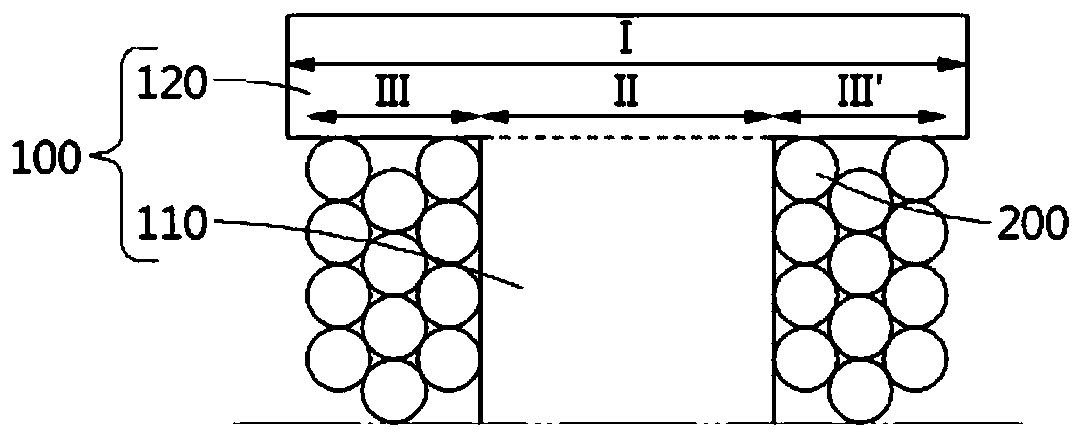

Magnet structure, magnet unit and magnetron sputtering device comprising same

A magnetron sputtering, magnet unit technology, applied in the direction of magnets, magnetic objects, permanent magnets, etc., can solve the problems of excessive working time, increased manufacturing costs, and the adjustment of magnetic field strength cannot be formed locally, and achieves improvement. The effect of internal distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

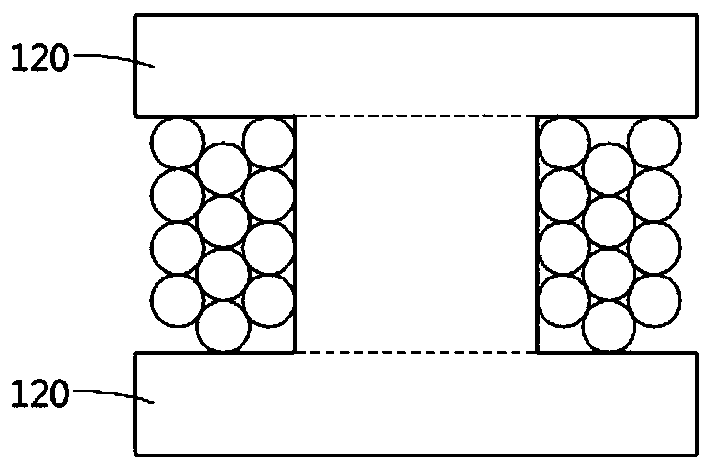

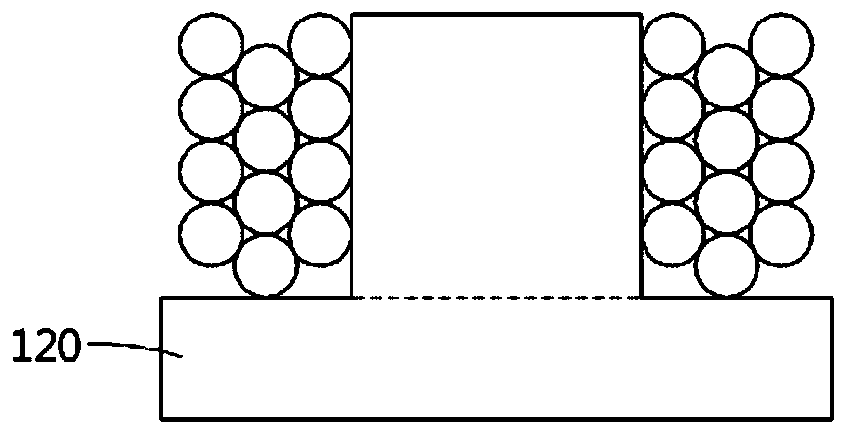

[0036] Hereinafter, an embodiment will be described in detail with reference to the drawings. The same reference symbols shown in the various figures denote the same components.

[0037] Various modifications can be added to the embodiments described below. The examples described below are not limited to the embodiments, and should be understood to include all changes, equivalents, and substitutions thereto.

[0038] The terms used in the examples are used only to describe a specific example, and do not limit the examples. A singular expression includes a plural expression unless it is clearly defined in the text. In this specification, terms such as "comprising" or "having" designate the existence of features, numbers, steps, actions, constituent elements, parts or combinations described in the specification. It should be understood that one or more than one The existence or additional possibility of other features or numbers, steps, actions, constituent elements, componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com