Cold pickling solution for identifying surface defects of high-nitrogen stainless steel and application of cold pickling solution

A high nitrogen stainless steel, cold acid technology, applied in the preparation of test samples, reducing greenhouse gases, instruments, etc., can solve the problems of low effective use frequency and high cost, and achieve extended effective service life, enhanced corrosion, and improved corrosion. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

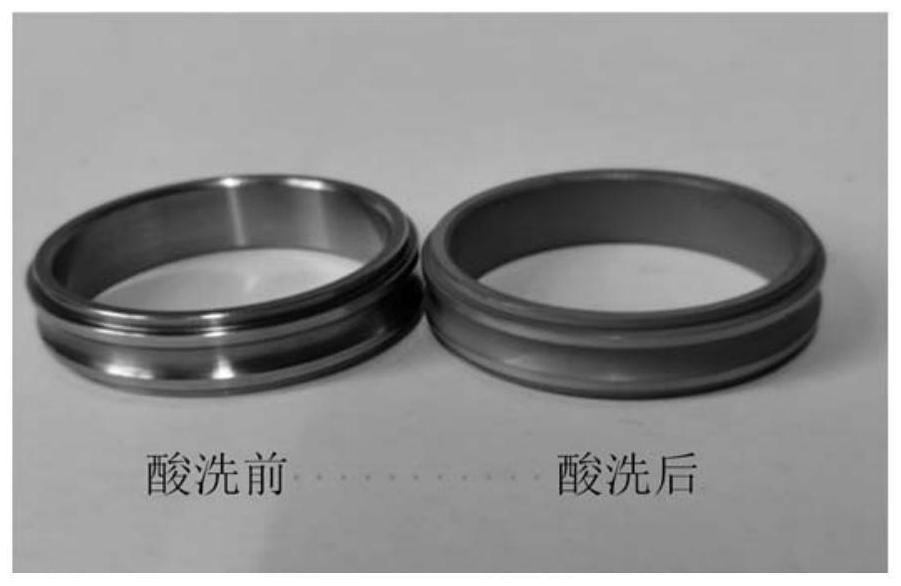

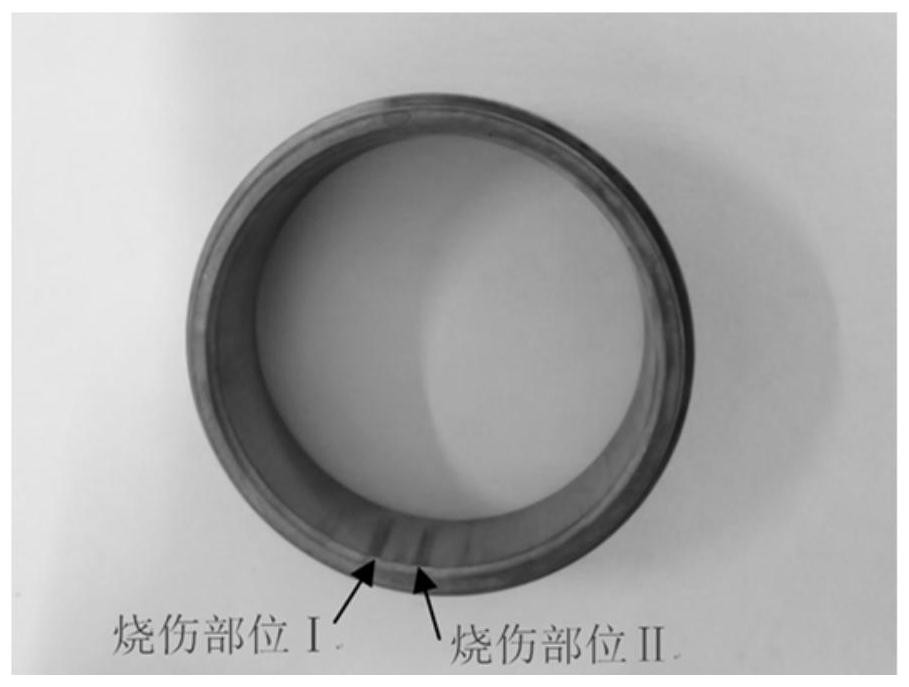

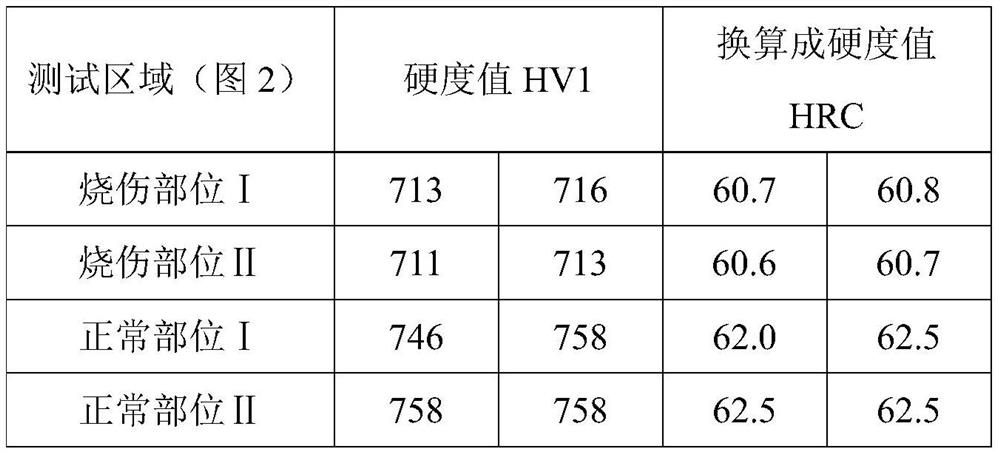

Method used

Image

Examples

Embodiment 1

[0026] The cold pickling solution for identifying surface defects of high nitrogen stainless steel in this embodiment is composed of the following components in mass fractions: HCl 2.1%, H 3 PO 4 19.5%, FeCl 3 17%, the balance is water.

Embodiment 2

[0028] The cold pickling solution for identifying surface defects of high nitrogen stainless steel in this embodiment is composed of the following components in mass fractions: HCl 4.3%, H 3 PO 4 25.5%, FeCl 3 8%, the balance is water.

Embodiment 3

[0030] The cold pickling solution for identifying surface defects of high nitrogen stainless steel in this embodiment is composed of the following components in mass fractions: HCl 3.6%, H 3 PO 4 22.9%, FeCl 3 12%, the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com