Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Act as a compatibilizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long glass fiber reinforced recycled polypropylene material and preparation method thereof

The invention discloses long glass fiber reinforced recycled polypropylene material and a preparation method thereof. The long glass fiber reinforced recycled polypropylene material comprises components according to mass percent: 25-55% of polypropylene, 30-60% of long glass fiber, 0.4-0.8% of coupling agent, 3-8% of graft of thermoplastic elastomer, 0.1-0.3% of fused finger modifier, 0.2-0.4% ofantioxygens, 1-4% of lubricant and 1-3% of selective assistant. The preparation method is as follows: mixing and stirring components except for long glass fiber, and then adding the components exceptfor long glass fiber to a screw extruder; adding long glass fiber, mixing, extruding, cooling, air drying and pelleting; as the fused finger modifier is added, the requirements on polypropylene are reduced; various recycled polypropylene materials can be used as backing material. The preparation method is simple and has low cost; the prepared long glass fiber einforced recycled polypropylene material has good comprehensive performances and can replace a plurality of metal parts to be applied to various fields.

Owner:惠东美化塑胶实业有限公司

SBS modified emulsified bitumen having a high softening point and a preparing method thereof

InactiveCN106554635AHigh in SBSImprove high temperature performanceBuilding insulationsDuctilityColloid mill

The invention relates to SBS modified emulsified bitumen having a high softening point and a preparing method thereof. The SBS modified emulsified bitumen comprises, by weight, 45.0-60.0% of matrix bitumen, 1.5-3.0% of an SBS modifier, 3-15% of catalytic cracking oil slurry, 0.05-0.5% of a stabilizing agent, 0.8-2.5% of a cation emulsifier, 0-0.2% of an auxiliary agent and 32.0-42.0% of water. During preparation, SBS modified bitumen is firstly prepared, then the cation emulsifier and the auxiliary agent are added into hot water having a temperature of 50-70 DGE C to prepare a soap solution, and finally the SBS modified bitumen and the soap solution are subjected to emulsification together through a colloid mill, pressurization and cooling to obtain the SBS modified emulsified bitumen. The preparing method is simple and steps are easy to operate. The prepared SBS modified emulsified bitumen has a high SBS content, the high softening point, high ductility at 5 DEG C, and excellent high-temperature performance and low-temperature performance. An effective route is provided for high value-added utilization of the catalytic cracking oil slurry.

Owner:CNPC JIANGSU FUEL ASPHALT

High-strength and high-toughness polylactic acid composite film with antimicrobial and barrier properties

ActiveCN105440611AFusion wellImprove flexibilitySynthetic resin layered productsLaminationGlycidyl methacrylateComposite film

The present invention relates to high-strength and high-toughness polylactic acid composite film with antimicrobial and barrier properties. Raw materials of the high-toughness polylactic acid composite film comprises polylactic acid, EVOH, polylactic acid grafted glycidyl methacrylate, ethylene-octene copolymer grafted glycidyl methacrylate, eight-arm maleic anhydride POSS, nano TiO2, an antioxidant, and an anti-UV agent. The composite film is formed through multilayer coextrusion. The composite film has excellent strength and toughness, a good oxygen barrier property to gas, and a good antimicrobial effect, and can be used in the field of the environmentally friendly packaging film.

Owner:HUNAN YIYONGFENG PRINGTING PACKAGING

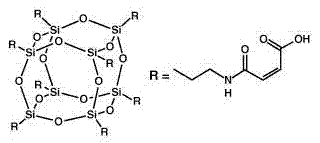

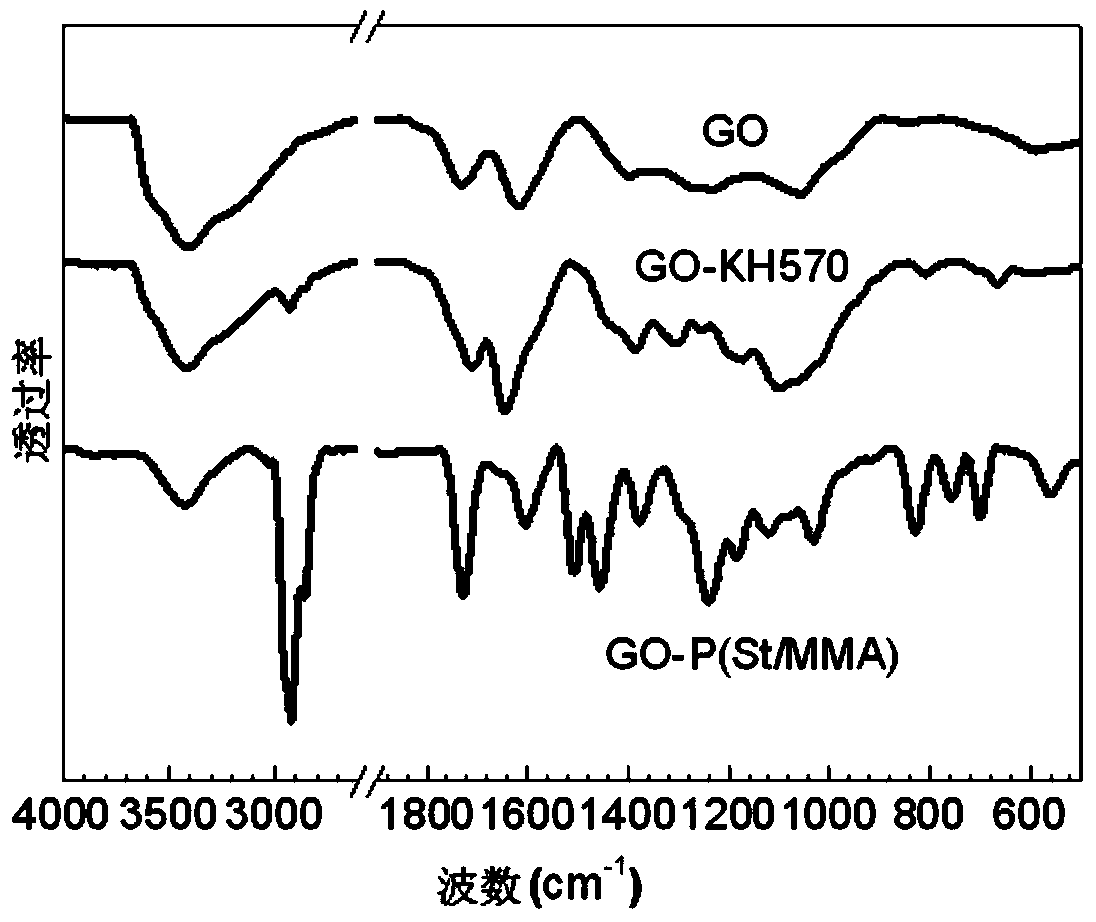

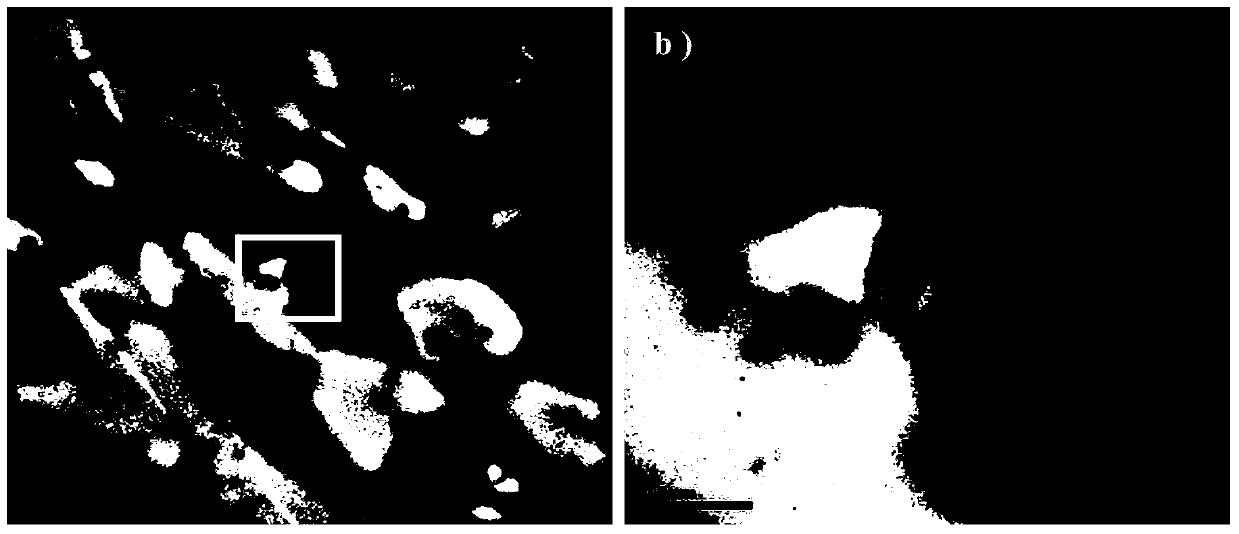

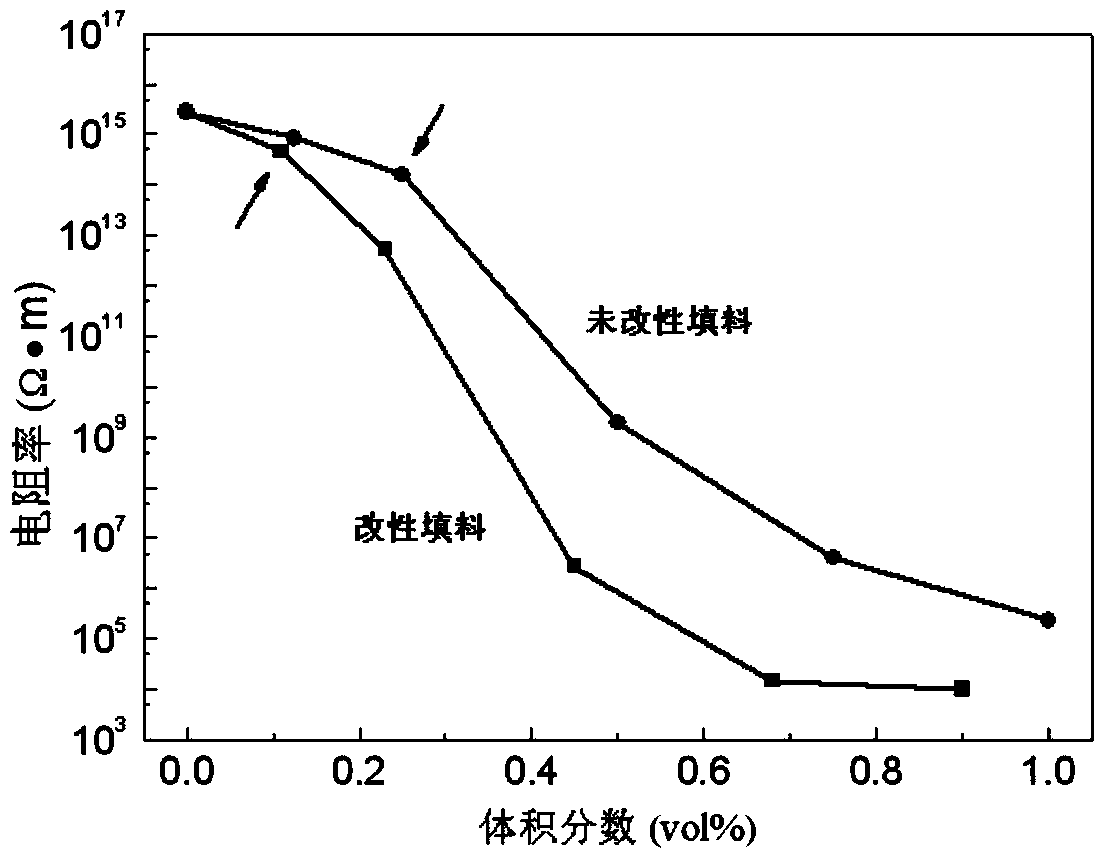

Method for preparing graphene composite with low percolation threshold value and high heat stability

The invention relates to a method for preparing a graphene composite with a low percolation threshold value and high heat stability. The method comprises the following steps: introducing double bonds by the grafting of graphene oxide with a silane coupling agent; polymerizing preliminarily-modified fillers with styrene and methyl methacrylate fine emulsion, and preparing modified fillers of grafting random copolymers; mixing the modified fillers with polystyrene and a poly methyl methacrylate solution, and using hydrazine hydrate for synchronous reduction; precipitating polymers, drying and performing. TEM tests for the graphene composite provided by the utility model show that part of fillers are distributed at two phases of interfaces and generates good compatibilization to a system, and the percolation threshold value is only 0.11 vol%. Meanwhile, SEM tests show that phase coarsening is inhibited before and after heat treatment, the heat stability of the system is obviously increased, and the graphene composite can be widely used in the field of conductive polymer composites.

Owner:SHANGHAI JIAO TONG UNIV

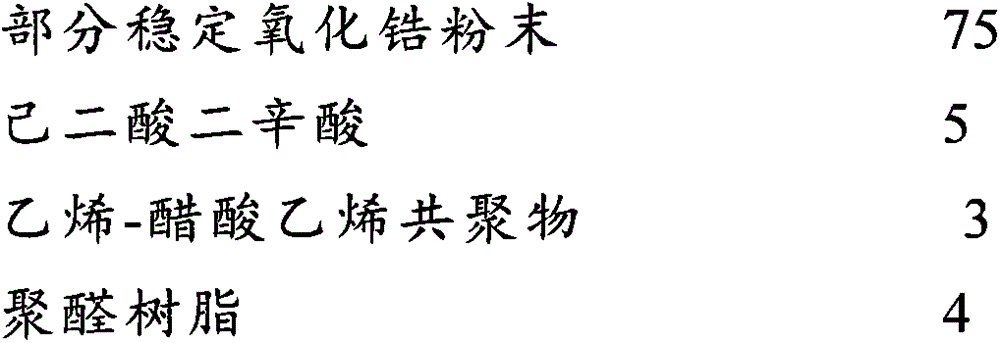

Method for manufacturing high-strength zirconia ceramic core insert

ActiveCN104961462AExcellent coefficient of linear expansionImprove thermomechanical propertiesBenzenePolystyrene

The invention provides a method for manufacturing a high-strength zirconia ceramic core insert and a method for preparing part of zirconia stabilizing powder for the high-strength zirconia ceramic core insert. According to the method for manufacturing the high-strength zirconia ceramic core insert, firstly, scandia and cerium oxide are made to react with zirconia, nano titania and aluminum oxide are mixed at the same time, so that the linear expansion coefficient and thermal stress performance which are more excellent than that of pure zirconia ceramic are obtained, in this way, the material can have high strength, high tenacity and excellent thermal shock resistance, and deformation is unlikely to occur; secondly, an SEBS elastomer, polrvinyl benzene, aldehyde resin and the like are inserted into part of zirconia stabilizing powder for polymerization, so that an interspersed network structure is formed, a stable structural system is obtained, and deformation is unlikely to occur; thirdly, the aldehyde resin and the polrvinyl benzene are taken as main binding agents, in this way, the strength of formed blank is high, conformality is good, the degreasing speed is high, and the precision is high; fourthly, stearate radical is removed during sintering of zinc stearate, so that the zinc stearate is oxidized into zinc oxide, and thus the strength of the core insert is improved.

Owner:NINGBO BRIGHT PHOTOELECTRIC TECH

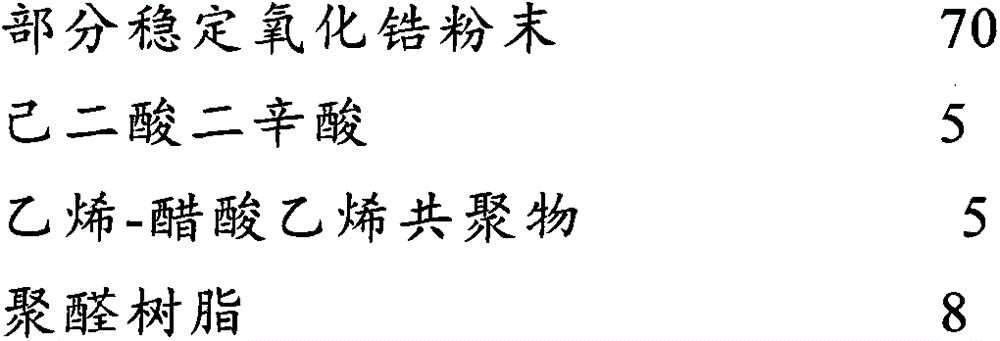

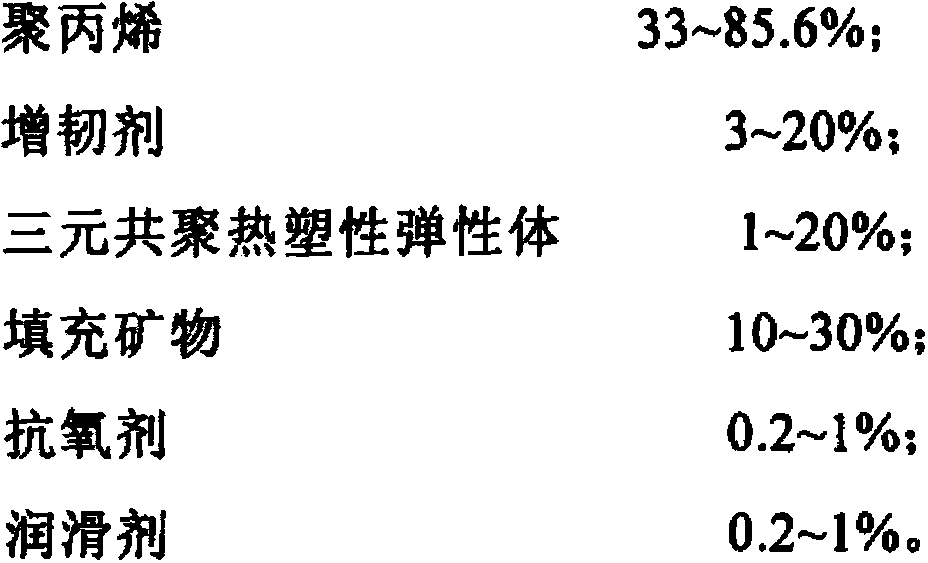

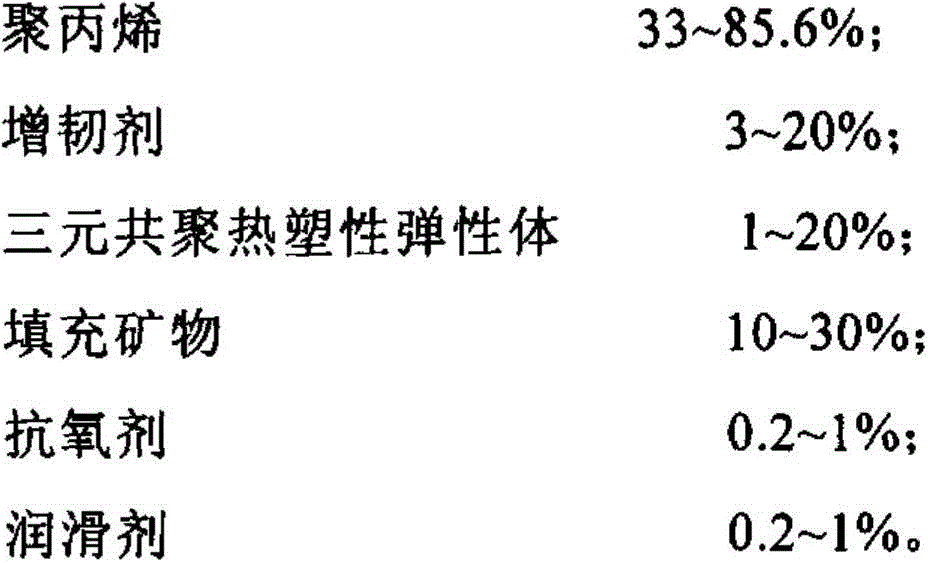

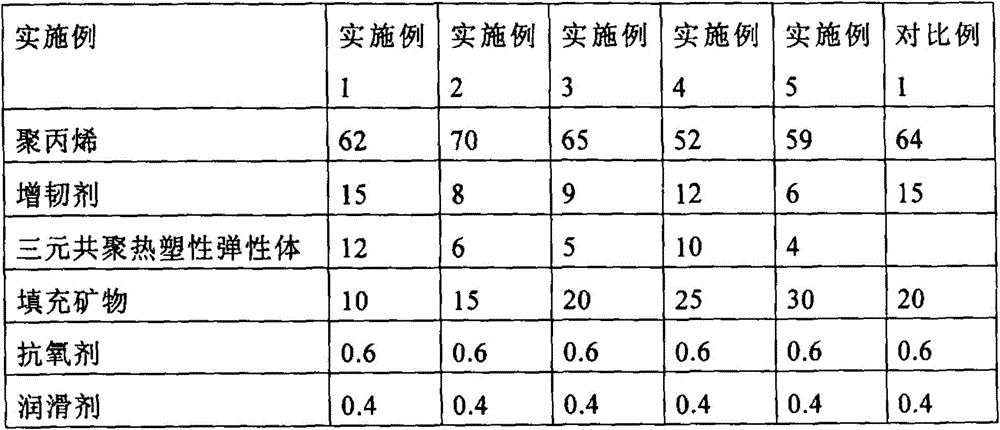

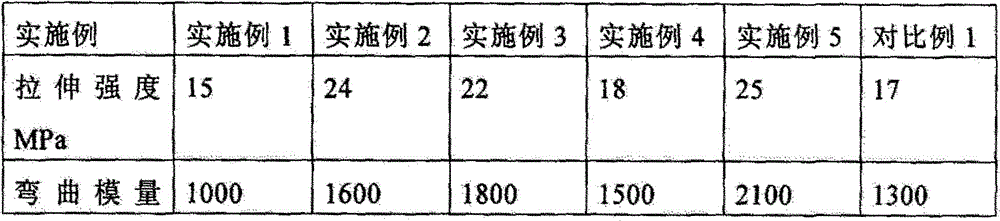

Polypropylene composite material with good appearance and preparation method thereof

The invention relates to a polypropylene composite material with good appearance and a preparation method thereof. The preparation method comprises the following steps: (1) weighing the following components by weight percent: 33%-85.6% of polypropylene, 3-20% of flexibilizer, 1-20% of ternary polymerization thermoplastic elastomer, 10-30% of filling mineral, 0.2-1% of antioxygen, and 0.2-1% of lubricant; (2) putting the raw materials of the step (1) into a high-speed mixer and mixing for 2-5 minutes, and discharging; (3) putting the materials mixed in the step (2) into a twin screw extruder and pelleting through extrusion so as to prepare the polypropylene composite material with good appearance, wherein the rotation speed of the twin screw extruder is 200-400 rpm (revolutions per minute), and the temperature is 180-220 DEG C. Compared with the prior art, the polypropylene composite material has good mechanical property, has no defects such as marks and tiger skin left on the surface, is environment-friendly, and can be widely used in the fields of automobiles, household appliances, sports goods and the like.

Owner:SHANGHAI SUNNY

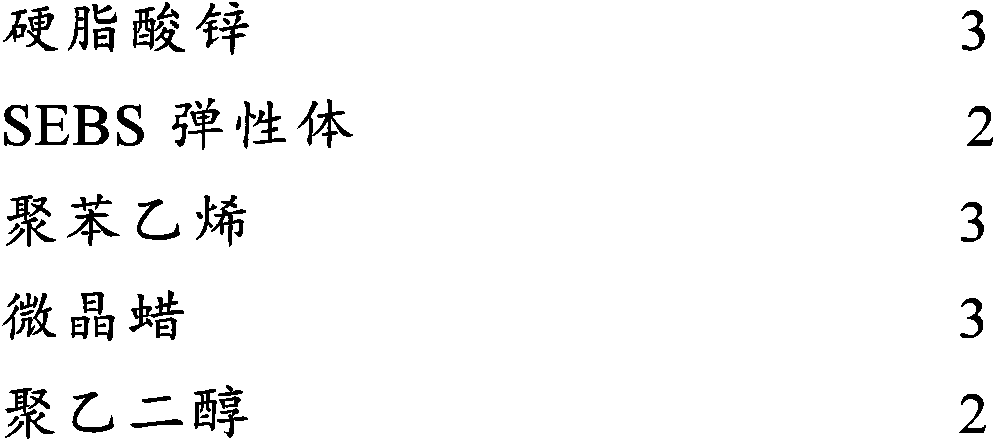

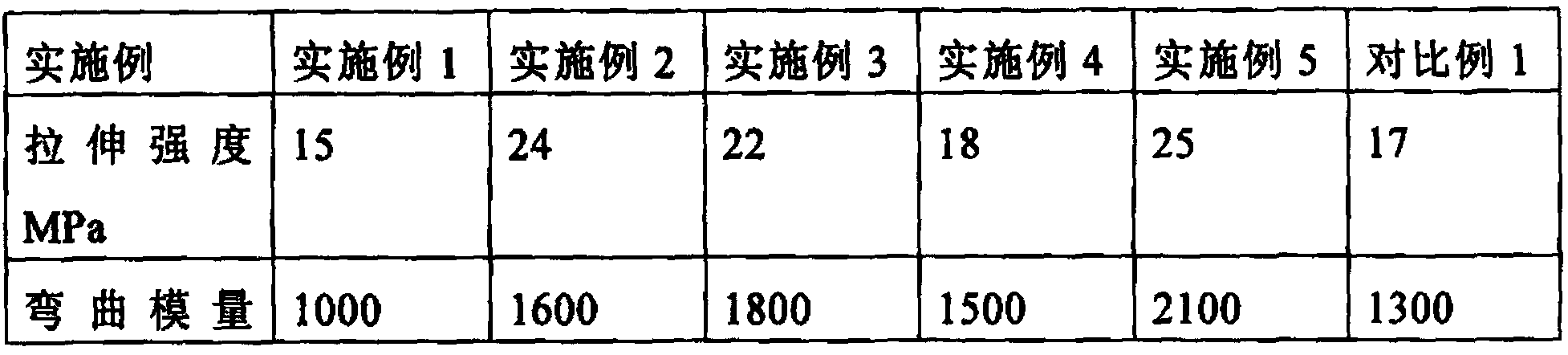

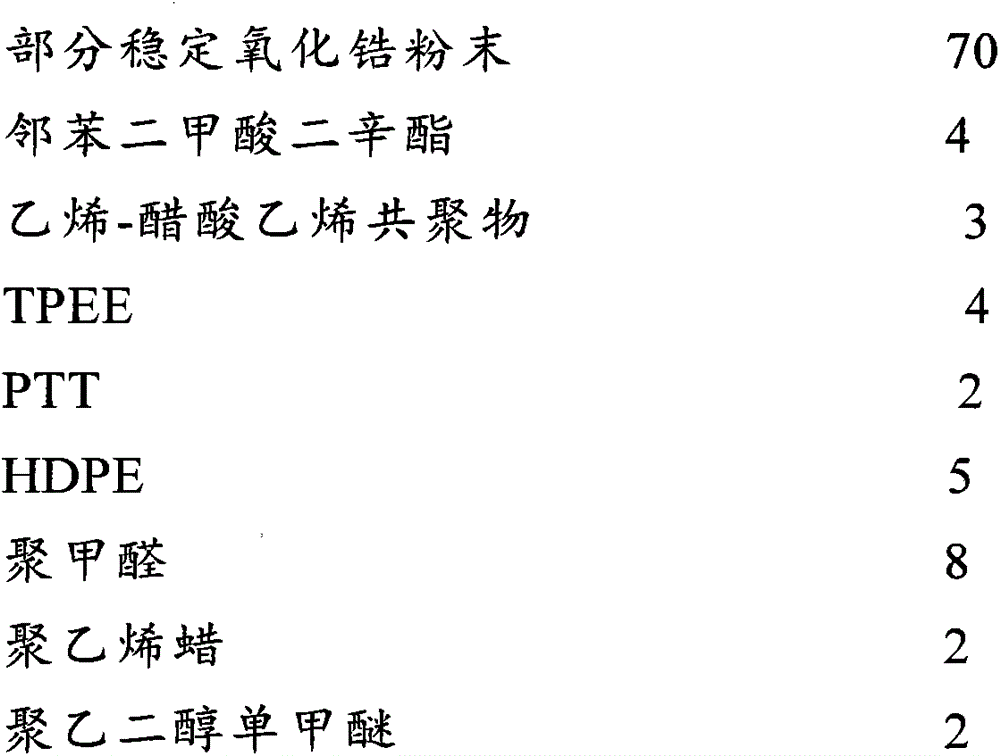

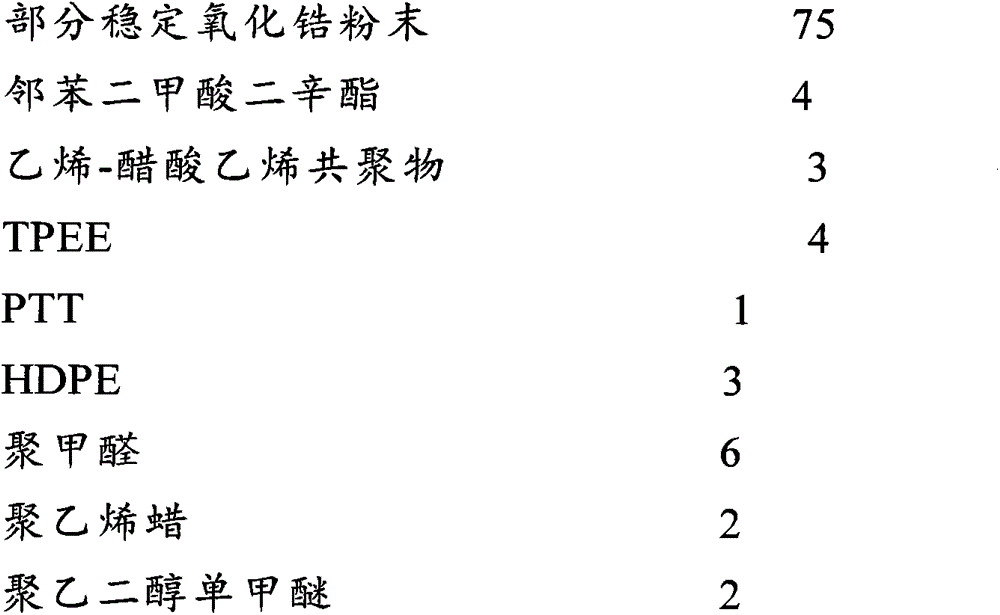

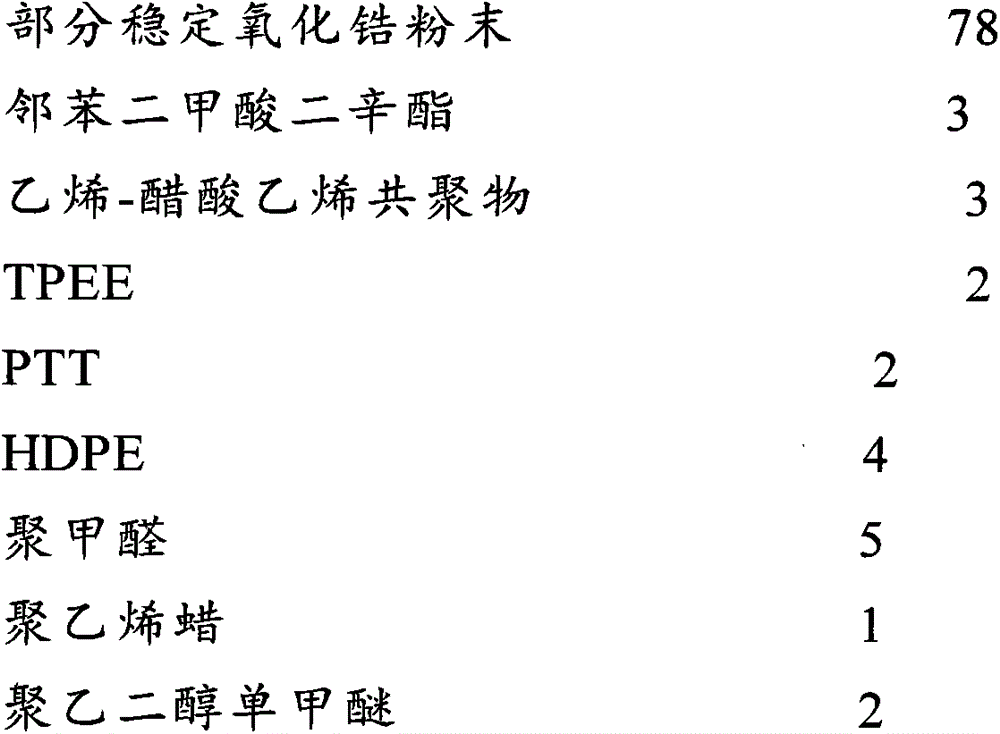

Preparation method of high-precision ceramic ferrule

The invention provides a preparation method of a high-precision ceramic ferrule and a preparation method of partially stabilized zirconium oxide powder for the high-precision ceramic ferrule. The preparation methods provided by the invention have the following advantages: firstly, silicon oxide, molybdenum oxide, zinc oxide, scandium oxide and holmium oxide are adopted, so that the thermal stress property of partially stabilized zirconium ceramic is high, the thermo-mechanical property of zirconium oxide is improved, and the ferrule material can be higher in strength, high in thermal shock resistance, low in deformation possibility and free from cracking; secondly, through an ethylene-vinyl acetate copolymer, TPEE, PTT, HDPE, polyformaldehyde and the like are polymerized in an interpenetrated manner to form an interpenetrated network structure, so that the obtained ceramic ferrule is low in deformation possibility and relatively high in precision; thirdly, an adopted organic binding agent has high liquidity, so that the ceramic ferrule is high in homogeneity and free from cracking; finally, due to the sequence of adding the organic binding agent during mixed refining, the feeding rheological property can be relatively high, a blank material can be easier to degrease, and then the prepared ceramic ferrule can be prevented from cracking.

Owner:NINGBO BRIGHT PHOTOELECTRIC TECH

Toughening-modified PA-PP mixed resin material and preparation method thereof

InactiveCN110079019AImprove hydrophilic and hydrophobic propertiesImprove compatibilityMaleic anhydridePolypropylene

The invention discloses a toughening-modified PA-PP mixed resin material and a preparation method thereof. The preparation method comprises the following steps: performing modification treatment on the surface of montmorillonite with a rare earth coupling agent, then introducing modified montmorillonite into polypropylene melt grafted maleic anhydride by adopting a melt grafting method, and finally adding the maleic anhydride grafted polypropylene / modified montmorillonite masterbatch and the rare earth modified montmorillonite into a melt blending system of polypropylene and nylon to obtain the mixed resin material. The montmorillonite modified by the rare earth coupling agent has the functions of inducing beta-crystal heterogeneous nucleation, effectively promoting the transformation of acrystal form in a PP matrix, and facilitating the improvement on the knot toughness of a composite material; by introducing the modified montmorillonite into the grafting reaction of polypropylene with maleic anhydride, the improvement on the grafting rate is facilitated, the compatibility of polypropylene and nylon is enhanced, and effective compatibilization is achieved.

Owner:合肥市丽红塑胶材料有限公司

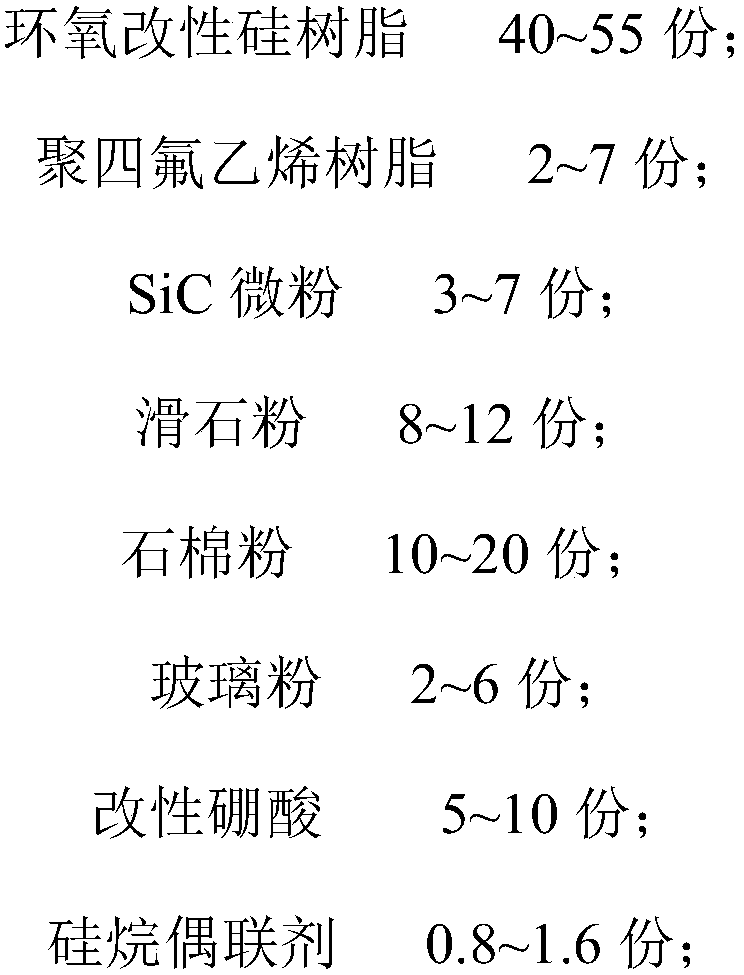

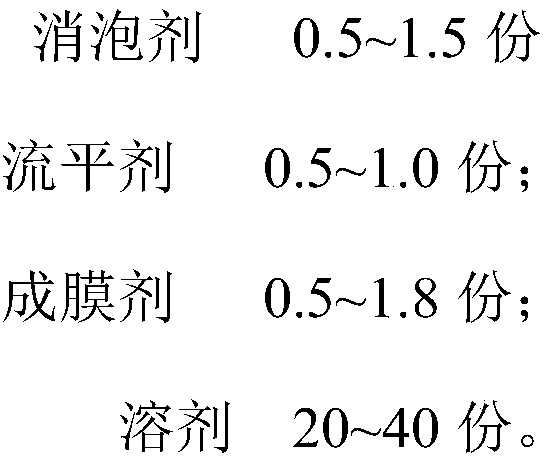

High temperature-resistant anticorrosive paint and preparation method thereof

InactiveCN109054633AImprove adhesionReduce surface tensionFireproof paintsAnti-corrosive paintsEpoxyPolymer science

The invention discloses high temperature-resistant anticorrosive paint and a preparation method thereof. The high temperature-resistant anticorrosive paint is prepared from the following raw materials: epoxy-modified silicon resin, polytetrafluoroethylene resin, SiC micro powder, talcum powder, asbestos powder, glass powder, modified boric acid, a silane coupling agent, a defoaming agent, a flatting agent and a film-forming agent. The paint not only has excellent high temperature resistance performance and flame retardation performance, but also has good anticorrosive performance of salt fog resistance, water resistance, salt water resistance, ageing resistance and the like, can adapt to different construction modes, and is ideal heat-resistant anticorrosive paint.

Owner:WUHU ZHANGHONG ENG TECH CO LTD

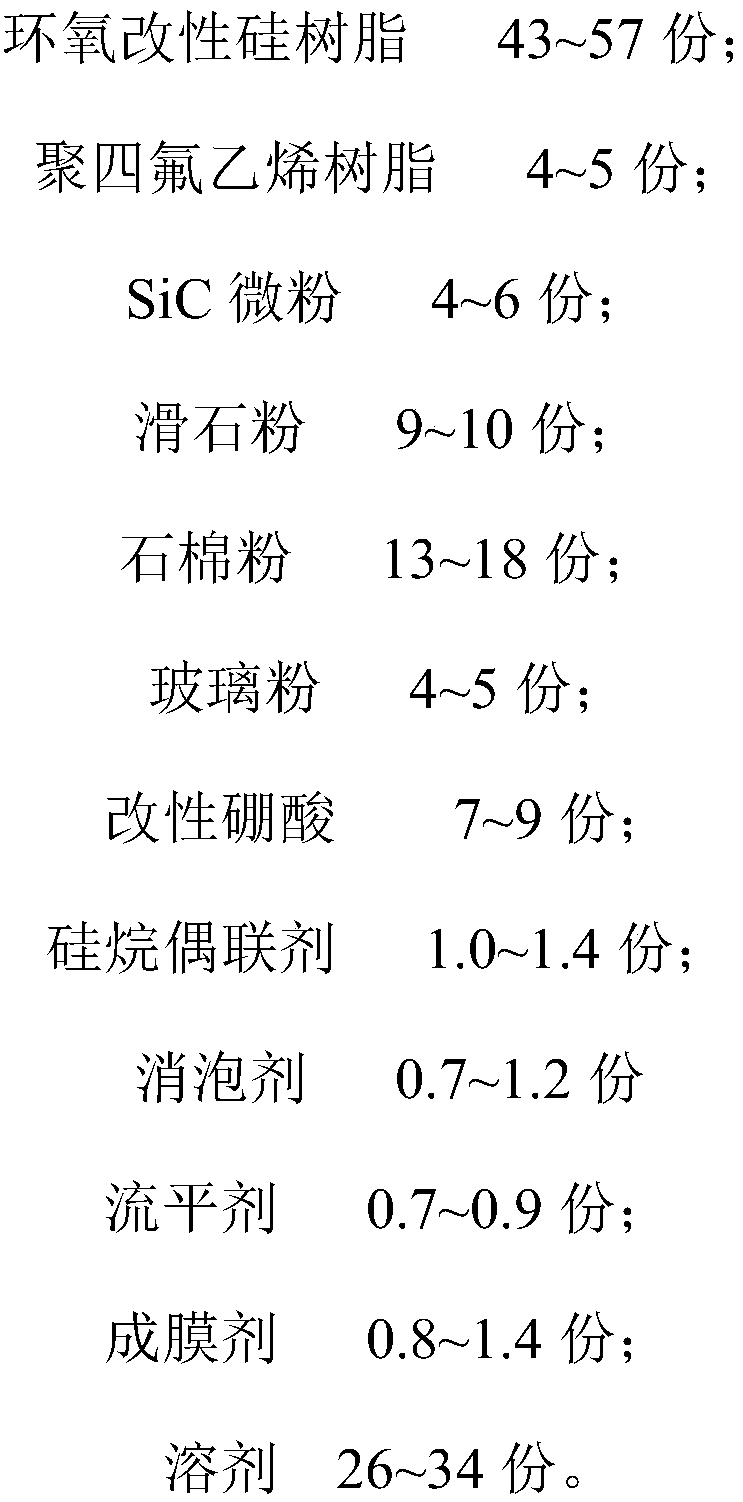

Talcum powder master batch and preparation method thereof

The invention relates to a talcum powder master batch and a preparation method thereof. The talcum powder master batch is prepared from the following raw materials in parts by weight: 11-30 parts of polypropylene, 3-10 parts of a compatilizer, 5-10 parts of a siloxane master batch, 60-70 parts of talcum powder, and 0.3-0.6 parts of an anti-oxidant, wherein the compatilizer is formed by polyolefinresin and dialkyl-terminated amino silicon oil; and the polyolefin resin is a copolymer of propylene and ethylene. The polyolefin resin is specifically selected to be combined with the dialkyl-terminated amino silicon oil, the effect of the compatilizer is achieved, and good infiltrating and coating effects are realized for the talcum powder. Dispersion of the talcum powder in PP resin is improved, scratch resistance is improved, and a dosage of the siloxane master batch can be reduced, so rigidity of a material can be further improved, and cost is reduced under the precondition of the good scratch resistance.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

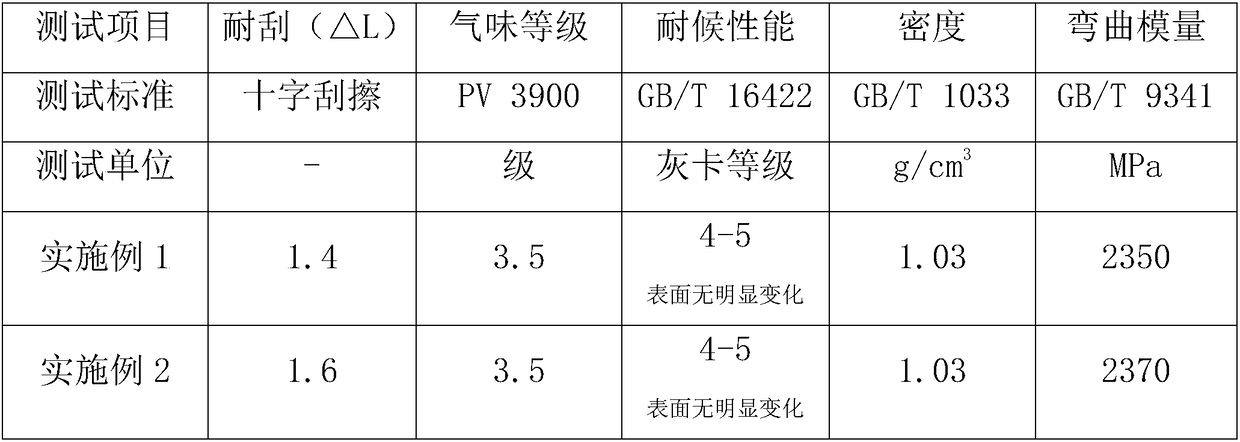

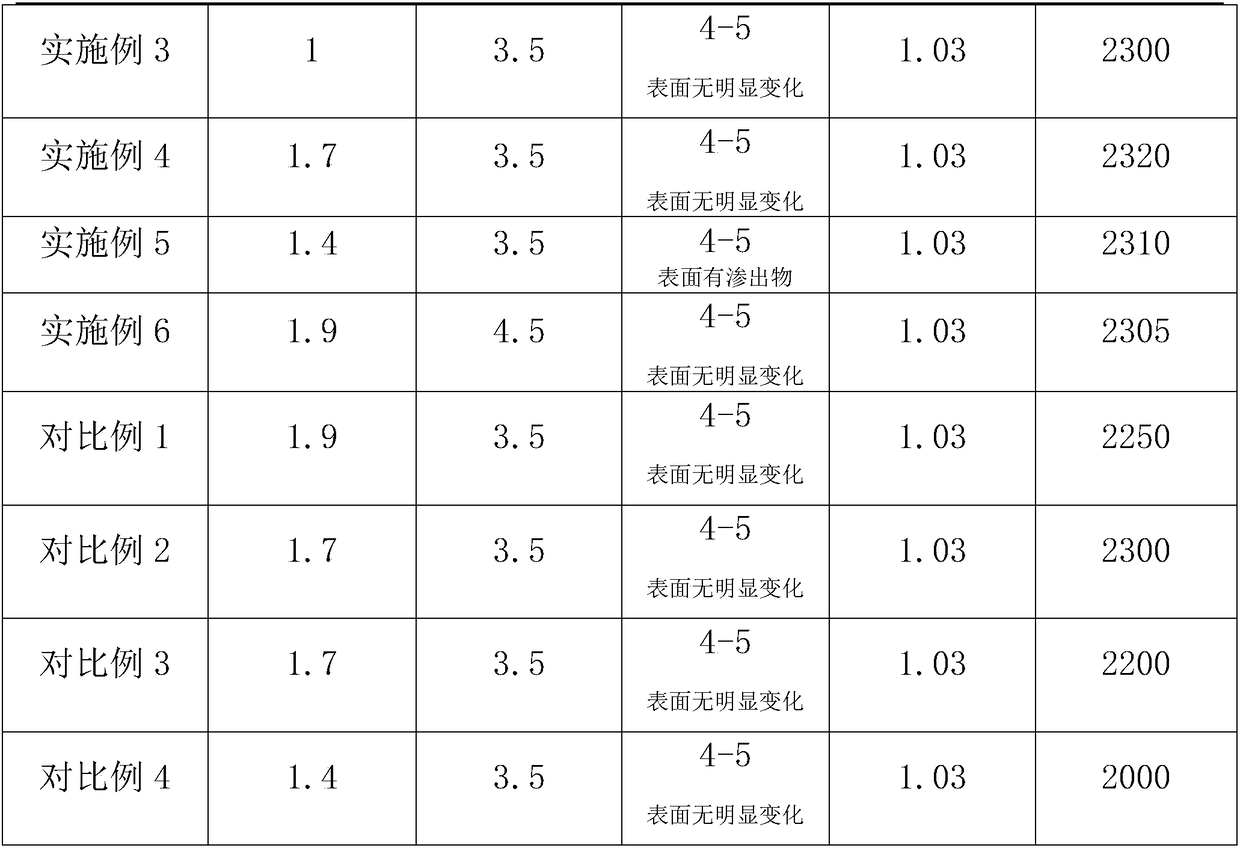

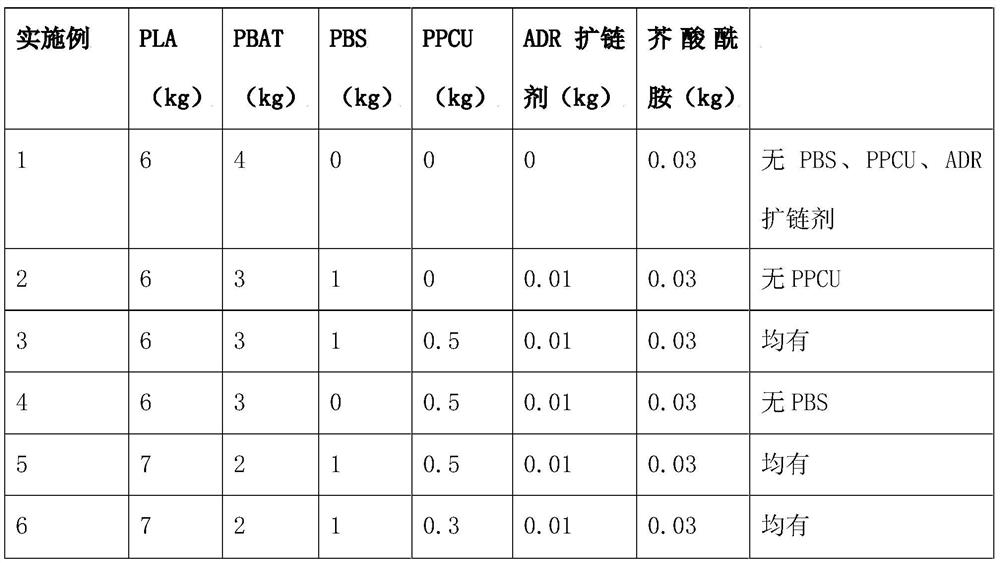

Degradable packaging material, packaging film bag and preparation method

ActiveCN113185820AImprove mechanical propertiesExtended shelf lifeBio-packagingPolymer scienceButanedioic acid

The invention discloses a degradable packaging material, and belongs to the field of packaging materials. The degradable packaging material comprises polylactic acid (PLA), poly(butylene adipate-co-terephthalate) (PBAT), poly(butylene succinate) (PBS), carbon dioxide-based thermoplastic polyurethane (PPCU), an ADR chain extender and an additive. The degradable packaging material is a quaternary blending system formed by PLA serving as a main material, PBAT, PBS and PPCU, ADR is taken as a chain extender, and a film high in transparency and excellent in mechanical property is prepared through a cold crystallization mode.

Owner:绍兴仁宇生物材料有限公司

Low-smoke-zero-halogen high-flame-retardance power cable

ActiveCN103440921AStay resilientMaintain wear resistanceInsulated cablesPower cablesLow smoke zero halogenFiber

The invention discloses a low-smoke-zero-halogen high-flame-retardance power cable which structurally comprises a guiding wire. A flame retardant insulation layer is arranged on the outer side of the guiding wire. A carbon fiber flame retardant layer is arranged on the outer side of the flame retardant insulation layer. A foam flame retardant layer is arranged on the outer side of the carbon fiber flame retardant layer. The carbon fiber flame retardant layer is connected with the flame retardant insulation layer through a cross-linking layer, and the carbon fiber flame retardant layer is connected with the foam flame retardant layer through a cross-linking layer. According to the low-smoke-zero-halogen high-flame-retardance power cable, power cable flame retardant capacity is improved, and meanwhile release of toxic smoke is lowered during burning.

Owner:NINGXIA RUIYIN NONFERROUS METAL TECH CO LTD

High-efficiency flame-retardant polycarbonate material and preparation method thereof

InactiveCN109988407AFacilitate cross-linkingImprove cross-linking efficiencyHeat deflection temperatureThermal deformation

The invention relates to a polycarbonate material, a high-efficiency flame-retardant polycarbonate material and a preparation method thereof. The high-efficiency flame-retardant polycarbonate materialis prepared from the following raw materials in parts by mass: 100 parts of PC resin, 0.02-0.2 part of a sulfonate flame retardant, and 1-9 parts of filling mineral powder; PDMS, mineral powder and stannous chloride are uniformly mixed in proportion and heated to 90-120 DEG C; stirring is kept, a reaction is conducted for 4 h, and filtering, washing and drying are conducted after the reaction isfinished to obtain the filling mineral powder; the preparation method comprises the following steps: weighing the PC resin, the sulfonate flame retardant, the filling mineral powder and other raw materials in parts by mass, adding the weighed materials into a high-speed mixer, and uniformly stirring and mixing to obtain a mixed material A; putting the mixed material A into a twin-screw extruder with a screw length-diameter ratio of 32-36 to be subjected to extruding and granulating to obtain the high-efficiency flame-retardant polycarbonate material, and the flame-retardant polycarbonate material is economical in cost and has good flame-retardant properties, thermal deformation temperature and mechanical properties.

Owner:NINGBO ZHETIE DAPHOON CHEM

Reinforced and toughened PP single-wall corrugated pipe and preparation method thereof

InactiveCN104277334AIncrease the strength of actionHigh elongation at breakPolymer scienceAntioxidant

The invention provides a reinforced and toughened PP single-wall corrugated pipe. The reinforced and toughened PP single-wall corrugated pipe is prepared from the following raw materials in percentage by mass: 70% of PP a polypropylene raw material, 5% of a PP polypropylene reclaimed material, 8%-10% of reinforcing functional talcum powder, 2%-4% of carbon black, 0.5%-0.6% of a defoamer, 2%-4% of a silane coupling agent, 0.2%-0.3% of a maleic anhydride grafted polymer, 1.3%-1.4% of an antioxidant, and 5%-8% of an ethylene / vinyl acetate copolymer. The preparation method comprises the steps of proportionally mixing the raw materials and preparing the reinforced and toughened PP single-wall corrugated pipe by use of an extruder or a forming machine. The reinforced and toughened PP single-wall corrugated pipe has the advantages that the rigidity and the flexibility of the PP single-wall corrugated pipe are improved, rigid and flexible complementation is realized, and the elongation at break is increased to 350% or more, and consequently, the usability of the product is improved and the cost is reduced.

Owner:HUNAN QIANYUAN NEW MATERIAL

Biodegradable PLA film and preparation method thereof

The invention discloses a biodegradable polylactic acid film and a preparation method thereof. The biodegradable polylactic acid film comprises the following components: 70-95 parts of polylactic acid (PLA), 4-29 parts of poly (butyl carbonate) (PBC), 0.1-1 part of a chain extender epoxy acrylic copolymer, 0.1-10 parts of a plasticizer tung oil anhydride, 0.1-1 part of a heat stabilizer zinc stearate and 0.1-5 parts of a nucleating agent phenyl phosphonic acid loaded calcium carbonate powder. The preparation method comprises the steps of uniformly mixing the raw materials in proportion, carrying out melt blending by a twin-screw extruder to obtain the modified polylactic acid film blowing special resin, and carrying out blow molding by a film blowing machine to form the film. The PLA film prepared by the method has high tensile strength, good opening performance and good transparency.

Owner:SINOCHEM QUANZHOU ENERGY TECH CO LTD

Polypropylene voltage-resisting insulating resin and preparation method thereof

The invention provides a polypropylene voltage-resisting insulating resin and a preparation method thereof. The polypropylene voltage-resisting insulating resin comprises the following components in parts by mass: 100 parts of mixed resin and 0.5-5 parts of silicon dioxide, wherein the mixed resin comprises the following components in parts by mass: 10-30 parts of pre-irradiated polypropylene resin, 45-80 parts of polypropylene resin and 10-25 parts of polypropylene-polystyrene resin. The invention further provides the preparation method of the polypropylene voltage-resisting insulating resin. The polypropylene voltage-resisting insulating resin is good in voltage breakdown resistance and the breakdown field strength is up to 33.2KV / mm.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Polyester/nylon composite material as well as preparation method and application thereof

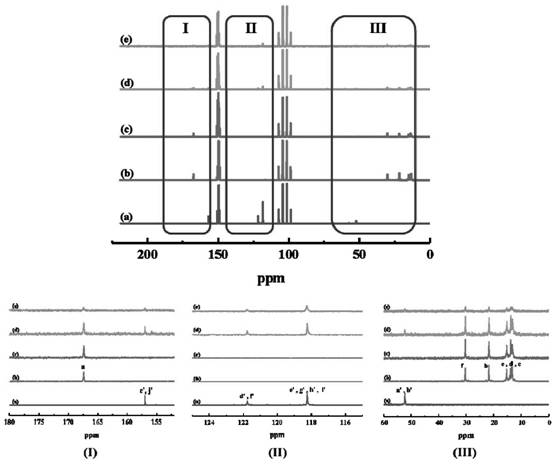

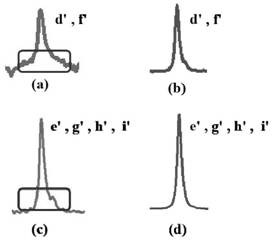

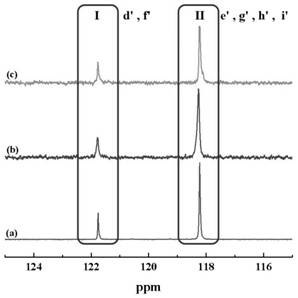

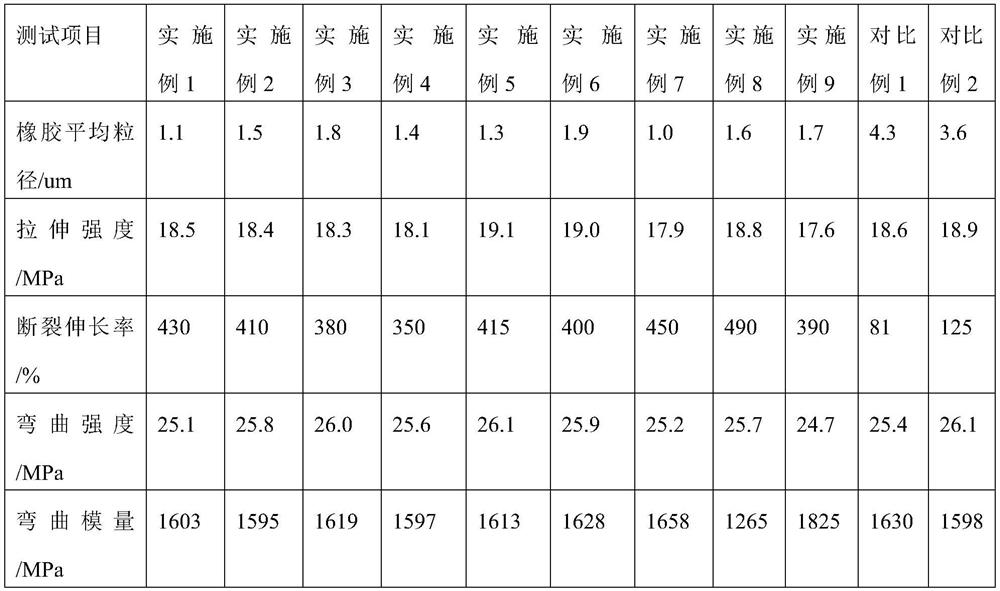

The invention discloses a polyester / nylon composite material as well as a preparation method and application thereof. The polyester / nylon composite material comprises an amide group-[NHCO]-, an ester group-[COO]- and an internal compatibilization chain segment; the mass content of polyester in the polyester / nylon composite material is 20-80%; the internal compatibilization chain segment comprises a -SO2-NH-group and has a polyester / nylon internal compatibilization interface, and the internal compatibilization chain segment has a characteristic shoulder peak with chemical shift in a range of 118 ppm to 119 ppm in a nuclear magnetic carbon spectrum. According to the polyester / nylon composite material as well as the preparation method and application thereof of the invention, a sulfonate compound is grafted on a modified polyester on a polyester macromolecular chain so as to be subjected to ester exchange reaction with the nylon, and the formed internal compatibilization chain segment can enhance the compatibility of the polyester and the nylon, so that the prepared polyester / nylon composite material has good mechanical properties and can also be applied to the fields of textile fibers, engineering plastics and the like.

Owner:ZHEJIANG UNIV

Polypropylene composition special for automobile hard plastic blasting instrument board and preparation method thereof

The invention relates to a polypropylene composition for an automobile hard plastic blasting instrument board and a preparation method of the polypropylene composition. The composition is prepared from the following raw materials in parts by weight: 45 to 72.5 parts of polypropylene, 10 to 25 parts of an elastomer, 3 to 7 parts of an ionic polymer, 10 to 25 parts of talcum powder, 0.2 to 1.0 part of a heat stabilizer, 0.2 to 0.5 part of a light stabilizer and 0.1 to 0.5 part of a processing aid. The composition has good rigidity and toughness, and can meet the use requirements of automobile hard plastic blasting instrument board materials.

Owner:SHANGHAI KINGFA SCI & TECH +1

Polypropylene compound as well as application and preparation method thereof

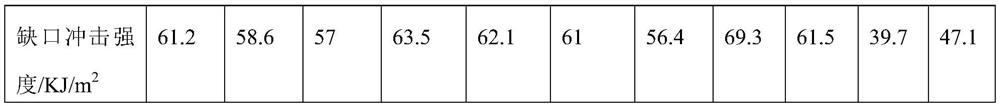

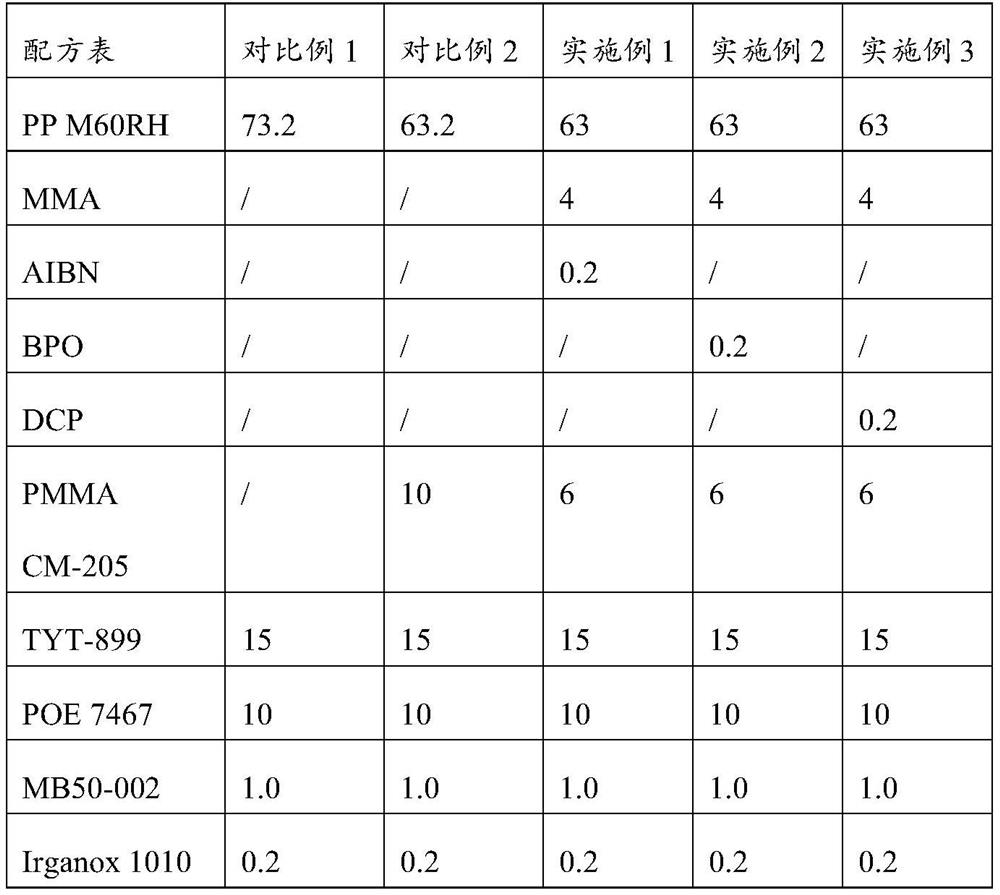

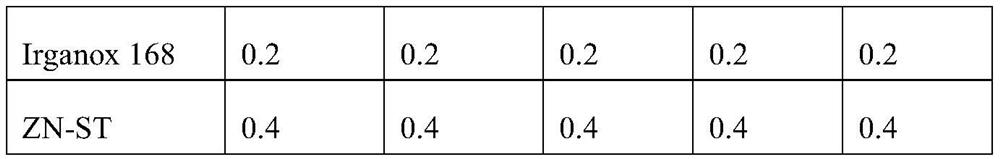

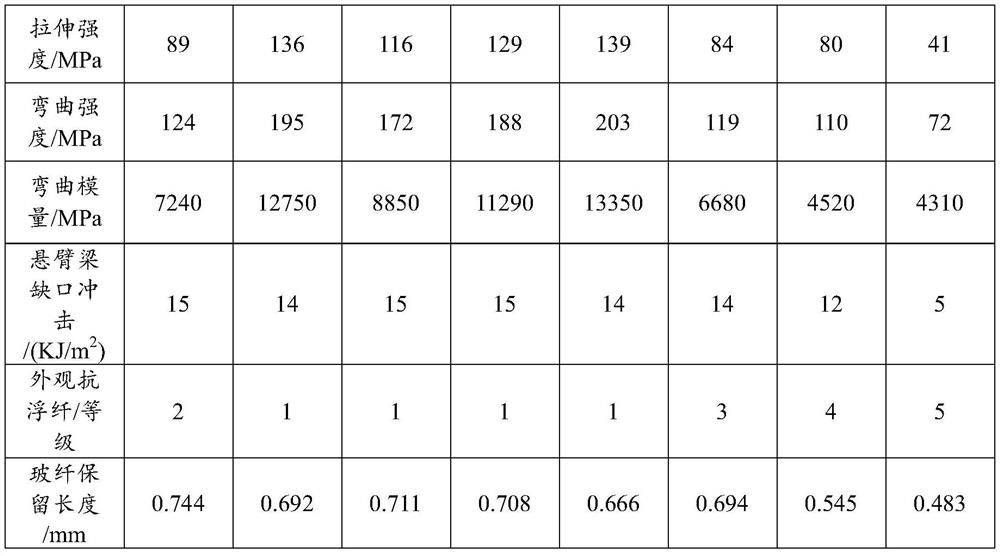

The invention relates to the technical field of high-molecular polymers, in particular to a polypropylene compound as well as application and a preparation method thereof. The polypropylene compound comprises the following raw materials in parts by weight: 46.7-78.1 parts of polypropylene, 1-5 parts of methyl methacrylate, 0.1-0.3 part of a free radical initiator, 5-10 parts of polymethyl methacrylate, 5-15 parts of an elastomer, 10-20 parts of talcum powder, 0.5-2.0 parts of a silicone scratching agent, 0.2-0.5 part of a stabilizer and 0.1-0.5 part of a processing aid. The polypropylene compound has the advantages of excellent scratch resistance and comprehensive mechanical properties; and the polypropylene compound with excellent scratch resistance and comprehensive mechanical properties can be prepared from the polypropylene compound through a first-stage space reaction of a double-screw extruder and a second-stage space blending reaction of the double-screw extruder.

Owner:KINGFA SCI & TECH CO LTD +1

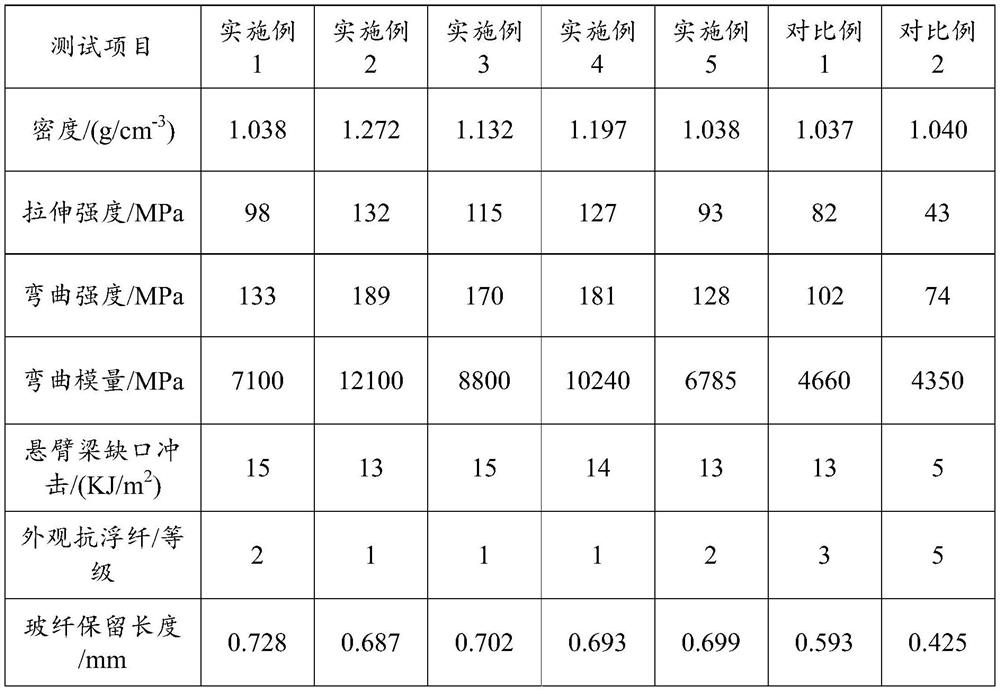

Compatilizer and glass fiber reinforced polypropylene composite material

InactiveCN111825803APlay the role of anti-floating fiberPromote infiltrationPolypropylene compositesGlass fiber

The invention discloses a compatilizer and a preparation method thereof. Meanwhile, the invention further discloses a glass fiber reinforced polypropylene composite material. The polypropylene composite material comprises the following components by weight: 35-90 parts of polypropylene, 20-50 parts of glass fiber, 5-15 parts of a compatilizer and 0.2-0.6 part of an antioxidant, wherein the polypropylene contains polypropylene A, and the melt flow rate of the polypropylene A under the condition of 230DEG C and 2.16kg is 800-1800g / 10min. By using the polypropylene A and the specific compatilizer, the glass fiber can be better wrapped and infiltrated, so that the appearance anti-floating fiber effect is good; meanwhile, the invention further discloses a preparation method of the glass fiber reinforced polypropylene composite material.

Owner:KINGFA SCI & TECH CO LTD

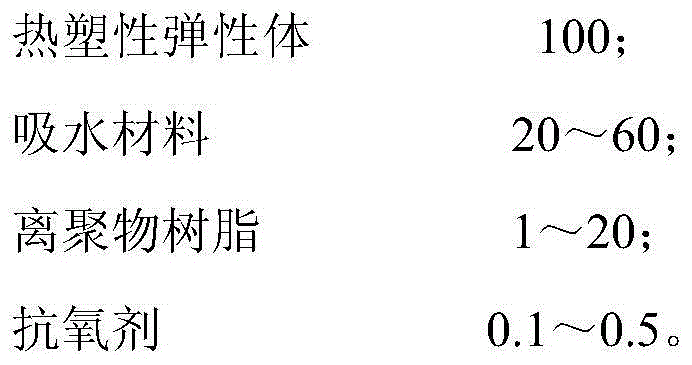

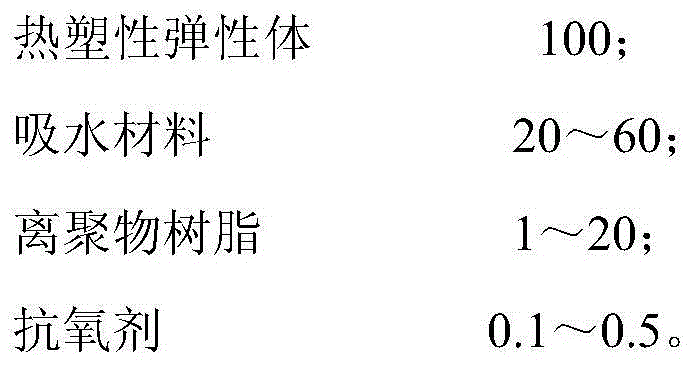

Thermoplastic water-swellable elastomer and preparing method and application thereof

InactiveCN104693665AEasy to solveImprove fatigue resistanceOther chemical processesElastomerThermoplastic elastomer

The invention relates to a thermoplastic water-swellable elastomer and a preparing method and application thereof and belongs to the technical field of rubber products. The thermoplastic elastomer is used for water resistance, leaking stoppage and sealing. Water-swellable rubber comprises, by weight, 100 parts of thermoplastic elastomer, 20-60 parts of water absorbing material, and 1-20 parts of ionomer resin. The preparing method of the water-swellable elastomer comprises the steps of conducting plastication and fusion on the thermoplastic elastomers, adding the water absorbing materials and ionomer resin in the plasticated object for shearing blending, and conducting secondary plastication to obtain the high-performance thermoplastic water-swellable elastomer. The water-swellable elastomer has excellent mechanical property and can expand by multiple times or even hundred of times of the mass or volume of itself after absorbing water, preparing process is simple and continuous, large-scale production can be achieved, and repeated forming and machining can be achieved.

Owner:EAST CHINA UNIV OF SCI & TECH

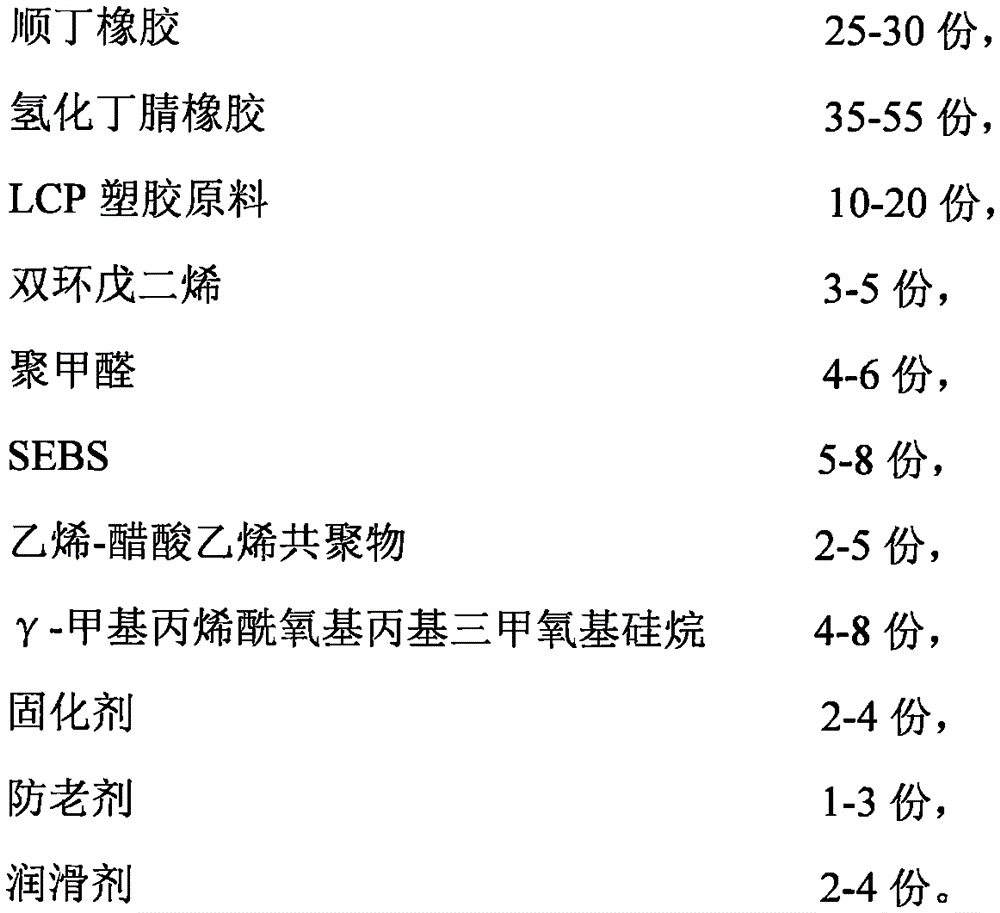

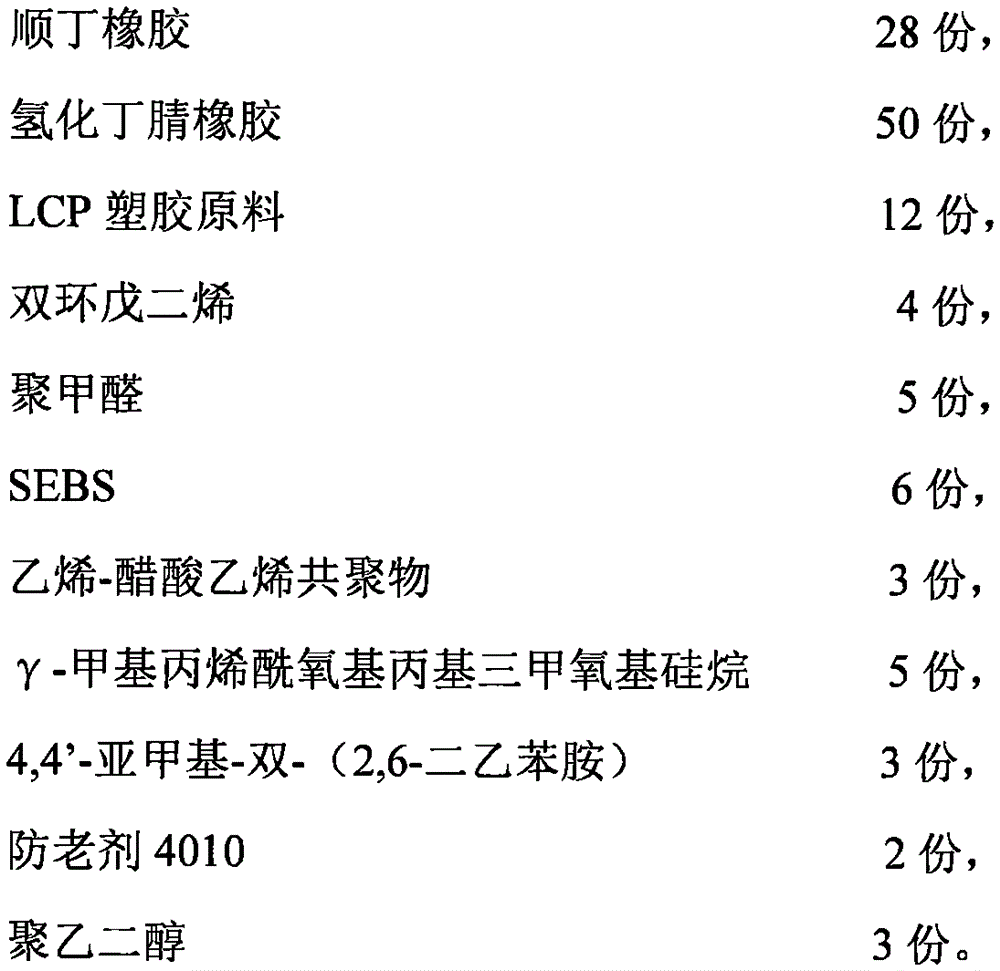

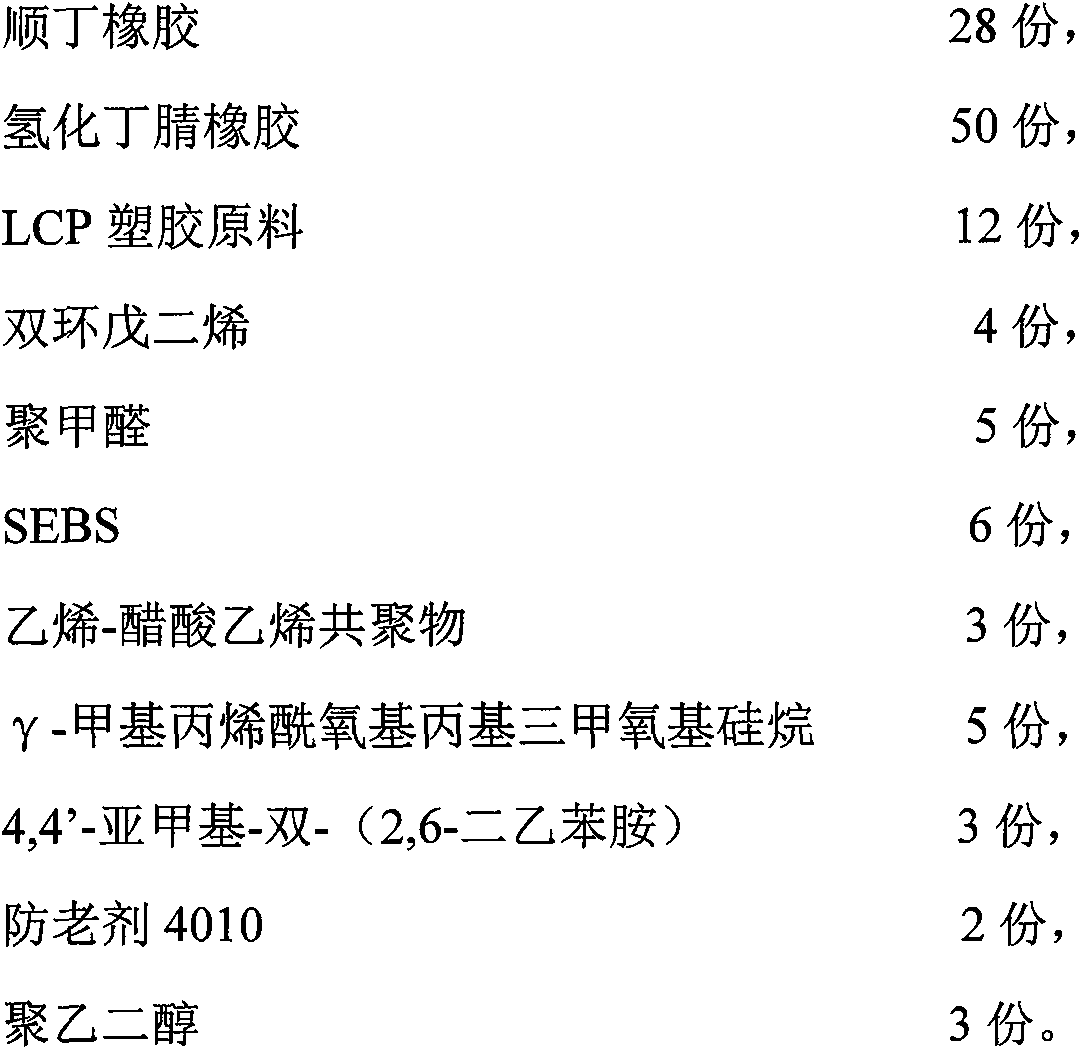

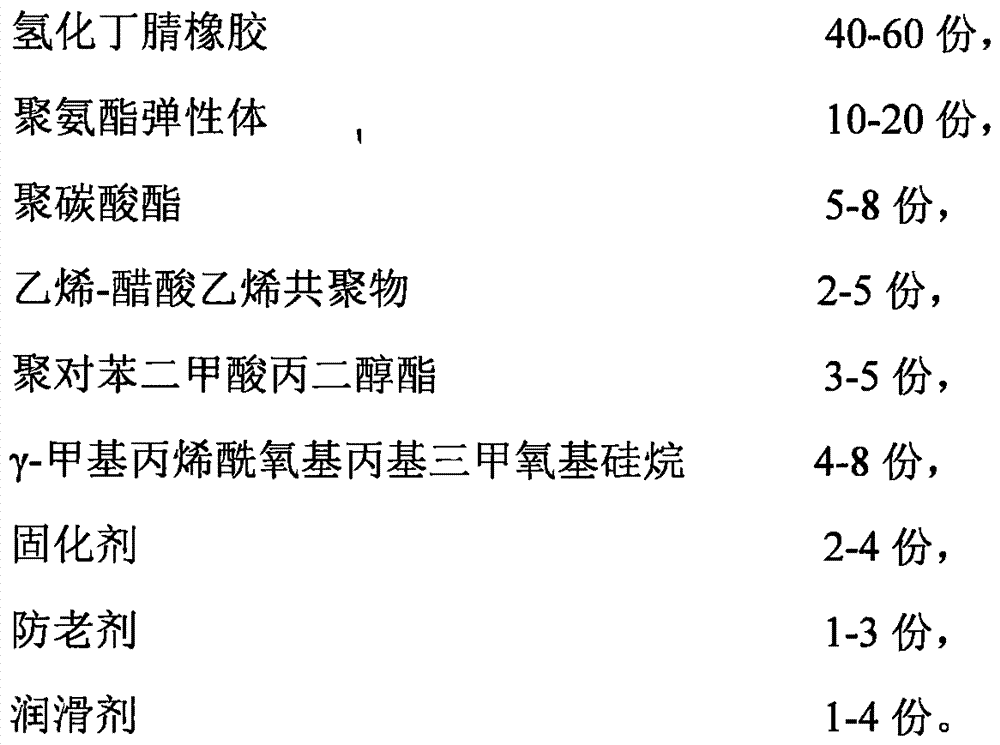

Novel synchronous belt

ActiveCN105237843AIncrease elasticityImprove wear resistanceDriving beltsBeltsManufacturing technologySilanes

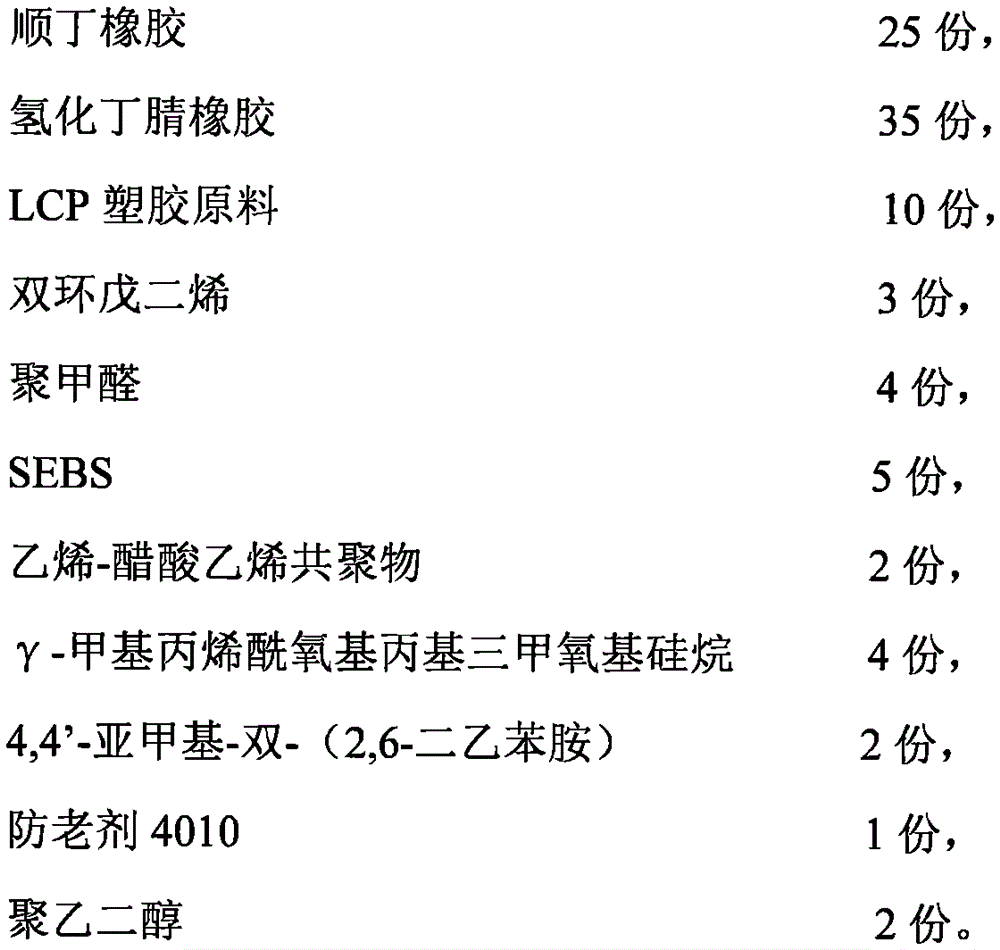

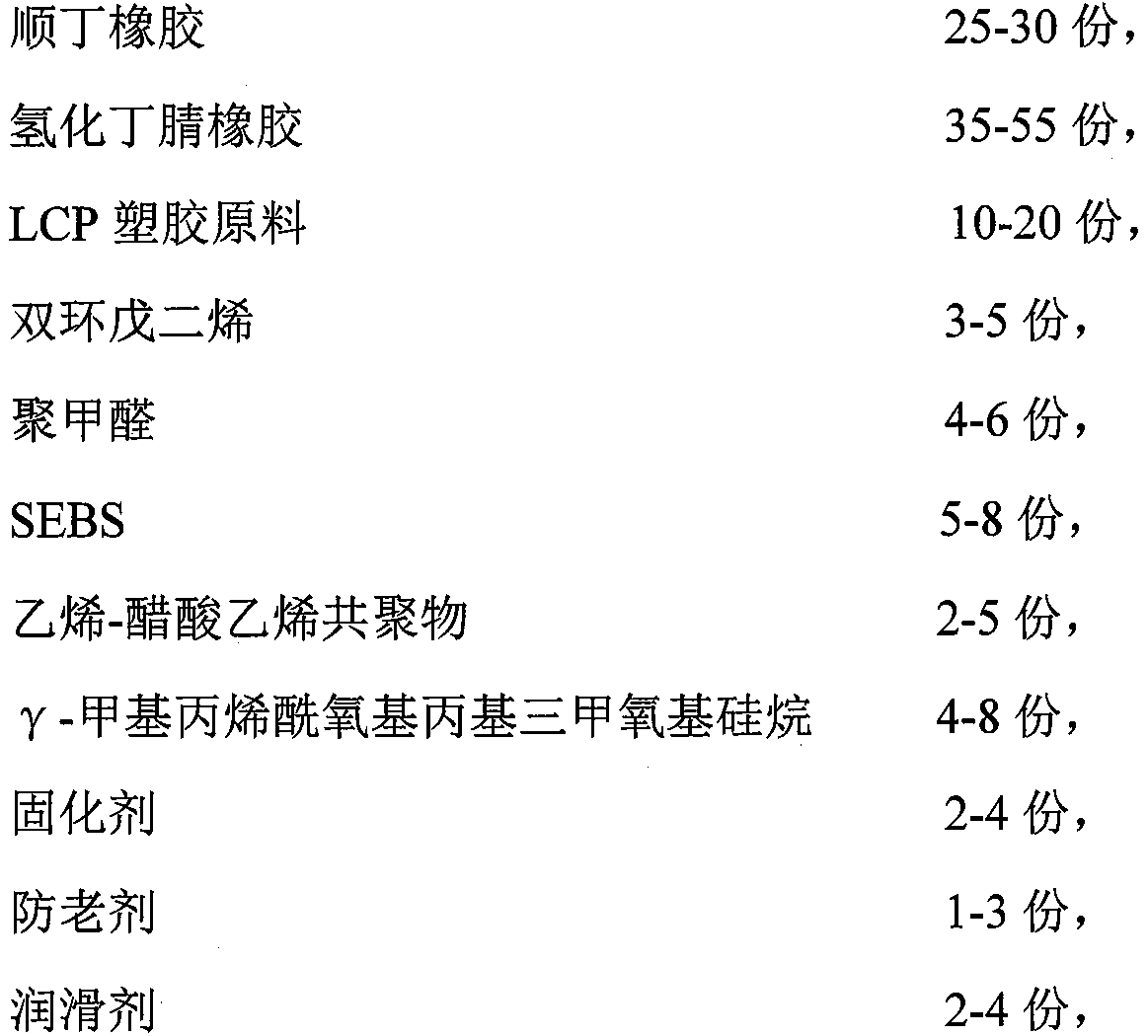

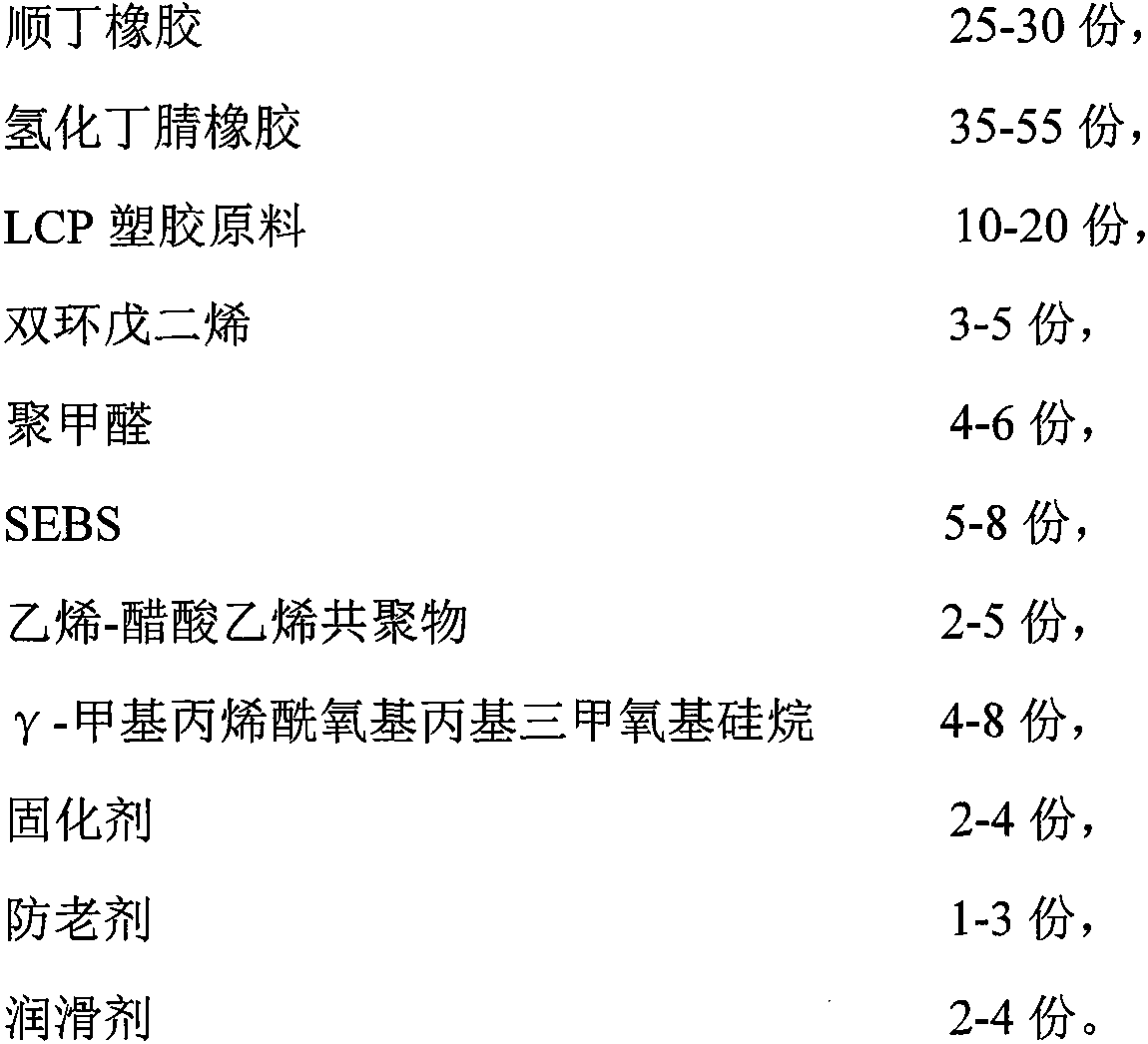

The invention discloses a novel synchronous belt. The synchronous belt comprises a synchronous belt skeleton, a synchronous rubber piece attached to the outside of the synchronous belt skeleton in a wrapping mode, and a synchronous belt wrapping cloth layer. The synchronous rubber piece is prepared from 25-30 parts of butadiene rubber, 35-55 parts of hydrogenated butadiene-acrylonitrile rubber, 10-20 parts of LCP plastic raw materials, 3-5 parts of dicyclopentadiene, 4-6 parts of polyformaldehyde, 5-8 parts of SEBS, 2-5 parts of ethylene-vinyl acetate copolymers, 4-8 parts of gamma-(methacryloxypropyl)trimethoxy silane, 2-4 parts of curing agents, 1-3 parts of anti-aging agents and 2-4 parts of lubricating agents. According to the novel synchronous belt, the butadiene rubber, the hydrogenated butadiene-acrylonitrile rubber, the LCP plastic raw materials, dicyclopentadiene, polyformaldehyde, ethylene-vinyl acetate copolymers and the like are used together, properties of the components are complemented, the manufacturing technology of the synchronous belt is improved, heat resistance and wear resistance of the synchronous belt are effectively improved, and the service life of the synchronous belt is prolonged.

Owner:NINGBO FULONG SYNCHRONOUS BELT

Anti-floating fiber agent and anti-floating fiber polypropylene reinforced composite material

The invention discloses an anti-floating fiber agent and a preparation method thereof. Meanwhile, the invention also discloses an anti-floating fiber polypropylene reinforced composite material. The anti-floating fiber polypropylene reinforced composite material comprises the following components in parts by weight, 35-90 parts of polypropylene, 20-50 parts of glass fibers, 5-15 parts of the anti-floating fiber agent and 0.2-0.6 part of an antioxidant, the polypropylene comprises polypropylene A, and the melt flow rate of the polypropylene A at 230 DEG C and 2.16 kg is 1000-1500g / 10min. By using the polypropylene A and the anti-floating fiber agent, the glass fiber can be better wrapped and infiltrated, so that the appearance anti-floating fiber effect is good; in addition, the invention also discloses a preparation method of the anti-floating fiber polypropylene reinforced composite material.

Owner:KINGFA SCI & TECH CO LTD

TPU acoustic film and preparation method thereof

ActiveCN110774717ASimple processEasy to operateSynthetic resin layered productsLaminationEpoxyPolymer science

The invention discloses a TPU acoustic film, which sequentially comprises a first outer layer, a first adhesion layer, a core layer, a second adhesion layer and a second outer layer from top to bottom, wherein the core layer is formed by a modified 1-chloromethyl-2,4-diisocyanobenzene / dimethyl dioxime polycondensate film, the first outer layer and the second outer layer are independently a modified TPU film, and the first adhesion layer and the second adhesion layer are independently formed by carrying out melt extrusion, cooling curing and roller calendering on at least one selected from an ethylene-vinyl acetate copolymer adhesive, an epoxy resin adhesive and a polyurethane adhesive at 220-250 DEG C. According to the invention, the TPU acoustic film retains the excellent characteristicsof high strength, tear resistance, wear resistance and the like of the TPU material, and further has characteristics of excellent heat resistance, excellent flame retardance, excellent environmental protection performance, high sensitivity, high consistency, good performance stability and long service life.

Owner:苏州市伽俐电子有限公司

Preparation method of corrosion-resisting underground communication tubing

The invention discloses a preparation method of a corrosion-resisting underground communication tubing, the corrosion-resisting underground communication tubing comprises the following raw materials by weight part: 50-52 parts of amber resin, 7-9 parts of vinyl acetate, 1.5-3 parts of modified chabazite, 4.5-6 parts of calcium zinc stabilizing agent, 2.5-3.5 parts of calcium antimonite, 1.8-2.2 parts of polyethylene wax, 3.5-4. 5 parts of antiseptic, 8.5-10.5 parts of nano level silica and 1.3-2.5 parts of lead-containing zinc oxide. According to the invention, toughness is increased, tubing destroy sensitivity is reduced, corrosion resistant performance is good, long-term intensity influence is little, service life of the communication tubing is prolonged, comprehensive performance of the product is greatly increased, and the preparation method has wide market prospect.

Owner:安徽电信器材贸易工业有限责任公司

A kind of polypropylene voltage-resistant insulating resin and preparation method thereof

The invention provides a polypropylene voltage-resisting insulating resin and a preparation method thereof. The polypropylene voltage-resisting insulating resin comprises the following components in parts by mass: 100 parts of mixed resin and 0.5-5 parts of silicon dioxide, wherein the mixed resin comprises the following components in parts by mass: 10-30 parts of pre-irradiated polypropylene resin, 45-80 parts of polypropylene resin and 10-25 parts of polypropylene-polystyrene resin. The invention further provides the preparation method of the polypropylene voltage-resisting insulating resin. The polypropylene voltage-resisting insulating resin is good in voltage breakdown resistance and the breakdown field strength is up to 33.2KV / mm.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

a timing belt

ActiveCN105237843BIncrease elasticityImprove wear resistanceDriving beltsBeltsPolyoxymethyleneNitrile rubber

The invention discloses a novel synchronous belt. The synchronous belt comprises a synchronous belt skeleton, a synchronous belt film wrapped outside the synchronous belt skeleton and a synchronous belt wrapping cloth layer. The synchronous belt film is made of 25-30 parts of Rubber, 35-55 parts of hydrogenated nitrile rubber, 10-20 parts of LCP plastic raw materials, 3-5 parts of dicyclopentadiene, 4-6 parts of polyoxymethylene, 5-8 parts of SEBS, 2-5 parts of ethylene-acetic acid Ethylene copolymer, 4-8 parts of γ-methacryloxypropyl trimethoxysilane, 2-4 parts of curing agent, 1-3 parts of anti-aging agent, 2-4 parts of lubricant. The present invention uses butadiene rubber, hydrogenated nitrile rubber, LCP plastic raw materials, dicyclopentadiene, polyoxymethylene, ethylene-vinyl acetate copolymer, etc. to complement each other in performance, and improves the manufacturing process of the synchronous belt, effectively Improve the heat resistance and wear resistance of the synchronous belt and increase its service life.

Owner:NINGBO FULONG SYNCHRONOUS BELT

A kind of polypropylene composite material with good appearance and preparation method thereof

Owner:SHANGHAI SUNNY

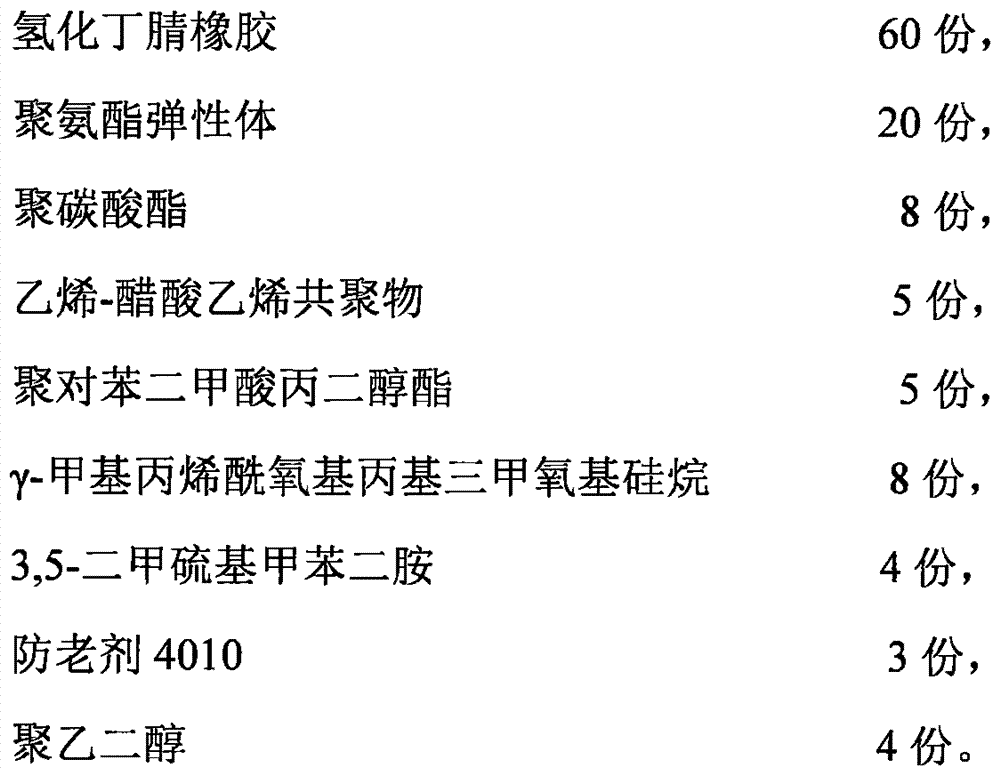

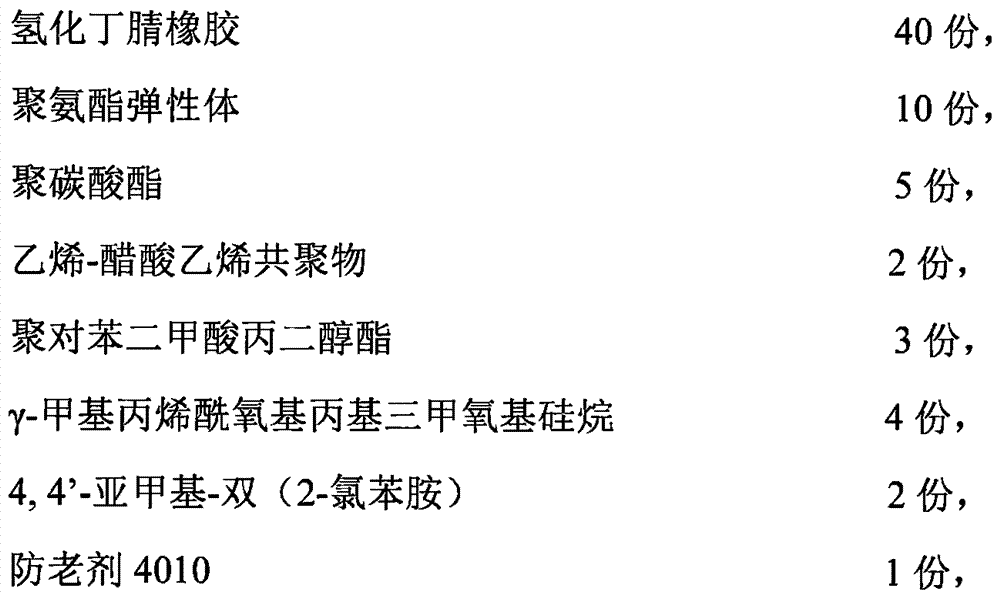

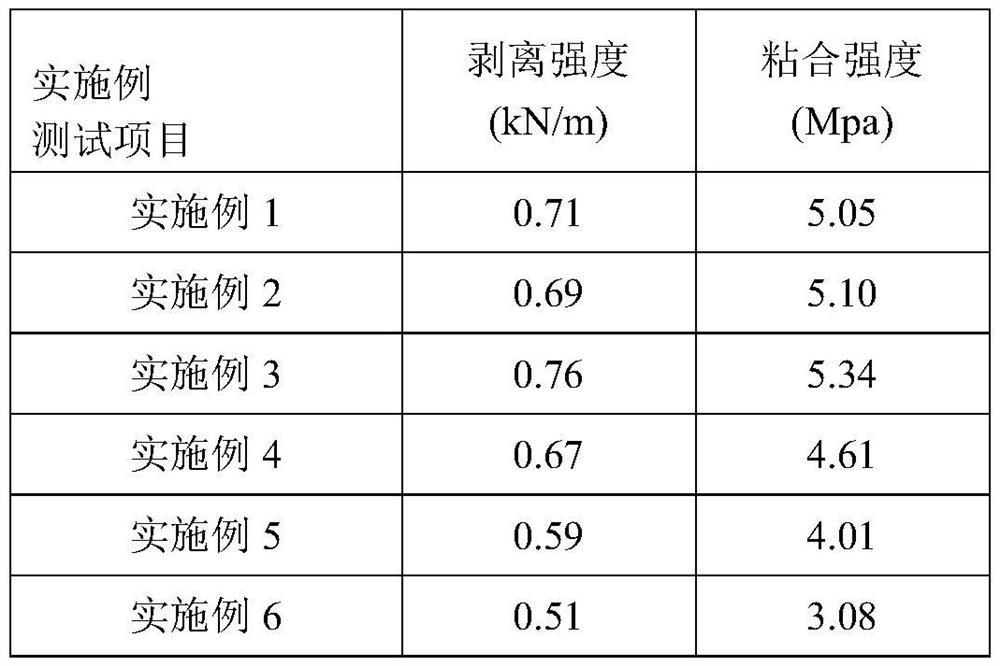

A kind of synchronous belt and its manufacturing method

ActiveCN105218909BImprove high temperature resistanceImprove mechanical propertiesDriving beltsPolyethylene terephthalate glycolAntioxidant

The invention discloses a synchronous belt and a manufacturing method thereof. The synchronous belt includes a synchronous belt frame and a synchronous belt film wrapped outside the synchronous belt frame. The synchronous belt film is composed of the following raw materials in parts by weight: 40 ‑60 parts hydrogenated nitrile rubber, 10‑20 parts polyurethane elastomer, 5‑8 parts polycarbonate, 2‑5 parts ethylene‑vinyl acetate copolymer, 3‑5 parts polytrimethylene terephthalate, 4 parts -8 parts of γ-methacryloxypropyl trimethoxysilane, 2-4 parts of curing agent, 1-3 parts of anti-aging agent, 1-4 parts of lubricant. In the present invention, hydrogenated nitrile rubber, polyurethane elastomer, polycarbonate, ethylene-vinyl acetate copolymer, polytrimethylene terephthalate, etc. are used in combination to complement their performance, effectively improving the heat-resistant and wear-resistant properties of the synchronous belt. elasticity.

Owner:NINGBO FULONG SYNCHRONOUS BELT

Adhesive for medical aluminum foil packaging and its processing technology

ActiveCN112662351BGood compatibilityLow toxicityNon-macromolecular adhesive additivesClimate change adaptationPolymer scienceAdhesive

The invention discloses an adhesive for medical aluminum foil packaging and its processing technology. The adhesive is prepared from the following raw materials in parts by weight: maleic anhydride grafted ethylene propylene diene monomer rubber: 40-60 parts; high crystalline polypropylene: 20‑30 parts; highly reactive polybutene: 6‑15 parts; polyvinyl chloride: 10‑20 parts; polyethyleneimine: 5‑10 parts; main emulsifier: 1‑3 Auxiliary emulsifier: 0.7-2.5 parts; Plasticizer: 5-7 parts; Antioxidant: 0.8-1.2 parts; Tackifier: 1-3 parts; Initiator: 1-2 parts; Coupling agent: 0.3-0.5 parts; diluent: 0.5-1 part; deionized water: 10-20 parts; the adhesive obtained by the present invention is prepared by reasonably selecting the weight components and adopting appropriate steps to make the adhesive The bonding strength is high and the bonding performance is good; and the preparation method is simple, the process condition is low, and the product quality is stable.

Owner:安徽虹源医药包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com