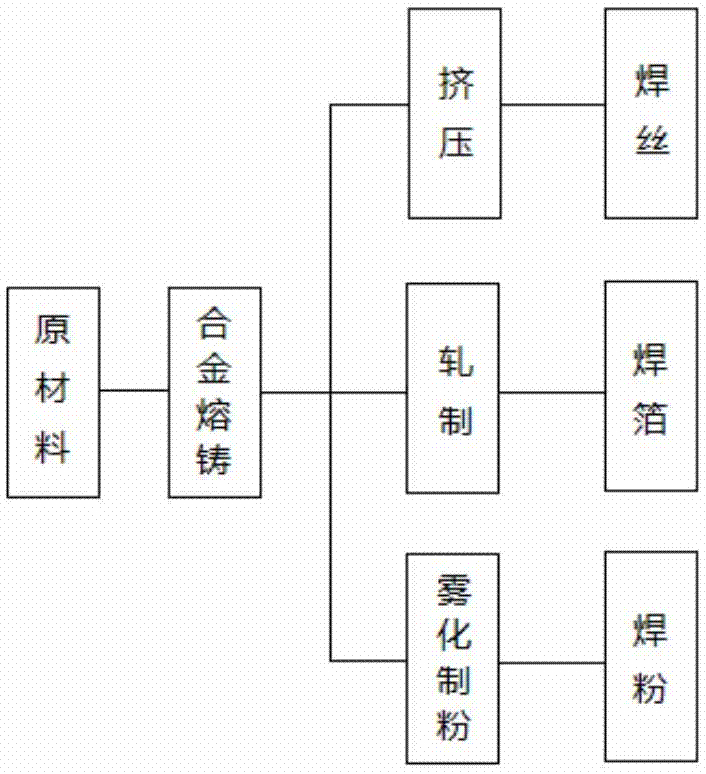

Pb-Sn-Sb-Ag alloy brazing filler metal and manufacturing method thereof

A pb-sn-sb-ag, alloy brazing filler metal technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of inability to meet the use requirements, insufficient Cu wettability, etc., and achieve brazing manufacturability. Good, avoid excessive erosion, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: prepare Pb-Sn-Sb-Ag alloy solder (one)

[0026] Step 1: Weighing the metal raw material

[0027] Weigh 158 grams of Sn, 0.1 grams of Ag, 78 grams of Sb and 763.9 grams of Pb respectively;

[0029] Put the weighed Pb, Sn, Sb and Ag metal raw materials in a graphite crucible by using an intermediate frequency induction furnace, heat to 500°C for melting by using an intermediate frequency induction furnace, cool down to 350°C after the metal is melted, and keep it warm for 5 minutes. Carry out casting, make the Pb-Sn-Sb-Ag alloy ingot of diameter 30mm bar;

[0030] Step 3: Wire Preparation

[0031] The casted alloy rod-shaped ingot is extruded by an extruder to make a welding wire with a diameter of 1 mm.

Embodiment 2

[0032] Embodiment 2: prepare Pb-Sn-Sb-Ag alloy solder (two)

[0033] Step 1: Weighing the metal raw material

[0034] Weigh 159 grams of Sn, 0.5 grams of Ag, 76 grams of Sb and 764.5 grams of Pb respectively;

[0036] Put the weighed Pb, Sn, Sb and Ag metal raw materials in a graphite crucible by using an intermediate frequency induction furnace, heat to 500°C for melting by using an intermediate frequency induction furnace, cool down to 350°C after the metal is melted, and keep it warm for 5 minutes. Carry out casting, make the Pb-Sn-Sb-Ag alloy ingot of thickness 5mm plate;

[0037] Step 3: Solder Foil Preparation

[0038] The alloy plate-shaped ingot after melting and casting is rolled by a rolling mill to make a welding foil with a thickness of 0.1 mm.

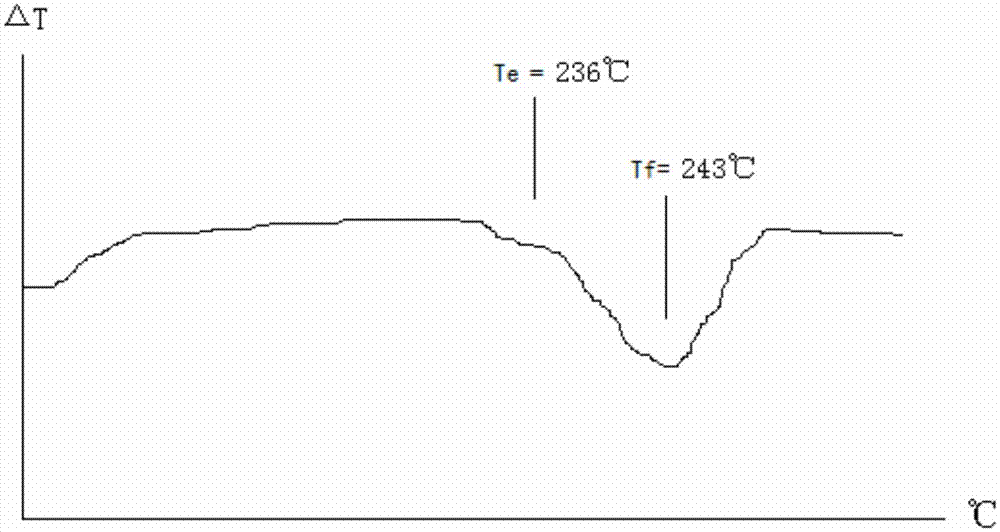

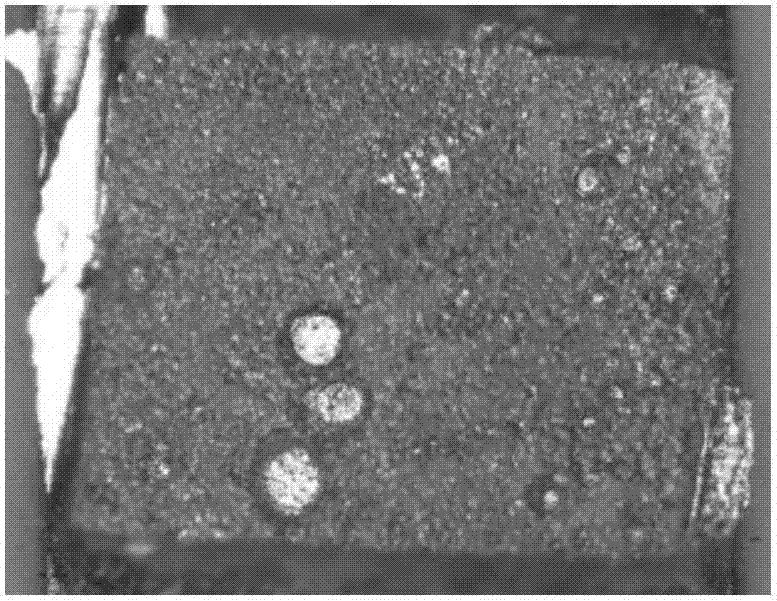

[0039] The obtained Pb-Sn-Sb-Ag alloy solder was used for brazing test, the base material was pure Cu sheet, brazing was completed on a heating platform, and the brazing temperature was 2...

Embodiment 3

[0040] Embodiment 3: prepare Pb-Sn-Sb-Ag alloy solder (three)

[0041] Step 1: Weighing the metal raw material

[0042] Weigh 160 grams of Sn, 10 grams of Ag, 75 grams of Sb and 755 grams of Pb respectively;

[0044] Put the weighed Pb, Sn, Sb and Ag metal raw materials in a graphite crucible by using an intermediate frequency induction furnace, heat to 500°C for melting by using an intermediate frequency induction furnace, cool down to 350°C after the metal is melted, and keep it warm for 5 minutes. Carry out casting, make the Pb-Sn-Sb-Ag alloy ingot of diameter 30mm bar;

[0045] Step 3: Solder Powder Preparation

[0046] Using the gas atomization powder making method, using nitrogen as the atomizing gas, place the obtained rod-shaped ingot under the conditions of a pressure of 0.6MPa and a temperature of 350°C, and gas atomize it into an alloy powder. The alloy powder, Through sieving, the alloy solder powder with a particle size of 25um-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com