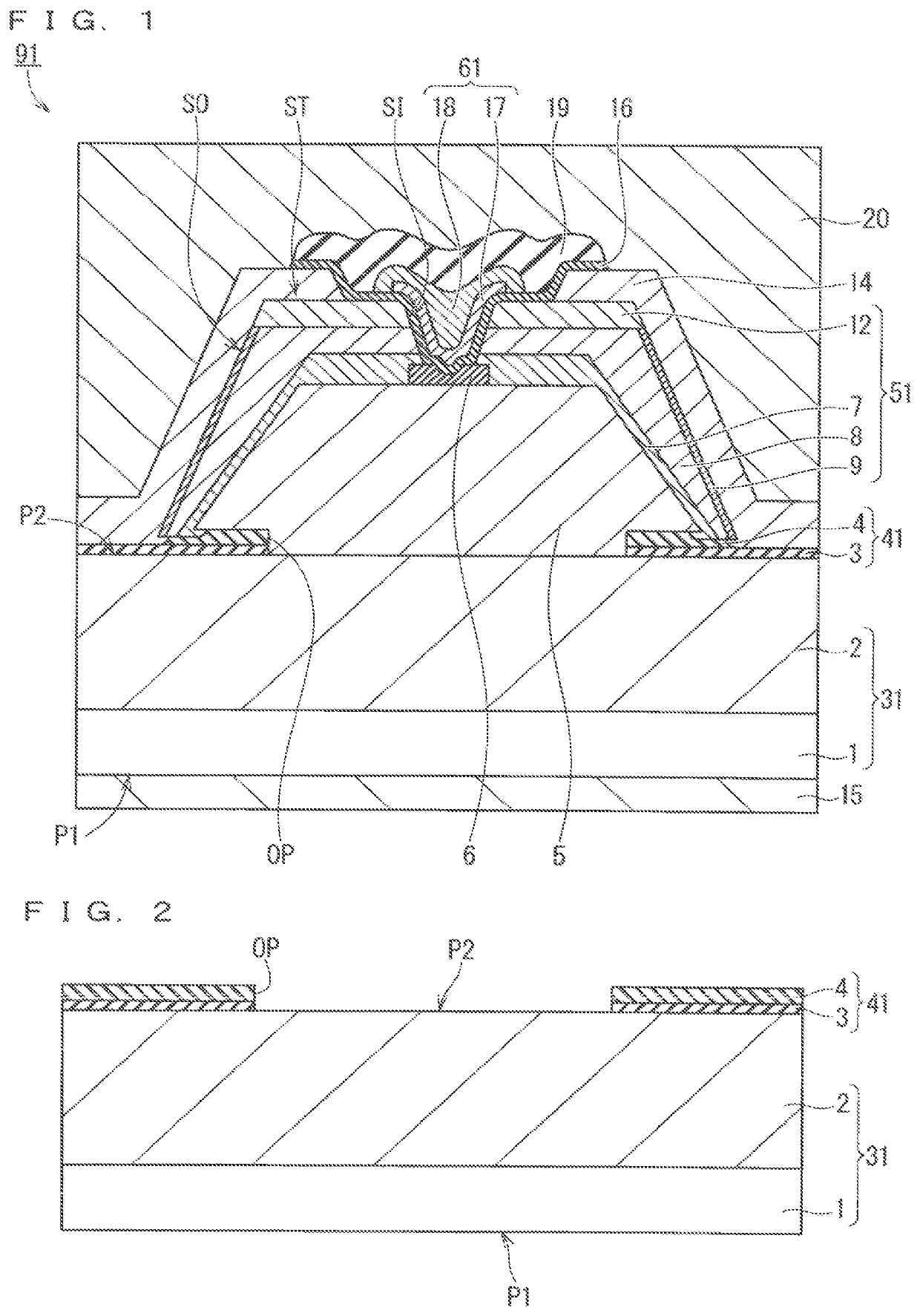

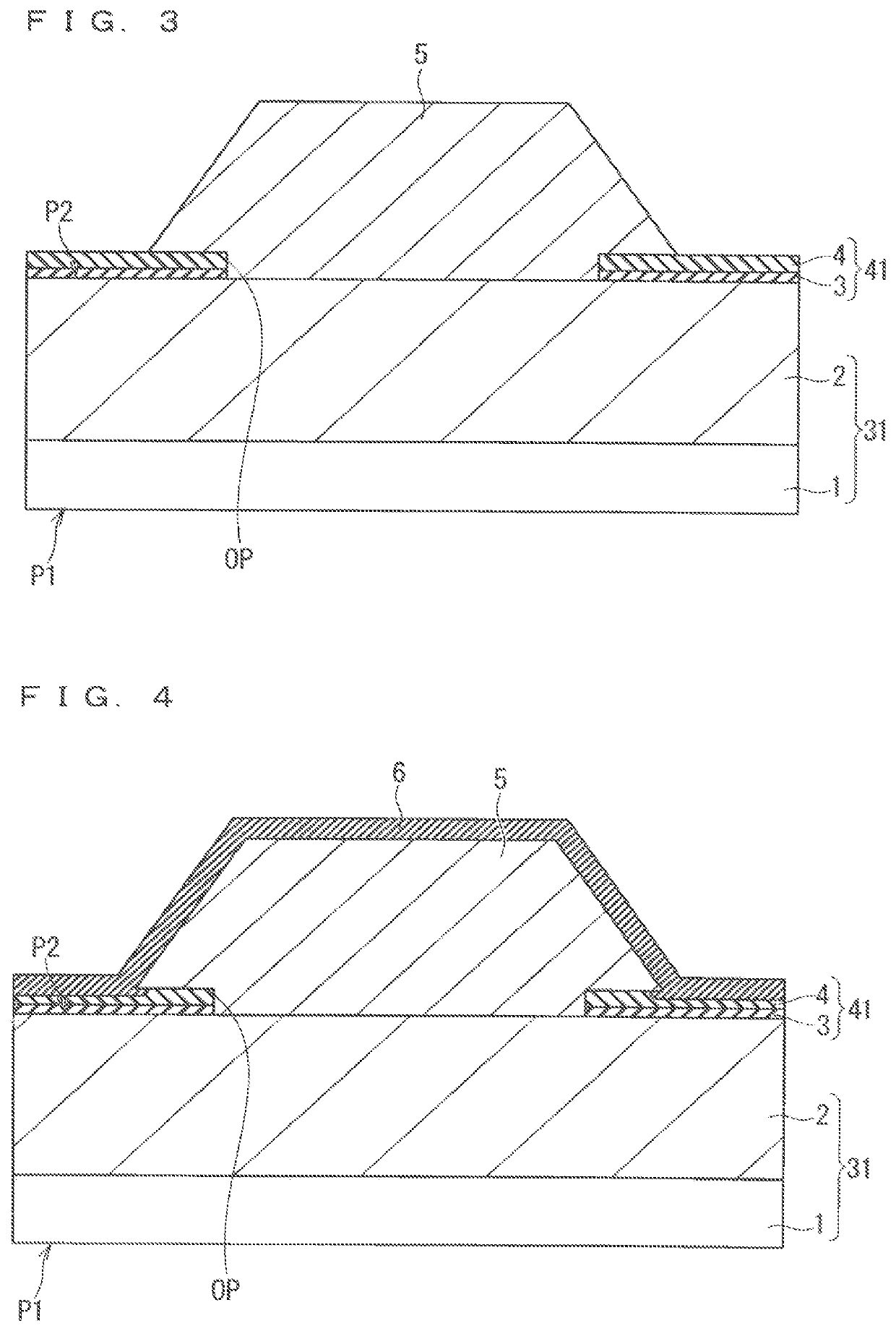

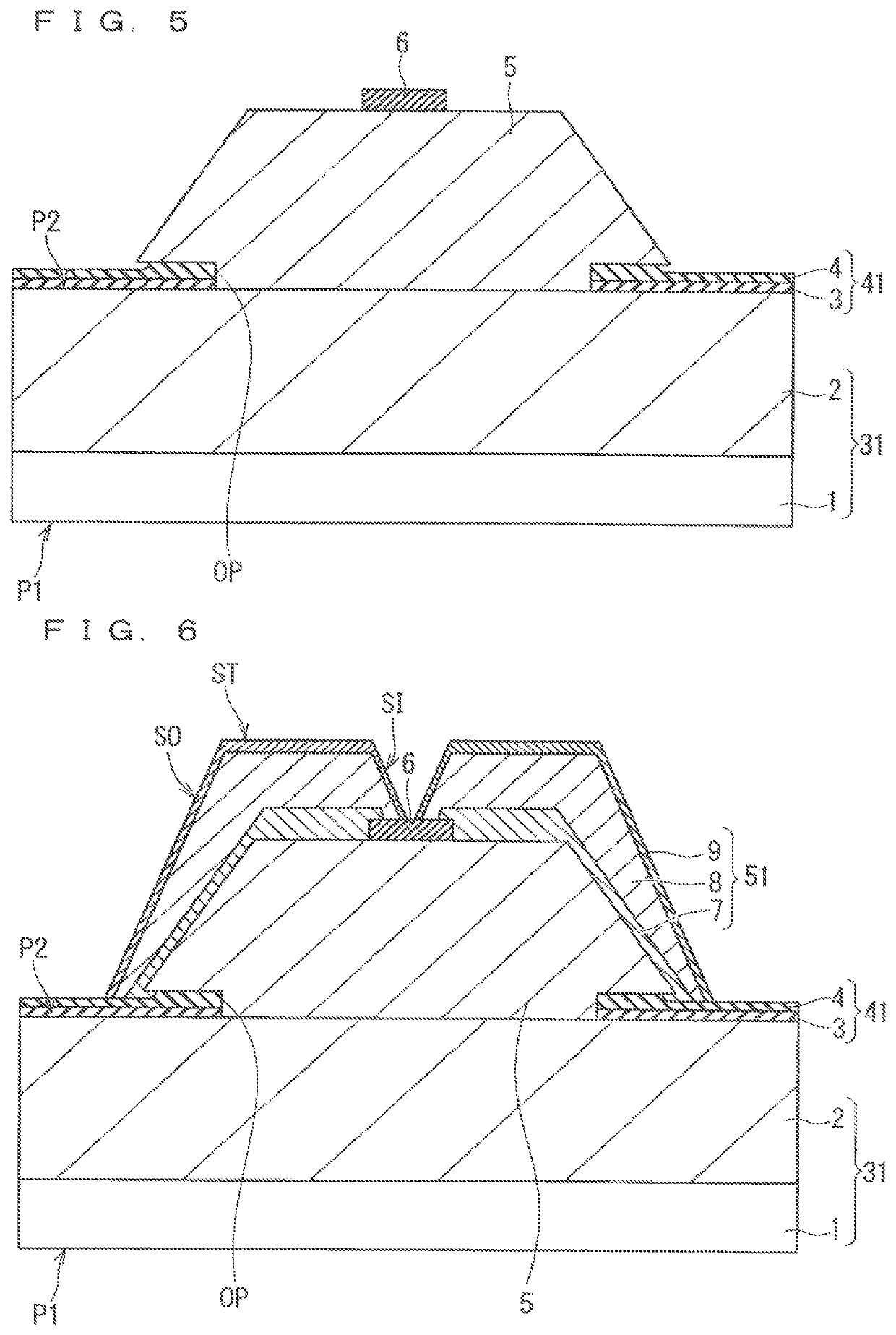

Semiconductor device and method for manufacturing semiconductor device

ActiveCN108780815AHigh activityAvoid excessive erosionSemiconductor/solid-state device manufacturingDiodeDevice materialEngineering

A first insulating layer (41) is provided on a second surface (P2) of a semiconductor substrate (31), and has an opening (OP). A second insulating layer (6) is provided on the second surface (P2), andis separated from the first insulating layer (41). A laminate (51) sequentially comprises, on the second surface (P2), a lateral n-type epitaxial layer (7) and first and second p-type epitaxial layers (8, 9), said layers being formed from a gallium nitride material. The laminate (51) has an outer side wall (SO) which has a portion that is formed of the second p-type epitaxial layer (9), an innerside wall (SI) which extends from the second insulating layer (6), and a top surface (ST). An n-type contact layer (12) is provided on the top surface (ST). A source electrode part (14) is in contactwith the n-type contact layer (12) on the top surface (ST), while being in contact with the second p-type epitaxial layer (9) on the outer side wall (SO). A gate insulating film (16) is provided on the inner side wall (SI).

Owner:MITSUBISHI ELECTRIC CORP

A production process of aluminized laser paper

ActiveCN108103850BImprove low temperature resistanceAvoid excessive erosionFlexible coversWrappersPhysical chemistryLaser patterning

The invention relates to the technical field of packaging bag paper production, in particular to a production process of aluminized laser paper. The production process comprises the following steps: 1) coating a release agent on a substrate to form a release layer; 2) drying the substrate coated with a release material; 3) imprinting a dried film so that the surface of the substrate can have a laser pattern; 4) conducting vacuum aluminum plating on the substrate, and then conducting protected layer coating on a specified position; 5) immersing the substrate coated with the protected layer in an alkaline liquid pool for aluminum washing and drying again; 6) conducting spot-coating on the surface of the substrate, then compounding the substrate and base paper through a compound device and then drying again; 7) curing composite paper, peeling off the substrate, and transferring the laser pattern to the surface of the base paper. After the release agent is used on the substrate, the durability, compression resistance, solvent resistance, and low temperature resistance are improved, and at the same time, and an alkaline solution can be effectively prevented from excessively eroding thesubstrate when aluminum is washed.

Owner:湖北华源包装有限公司

Systems, assemblies, and methods of reducing head loss in heating devices

ActiveUS20160194892A1Reduce head lossLess energyCheck valvesMultiple way valvesWater flowEngineering

Owner:ZODIAC POOL SYST LLC

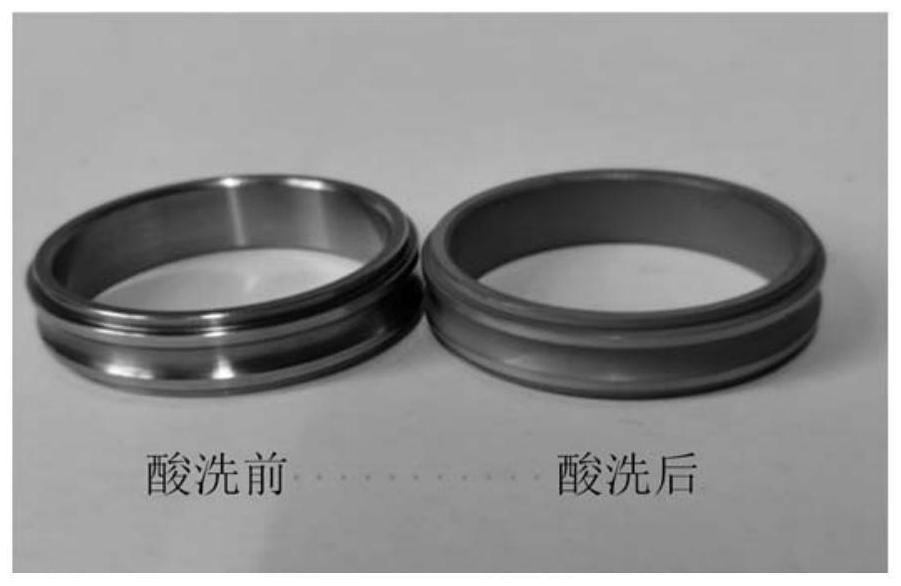

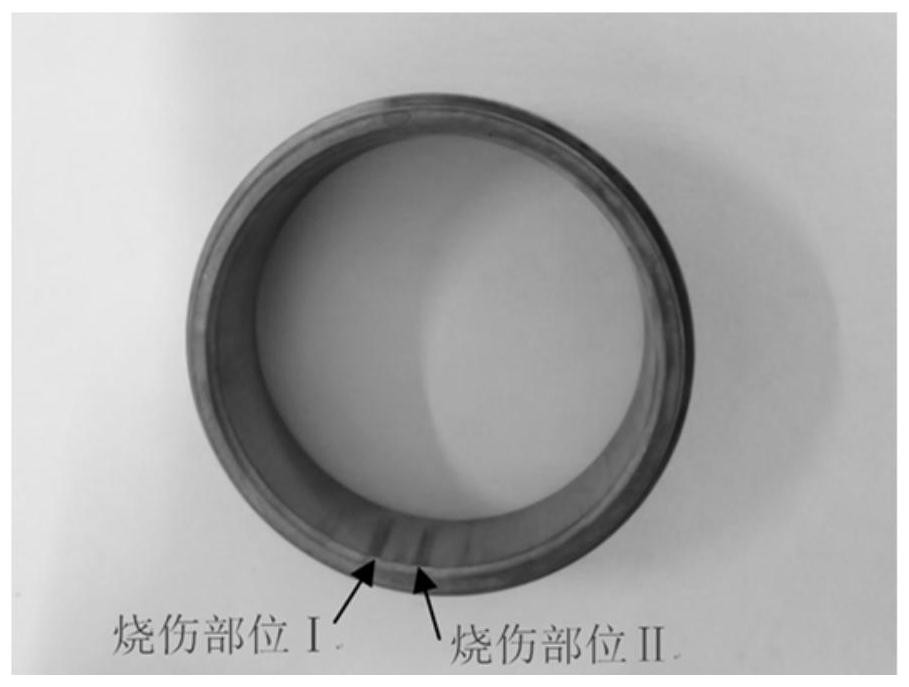

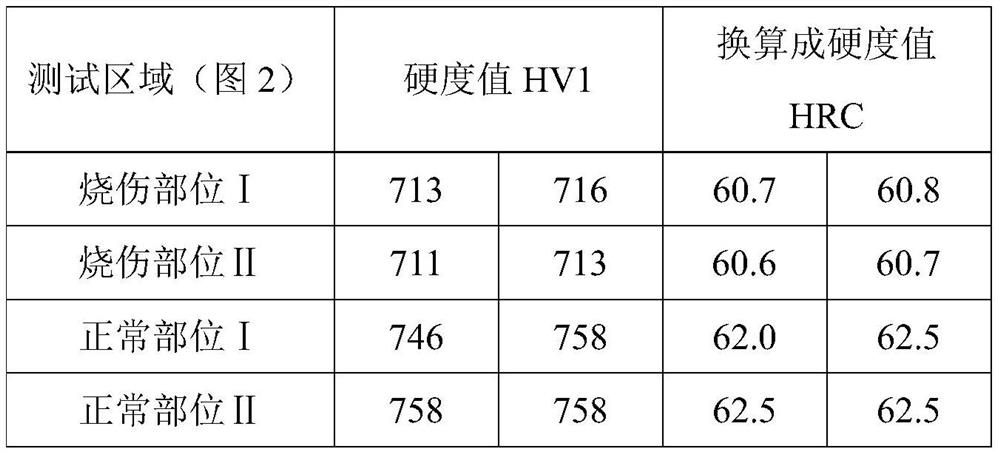

Cold pickling solution for identifying surface defects of high-nitrogen stainless steel and application of cold pickling solution

ActiveCN114839030APromotes corrosion propertiesReduce harmNuclear energy generationPreparing sample for investigationSS - Stainless steelSurface corrosion

The invention relates to a cold pickling solution for identifying surface defects of high-nitrogen stainless steel and application of the cold pickling solution, and belongs to the technical field of alloy surface defect identification. The cold pickling solution for identifying the surface defects of the high-nitrogen stainless steel is prepared from the following components in percentage by mass: 2.1 to 4.3 percent of HCl, 19.5 to 25.5 percent of H3PO4, 8 to 17 percent of FeCl3 and the balance of water. According to the formula of the cold pickling solution, the surface of high-nitrogen stainless steel can be quickly corroded, the corrosion time is only 1-2 min, the pickling amount after corrosion is 2 microns or below, excessive damage to the surface quality of parts is avoided, the identification accuracy rate of the grinding burn defects of the surface of the high-nitrogen stainless steel bearing reaches 100%, and in addition, long-term stable storage of the cold pickling solution can be guaranteed; and the effective service life is more than three months.

Owner:LUOYANG BEARING RES INST CO LTD

Magnet structure, magnet unit and magnetron sputtering device comprising same

ActiveCN110073464AImproved in-plane distributionAvoid excessive erosionElectric discharge tubesVacuum evaporation coatingMagnetMaterials science

The present invention relates to a magnet and the like which can be used for a magnetron sputtering device. A magnet structure for a magnetron sputtering device of the present invention comprises: a permanent magnet; and a wire surrounding the permanent magnet.

Owner:ULVAC KOREA

A kind of solid chelating acid used for increasing injection of water injection well and preparation method thereof

ActiveCN109021950BIncrease salienceSelf-corrosion is smallDrilling compositionActive agentEnvironmental engineering

The invention discloses a solid chelating acid used for increasing injection of water injection wells and a preparation method thereof, and relates to the technical field of depressurization and increasing injection of water injection wells in oil fields. The solid chelating acid used for increasing injection of water injection wells is composed of the following weight Percentage of raw material composition: 30-40% for the main agent, 20-30% for the auxiliary agent, 10-15% for the enhancer, 3-8% for the active agent, 2-3% for the inhibitor, and 5-5% for the stabilizer 10% and binder at 15‑30%. Adoption of the present invention can reduce the safety and environmental hazards in the process of transportation, storage and use in acidification and plugging removal, greatly improve the slow-release rate of acid liquid, expand the radius of plugging removal, facilitate the removal of plugging in the deep part of water injection wells, and improve the measures for reducing pressure and increasing injection of water injection wells Efficient.

Owner:SHAANXI YOUBANG PETROLEUM ENG TECH CO LTD

Fed chemical material conveying and adding control system based on full-automatic textile bleaching and dyeing and bleaching and dyeing method

PendingCN113638167AAvoid excessive erosionWell mixedLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsElectric machineryChemistry

The invention discloses a fed chemical material conveying and adding control system based on full-automatic textile bleaching and dyeing and a bleaching and dyeing method. A conversion mechanism comprises a left supporting plate and a right supporting plate which are symmetrically arranged; a rotating rod is arranged between the sides, close to each other, of the outer surfaces of the two supporting plates; the outer surface of the rotating rod is rotationally connected with the interiors of the two supporting plates in a penetrating mode; and the outer surface of the right supporting plate is fixedly connected with a rotating motor. The invention relates to the technical field of bleaching and dyeing. According to the fed chemical material conveying and adding control system based on full-automatic textile bleaching and dyeing and the bleaching and dyeing method, the conversion mechanism is arranged, multiple sets of stirring rods make contact with a dye solution gradually for stirring, meanwhile, the stirring rods are triangular strips, and the edges of the stirring rods apply pressure to the solution, so that solution movement mixing is more uniform, meanwhile, dye reduction caused by the fact that the stirring rods are contaminated with the solution is avoided; and the problem that color difference during cloth coloring easily occurs along with dye solution supplementing during cloth bleaching and dyeing is solved through the combination of the structures.

Owner:佛山市顺德金纺集团有限公司

Spray nozzle for fluidized catalytic cracking

ActiveUS10095830B2Easy constructionReduce manufacturing costCatalytic crackingKernel methodsSpray nozzleEngineering

Owner:SPRAYING SYST

A kind of nursery method of coral tree

ActiveCN109757270BImprove permeabilityPromote degradationGrowth substratesCulture mediaAcid etchingRadicle

The invention provides a method for raising coral tree seedlings, which belongs to the technical field of coral tree planting, comprising: 1) pretreatment: taking coral tree seeds and disinfecting them in potassium permanganate solution at 36-38°C; The pretreated coral tree seeds are acid-etched with a mixed concentrated sulfuric acid solution containing ether; 3) Hormone treatment: the acid-etched coral tree seeds are soaked in an ethanol solution containing indole acetic acid and fluorenemethanol; 4) germination by low-temperature stratification : Carry out wet and cold stratification germination to coral tree seeds with 3-5 year old pine sawdust; 5) Sowing: Seedlings are sown after being disinfected and disinfested, and germinate and grow into seedlings. The beneficial effects are: the method is easy to implement, can effectively awaken coral tree seeds in a dormant state, helps to stimulate the growth and development of radicles, accelerates the germination of radicles, improves the germination rate of seeds, accelerates germination, and the germinated seedlings are strong and transplanted. Planted high survival rate.

Owner:日照新睿招商发展有限公司

Electrochemical polishing method for metallic uranium

InactiveCN109234790AAchieve electrochemical polishing effectAvoid excessive erosionPower flowRoom temperature

The invention discloses an electrochemical polishing method for metallic uranium. The electrochemical polishing method comprises three steps of preprocessing, electrochemical polishing and post-processing. As polishing solution in targeted preparation is selected, and as parameters and process during electrochemical polishing process is optimized in a targeted way, metallic uranium does not separate gas during electrochemical polishing process, thereby improving current utilization and shorten polishing time; and meanwhile, excessive corrosion of metallic uranium is avoided and the loss of metallic uranium is reduced. The electrochemical polishing method provided by the invention is fast in polishing speed, good in effect, simple in process, and can be carried out at room temperature, thus, the active effect on the application of metallic uranium is promoted.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Method for oxidizing brake master cylinder

The invention discloses a method for oxidizing a brake master cylinder, which comprises the following steps of: 1, hanging, namely hanging the brake master cylinder to a rack special for oxidizing the brake master cylinder; 2, performing weak acid oil removal treatment; 3, preparing anode oxidizing tank liquor; 4, performing anode oxidization treatment; and 5, taking out the brake master cylinder, cleaning, and performing enclosed drying treatment. The brake master cylinder treated by the method meets the industrial requirements on quality such as film thickness, roughness, hardness and the like.

Owner:JIANGSU RUIER LONGDING IND CO LTD

A kind of Pb-sn-sb-ag alloy solder and preparation method thereof

ActiveCN104741819BGuaranteed wettabilityImprove wettabilityWelding/cutting media/materialsSoldering mediaMetal coatingSoldering

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com