Method for oxidizing brake master cylinder

A technology of brake master cylinder and anodic oxidation tank, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of high equipment requirements, difficulties, and increased oxidation costs, so as to reduce energy consumption costs and improve hardness, avoiding the effect of protruding eutectic silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for oxidation of a brake master cylinder, comprising the steps of:

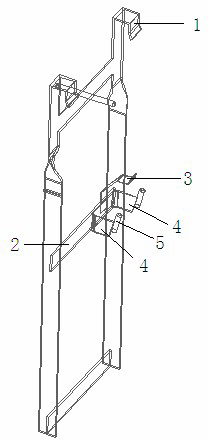

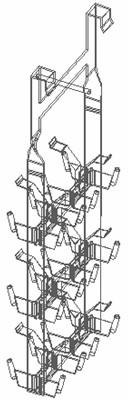

[0039] ① Hanging: Insert the two positioning holes on the brake master cylinder into the two titanium metal rods 5 of the hanger, and press the elastic titanium metal sheet 5 on the tail of the master cylinder. The thickness of the titanium metal sheet 5 is 0.5mm-1mm. Using the principle of leverage, due to the longer power arm, the main cylinder can be pressed tightly with a small elastic force. Note that the side with holes at the tail of the main cylinder is facing upwards, so as to facilitate the release of gas during the oxidation process.

[0040] ② Preparation of degreasing agent and degreasing treatment: amino acid 26%, disodium hydrogen phosphate 15%, sodium benzoate 10%, glycerin 16%, citric acid 6%, sodium dodecylbenzenesulfonate 2% and water 25% After mixing, dilute with water at a volume ratio of 4-10%, put the mounted brake master cylinder in the diluent, adjust the pH to 1.5-2....

Embodiment 2

[0045] A method for oxidation of a brake master cylinder, comprising the steps of:

[0046]① Hanging: Insert the two positioning holes on the brake master cylinder into the two titanium metal rods 5 of the hanger, and press the elastic titanium metal sheet 3 on the tail of the master cylinder. The thickness of the titanium metal sheet 3 is 0.5mm-1mm. Using the principle of leverage, due to the longer power arm, the main cylinder can be pressed tightly with a small elastic force. Note that the side with holes at the tail of the main cylinder is facing upwards, so as to facilitate the release of gas during the oxidation process.

[0047] ② Preparation of degreasing agent and degreasing treatment: amino acid 28%, disodium hydrogen phosphate 15%, sodium benzoate 10%, glycerin 16%, citric acid 8%, sodium dodecylbenzenesulfonate 1% and water 22% After mixing, dilute with water at a volume ratio of 4-10%, put the mounted brake master cylinder in the diluent, adjust the pH to 1.5-2.5...

Embodiment 3

[0052] A method for oxidation of a brake master cylinder, comprising the steps of:

[0053] ① Hanging: Insert the two positioning holes on the brake master cylinder into the two titanium metal rods 5 of the hanger, and press the elastic titanium metal sheet 3 on the tail of the master cylinder. The thickness of the titanium metal sheet 3 is 0.5mm-1mm. Using the principle of leverage, due to the longer power arm, the main cylinder can be pressed tightly with a small elastic force. Note that the side with holes at the tail of the main cylinder is facing upwards, so as to facilitate the release of gas during the oxidation process.

[0054] ② Preparation of degreasing agent and degreasing treatment: 32% amino acid, 10% disodium hydrogen phosphate, 12% sodium benzoate, 12% glycerin, 8% citric acid, 1% sodium dodecylbenzenesulfonate and 25% water After mixing, dilute with water at a volume ratio of 4-10%, put the mounted brake master cylinder in the diluent, adjust the pH to 1.5-2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com