Electrochemical polishing method for metallic uranium

An electrochemical and metal uranium technology, applied in the field of surface treatment, can solve problems such as shortening polishing time, and achieve the effects of shortening polishing time, fast polishing speed and improving polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Pretreatment: Grind the metal uranium sheet successively with 600#, 800#, 800#, 1000#, 1200# water-grinding sandpaper (such as figure 1 shown), then ultrasonically cleaned in absolute ethanol, and finally dried with Ar gas and stored in a low-humidity hypoxic glove box (both moisture and oxygen content were below 1 ppm);

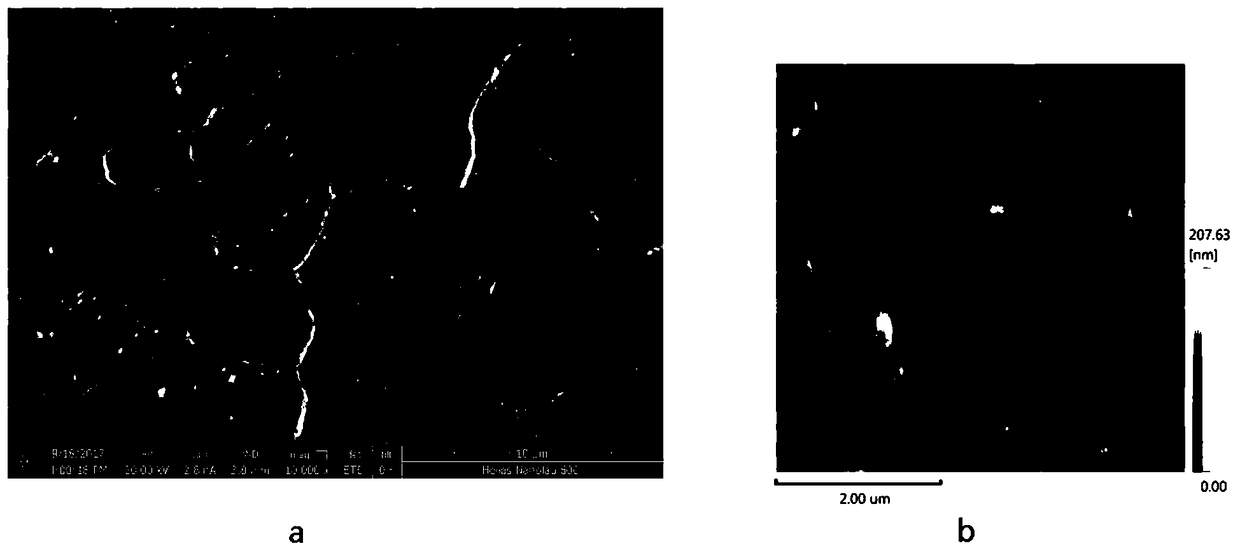

[0032] (2) Electrochemical polishing: the pretreated metal uranium substrate is used as the anode, and the Al plate is used as the cathode; 3 Electrochemical polishing was carried out in the prepared polishing solution; the temperature of the polishing solution was 40 °C, the electrochemical polishing time was 10 min, and the current density was 17 mA / cm 2 , the stirring rate of the polishing liquid is 400 r / min;

[0033] (3) Post-treatment: Rinse the electrochemically polished metal uranium sheet in the polishing solution for 3 times, take it out after power off, and wipe until the surface of the uranium sheet reveals a metallic luster, that is,...

Embodiment 2

[0035] (1) Pretreatment: The metal uranium slices are successively polished with 500#, 600#, 800#, 1000#, and 1200# water-grinding paper, then ultrasonically cleaned in absolute ethanol, and finally cleaned with N 2 Air-dried and stored in a low-humidity hypoxic glove box (moisture and oxygen content are both lower than 1 ppm);

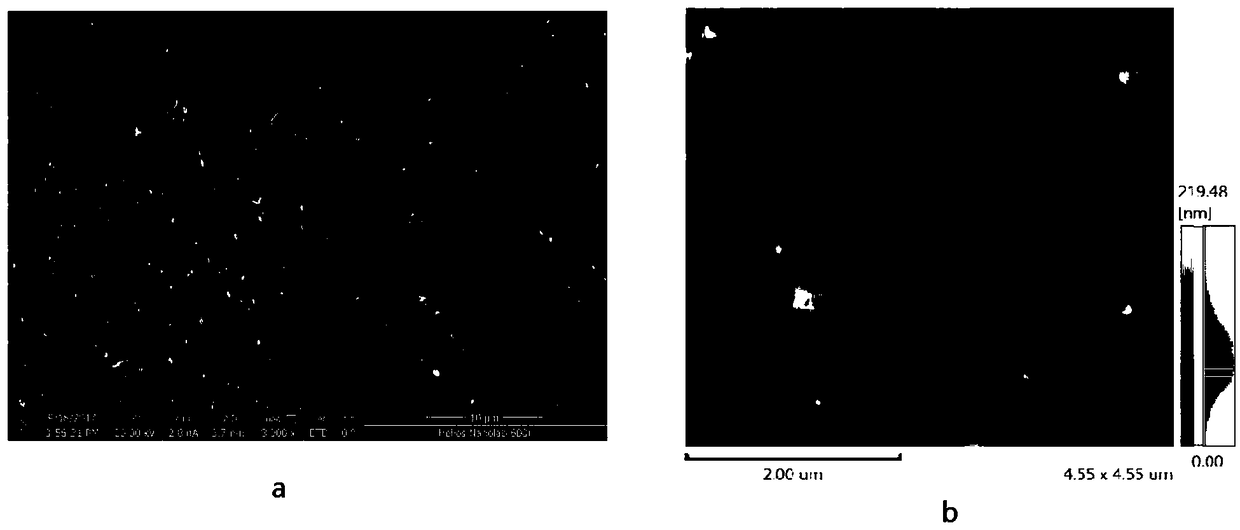

[0036](2) Electrochemical polishing: the pretreated metal uranium substrate is used as the anode, and the Pt plate is used as the cathode; 3 Electrochemical polishing was carried out in the prepared polishing solution; the temperature of the polishing solution was 80 °C, the electrochemical polishing time was 20 min, and the current density was 6 mA / cm 2 , the stirring rate of the polishing liquid is 600 r / min;

[0037] (3) Post-treatment: Rinse the electrochemically polished metal uranium slices in the polishing solution for 2 times, take them out after power off, and wipe until the surface of the uranium slices reveals a metallic luster, and then t...

Embodiment 3

[0039] (1) Pretreatment: Grind the metal uranium sheet with 800# water, then wash it in absolute ethanol, and finally dry it with Ar gas and place it in a low-humidity hypoxic glove box (the water and oxygen content are both lower than 1 ppm);

[0040] (2) Electrochemical polishing: the pretreated uranium metal substrate is used as the anode, and the Al plate is used as the cathode; 3 Electrochemical polishing was carried out in the prepared polishing solution; the temperature of the polishing solution was 15 °C, the electrochemical polishing time was 5 min, and the current density was 30 mA / cm 2 , the stirring rate of the polishing solution is 50 r / min;

[0041] (3) Post-treatment: Rinse the electrochemically polished metal uranium sheet in the polishing solution once, then take it out after power off, and wipe until the surface of the uranium sheet reveals a metallic luster, that is, the polished metal uranium sheet is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com